Professional Documents

Culture Documents

Formulation and In-Vitro Characterization of Losartan Potassium and Repaglinide Bilayer Tablets

Uploaded by

Baru Chandrasekhar RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation and In-Vitro Characterization of Losartan Potassium and Repaglinide Bilayer Tablets

Uploaded by

Baru Chandrasekhar RaoCopyright:

Available Formats

IAJPS 2017, 4 (12), 4207-4213 M. Sunitha Reddy and G.

Charitha ISSN 2349-7750

CODEN [USA]: IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.1095022

Available online at: http://www.iajps.com Research Article

FORMULATION AND IN-VITRO CHARACTERIZATION OF

LOSARTAN POTASSIUM AND REPAGLINIDE BILAYER

TABLETS

Dr. M. Sunitha Reddy* and Gadam Charitha

Department of Pharmaceutics, Center for Pharmaceutical Sciences, IST, JNTUH

Abstract:

The purpose of this study is to formulate and evaluate bilayer anti-hypertensive and anti-diabetic tablets.

Bilayer tablet contains Losartan potassium for immediate release and Repaglinide for a sustained release. The

bilayer tablets were prepared using crospovidone and sodium starch glycolate as super-disintegrants for the

immediate release layer, hydroxyl propyl methyl cellulose K 100M and hydroxyl propyl methyl cellulose K 15M

as polymers at various concentrations to retard the release of drug for a period of time. Immediate release

layer was prepared by direct compression and wet granulation method was followed for sustained release. FT-

IR studies revealed that there was no incompatibility between drugs and excipients. The tablets were evaluated

for weight variation test, hardness, thickness, friability, tablet disintegration time, content uniformity and in

vitro dissolution studies. In vitro drug release studies were performed using the type-II dissolution apparatus

(paddle) using 0.1N Hydrochloric acid for first 2 hours and the remaining hours with 6.8 pH phosphate buffer.

Among all the formulations, optimized formulation F5 showed a maximum of 99.4% drug release at 45 minutes

for Losartan potassium and Repaglinide has an in vitro drug release of 99.87%. Therefore, bilayer tablets in

combination of these two drugs can be used to improve the management of hypertension (high blood pressure)

and diabetes mellitus. II.

Keywords: Bilayer tablet, Losartan Potassium, Crospovidone, and Sodium starch glycolate, Repaglinide,

Hydroxy propyl methyl cellulose K100M, Hydroxy propyl methyl cellulose K15M.

Corresponding author:

Dr. M. Sunitha Reddy, QR code

Department of Pharmaceutics,

Center for Pharmaceutical Sciences, IST, JNTUH

E-Mail:baddam _sunitha@rediffmail.com,

Phone no: 9849958604

Please cite this article in press as M. Sunitha Reddy and G. Charitha , Formulation and In-Vitro

Characterization of Losartan Potassium and Repaglinide Bilayer Tablets, Indo Am. J. P. Sci, 2017; 4(12).

www.iajps.com Page 4207

IAJPS 2017, 4 (12), 4207-4213 M. Sunitha Reddy and G. Charitha ISSN 2349-7750

INTRODUCTION:

When two or more active pharmaceutical dosage form of Losartan potassium which gives

ingredients must be administered simultaneously faster onset of action, and reduces the high blood

and they are incompatible, the best option for the pressure. To prepare sustained release dosage form

formulation pharmacist would be to formulate a of Repaglinide which gives controlled onset of

multilayer tablet. The bilayer tablets are prepared action for a longer period of time with the desired

with drug layer for immediate release while the release pattern.

second layer is designed as to release the drug later,

as a second dose, or for a prolonged or MATERIALS AND METHODS:

conventional[1] manner. Bilayer tablet is suitable Materials: Losartan Potassium and Repaglinide

for the sequential release of two drugs in were obtained as a gift sample from Hetero Drugs

combination and separate two incompatible Pvt. Ltd. (Hyderabad, India). Crospovidone and

substances. Each layer may contain a different Sodium Starch Glycolate were donated by

medicinal agent with variable release profiles, and Granules India and Dow Corning. HPMC K 100 M

they are designed for many reasons such as and HPMC K 15 M were obtained as a gift sample

controlling the rate of administration of one or two from Colorcon. Polyvinyl pyrrolidone K 30, Spray

different active pharmaceutical ingredients and the Dried Lactose, Lactose Monohydrate came from

separation of the incompatible active MERCK. Hydrochloric acid and Methanol were

pharmaceutical ingredients, the ones with the obtained as a gift from Rankem..Magnesium

others, release of active pharmaceutical ingredients Stearate was donated by Peter Griven GMBH. Talc

from one layer using the functional property of the was obtained as a gift sample from Luzenac

other layer. Repaglinide [2] is used alone or with Pharma.

other medicines to control high blood sugar levels.

It is used in people with type 2 diabetes [3]. EXPERIMENTAL WORK:

Losartan Potassium is an angiotensin II receptor Preformulation studies

antagonist that is used to treat hypertension [4], and Physicochemical interaction of drugs and

help protect the kidney damage from diabetes. It is excipients

also used to reduce the risk of stroke in patients The absorption spectra of the

with high blood pressure and an enlarged heart. drugs,superdisintegrants and all the polymers [5,6]

Lowering high blood pressure helps prevent used as a combination polymers did not show a

strokes, heart attacks and kidney problems. The significant interaction. The graphs are shown in

present work focuses on the immediate release Figure 1.

Fig 1: IR overlay of drug and excepients

(a)-losartan potassium, (b)-repaglinide, (c)-crospovidone, (d)-sodium starch glycolate,

(e)-HPMC K 15 M, (f)- HPMC K 100 M

www.iajps.com Page 4208

IAJPS 2017, 4 (12), 4207-4213 M. Sunitha Reddy and G. Charitha ISSN 2349-7750

Manufacturing process of the immediate release 100 revolutions. After 100 revolutions, the tablets

[7] layer of losartan potassium were dusted and reweighed. Compressed tablets

The procedure for the preparation was direct should not lose more than 1% of their weight. A

compression. All ingredients were mixed, except conventional tablet should have less than 0.5-1% of

magnesium stearate and talc. Finally, dye was the friability of the weight tabulated in Table 3.

added together with magnesium stearate and

talc,later the powder mixture was punched with 12 Weight variation test

mm size punch. Select twenty tablets randomly from each lot and

weigh individually. Average weight and standard

Manufacturing process of the Sustained release deviation of 20 tablets were calculated. The lot

[8,9] granules of Repaglinide passes weight variation test, if not more than two of

wet granulation method was followed,all the the individual weights deviates from average

ingredients weremixed,except magnesium stearate weight by more than the percentage shown in the

and talc with water and a wet mass was formed. table and none should deviate more than the double

The formed mass was passed through mesh 10#and percentage shown. The average weight, standard

the formed granules were dried and then passed deviation of the tablets in each batch were given in

through mesh 24# and punched with 12mm size Table 3.

punch.

Disintegration time

Evaluation of tablets The in vitro disintegration time was determined by

All tablets were evaluated [10,11] for various the use of a disintegration test apparatus and a

parameters such as hardness, thickness, friability, tablet was placed in the apparatus. The complete

disintegration time, drug release in vitro dissolution disintegration time in seconds for the of the tablet

studies. without palpable mass in the apparatus was

measured. The results are shown in Table 3.

Thickness

From each batch six tablets were randomly selected Assay

and their thickness was measured using vernier The content uniformity test was done by uv

callipers. The average thickness with the standard method. Twenty tablets were weighed and

deviation of the tablets of each batch was measured randomly pick the tablets then immediately crush

and are tabulated in Table 3. it. Take required quanity of crushed tablet and the

powder was transferred into the volumetric flask

Hardness and mix with suitable diluent. Then it was checked

The tablet crushing load is the force required to by uv method and the assay was calculated.The

break the tablet by compression. Monsanto results are shown in Table 3.

hardness tester is used to measure hardness . From

each batch, six tablets were selected randomly and RESULTS AND DISCUSSION:

evaluated. The tablets must have a certain amount In vitro dissolution studies [12]:

of hardness or strength and the resistance and The in vitro dissolution test was carried out using

friability to withstand the mechanical shocks of the USP type II apparatus .The solution was carried

manufacturing, packaging and shipping hardness. out using 0.1 N HCl for the first 2 hours and with

Hardness is tabulated in Table3. phosphate buffer pH 6.8 during the remaining

hours. The paddle was rotated at 100 rpm at the

Friability temperature (37 C 0.5 C). The sampling was

The friability test is performed to evaluate the carried out at regular intervals and was replaced by

effect of friction and shock, which can often cause means after each sampling interval. The samples

the tablet to chip, clog or break. Roche friabilator are analyzed spectrophotometrically at max of the

was used for this purpose. Pre-weighed samples of drug. The in vitro dissolution studies were

twenty tablets were placed in the friabilator, which tabulated in Table 4.

was then operated at 25 RPM for 4 minutes, that is,

www.iajps.com Page 4209

IAJPS 2017, 4 (12), 4207-4213 M. Sunitha Reddy and G. Charitha ISSN 2349-7750

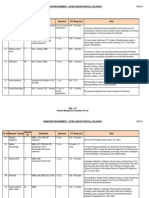

Table 1: Formulation trials of Bilayer tablets

Ingredients(mg/tablet) F1 F2 F3 F4 F5 F6 F7 F8 F9

Immediate release layer

Losartan potassium 50 50 50 50 50 50 50 50 50

Crospovidone 50 75 100 125 150 NA NA NA NA

Sodium starch glycolate NA NA NA NA NA 50 75 100 125

Polyvinyl pyrrolidone 5 5 5 5 5 5 5 5 5

Lactose monohydrous 191.5 166.5 141.5 116.5 91.5 191.5 166.5 141.5 116.5

Magnesium Stearate 1 1 1 1 1 1 1 1 1

Talc 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Colour Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S

IR layer wt 300 300 300 300 300 300 300 300 300

Sustained release layer

Repaglinide 4 4 4 4 4 4 4 4 4

HPMC k 100 M 2 4 6 8 10 NA NA NA NA

HPMC k 15 M NA NA NA NA NA 2 4 6 8

pvp 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Spray dried lactose 192.5 190.5 188.5 186.5 184.5 192.5 190.5 188.5 184.5

Talc 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Magnesium stearate 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

SR layer wt 200 200 200 200 200 200 200 200 200

Total tablet weight 500 500 500 500 500 500 500 500 500

Table 2:Pre compression parameters for Losartan Potassium blend and Repaglinide granules

Bulk Tapped Hausners Carrs Angle of Repose

Formulation

density(g/ml) Density(g/ml) Ratio index(%) ()

L1 0.6820.004 0.7520.002 1.160.02 20.600.65 26.30.98

L2 0.5750.013 0.8240.004 1.250.03 18.980.87 29.80.17

L3 0.8230.215 0.6850.002 1.130.02 19.241.11 28.30.76

L4 0.6720.153 0.8140.003 1.90.02 21.290.87 29.40.88

L5 0.4260.023 0.6150.001 1.80.01 20.520.76 28.50.12

L6 0.7650.012 0.7340.004 1.230.03 17.850.65 25.80.23

L7 0.5210.006 0.6240.003 1.140.01 18.760.45 29.70.92

L8 0.6780.032 0.6540.004 1.190.02 20.320.96 26.90.47

L9 0.4790.041 0.8560.002 1.210.019 19.430.12 27.60.80

R1 0.5320.002 0.8220.006 1.120.01 18.600.45 21.30.98

R2 0.4740.003 0.8140.003 1.280.02 14.980.89 26.30.17

R3 0.8720.241 0.6890.001 1.230.02 19.240.21 21.90.76

R4 0.6340.231 0.7150.002 1.90.03 20.290.34 23.80.88

R5 0.3980.021 0.6190.001 1.80.01 21.520.65 28.10.12

R6 0.7630.014 0.7180.002 1.160.02 18.850.43 25.30.23

R7 0.4260.003 0.6540.004 1.180.01 16.760.29 26.30.92

R8 0.7320.051 0.7830.002 1.200.03 15.320.72 24.70.47

R9 0.5640.041 0.6910.002 1.170.02 17.430.14 27.20.80

www.iajps.com Page 4210

IAJPS 2017, 4 (12), 4207-4213 M. Sunitha Reddy and G. Charitha ISSN 2349-7750

Table 3: Post compression parameters for bilayer tablets

Batch Thickness Hardness Friability Disintegration Weight Assay%

time variation Losartan Repaglinide

F1 5.890.015 8.2 0.14 12m 53s 4981.95 85.180.01 87.490.23

F2 5.920.013 8.7 0.17 11m 47s 4951.23 89.720.04 89.450.41

F3 5.860.025 8.5 0.27 9m 18s 5001.35 92.170.21 85.410.18

F4 5.880.014 7.8 0.25 6m 41s 5121.29 97.360.11 95.130.56

F5 6.120.032 9.5 0.1 5m 30s 5001.56 99.18052 99.370.11

F6 5.990.153 7.6 0.21 8m 32s 5061.8 96.430.03 97.920.29

F7 5.960.231 8.3 0.18 9m 12s 5031.2 94.650.01 98.510.04

F8 6.10.051 7.9 0.16 11m 24s 4991.25 93.470.06 91.330.12

F9 5.920.061 8.8 0.13 7m 86s 4981.12 97.230.21 92.430.34

Table 4: In-vitro percent drug release of Losartan potassium immediate release layer (L1-L9)

Time Losartan IR layer %Drug Release

(min) L1 L2 L3 L4 L5 L6 L7 L8 L9

0 0 0 0 0 0 0 0 0 0

5 25.20.05 26.80.321 18.10.208 19.240.01 13.80.1 17.270.03 18.920.01 12.90.30 14.710.01

10 69.20.37 58.20.264 46.170.026 52.410.03 34.890.01 39.720.02 42.790.03 28.90.26 32.40.04

15 81.20.20 74.10.2 67.870.02 78.260.02 67.410.32 59.270.02 61.910.02 60.210.20 65.40.24

30 82.30.15 79.20.1 73.790.026 84.20.1 89.70.26 79.140.03 78.280.04 78.40.26 84.70.41

45 73.60.01 76.10.35 85.890.030 95.30.05 99.40.26 83.590.04 85.290.02 85.890.36 89.30.31

60 69.20.15 71.90.55 81.270.02 88.10.15 91.60.15 77.980.01 79.630.01 81.230.02 87.720.26

Fig 6: In- vitro dissolution % drug release profile of bilayer tablet (L1-L9)

www.iajps.com Page 4211

IAJPS 2017, 4 (12), 4207-4213 M. Sunitha Reddy and G. Charitha ISSN 2349-7750

Table 4: In-vitro percent drug release of Repaglinide sustained release layer (R1-R9)

Time Repaglinide SR layer % drug release

(min)

R1 R2 R3 R4 R5 R6 R7 R8 R9

0 0 0 0 0 0 0 0 0 0

0.5 8.920.01 9.820.04 12.40.15 4.20.01 1.80.17 7.210.13 8.540.02 2.40.01 1.20.29

1 28.410.02 32.250.02 39.670.02 15.70.23 12.80.26 24.780.03 28.670.01 14.90.02 13.20.13

28.0.5470.

2 58.670.02 68.910.06 56.370.02 38.270.02 30.210.24 42.560.01 52.910.04 32.80.34

36

4 69.270.02 78.960.07 72.810.03 64.890.14 58.70.12 68.240.04 67.290.01 49.40.72 60.810.23

6 73.240.55 80.120.02 81.820.02 86.710.01 87.490.32 72.930.01 75.810.12 72.90.21 82.470.62

8 78.270.02 85.60.01 83.970.02 94.780.03 99.870.02 89.370.05 89.40.48 92.720.18 93.60.01

Fig 7: In- vitro percent % drug release of bilayer tablet (R1-R9)

Fig 8: In vitro Percent % drug release of optimized formulation

www.iajps.com Page 4212

IAJPS 2017, 4 (12), 4207-4213 M. Sunitha Reddy and G. Charitha ISSN 2349-7750

Fig 9: IR overlay of optimized formulation

CONCLUSION: 5.M. Sunitha Reddy et al., formulation and

The present research was carried out to develop a evaluation of ibuprofen sustained release matrix

bilayer tablet of Losartan potassium and tablets using manlikara zapota gum as a release

Repaglinide by using different super disintegrants retarding polymer IJPSR,2015;3(9):1350-1361.

in various concentrations for immediate release, 6.M. Sunitha Reddy et al., formulation and

where polymers are used to retard the release of evaluation of sustained release matrix tablets of

Repaglinide. The FT-IR studies revealed that there Metformin by using the combination of natural and

was no interaction between the drugs and the synthetic polymers. World journal of pharmacy and

excipients. Different formulations were prepared in pharmaceutical sciences, 2013.

increasing concentrations of super disintegrants and 7.N. Patel, R. Natarajan, N.N. Rajendran and M.

polymers. Direct compression was performed for Rangapriya, formulation and evaluation of

immediate release and wet granulation for the immediate release bilayer tablets of Telmisartan

sustained release layer. Various batches were and hydrochlorthiazide, Int. J. pharm sci and

prepared and evaluated, among the nine nanotech.2011;(4):1477-1482.

formulations, F5 formulation was optimized and 8.M. Sunitha Reddy et al., formulation and

showed the maximum drug release compared to the evaluation of Diclofenac sustained tablets using

other formulations. mucilage of ocimum sanctum as a release modifier

IJPSR2015;3(9):1350-1361.

REFERENCES: 9.M.Sunitha Reddy et al., formulation and

1.MC Gohel, RK Parikh, SA Nagori, BA Jethwa. evaluation of sustained release matrix tablets using

Fabrication and evaluation of bilayer tablet jack fruit seed extract as release retardant WJPPS,

containing conventional Paracetamol and modified 2017; 4:8793.

release Dichlofenac sodium. Indian journal of 10.Ramesh .D, Satish kumar, Guraviah, A.

pharmaceutical sciences 2010; 72(2); 191-96. Harinini., formulation and evaluation of bilayered

2.Patel. N. and Patel. K.. Development and sustained release matrix tablets of Metformin

validation of ultraviolet spectrophotometric method hydrochloride and Pioglitazone. int. j. sci

for the simultaneous estimation of Metformin Res.2010; 5(3):176-182.

hydrochloride and Repaglinide in bilayer tablet. 11. Arunachalam, S. Sethuraman, D Vinay kumar,

Journal of pharmaceutical sciences and R.Senthiel raj, Kishore Konam, and A.

bioscientific research, 2015;5(1): 104-109. Umarunisha. Formulation and evaluation of bilayer

3.Jithendra R. Amruthkar, Mohan.et al., bilayer sustained release tablets of Metoprolol succinate

tablet formulation of Metformin hydrochloride and and Telmisartan. Int J pharm Sci Bio 2010; 1:250-

Gliclazide: A novel approach in the treatment of 255.

diabetes. International journal of pharmaceutical 12.Uttam Mandal, Tapan kumar paul et al.,

research and development.2009 may, (1). formulation and in vitro studies of a fixed dose

4.Atram SC formulation of bilayer tablet combination of a bilayer matrix tablet containing

containing Metoprolol succinate and Amlodipinbe Metformin hydrochloride as sustained release and

besyltate as a model drug for antihypertensive Glipizide as immediate release, drug

therapy: journal of pharmacy research 2009; dev.ind.pharm,2008,34(3):305-313.

2(8):1335-1347.

www.iajps.com Page 4213

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Formulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleDocument9 pagesFormulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleBaru Chandrasekhar RaoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Simultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodDocument6 pagesSimultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodBaru Chandrasekhar RaoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Genetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Document5 pagesGenetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Baru Chandrasekhar RaoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocument11 pagesDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Development of Cell Culture System From Selected Tissues of Pangaius HypopthalmusDocument6 pagesDevelopment of Cell Culture System From Selected Tissues of Pangaius HypopthalmusBaru Chandrasekhar RaoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocument8 pagesAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoNo ratings yet

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocument8 pagesKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesDocument8 pagesThe Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesBaru Chandrasekhar RaoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Preparation of Silver Nanoparticles From Herbal PlantDocument9 pagesPreparation of Silver Nanoparticles From Herbal PlantBaru Chandrasekhar RaoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocument7 pagesGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Non-Adherence in Hyppertensive Patients of Peshawar, PakistanDocument13 pagesNon-Adherence in Hyppertensive Patients of Peshawar, PakistanBaru Chandrasekhar RaoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Nephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsDocument12 pagesNephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsBaru Chandrasekhar RaoNo ratings yet

- A Brief Review On YawsDocument7 pagesA Brief Review On YawsBaru Chandrasekhar RaoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Review On: Inventory ManagementDocument8 pagesReview On: Inventory ManagementBaru Chandrasekhar RaoNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Role of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenDocument4 pagesRole of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenBaru Chandrasekhar RaoNo ratings yet

- C-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsDocument5 pagesC-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsBaru Chandrasekhar RaoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocument4 pagesRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoNo ratings yet

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocument4 pagesDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- An Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchDocument6 pagesAn Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchBaru Chandrasekhar RaoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocument7 pagesPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocument7 pagesAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoNo ratings yet

- Association of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyDocument4 pagesAssociation of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyBaru Chandrasekhar RaoNo ratings yet

- An Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsDocument6 pagesAn Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsBaru Chandrasekhar RaoNo ratings yet

- Isolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Document8 pagesIsolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Baru Chandrasekhar RaoNo ratings yet

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDocument6 pagesAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoNo ratings yet

- Study of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Document6 pagesStudy of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Baru Chandrasekhar RaoNo ratings yet

- A Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreDocument8 pagesA Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreBaru Chandrasekhar RaoNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocument11 pagesThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoNo ratings yet

- After Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsDocument4 pagesAfter Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsBaru Chandrasekhar RaoNo ratings yet

- Oppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyDocument10 pagesOppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyBaru Chandrasekhar RaoNo ratings yet

- Pharmacological Screeing of DrugsDocument59 pagesPharmacological Screeing of Drugsrajender100% (1)

- The Future of Biosimilars and Biobetters in Ophthalmology: EditorialDocument2 pagesThe Future of Biosimilars and Biobetters in Ophthalmology: EditorialMohammad A. BawtagNo ratings yet

- "To Study OF The Marketing Strategies of Pharmaceutical Sector" at Nova Global Medicare PVT LTDDocument6 pages"To Study OF The Marketing Strategies of Pharmaceutical Sector" at Nova Global Medicare PVT LTDManishaNo ratings yet

- Lampiran Telahan StafDocument13 pagesLampiran Telahan StafIna Rama BahtiarNo ratings yet

- GoutDocument10 pagesGoutAmberNo ratings yet

- Thesis of ProcessDocument184 pagesThesis of Processrohan satwaraNo ratings yet

- 8b.pharm Semester Viii PDFDocument13 pages8b.pharm Semester Viii PDFDrAnisha PatelNo ratings yet

- Oral Lipid-Based Formulations: David J. HaussDocument10 pagesOral Lipid-Based Formulations: David J. HaussAna KovačevićNo ratings yet

- Radiopharmaceutical Production: Filter Integrity TestDocument8 pagesRadiopharmaceutical Production: Filter Integrity TestNitin JainNo ratings yet

- Cost and Management Accounting in Practise: An Industry Specific PerspectiveDocument16 pagesCost and Management Accounting in Practise: An Industry Specific PerspectivediveshNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Kul Bioprocess DevelopmentDocument25 pagesKul Bioprocess Developmentuntia_sariNo ratings yet

- Experiment 9 Formal Report On Classification Test of Hydroxyl-Containing and Carbonyl-Containing Organic CompoundsDocument16 pagesExperiment 9 Formal Report On Classification Test of Hydroxyl-Containing and Carbonyl-Containing Organic CompoundsLuisGabito100% (1)

- KebayoranDocument94 pagesKebayoranaditiya tegarNo ratings yet

- What Is Cephalexin?: Important Information About CephalexinDocument9 pagesWhat Is Cephalexin?: Important Information About CephalexinYaleswari Hayu PertiwiNo ratings yet

- Inp Pharma2023 PDFDocument12 pagesInp Pharma2023 PDFDenesa Joyce BustamanteNo ratings yet

- Jbptitbche GDL Publ 2003 Yasuhikohi 1 AAA221282 4Document11 pagesJbptitbche GDL Publ 2003 Yasuhikohi 1 AAA221282 4Anonymous cgKtuWzNo ratings yet

- Enzyme KineticsDocument72 pagesEnzyme Kineticsitokki otoya100% (1)

- Good Manufacturing Practices in Pharmaceutical IndustryDocument4 pagesGood Manufacturing Practices in Pharmaceutical IndustryJackieNo ratings yet

- Goodman and Gilman 12th Edition Price in IndiaDocument3 pagesGoodman and Gilman 12th Edition Price in IndiaTimNo ratings yet

- Recruitment Aadhar ClinicalDocument7 pagesRecruitment Aadhar ClinicalVishram LomteNo ratings yet

- Nanotechnology and Drug DeliveryDocument166 pagesNanotechnology and Drug DeliveryNgoc Hanh CaoNo ratings yet

- Pcol2 New SyllabusDocument15 pagesPcol2 New SyllabusChynna Ulep AlbertNo ratings yet

- Airflow VisualisationDocument7 pagesAirflow Visualisationkishor_more47No ratings yet

- Formulation and Evaluation of Orodispersible Tablets of CelecoxibDocument8 pagesFormulation and Evaluation of Orodispersible Tablets of CelecoxibdadaNo ratings yet

- Chapter 9 Import Operations and ActionsDocument96 pagesChapter 9 Import Operations and ActionsrogerNo ratings yet

- Zolendronat NEJMDocument11 pagesZolendronat NEJMnoveldycb89No ratings yet

- Medical FormDocument2 pagesMedical FormPushpendra KumarNo ratings yet

- ADC Skan Occupational SafetyDocument6 pagesADC Skan Occupational SafetyjmittalNo ratings yet

- Kelompok Bahasa InggrisDocument13 pagesKelompok Bahasa InggrisFajri NurramadhanNo ratings yet

- Cafer's: Mood Stabilizers and AntiepilepticsDocument67 pagesCafer's: Mood Stabilizers and Antiepilepticskaw gdNo ratings yet