Professional Documents

Culture Documents

Flanged Pressure Independent Control Valve (P.I.C.V.) : Technical Data Sheet

Uploaded by

rasheedillikkalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flanged Pressure Independent Control Valve (P.I.C.V.) : Technical Data Sheet

Uploaded by

rasheedillikkalCopyright:

Available Formats

technological solutions

TECHNICAL DATA SHEET

FLANGED PRESSURE INDEPENDENT

CONTROL VALVE (P.I.C.V.)

3776B

PN 16

Main features:

Cim 3776B is used for balancing the flow in cooling, heating and domestic water systems.

Cim 3776B is an automatic balancing valve with following features:

Easy required flow rate selection;

Automatic balancing in the event of fluctuating pressure conditions in system bran-

ches;

Flow rate modulation;

Flexibility if the system is modified after the first installation;

Reduction of balancing costs, improved energy saving and high environmental comfort;

It is supplied with flanged ends.

It is made of cast iron.

This article is made in compliance with the quality management requirements of ISO 9001

standard.

All articles are tested according to the EN 12266-1:2003 standard.

It can be used in a wide variety of sectors: heating, air conditioning, water, sanitary systems

and generally with any non corrosive liquid.

Technical data:

Max. static working pressure 16 bar

Max. differential pressure 4 bar (400 kPa)

Max. flow temperature 120 C

Min. temperature -10C

Fluids: Water and Glycol

Material of parts in contact with water:

Valve body;

Shutter, etc.

Materials: EN GJL 250;

Membrane: EPDM

Flanges: EN1092 PN16;

Face to face dimension standard: EN 558-1/1.

Rev.01 del 11/2016

Cav. Uff. Giacomo Cimberio S.p.A. 1

technological solutions

TECHNICAL DATA SHEET

Models:

Cim 3776B - Pressure independent control valve - PN 16 - Cast Iron

Flow rate range

DN Material Technical code

(l/s) (m3/h) (GPM)

65 1.167 7.778 4.2 28.0 18.49 123.28 DA03448065

80 1.583 10.556 5.7 38.0 25.10 167.31 DA03448080

Cast Iron

100 2.083 20.833 7.5 75.0 33.02 330.22 DA03448100

EN GJL 250

125 3.472 34.722 12.5 125.0 55.04 550.36 DA03448125

150 4.444 44.444 16.0 160.0 70.45 704.46 DA03448150

Actuator:

Cim 3776B P.I.C.V. is designed to be upgraded with different type of actuators to open,

close and modulate the valve on circuit.

DN 65-80

Different types of electric actuator are available, as follows:

EMV213/145: operating voltage 24 V AC/DC - 010 V DC control signal and 3-position

control signal;

EMV213/147: operating voltage 230 V AC - 3-position control signal;

DN 100-550

Two types of electric actuator are available, as follows:

EMV213/148: operating voltage 24 V AC/DC - 010 V DC control signal and 3-position

control signal;

EMV213/150: operating voltage 230 V AC - 3-position control signal;

Cim 3776B can be updated with manual gear Cim 920/3776B.

Cav. Uff. Giacomo Cimberio S.p.A. 2

technological solutions

TECHNICAL DATA SHEET

Model EMV213/145 EMV213/147

Technical code RC11150000 RC11160000

Voltage 24 V AC 20% 24 V AC 20%

230 V AC 15%

24 V DC 20% 24 V DC 20%

Control 0-10 V, Ri >100 k 3 positions 3 positions

Frequency 50/60 Hz 50/60 Hz 50 Hz

Feedback signal 0-10 V, load >10 k 0-10 V, load >10 k -

Power 4.8 W - 8.7 VA 4.8 W - 8.7 VA 2.0 W - 5.0 VA

Closing and opening times 60/120 s 60/120 s 120 s

Degree/Class of protection IP 54 IP 54 IP 54

Angle of rotation Max 95 Max 95 Max 95

Actuating torque 10 Nm 10 Nm 10 Nm

Cable length 1.2 m 1.2 m 1.2 m

Model EMV213/148 EMV213/150

Technical code RC11170000 RC111

Voltage 24 V AC 20% 24 V AC 20%

230 V AC 15%

24 V DC 20% 24 V DC 20%

Control 0-10 V, Ri >100 k 3 positions 3 positions

Frequency 50/60 Hz 50/60 Hz 50 Hz

Feedback signal 0-10 V, load >10 k 0-10 V, load >10 k -

Power 2.4 W - 4.4 VA 2.4 W - 4.4 VA 2.9 W - 5.6 VA

Closing and opening times

60/120 s 60/120 s 12

Degree/Class of protection IP 54 IP 54 IP 54

Actuator stroke Max 95 Max 95 Max 95

Actuating torque 15 Nm 15 Nm 18 Nm

Cable length 1.2 m 1.2 m 1.2 m

Model 920/3776B

Technical code RC11140000

S

Cav. Uff. Giacomo Cimberio S.p.A. 3

technological solutions

TECHNICAL DATA SHEET

Cross section:

P P L L MM

R

R

1. Body

Q

Q

2. Cap 4848

4949

3. Ring nut 3535

3232

4.31Housing 2828 3 32626

2 22626 3333

31 3333 3636

9 9

5. Spring housing 1010 3434 3535

2727 7 7 3737

nn

6.

x xdd

Spring 262638 38 3535

7. Sthutter 1111 3939

H

H

2626 2626

8. Shutter box

4040

9. Compensating cylinder 4141

10. Plate 4242

4343

11. Antifriction ring

C

C

F

F

4444

12. Shutter Stem 4545

13 .Membrane Stem 3333

H1

H1

4646

14. Guide Bush

25258 81212 1 1

15. Antifriction ring

16. Nut 1414 2929 4 4

17. By-pass shutter 2626

18. By-pass spring 2626

2222 1515

19. By-pass plug 2020 1313

2121 5 5

20. Rotochamber 1717

2929 2727 2323

21. Support plate 2626

2424 1616

1919 1818 6 6

22. Support B Bplate AA

23.SpingWpin W

ISO 8752 Y Y

24. Plug

25. By-pass screw 5050

V

V

Z1

Z1

26. O-Ring 5151

Z

Z

27. Binder point

28.

ISO5211 Ball

ISO5211 F F valve MF 1/4

29. Fittings J J K K

30. Copper pipe

31. Actuator stand

32. Stem

33. Retaining ring DIN 472

34. Washer

35. Dowel pin ISO 2338-B

36. Overtorque preventing spring

37. Stem

38. Sliding washer 2727

GG

39. Spacer 2929

40. Bushing 3030

41. Disc seat

42. Overpressure relief shutter

43. Overpressure relief spring

44. Cover DN100

Cover

45. Disc

46. Pin revrev5.5.16

5.5.16

47. Bolts and nuts

48. Electric actuator

49. Electric actuator support

51. Spacer

Cav. Uff. Giacomo Cimberio S.p.A. 4

technological solutions

TECHNICAL DATA SHEET

Installation procedure:

Before installation of Cim 3776B, check that inside the valve and the pipes there are no

OK

foreign matters which might damage the tightness of the valve.

Cim 3776 shall be installed to the flanges of the pipe perfectly aligned with its flanges, by

assuring that coupled parts will not suffer any stress. The valve shall not be used as anchor

for hanging pipes, rather it is the pipe that shall support the valve itself. Make sure to true

up the tightening gaskets of the flanges before tightening the bolts.

NO Pay attention to any welding procedure carried out in the installation, for this could cause

high temperatures exceeding the working limits of the valve. Pipes should be equipped

with thermal expansion joint.

Use gasket suitable for valve DN, PN, and working conditions. We recommend to use gas-

ket conforming to standards: EN DIN 1514-1 (former DIN 2690), suitable for raised face PN16

flanges according to: EN 1092 - ISO 7005 - DIN2526 form C - UNI 2229.

Pay attention to gasket placement: gasket must not disturb the flow.

The lower part of valve body contains compressed spings. DO NOT OPEN.

WARNING

DO NOT OPEN

COMPRESSED

SPRING

Typical installations:

Cim 3776B is suitable for variable volume system to control fan coil flow rate directly. Below

a typical installation: in each moment the flow rate is the required one and there will be no

extra-flow due to the pressure fluctuations.

Controller

LOAD:

Power (kW)

Differential

temperature (C)

Cav. Uff. Giacomo Cimberio S.p.A. 5

technological solutions

TECHNICAL DATA SHEET

Balancing:

Valve can regulate a wide flow rate range. The flow regulation is done by means of a triple

offset butterfly valve that assure low operating torque and accurate regulation.

The disc shape determines the regulation characteristic: linear (standard) or equipercent-

age (on request).

Design includes specific features to avoid damages to the internal component and the

actuator in case of water hammers.

The angle of rotation can be limited on the device between 0 and 90 and continuously

adjusted between 5 and 80.

The limit is fixed using a set screw directly on the actuator or the gear box and the limit stop

on the self-centring spindle adapter.

The flow rate can be measured as describe in the following pages.

Limit stops with gear box Cim 920/3776B Limit stops in EMV213/145 and EMV213/147

Limit stops in EMV213/148 and EMV213/150

Cav. Uff. Giacomo Cimberio S.p.A. 6

technological solutions

TECHNICAL DATA SHEET

Sizing:

Thanks to their unique design, these valves are able to perform the following functions:

REGULATION: selection of required flow rate within the operating range;

The electrical actuator allows to set the flow rates working limits.

CONTROL: constant flow rate despite of pressure fluctuations;

Two different pressures operate on the DPC controller . The first one is transmitted from

the valve inlet to the lower section; the second one is registered at valve outlet by the

flow rate selecting device pa. In order to keep constant the difference between the

mentioned pressures, the DPC controller obturator operates by closing the water outlet

bore to reach the preset flow rate, regardless of fluctuating pressure conditions of the

system.

MODULATION: flow rate modulation for temperature control;

The electrical actuator performs the modulating function changing the section of flow

passage. When continuous modulation is carried out, the temperature is kept under

control. With continuous modulation, control is excellent even with small flow opening.

This eliminates on/off effect.

Relative density Constant flow is obtained through the valve, despite of pressure fluctuations.

Fluid r By simply measuring differential pressure (see below picture), the flow is obtained as fol-

Water 1.000 lows:

Water and glycol 10% 1.012

Water and glycol 20% 1.028

Water and glycol 30% 1.040 where:

Water and glycol 40% 1.054

Q is the flow rate in m3/h, r is the relative density, p is the pressure drop across the valve

Water and glycol 50% 1.067

(see picture below); Kvs - Kv at specified preset(see table below).

Opening KVs

Position

DN65 DN80 DN100 DN125 DN150

10 6.2 7.5 15.5 27.4 42.2

20 12.2 14.5 32.0 53.9 68.3

30 18.2 21.6 50.7 69.7 93.2

40 24.2 30.7 67.6 87.9 124.4

50 31.8 39.8 83.7 112.2 169.5

60 36.2 49.5 100.0 136.5 201.3

70 40.4 59.2 129.1 167.4 257.2

80 46.7 71.0 153.1 204.2 307.2

90 51.5 77.7 175.2 222.3 326.8

Constant flow is obtained through the valve, despite pressure fluctuations.

If differential pressure across the whole valve is above pmin (start-up pressure), the flow

rate is the same as the one stated on the valve table (function) of the pre-set;

Working range at 100%

Working range at 65%

Working range at 33%

Working range at 20%

EKOFLUX.PICV Istruzioni rev 9.05.16

Misura portata

Cav. Uff. Giacomo Cimberio S.p.A. 7

technological solutions

TECHNICAL DATA SHEET

EXAMPLE

Q It is required to balance the circuit in the figure, the given data are:

Circuit pressure drop: pc=10 kPa;

Flow rate: Q= 48 m3/h=13.33 l/s;

pa

pc

Maximum head: pa,max = 60 kPa (Pump head);

Pipeline size: DN 100.

pb

It is possible to install a valve with the same diameter of the pipe, to avoid fittings instal-

lation. Using a Cim 3776B DN100, it is possible to check from the attached tables the flow

pa = pb + pc rate (7,5 - 75 m3/h).

pb Pressure drop across Cim 3776B

In this conditions P.I.C.V. needs at least 30 kPa of differential pressure in order to work prop-

pc Circuit pressure drop erly, the available pressure on the riser should be at least:

pa Available pressure for the riser

SUGGESTED VALUES AND TIPS: The maximum allowable differential pressure across the balancing valve is 400 kPa, it

means that the maximum head at the riser should be:

Velocities in the pipeline:

Max = 3 m/s

Min = 0.75 m/s Being the maximum head less than the calculated limit, the installation is correct.

For the preliminary sizings where the

value of maximum available pressure is

not known, it is possible to use the ma-

ximum head of the pump directly.

Cav. Uff. Giacomo Cimberio S.p.A. 8

technological solutions

TECHNICAL DATA SHEET

Measurement conversion Pressure

chart: FROM MULTIPLY BY TO OBTAIN

Pressure

Pa, Pascal 0,001 kPa, kiloPascal

Pa, Pascal 0,000001 MPa, Mega Pascal

FROM

Pa, Pascal MULTIPLY

0,00001 BY bar TO OBTAIN

Pa, Pascal 0,00010972 mH2O , metres of water

Pa, Pascal

Pa, Pascal 0,001

0,000145038 kPa,per

psi, pound kiloPascal

square inch

Pa, Pascal

bar 0,000001

1,01325 MPa, Mega Pascal

atm, atmosphere

Pa, Pascal

bar 0,00001

0,980665 barsquare centimetre

Kg/cm2, kilograms per

Pa, Pascal

bar 0,00010972

10,1972 mH2O,,metres

m metresofofwater

water

H2O

Pa, Pascal

bar 0,000145038

14,5038 psi,

psi, pound

pound per

per square

square inch

inch

bar atmosphere

atm, 1,01325

1,03323 atm, atmosphere

Kg/cm2, kilograms per square centimetre

bar atmosphere

atm, 0,980665

10,3323 Kg/cm2,m

kilograms per square

, metres centimetre

of water

H2O

bar atmosphere

atm, 10,1972

14,6959 psi,m H2O , metres

pound of water

per square inch

bar 2

Kg/cm 14,5038

10 psi,mpound per square inch

H2O , metres of water

atm, atmosphere

Kg/cm 2 1,03323

14,2233 Kg/cm

psi,, kilograms

2

pound per persquare

squareinch

centimetre

matm, atmosphere 10,3323

1,42233 psi,m H2O , metres

pound of water

per square inch

H2O

atm, atmosphere 14,6959 psi, pound per square inch

Kg/cm 2

TO OBTAIN DIVIDE 10 BY mH2O , metres of water FROM

Kg/cm 2 14,2233 psi, pound per square inch

mH2O 1,42233 psi, pound per square inch

TO OBTAIN DIVIDE BY FROM

Length, Area, Volume, Density

FROM MULTIPLY BY TO OBTAIN

Length, Area, Volume, Density

inches 0,0254 m, metres

inches 2,54 cm, centimetres

FROM

feet MULTIPLY

0,3048 BY TOmetres

m, OBTAIN

feet 30,48 cm, centimetres

inches

yards 0,0254

0,9144 m,metres

m, metres

inches inches

square 2,54

0,00064516 mcm,2 centimetres

, metri quadrati

feet feet

square 0,3048

0,09290304 m2, squarem, metres metres

feet inches

square 30,48

6,4516 2 cm, centimetres

cm , square centimetres

yards feet

square 0,9144

929,0304 m, metres

cm , square centimetres

2

squareyards

square inches 0,00064516

0,8361274 mm2, ,square

2

metri quadrati

metres

l,square

litres feet 0,09290304 m

m3,, square metres

2

0,001 cubic metres

square inches

gallons 6,4516

0,003789412 cm m

2

, square

3 centimetres

, cubic metres

square

cubic feet

yards 929,0304

0,7645549 cm m

2

, square

3

, cubic centimetres

metres

square

cubic feetyards 0,8361274

0,02831685 m

m3,, square

2

metres

cubic metres

l, litresinches

cubic 0,001

0,0000164 mm3,,cubic

3

cubicmetres

metres

gallons

cubic inches 0,003789412

16,38706 cm 3m

3

, cubic

, cubic metres

centimetres

cubicfeet

cubic yards 0,7645549

28,31685 m3, cubic metres

l, litres

cubic feet

gallons 0,02831685

3,875412 m , cubic

3

metres

l, litres

cubic inches 0,0000164 m , cubic metres

3

cubic inches

TO OBTAIN 16,38706

DIVIDE BY cm 3, cubic centimetres FROM

cubic feet 28,31685 l, litres

gallons 3,875412 l, litres

Pressure-temperature

ratings: TO OBTAIN DIVIDE BY FROM

0 29 58 87 116 145 174 203 232 261 290 319 349 377 406 p 2

[lbf/in ]

180 356

160 320

140 284

120 248

T [C]

T [F]

100 212

80 176

60 140

40 104

20 38

0 32

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 p [bar]

Cav. Uff. Giacomo Cimberio S.p.A. 9

technological solutions

TECHNICAL DATA SHEET

Flow rates - DN 65

52

Cim 3776B

48

44

40

Flow rate - Q (m3/h) 36

32

28

24

20

16

DN 65

12

0

Q = Kvs p 0% 12,5% 25% 37.5% 50% 62.5% 75% 87.5% 100%

Setting

Pre-Set 10% 15% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Angle 9 13.5 18 27 36 45 54 63 72 81 90

m3/h

Flow Rate

- 42 5,6 8,4 11,2 14,0 16,8 19,6 22,4 25,2 28

Flow

l/s - 1,167 1,556 2,333 3,111 3,889 4,667 5,444 6,222 7,000 7,778

Rate

5%

GPM - 18,49 24,66 36,98 49,31 61,64 73,97 86,30 98,62 110,95 123,28

10%

Min p kPa - 30 30 30 30 30 30 30 50 50 50

30 kPa 400 kPa

Cav. Uff. Giacomo Cimberio S.p.A. 10

technological solutions

TECHNICAL DATA SHEET

Flow rates - DN 80

52

Cim 3776B

48

44

40

Flow rate - Q (m3/h) 36

32

28

24

20 DN 80

16

12

0

Q = Kvs p 0% 12,5% 25% 37.5% 50% 62.5% 75% 87.5% 100%

Setting

Pre-Set 10% 15% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Angle 9 13.5 18 27 36 45 54 63 72 81 90

m3/h

Flow Rate

- 5,7 7,6 11,4 15,2 19,0 22,8 26,6 30,4 34,2 38

Flow

l/s - 1,583 2,111 3,167 4,222 5,278 6,333 7,389 8,444 9,500 10,556

Rate

5%

GPM - 25,10 33,46 50,19 66,92 83,65 100,39 117,12 133,85 150,58 167,31

10%

Min p kPa - 30 30 30 30 30 30 30 50 50 50

30 kPa 400 kPa

Cav. Uff. Giacomo Cimberio S.p.A. 11

technological solutions

TECHNICAL DATA SHEET

Flow rates - DN 100

130

Cim 3776B

120

110

100

Flow rate - Q (m3/h) 90

80

70

60

50

40 DN 100

30

20

10

0

Q = Kvs p 0% 12,5% 25% 37.5% 50% 62.5% 75% 87.5% 100%

Setting

Pre-Set 10% 15% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Angle 9 13.5 18 27 36 45 54 63 72 81 90

m3/h

Flow Rate

7,5 11,3 15,0 22,5 30,0 37,5 45,0 52,5 60,0 67,5 75

Flow

l/s 2,083 3,125 4,167 6,250 8,333 10,417 12,500 14,583 16,667 18,750 20,833

Rate

5%

GPM 33,02 49,53 66,04 99,06 132,09 165,11 198,13 231,15 264,17 297,19 330,22

10%

Min p kPa 30 30 30 30 30 30 30 50 50 50 50

30 kPa 400 kPa

Cav. Uff. Giacomo Cimberio S.p.A. 12

technological solutions

TECHNICAL DATA SHEET

Flow rates - DN 125

150

Cim 3776B

140

120

100

Flow rate - Q (m3/h) 90

80

70

DN 125

60

50

40

30

20

10

0

Q = Kvs p 0% 12,5% 25% 37.5% 50% 62.5% 75% 87.5% 100%

Setting

Pre-Set 10% 15% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Angle 9 13.5 18 27 36 45 54 63 72 81 90

m3/h

Flow Rate

12,5 18,8 25,0 37,5 50,0 62,5 75,0 87,5 100,0 112,5 125

Flow

l/s 3,472 5,208 6,944 10,417 13,889 17,361 20,833 24,306 27,778 31,250 34,722

Rate

5%

GPM 55,04 82,55 110,07 165,11 220,14 275,18 330,22 385,25 440,29 495,32 550,36

10%

Min p kPa 30 30 30 30 30 30 30 30 30 50 50

30 kPa 400 kPa

Cav. Uff. Giacomo Cimberio S.p.A. 13

technological solutions

TECHNICAL DATA SHEET

Flow rates - DN 150

195

Cim 3776B

180

165

150

Flow rate - Q (m3/h) 135

120

105

90

DN 150

75

60

45

30

15

0

Q = Kvs p 0% 12,5% 25% 37.5% 50% 62.5% 75% 87.5% 100%

Setting

Pre-Set 10% 15% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Angle 9 13.5 18 27 36 45 54 63 72 81 90

m3/h

Flow Rate

16,0 24,0 32,0 48,0 64,0 80,0 96,0 112,0 128,0 144,0 160

Flow

l/s 4,444 6,667 8,889 13,333 17,778 22,222 26,667 31,111 35,556 40,000 44,444

Rate

5%

GPM 70,45 105,67 140,89 211,34 281,78 352,23 422,68 493,12 563,57 634,01 704,46

10%

Min p kPa 30 30 30 30 30 30 30 30 30 50 50

30 kPa 400 kPa

Cav. Uff. Giacomo Cimberio S.p.A. 14

technological solutions

P L M

R

TECHNICAL DATA SHEET

Q

48

49

35

Main dimensions: 28 3 26 2 26 33

32

31 36

33 9

10 34 35

27 7 37

Cim 3776B n x d 26 38

11

35

39

H

26 26

40

41

42

43

C

F

44

45

33

H1

46

25 8 12 1

14 29 4

26

26

22 15

20 13

21 5

27 17 23

29

26

24 16

19 18 6

B A

W Y

50

V

Z1

51

Z

ISO5211 F

J K

27

G

29

30

DN 65 80 100 125 150

rev 5.5.16

kg (without 21.6 28.1 33.6 46.4 75.4

actuator)

kg (with gear box) 23.0 29.5 35.0 47.8 76.8

A 290 310 350 400 480

H 205 214 224 272 301

H1 217 281 295 317 341

B 200 242 242 242 242

E 60 60 60 60 60

S 14 14 14 14 14

J 15 15 15 28 28

K 18 18 18 18 18

G 18 23 36 47 68

C 185 200 220 250 285

F 145 160 180 210 240

nxD 4 x 18 8 x 18 8 x 18 8 x 18 8 x 22

ISO 52110 F05 F05 F05 F07 F07

W 98 99 101 103 105

V 100 100 100 100 100

Z 110 110 110 110 110

Z1 134 134 134 134 134

Y 43 43 43 43 43

Cav. Uff. Giacomo Cimberio S.p.A. 15

technological solutions

TECHNICAL DATA SHEET

Main dimensions:

Cim EMV213/145

Cim EMV213/147

Cim EMV213/148

Cim EMV213/150

Cim EMV213/145 and Cim EMV213/147

84

92 70

40 36 32

54

21 28

170

2 >90

74 45

Cim EMV213/148 and Cim EMV213/150

Maintenance:

As a rule, the balancing valve does not need any maintenance. In case of replacement or

need of disassembling of some components of the valve make sure that the installation is

not under service or pressure.

Cav. Uff. Giacomo Cimberio S.p.A. 16

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A.

28017 San Maurizio dOpaglio (NO) - Italy - Via Torchio, 57 - C.P. 106

Te l . + 3 9 0 3 2 2 9 2 3 0 0 1 - F a x : + 3 9 0 3 2 2 9 6 7 2 1 6 / 9 6 7 7 5 5

skype: cimberiosk1, cimberiosk2

info@cimberio.it

www.cimberio.com

Copyright - Cav. Uff. GIACOMO CIMBERIO S.p.A. - All rights reserved. Tutti i diritti riservati.

IMR 562637 FM 01820 SA 551551 EMS 551553 OHS 551552 ENMS 577357

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Unistrut Seismic BracingDocument48 pagesUnistrut Seismic BracingrasheedillikkalNo ratings yet

- Self Consolidating ConcreteDocument2 pagesSelf Consolidating ConcreteaaNo ratings yet

- Rexroth Bomba HidraulicaDocument52 pagesRexroth Bomba HidraulicaHernan LopezNo ratings yet

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- UCDM Version 1 English PDFDocument246 pagesUCDM Version 1 English PDFKhalid AwanNo ratings yet

- Dat004 Eng PDFDocument68 pagesDat004 Eng PDFAslam ShaikhNo ratings yet

- A Method of Damper Control For Corridor Ventilation and Smoke ExtractionDocument15 pagesA Method of Damper Control For Corridor Ventilation and Smoke ExtractionrasheedillikkalNo ratings yet

- Mechanical Systems BuildingsDocument6 pagesMechanical Systems BuildingsrasheedillikkalNo ratings yet

- Technical Training CoilsDocument46 pagesTechnical Training CoilsrasheedillikkalNo ratings yet

- Robotics SyllabusDocument1 pageRobotics SyllabusdsathiyaNo ratings yet

- GRP Product GuideDocument20 pagesGRP Product Guidedp75No ratings yet

- Technical Training - Air DistributionDocument163 pagesTechnical Training - Air Distributionrasheedillikkal100% (1)

- TN19 2001 (AirDocument15 pagesTN19 2001 (AirmichaelmangaaNo ratings yet

- Electromotoric Actuators For Air Dampers and Control Valves of Oil or Gas Burners of Small To Medium CapacityDocument11 pagesElectromotoric Actuators For Air Dampers and Control Valves of Oil or Gas Burners of Small To Medium CapacityalexjoelNo ratings yet

- CCS 3000 - Compressor Controller: Standard FeaturesDocument2 pagesCCS 3000 - Compressor Controller: Standard Featuresمحمد فرحاتNo ratings yet

- Atrium Smoke ControlDocument12 pagesAtrium Smoke ControlOmar Al-GubuoryNo ratings yet

- Dana32 Presentation (Read-Only) (Compatibility Mode)Document43 pagesDana32 Presentation (Read-Only) (Compatibility Mode)ncthanhck100% (1)

- 72957d3bb1659d7c77dbf6b6c550abeeDocument41 pages72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNo ratings yet

- Reflux 819: Pressure RegulatorDocument20 pagesReflux 819: Pressure RegulatorRafael Jose Tasco ZabaletaNo ratings yet

- SPEC 11669 Rev C Product Specification Subsea LF CIMVDocument2 pagesSPEC 11669 Rev C Product Specification Subsea LF CIMVshengguoNo ratings yet

- Product Data Sheet Damcos Solenoid Operated Directional Control Valves Type 2 en 60682 PDFDocument7 pagesProduct Data Sheet Damcos Solenoid Operated Directional Control Valves Type 2 en 60682 PDFHendiko PanggabeanNo ratings yet

- STE0363 - 92 Rev.06 - 22-07-2022Document22 pagesSTE0363 - 92 Rev.06 - 22-07-2022emunozNo ratings yet

- 04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Document4 pages04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Muse AFNo ratings yet

- 3 Way Sauter ValveDocument8 pages3 Way Sauter ValverkssNo ratings yet

- ES - Model W-PICV-16,25Q (DN200-DN250)Document1 pageES - Model W-PICV-16,25Q (DN200-DN250)AssaadNo ratings yet

- 2240 1312 EKN Steelwelded Edition3 en 0607Document7 pages2240 1312 EKN Steelwelded Edition3 en 0607AhmedRamadanNo ratings yet

- Series 4D01 (Denison) Characteristics: Directional Control ValveDocument6 pagesSeries 4D01 (Denison) Characteristics: Directional Control ValveKhaled MahranNo ratings yet

- Banco Con Control Electrico Proporcional L218Document60 pagesBanco Con Control Electrico Proporcional L218Agustín TorresNo ratings yet

- GSR Data Sheet Solenoid Valve Type 27Document4 pagesGSR Data Sheet Solenoid Valve Type 27BaoLCNo ratings yet

- Rotary Limit Switch GF4CDocument16 pagesRotary Limit Switch GF4CIvan PimentelNo ratings yet

- E8 SeriesDocument2 pagesE8 SeriesMagin Idelfonso TorreblancaNo ratings yet

- Slide Valve SV and SV1 Series (U)Document9 pagesSlide Valve SV and SV1 Series (U)Enis LoureiroNo ratings yet

- DiscoverEVL16A ADocument4 pagesDiscoverEVL16A Ainsiste27No ratings yet

- MODEL PC-171 - Transformer Temperature IndicatorDocument6 pagesMODEL PC-171 - Transformer Temperature IndicatorMKNo ratings yet

- Optically Coupled Isolator Phototransistor Output: 4N25X, 4N26X, 4N27X, 4N28X 4N25, 4N26, 4N27, 4N28Document3 pagesOptically Coupled Isolator Phototransistor Output: 4N25X, 4N26X, 4N27X, 4N28X 4N25, 4N26, 4N27, 4N28vandertpradoNo ratings yet

- D1wwed02e DPC Ing Kbs New 28621Document76 pagesD1wwed02e DPC Ing Kbs New 28621Gustavo Henrique FagundesNo ratings yet

- Salami Catalog vdm8 PDFDocument38 pagesSalami Catalog vdm8 PDFHeather Murphy0% (1)

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionalbertoNo ratings yet

- 2/2 Solenoid Cartridge Valve, Size 10: 1 DescriptionDocument5 pages2/2 Solenoid Cartridge Valve, Size 10: 1 Descriptionsandeep100% (1)

- A6V10387805 - 2-Port Shutoff Valves and 3-Port Changeover Ball V - enDocument16 pagesA6V10387805 - 2-Port Shutoff Valves and 3-Port Changeover Ball V - enhugoNo ratings yet

- Gas CoolerDocument9 pagesGas CoolerKHANNNNo ratings yet

- Copa-Cm / Mag-Cm: Electromagnetic Flowmeter With Capacitive Electrodes in Compact and Remote DesignsDocument20 pagesCopa-Cm / Mag-Cm: Electromagnetic Flowmeter With Capacitive Electrodes in Compact and Remote DesignsAli JawadNo ratings yet

- Technical Data Compressor: SC12CLDocument6 pagesTechnical Data Compressor: SC12CLKokoNo ratings yet

- Service Manual: Mod.: F400-SAEV-TS F400 SAEW TS F400 SAEC TSCDocument18 pagesService Manual: Mod.: F400-SAEV-TS F400 SAEW TS F400 SAEC TSCCông ty CP Công nghệ An PhúcNo ratings yet

- Cca-1112a-Ce BrochureDocument6 pagesCca-1112a-Ce BrochuretswNo ratings yet

- General SpecificationsDocument6 pagesGeneral SpecificationsUrooj IlyasNo ratings yet

- Taeevo: Air-Cooled Process Chillers With Scroll Compressors - R449ADocument2 pagesTaeevo: Air-Cooled Process Chillers With Scroll Compressors - R449ABellota03No ratings yet

- Active Module - UM-D37SUB/M/HC3/16DO/MR/MT - 2900068: Key Commercial DataDocument3 pagesActive Module - UM-D37SUB/M/HC3/16DO/MR/MT - 2900068: Key Commercial Datambid_2005No ratings yet

- DW115CNC Technical ParametersDocument11 pagesDW115CNC Technical ParametersProfCarlos GamaNo ratings yet

- Manual CO2 Laser SHPower SupplyDocument9 pagesManual CO2 Laser SHPower SupplyDawid RyżakNo ratings yet

- Nle11cnl 105h6174 r290 220v 50hz 09-2019 DsDocument6 pagesNle11cnl 105h6174 r290 220v 50hz 09-2019 Dspadilla.marcos.420No ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- S753 E-32 6e2838105 TransformerDocument27 pagesS753 E-32 6e2838105 TransformerJosip ZohilNo ratings yet

- N en en 5 8 120 82090Document2 pagesN en en 5 8 120 82090refaeNo ratings yet

- V3 Microsquirt® - Quickstart Guide: Intake Air Temperature SensorDocument4 pagesV3 Microsquirt® - Quickstart Guide: Intake Air Temperature SensorPeter TNo ratings yet

- SPEC Pulsatron E PLUS SeriesDocument2 pagesSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNo ratings yet

- 8038 - Data SheetDocument5 pages8038 - Data SheetJakub KjubNo ratings yet

- CV300 2Document13 pagesCV300 2Achariya ParpromNo ratings yet

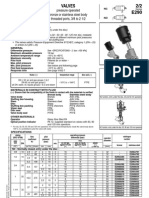

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- ArcsDocument18 pagesArcsSudhirNo ratings yet

- Proportional Pressure Relief Valve, Pilot Operated: List of Contents FeaturesDocument12 pagesProportional Pressure Relief Valve, Pilot Operated: List of Contents FeaturescutoNo ratings yet

- JJ.J3C v2Document2 pagesJJ.J3C v2GOLIANDRONo ratings yet

- Elmag 200Document5 pagesElmag 200deepak ranakotiNo ratings yet

- EMCODocument12 pagesEMCOesen hawerNo ratings yet

- 3KSMC12AH - 3KSMC47AH: Taiwan SemiconductorDocument5 pages3KSMC12AH - 3KSMC47AH: Taiwan Semiconductorn tanevarNo ratings yet

- DS0256 Standard US ENDocument4 pagesDS0256 Standard US ENkicsnerNo ratings yet

- Proportional Directional Valve - Not Pressure Compensated - Q 40 L/min - Q 32 L/min - P 350 BarDocument3 pagesProportional Directional Valve - Not Pressure Compensated - Q 40 L/min - Q 32 L/min - P 350 BarDavidson GattoniNo ratings yet

- RD 102Document2 pagesRD 102Ventas Control HidráulicoNo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Measurement and Safety Devices For Distribution and Power Transformers - ABB - Comem-EN - catalogue-REV-B-24-06-2019Document34 pagesMeasurement and Safety Devices For Distribution and Power Transformers - ABB - Comem-EN - catalogue-REV-B-24-06-2019snooty.eli.gamedogsNo ratings yet

- Rockwool Fire Barrier DatasheetDocument12 pagesRockwool Fire Barrier DatasheetrasheedillikkalNo ratings yet

- TFBP ChecDocument2 pagesTFBP ChecrasheedillikkalNo ratings yet

- TFP230 03 2014Document6 pagesTFP230 03 2014rasheedillikkalNo ratings yet

- 3 M Fire Barrier Duct Wrap 15 ADocument20 pages3 M Fire Barrier Duct Wrap 15 ArasheedillikkalNo ratings yet

- 13-2016 FAQsDocument8 pages13-2016 FAQsJulianSamayoaNo ratings yet

- 5916a695707ef Duct Coating IntumescentDocument1 page5916a695707ef Duct Coating IntumescentrasheedillikkalNo ratings yet

- Fire Duct SystemsDocument16 pagesFire Duct SystemsrasheedillikkalNo ratings yet

- Ag5 2002Document134 pagesAg5 2002rasheedillikkalNo ratings yet

- HOBAS Pipe ClassificationDocument2 pagesHOBAS Pipe ClassificationrasheedillikkalNo ratings yet

- 1and2level1 PDFDocument2 pages1and2level1 PDFrasheedillikkalNo ratings yet

- Technical Training ValvesDocument24 pagesTechnical Training ValvesrasheedillikkalNo ratings yet

- JBB Idea CwsizingDocument13 pagesJBB Idea CwsizingrasheedillikkalNo ratings yet

- Heat ExchangerDocument16 pagesHeat ExchangerAudrey Patrick KallaNo ratings yet

- PBRS Version 1.0Document233 pagesPBRS Version 1.0Khader Abu-daggaNo ratings yet

- Weight Comparison TB UK v7Document12 pagesWeight Comparison TB UK v7Santhosh ThekkethottiyilNo ratings yet

- Commissioning ReportDocument212 pagesCommissioning ReportrasheedillikkalNo ratings yet

- 2 SpecificationDocument16 pages2 SpecificationrasheedillikkalNo ratings yet

- Displacement Diffuser DataDocument1 pageDisplacement Diffuser DatarasheedillikkalNo ratings yet

- White Paper Case Study SEC Template V2Document5 pagesWhite Paper Case Study SEC Template V2rasheedillikkalNo ratings yet

- HB v5 ch7Document91 pagesHB v5 ch7Ali Abdurrahman SungkarNo ratings yet

- Scrap MGT - Optimization SolutionsDocument25 pagesScrap MGT - Optimization SolutionsRodolfoMarínNo ratings yet

- Knife Type TB CaburDocument1 pageKnife Type TB CaburAnonymous IBm7FaYNo ratings yet

- 2011 08 Sprayer MevaTrenn GBDocument2 pages2011 08 Sprayer MevaTrenn GBmma87No ratings yet

- Alustar 300 eDocument3 pagesAlustar 300 eThiago BerthaudNo ratings yet

- 2701 MSDSDocument5 pages2701 MSDSAhmed Emad AhmedNo ratings yet

- UNIVER Tratamento ArDocument22 pagesUNIVER Tratamento ArhenriqueNo ratings yet

- Bearing Design CalculationsDocument42 pagesBearing Design Calculationsarunurs1100% (1)

- 10.6 Schedule of Accreditation: Product Certification Body Accreditation No. APC0002Document16 pages10.6 Schedule of Accreditation: Product Certification Body Accreditation No. APC0002erwerwerwerwewNo ratings yet

- Tofflon Service Engineer JD - IndonesiaDocument4 pagesTofflon Service Engineer JD - IndonesiaTamilNo ratings yet

- MT6050i 8050i Installation 101102Document8 pagesMT6050i 8050i Installation 101102gabyNo ratings yet

- Dow Corning 111 Valve Lubricant and Sealant 10.15.10Document7 pagesDow Corning 111 Valve Lubricant and Sealant 10.15.10Syifa Alfi HabibiNo ratings yet

- DL8000 Emerson PDFDocument322 pagesDL8000 Emerson PDFAgustin AguilarNo ratings yet

- PALIMEX R - 855 Product Information PR00331304Document2 pagesPALIMEX R - 855 Product Information PR00331304Muhammad ThohirNo ratings yet

- Advanced Tool Design Question PaperDocument1 pageAdvanced Tool Design Question PaperMr. N. GnaneswaranNo ratings yet

- Argon Pure GasDocument1 pageArgon Pure GasAriyan AriyanNo ratings yet

- Layout Room INDUSTRI FARMASIDocument1 pageLayout Room INDUSTRI FARMASIDwi MeliniaNo ratings yet

- Tesa 60150 Adhesion Promoter Data SheetDocument1 pageTesa 60150 Adhesion Promoter Data SheetBalagopal U RNo ratings yet

- A Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Document9 pagesA Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Shreya Giri0% (1)

- Manual Aire Acondicionado HaierDocument48 pagesManual Aire Acondicionado Haierjguerrero.067100% (3)

- TalbrosDocument26 pagesTalbrossk9568270% (1)

- Manual de CambiadoresDocument11 pagesManual de CambiadoresMiguel Angel Medina CastellanosNo ratings yet

- For Chocking Between Steel & Concrete: Bulletin DescriptionDocument2 pagesFor Chocking Between Steel & Concrete: Bulletin Descriptionamitparabolicdrugs3No ratings yet

- CWWS ULTRA-SEP Brochure (2008)Document12 pagesCWWS ULTRA-SEP Brochure (2008)Steve OsuohaNo ratings yet

- Mapefloor FC 200 ME: High Build Epoxy Resin Floor CoatingDocument4 pagesMapefloor FC 200 ME: High Build Epoxy Resin Floor Coatingdiv_bamaniaNo ratings yet

- Modern Equipment Ladles Brochure 6 14 PDFDocument20 pagesModern Equipment Ladles Brochure 6 14 PDFCristian Osorio RonquiloNo ratings yet

- El FF TD 01Document2 pagesEl FF TD 01Masood Alam FarooquiNo ratings yet

- BdeM Taller No. 2Document2 pagesBdeM Taller No. 2Luisfer PriceNo ratings yet

- Ecological and Energetic Assessment of Re-Refining Used Oils To Base OilsDocument104 pagesEcological and Energetic Assessment of Re-Refining Used Oils To Base OilsFernando SImonelliNo ratings yet