Professional Documents

Culture Documents

The Chlorine Manual Sixth Edition

Uploaded by

frapa070Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Chlorine Manual Sixth Edition

Uploaded by

frapa070Copyright:

Available Formats

THE CHLORINE MANUAL SIXTH EDITION

In humid conditions, condensation will

form on the outside of the container. At

excessive withdrawal rates, the liquid will be

cooled to such an extent that frost will form

on the outside of the container. The

insulating effect of the frost will cause a

further decrease in the discharge rate.

Discharge rates will diminish as the

container empties because there is progressively

less area of container wall in contact

with the remaining liquid chlorine. Discharge

rates may be increased by circulating room

temperature air around the container with a

fan.

Note: Never heat a container in a bath

of water, or apply direct steam, heat

belts, etc.

3.2.4.3 Pressure Padding

Liquid chlorine usually is unloaded by

tank car pressure. See Pamphlet 66. The

vapor pressure of the chlorine is frequently

augmented by a pad of dry air or nonreactive

gas. It is essential that the air used

for padding be free from oil and foreign

matter and be dried to a dew point -400F (-

400C) or below.

Air for padding should be supplied by a

separate air compressor which is not used

for any other purpose. To minimize the

potential of a chlorine-hydrocarbon oil

reaction, either a non-lubricated compressor

or a compressor lubricated with a nonreactive

synthetic oil, should be utilized.

Filters ahead of the dryers are required to

ensure oil free dry air if a lubricated

compressor is used.

The air pad system should be designed

to prevent the backflow of chlorine vapors

from the car. Lack of a positive backflow

protection with a hydrocarbon lubricated

compressor may result in a violent reaction

of chlorine and oil. A check valve alone

should not be considered adequate to

prevent back flow. See Pamphlet #6.

3.2.4.5 Disconnecting

A noticeable drop in tank car pressure

usually indicates that the tank car is empty.

It is desirable to discharge as much of the

residual chlorine as possible to the process.

Chlorine lines should be purged with dry air

or nonreactive gas to an absorption system

or vented to a vacuum system before

disconnecting.

After the transfer lines have been

disconnected, the valve outlet plugs should

be installed immediately. This is essential to

prevent corrosion of the threads by

atmospheric moisture. After checking for

leaks the protective housing cover must be

closed. After unloading, the DOT placards

must indicate the car last contained

chlorine. The open end of the chlorine

transfer lines should also be protected from

atmospheric moisture with suitable closures.

7.8.3 Preparation of Systems for Use

7.8.3.1 Cleaning

All portions of new piping systems must

be cleaned before use because chlorine can

react violently with cutting oil, grease, and

other foreign materials. Cleaning must not

be done with hydrocarbons or alcohols,

since chlorine may react violently with many

solvents. New valves or other equipment

received in an oily condition should be

dismantled and cleaned before use. See

Pamphlet 6.

7.8.3.2 Pressure Testing

New chlorine piping systems should be

tested according to one of the methods

recommended in Pamphlet 6. Components

which may be damaged during testing

should be removed or blocked off After

testing, all moisture-absorbing gaskets and

valve packings should be replaced; it is

essential that chlorine systems be dried as

described below prior to being placed into

service.

7.8.3.3 Drying

Chlorine piping systems must always

be dried prior to use. Even if water has not

been purposely introduced into the system

from hydrostatic testing or cleaning, drying

is still required due to the introduction of

moisture from the atmosphere or other

sources during maintenance and new

construction.

39

Drying can be facilitated as the system

is cleaned by passing steam through the

lines from the high end until the lines are

heated. While steaming, the condensate

and foreign matter is drained out. The

steam supply then should be disconnected

and all the pockets and low spots in the line

drained. While the line is still warm, dry air

or inert gas (e.g., nitrogen) having a dew

point of -400F (-400C) or below should be

blown through the line until the discharge

gas is also at a dew point of -400F (-400C)

or below.

If steam or dry utility system air are not

available, particular care must be taken in

cleaning sections of pipe and other

equipment before assembly, and careful

inspection is necessary as construction

proceeds. The final assembled system

should be purged with dry cylinder air or

nitrogen until the discharge gas is at a dew

point of -400F (-400C) or below.

7.8.3.4 Leak Testing

After drying, the system should be leaktested

with dry air or nitrogen. A soap

solution should be utilized to test for leaks at

piping joints. Chlorine gas may then be

introduced gradually and the system further

tested for leaks with 200 Baume aqua

ammonia vapor. Care must be taken that

chlorine has diffused throughout the piping

systems before testing for leaks. Never

attempt to repair leaks by welding until all

chlorine has been purged from the system.

When leaks have been repaired, the line

should be retested.

7.11 Equipment Maintenance

7.11.1 General

Maintenance of chlorine equipment

and tanks should be under the direction of

trained personnel. All precautions pertaining

to safety education, protective equipment,

health and fire hazards should be reviewed

and understood. Workers should not

attempt to repair chlorine piping or other

equipment while it is in service. When a

chlorine system is to be cleaned or repaired,

tanks, piping and other equipment should

always be purged with dry air or nonreactive

gas.

Decontamination is especially important

where cutting or welding operations are

undertaken because iron and steel will

40

ignite in chlorine near 4830F (2510C).

Immediate drying of a chlorine pipe or

container into which water has been

introduced or which has been opened for

repairs or cleaning is essential to prevent

corrosion.

7.11.2 Cleaning of Piping

and Other Equipment

If moisture enters a chlorine system

containing metallic components, such as

when connections are being made or

broken at a chlorine container or while

maintenance is being performed, ferric

chloride, already present in small amounts,

will absorb moisture and change to a

corrosive, brown, viscous liquid. If not

removed, this viscous liquid will continue to

corrode the metal and can rapidly plug

chlorine lines and equipment such as

vaporizers. This hydrated ferric chloride is

corrosive to many metals including

Hastelloy C.

Steam or hot water rapidly dissolves

ferric chloride. However, lines or equipment

cleaned in this manner must be dried

carefully before they are put back in service.

Steam should not be used on plastic

equipment unless it is known that the

specific plastic material can stand the

temperature. Any in-line instrumentation

should be protected during the cleaning

process. Cleaning of piping and various

other equipment is addressed in Pamphlet

6.

You might also like

- Brines Purification by Chemical Precipit 2Document10 pagesBrines Purification by Chemical Precipit 2amirNo ratings yet

- Alum Sulphate LiqDocument7 pagesAlum Sulphate LiqMuhammad Farhan AfifuddinNo ratings yet

- Study On The Precipitation of Magnesium Hydroxide From BrineDocument7 pagesStudy On The Precipitation of Magnesium Hydroxide From BrineJoel Jose Quisberth RodriguezNo ratings yet

- Week 7 - Reading 1 - MBRs in Wastewater Treatment (2010)Document10 pagesWeek 7 - Reading 1 - MBRs in Wastewater Treatment (2010)Weixuan ZhangNo ratings yet

- Feralco Liquid Aluminium Sulphate BrochureDocument5 pagesFeralco Liquid Aluminium Sulphate BrochurenoelhalloranNo ratings yet

- Seminar Om MBRDocument7 pagesSeminar Om MBRઅવિનાશ મીણા100% (1)

- TC Owtu 502 PDFDocument288 pagesTC Owtu 502 PDFRon100% (1)

- Formation Filtres Leopold (Xylem) PDFDocument40 pagesFormation Filtres Leopold (Xylem) PDFManoakiNo ratings yet

- Chlorine Contact Basin Design: White's Handbook of Chlorination and Alternative Disinfectants, 5th EditionDocument5 pagesChlorine Contact Basin Design: White's Handbook of Chlorination and Alternative Disinfectants, 5th Editionmaicana building100% (1)

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyDocument6 pagesUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriNo ratings yet

- HydroClear BrochureDocument12 pagesHydroClear BrochuremutazsalihNo ratings yet

- Guideline for Safe Transportation of Dry Chlorine Gas by PipelineDocument40 pagesGuideline for Safe Transportation of Dry Chlorine Gas by PipelineDarshan PatelNo ratings yet

- Decomposition of Sodium ChlorateDocument3 pagesDecomposition of Sodium Chlorateعبد القادر حدادNo ratings yet

- Water Treatment Chemicals ListDocument7 pagesWater Treatment Chemicals ListAlvin KimNo ratings yet

- IR 3x3 350 P Maintenance ManualDocument12 pagesIR 3x3 350 P Maintenance ManualAngelNo ratings yet

- Teza Namol EpurareDocument267 pagesTeza Namol EpurareMarcel BurlacuNo ratings yet

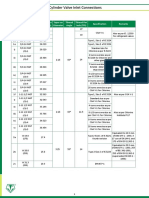

- Cylinder Valve ConnectionsDocument2 pagesCylinder Valve ConnectionsGore JiangNo ratings yet

- Main CatalogueDocument10 pagesMain CatalogueMohamed SalahNo ratings yet

- Coagulation For Wastewater Treatment A RDocument5 pagesCoagulation For Wastewater Treatment A RHenryPeña100% (1)

- Water TechnologyDocument58 pagesWater TechnologyAdi Mantha اديتية منتة100% (3)

- VortexIntake4UrbDrain JHEDocument11 pagesVortexIntake4UrbDrain JHERob616No ratings yet

- SyllabusDocument25 pagesSyllabusShashank TiwariNo ratings yet

- Chlorination Guide Presentation PDFDocument168 pagesChlorination Guide Presentation PDFAmit nayakNo ratings yet

- Lab Waste WaterDocument10 pagesLab Waste WaterAriffNo ratings yet

- CEE 311 Environmental Engineering I Dr. Kauser Jahan CHAPTER 3: ReactorsDocument4 pagesCEE 311 Environmental Engineering I Dr. Kauser Jahan CHAPTER 3: Reactorsinayatullah sakhiNo ratings yet

- Brochure Producedwater Sorbwater For WEBDocument12 pagesBrochure Producedwater Sorbwater For WEBManvendra SinghNo ratings yet

- Basic Ion Exchange ProcessesDocument9 pagesBasic Ion Exchange ProcessesSAYEDNo ratings yet

- Sodium Hypochlorite Incompatibility Chart: Avoid Dangerous MixingDocument1 pageSodium Hypochlorite Incompatibility Chart: Avoid Dangerous MixingastromoNo ratings yet

- RBBR System Description PDFDocument8 pagesRBBR System Description PDFChokri HmeidiNo ratings yet

- II. Properties of SeawaterDocument34 pagesII. Properties of SeawaterSiva Fauziah AzmiNo ratings yet

- Decomposition of NaOClDocument10 pagesDecomposition of NaOClswongNo ratings yet

- DisinfectionDocument82 pagesDisinfectionJoby AbrahamNo ratings yet

- D399DDocument5 pagesD399DHilarie Jonathan100% (1)

- JVK Filter Elements enDocument16 pagesJVK Filter Elements enArun GuptaNo ratings yet

- Discharge Relations For Hydraulic Structures and Head Losses From Different ComponentsDocument160 pagesDischarge Relations For Hydraulic Structures and Head Losses From Different ComponentsEdgar Chuquipiondo VargasNo ratings yet

- Lab DI Water Systems Guide - Filtration, RO, Resin Filters ExplainedDocument6 pagesLab DI Water Systems Guide - Filtration, RO, Resin Filters ExplainedHaidee Che RizminNo ratings yet

- Saturator Design and CalsDocument11 pagesSaturator Design and Calschuanpham08No ratings yet

- OTRDocument51 pagesOTRNithi AnandNo ratings yet

- V&T Hydrocyclone enDocument4 pagesV&T Hydrocyclone enIon_RiswanNo ratings yet

- 2.3.3 Intake Design: 2 Design Considerations For Tunnelled Seawater Intakes 25Document2 pages2.3.3 Intake Design: 2 Design Considerations For Tunnelled Seawater Intakes 25Abdul Asad100% (1)

- Environmental Engineering QuestionsDocument10 pagesEnvironmental Engineering QuestionsSuresh Raju0% (1)

- WQ Submersible Sewage Pump Catalogue-Guomei PumpDocument11 pagesWQ Submersible Sewage Pump Catalogue-Guomei PumpOscarNo ratings yet

- PC 56 Biocide (Old)Document13 pagesPC 56 Biocide (Old)Hyun Jin YooNo ratings yet

- Conference of Junior Researchers in Civil Engineering - Ammonium removal comparisonDocument7 pagesConference of Junior Researchers in Civil Engineering - Ammonium removal comparisonOssian89No ratings yet

- Catalogo Hydroballs®Document9 pagesCatalogo Hydroballs®alberto fuentealbaNo ratings yet

- Gas Chlorine StationsDocument46 pagesGas Chlorine StationsakramhomriNo ratings yet

- Membrane MBR - Depliant 1Document8 pagesMembrane MBR - Depliant 1gsaviNo ratings yet

- Chlorine FAODocument289 pagesChlorine FAOTrầnĐứcHùngNo ratings yet

- Course Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungDocument50 pagesCourse Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungAnnisa MaulinaNo ratings yet

- Chilled Water TreatmentDocument10 pagesChilled Water TreatmentacmvorgNo ratings yet

- DWG Chapter 15 Treatment Processes Disinfection Jun19Document84 pagesDWG Chapter 15 Treatment Processes Disinfection Jun19Alberto MeneghinNo ratings yet

- 2005 Bookmatter HandbookOfChlor-AlkaliTechnolo PDFDocument92 pages2005 Bookmatter HandbookOfChlor-AlkaliTechnolo PDFJimmy Miranda100% (1)

- Reduce Industrial Waste Volume with Classification, Conservation & Process ChangesDocument29 pagesReduce Industrial Waste Volume with Classification, Conservation & Process ChangesJne ByerNo ratings yet

- Effluent ClarifierDocument2 pagesEffluent ClarifierSutra IrawanNo ratings yet

- ENVI Trickling FiltersDocument23 pagesENVI Trickling FiltersbaBy daBy AnNetTeNo ratings yet

- 21810, Ultrapure Water Breakpoint CL andDocument5 pages21810, Ultrapure Water Breakpoint CL andWaleed EmaraNo ratings yet

- CleaningandDescalingStainlessSteel 9001Document38 pagesCleaningandDescalingStainlessSteel 9001Kiran DuggarajuNo ratings yet

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentFrom EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNo ratings yet

- Mil PRF 27210g AboDocument13 pagesMil PRF 27210g Abofrapa070No ratings yet

- HTTP WWW - LuxfercylindersDocument2 pagesHTTP WWW - Luxfercylindersfrapa070No ratings yet

- Brochure DOT 106A500XDocument2 pagesBrochure DOT 106A500Xfrapa070No ratings yet

- EIGA - Doc 30-13 Disposal of GasesDocument81 pagesEIGA - Doc 30-13 Disposal of Gasesfrapa070No ratings yet

- Catalogue EIGA PublicationsDocument21 pagesCatalogue EIGA Publicationsfrapa070No ratings yet

- AL Catalog 09 A Pages 1 404Document404 pagesAL Catalog 09 A Pages 1 404frapa070100% (1)

- AIGA 047 - 08 Safe Preparation of Gas MixturesDocument25 pagesAIGA 047 - 08 Safe Preparation of Gas Mixturesfrapa070No ratings yet

- Power Plant Condensers: Design Features & Performance IssuesDocument58 pagesPower Plant Condensers: Design Features & Performance IssuesAyush ChoudharyNo ratings yet

- Kenco Flat Glass Gauge Valve ManualDocument4 pagesKenco Flat Glass Gauge Valve ManualGuillermo CorderoNo ratings yet

- Fuel Tank TestDocument1 pageFuel Tank TestIvan RuedaNo ratings yet

- MCU-X NEF1 VEF1 Installation Manual - 10 2012 - EnglishDocument24 pagesMCU-X NEF1 VEF1 Installation Manual - 10 2012 - Englishchris_ohaboNo ratings yet

- Commissioning Generators and Its Auxiliary SystemDocument90 pagesCommissioning Generators and Its Auxiliary SystemSam100% (2)

- CV-Series High-Pressure Valves User Guide: 369 Syringa Ridge Sandpoint, ID 83864 281.782.8312Document44 pagesCV-Series High-Pressure Valves User Guide: 369 Syringa Ridge Sandpoint, ID 83864 281.782.8312Jorge PatarroyoNo ratings yet

- Cascade Roll Clamp 667442 - 70EPRCServ PDFDocument51 pagesCascade Roll Clamp 667442 - 70EPRCServ PDFsindelu60No ratings yet

- MP8 - D13 Injector Cup Info 45-sb211007-1Document6 pagesMP8 - D13 Injector Cup Info 45-sb211007-1ONE SOURCE DIESELNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual MTCDocument96 pages2003 Nissan Altima 2.5 Serivce Manual MTCAndy DellingerNo ratings yet

- Selection of Substitute, Non-Hazardous, Liquid Filling Substances For Packagings Subjected To The United Nations Performance TestsDocument5 pagesSelection of Substitute, Non-Hazardous, Liquid Filling Substances For Packagings Subjected To The United Nations Performance TestsasmaNo ratings yet

- 09931271C PinAAcle 500 Safety GuideDocument134 pages09931271C PinAAcle 500 Safety GuideNafaa HmidiNo ratings yet

- Remove corrosion from window framesDocument1 pageRemove corrosion from window framesmikeNo ratings yet

- Aircraft Systems Lab Manual Safety PrecautionsDocument42 pagesAircraft Systems Lab Manual Safety PrecautionscalinshabuNo ratings yet

- Valve Leakage Rates Test STDDocument5 pagesValve Leakage Rates Test STD윤병택No ratings yet

- 2005 Seadoo Rotax 1503 4 Tech Shop Manual - 1 25Document25 pages2005 Seadoo Rotax 1503 4 Tech Shop Manual - 1 25Oscar Eduardo GomezNo ratings yet

- Spe 102815 MS PDFDocument12 pagesSpe 102815 MS PDFIsaias Castro ArmendarizNo ratings yet

- 135 Guidelines For Classification and Categorization of Well Control Incidents and Well Integrity IncidentsDocument20 pages135 Guidelines For Classification and Categorization of Well Control Incidents and Well Integrity IncidentsAndrems SeremsNo ratings yet

- Maintenance and Repair of Heat Exchangers PDFDocument73 pagesMaintenance and Repair of Heat Exchangers PDFTehman Alam100% (2)

- Documento - Teste de Estanquidade em DutosDocument5 pagesDocumento - Teste de Estanquidade em DutosRogerio OliveiraNo ratings yet

- AnsiDocument2 pagesAnsiSonu SinghNo ratings yet

- Cement SqueezeDocument41 pagesCement SqueezeHadi HendizadehNo ratings yet

- MXT ManualDocument40 pagesMXT ManualManuel Hernández OrozNo ratings yet

- SHELL - Provision of FPSO Integrity and Specialized Pipeline Inspection and Maintenance Services On Bonga - 20221002Document4 pagesSHELL - Provision of FPSO Integrity and Specialized Pipeline Inspection and Maintenance Services On Bonga - 20221002Wale OyeludeNo ratings yet

- ESA25XW Instruction Manual7313-M13071 Rev1Document89 pagesESA25XW Instruction Manual7313-M13071 Rev1jaikp56No ratings yet

- A t3 Super Choke Operational ManualDocument64 pagesA t3 Super Choke Operational Manualcorsini99986% (7)

- Furn Svb10a enDocument9 pagesFurn Svb10a enapi-279886039No ratings yet

- Nfpa8 ADocument1 pageNfpa8 APOLPMENo ratings yet

- Underground Storage Tanks - The Basics: A Resource For UST System Owners and Operators in IowaDocument73 pagesUnderground Storage Tanks - The Basics: A Resource For UST System Owners and Operators in IowamiltonNo ratings yet

- Rce329a Home Installation GuideDocument28 pagesRce329a Home Installation GuideengrfahadkhanNo ratings yet

- Air Leakage Site Detection in Building Envelopes and Air Barrier SystemsDocument7 pagesAir Leakage Site Detection in Building Envelopes and Air Barrier SystemsSig BlackhysteriaNo ratings yet