Professional Documents

Culture Documents

Conv. v. Nonconv

Uploaded by

umesh vishwakarmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conv. v. Nonconv

Uploaded by

umesh vishwakarmaCopyright:

Available Formats

INTRODUCTION:

Manufacturing processes can be broadly divided into two groups and they are primary

manufacturing processes and secondary manufacturing processes. The former ones

provide basic shape and size to the material as per designers requirement. Casting,

forming, powder metallurgy are such processes to name a few. Secondary

manufacturing processes provide the final shape and size with tighter control on

dimension, surface characteristics etc. Material removal processes are mainly the

secondary manufacturing processes.

Material removal processes once again can be divided into mainly two groups and they

are Conventional Machining Processes and Non-Traditional Manufacturing

Processes.

Examples of conventional machining processes are turning, boring, milling, shaping,

broaching, slotting, grinding etc. Similarly, Abrasive Jet Machining (AJM), Ultrasonic

Machining (USM), Water Jet and Abrasive Water Jet Machining (WJM and AWJM),

Electro-discharge Machining (EDM) are some of the Non Traditional Machining

(NTM) Processes.

Conventional Machining VS. Non-Conventional Machining:

Conventional machining usually involves changing the shape of a work piece using

animplement made of a harder material. Using conventional methods to machine

hardmetals and alloys means increased demand of time and energy and therefore

increasesin costs; in some cases conventional machining may not be feasible.

Conventionalmachining also costs in terms of tool wear and in loss of quality in the

product owing toinduced residual stresses during manufacture. With ever increasing

demand formanufactured goods of hard alloys and metals, such as Inconel 718 or

titanium, moreinterest has gravitated to non-conventional machining methods.

Conventional machining can be defined as a process using mechanical (motion)

energy.

Non-conventional machining utilizes other forms of energy.

The three main forms ofenergy used in non-conventional machining processes

are as follows:

Thermal energy

Chemical energy

Electrical energy

Comparison

Conventional Manufacturing Non-Conventional

Processes Manufacturing Processes

1. Generally macroscopic chip 1. Material removal may occur with chip

formation by shear deformation. formation or even no chip formation

may take place. For example in AJM,

chips are of microscopic size and in case

of Electrochemical machining material

removal occurs due to electrochemical

dissolution at atomic level

2. There may be a physical tool 2. There may not be a physical tool

present. for example a cutting tool present. For example in laser jet

in a Lathe Machine, machining, machining is carried out

by laser beam. However in

Electrochemical Machining there is a

physical tool that is very much

required for machining.

3. Cutting tool is harder than work 3. There may not be a physical tool

piece at room temperature as well present. For example in laser jet

as under machining conditions machining, machining is carried out

by laser beam. However in

Electrochemical Machining there is a

physical tool that is very much

required for machining.

4. Material removal takes place due 4. Mostly NTM processes do not

to application of cutting forces necessarily use mechanical energy to

energy domain can be classified as provide material removal. They use

mechanical different energy domains to provide

machining. For example, in USM,

AJM, WJM mechanical energy is used

to machine material, whereas in ECM

electrochemical dissolution constitutes

material removal.

5. Conventional machining involves 5. Whereas unconventional machining

the direct contact of tool and work does not require the direct contact of

piece tool and work piece.

6. Lower accuracy and surface 6. Higher accuracy and surface finish.

finish.

7. Suitable for every type of material 7. Not Suitable for every type of material

economically economically

8. Tool life is lessdue to high surface 8. Tool life is more

contact and wear.

9. Higher waste of material due to 9. Lower waste of material due to low or

high wear. no wear.

10. Noisy operation mostly cause 10. Quieter operation mostly no sound

sound pollutions pollutions are produced.

11. Lower capital cost 11. Higher capital cost

12. Easy set-up of equipment. 12. Complex set-upequipment.

13. Skilled or un-skilled operator 13. Skilled operator required.

may required

14. Generally they are manual to 14. Generally they are fully automated

operate. process.

15. They cannot be used to produce 15. Can be used to produce prototype

prototype parts very efficiently parts very efficientlyAnd

and economically. economically.

You might also like

- Proses Manufaktur Minggu Ke 11Document34 pagesProses Manufaktur Minggu Ke 11RahmatullahNo ratings yet

- Year: Iv - I Mech: Unconventional Machining ProcessesDocument26 pagesYear: Iv - I Mech: Unconventional Machining ProcessesTanu RdNo ratings yet

- The Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsDocument3 pagesThe Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsNVNo ratings yet

- The Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsDocument3 pagesThe Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsSeshi ReddyNo ratings yet

- The Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsDocument3 pagesThe Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsNVNo ratings yet

- Unit VI - Modern Machining TechniquesDocument46 pagesUnit VI - Modern Machining TechniquesMr. Swapnil S. JadhavNo ratings yet

- New Microsoft Word DocumentDocument6 pagesNew Microsoft Word DocumentAbdulbasitHamzaNo ratings yet

- UMP R20 - 5 Units NotesDocument152 pagesUMP R20 - 5 Units Notesvijju vijju creativesNo ratings yet

- Ime 3Document11 pagesIme 3pavan06mceNo ratings yet

- Non Traditional Machining: SyllabusDocument36 pagesNon Traditional Machining: SyllabusMURTHY RAJNo ratings yet

- A.M. and CADocument17 pagesA.M. and CAAshis UgetconfusedNo ratings yet

- Department of Mechanical Engineering: SJB Institute of TechnologyDocument27 pagesDepartment of Mechanical Engineering: SJB Institute of TechnologyChidu KNo ratings yet

- 1st PDFDocument15 pages1st PDFKanchan MondalNo ratings yet

- Non-Traditional Machining: Unit - 1Document48 pagesNon-Traditional Machining: Unit - 1bunty231No ratings yet

- NCM IDocument23 pagesNCM IAbhishek KumarNo ratings yet

- Unconventional Machining MethodDocument26 pagesUnconventional Machining MethodSNEHIL DHIMANNo ratings yet

- Non-Traditional MachiningDocument48 pagesNon-Traditional MachiningSyedZameerNo ratings yet

- Advanced Manufacturing TechniqueDocument80 pagesAdvanced Manufacturing TechniqueMURTHY RAJNo ratings yet

- NTM QPDocument33 pagesNTM QPlikhithNo ratings yet

- Amp Notes Unit-1Document44 pagesAmp Notes Unit-1DJNo ratings yet

- Non-Traditionl Machining - Lecture NotesDocument47 pagesNon-Traditionl Machining - Lecture NotesSteven KanguyaNo ratings yet

- Ump e MaterialDocument93 pagesUmp e MaterialDushyanthkumar DasariNo ratings yet

- Chapter1 - 2nd LectureDocument16 pagesChapter1 - 2nd LectureKAMALJEET SINGHNo ratings yet

- Ucm - Unitwise Notes (r2017)Document168 pagesUcm - Unitwise Notes (r2017)A. AKASH 4001-UCE-TKNo ratings yet

- UNIT5 Non Traditional Manufacturing Processes Jitendra JadonDocument45 pagesUNIT5 Non Traditional Manufacturing Processes Jitendra JadonJibril WkNo ratings yet

- Nconventional Machining ProcessDocument15 pagesNconventional Machining ProcessNandam HarshithNo ratings yet

- Assignment On Non-Traditional Manufacturing Processes SubjectDocument18 pagesAssignment On Non-Traditional Manufacturing Processes SubjectAhmed EzwaiNo ratings yet

- Unit 4Document45 pagesUnit 4bmm16957No ratings yet

- Introduction To Non Traditional Machiniing TechniquesDocument24 pagesIntroduction To Non Traditional Machiniing TechniquesGunaseelapandian JayaprakashNo ratings yet

- Introduction To Non Traditional Machiniing TechniquesDocument24 pagesIntroduction To Non Traditional Machiniing TechniquesmedazNo ratings yet

- 084 - ME8073, ME6004 Unconventional Machining Processes - NotesDocument39 pages084 - ME8073, ME6004 Unconventional Machining Processes - NotesA. AKASH 4001-UCE-TKNo ratings yet

- Non ConventionalDocument13 pagesNon ConventionalAkash KumarNo ratings yet

- ME2026 Unconventional Machining - PDF.WWW - Chennaiuniversity.net NotesDocument27 pagesME2026 Unconventional Machining - PDF.WWW - Chennaiuniversity.net NotesSiva Raman100% (1)

- Unit I NotesDocument8 pagesUnit I NotesSadhasivam CNo ratings yet

- Unit I Part-A (Questions Wirh Answers)Document15 pagesUnit I Part-A (Questions Wirh Answers)rameshNo ratings yet

- Ucmp First Mid Course FileDocument160 pagesUcmp First Mid Course FileAraveetiCSReddyNo ratings yet

- Report On Non-Traditional Machining ProcessDocument29 pagesReport On Non-Traditional Machining ProcessRahul JHANo ratings yet

- UCM Question Bank 2 MarksDocument22 pagesUCM Question Bank 2 MarksManivannan JeevaNo ratings yet

- Institute of Technology & Management: Unconventional Machining ProcessDocument28 pagesInstitute of Technology & Management: Unconventional Machining ProcessAkash TripathiNo ratings yet

- Ch-12 Unconventional MachiningDocument24 pagesCh-12 Unconventional MachiningJAYANT KUMARNo ratings yet

- Ucmp 2 Mark With AnswerDocument17 pagesUcmp 2 Mark With AnsweranithayesurajNo ratings yet

- Ali Ubaid-284951-CDocument42 pagesAli Ubaid-284951-CDei mosNo ratings yet

- Advanced Manufacturing Technology (PC-ME701)Document23 pagesAdvanced Manufacturing Technology (PC-ME701)Deepak KumarNo ratings yet

- Non Traditining MachiningDocument68 pagesNon Traditining Machininganon_189991164No ratings yet

- UMP BookDocument135 pagesUMP BookSurendran MahalingamNo ratings yet

- Machining ProcessesDocument6 pagesMachining ProcessesUsama AnsariNo ratings yet

- Non-Traditional Machining - IDocument20 pagesNon-Traditional Machining - IRashida BegumNo ratings yet

- Unconventional Machining UNIT 1Document7 pagesUnconventional Machining UNIT 1rx135rakeshNo ratings yet

- Modern Manufacturing Methods: Unit IDocument17 pagesModern Manufacturing Methods: Unit IharinathNo ratings yet

- Electrochemical Machining Process: Presented By: Kanishq Gandhi A2399818011 5ME1XDocument10 pagesElectrochemical Machining Process: Presented By: Kanishq Gandhi A2399818011 5ME1XKanishq GandhiNo ratings yet

- Chap-1 - Introduction To AMPDocument25 pagesChap-1 - Introduction To AMPAmilin HatiaraNo ratings yet

- 1.introduction To NTMDocument14 pages1.introduction To NTMsillyhamNo ratings yet

- MT QB Unit 5Document7 pagesMT QB Unit 5Aditya BishtNo ratings yet

- Modern Manufacturing TechnologyDocument15 pagesModern Manufacturing TechnologyTHE NORTHCAP UNIVERSITYNo ratings yet

- NTM Notes PDFDocument89 pagesNTM Notes PDFSatish SatiNo ratings yet

- NTM NotesDocument89 pagesNTM NoteskushalambliNo ratings yet

- NDocument7 pagesNIstiak Ahmed PrinceNo ratings yet

- 35 Non Conventional MachiningDocument13 pages35 Non Conventional MachiningPRASAD326100% (8)

- Advanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingFrom EverandAdvanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingNo ratings yet

- Additive Manufacturing & CNCDocument28 pagesAdditive Manufacturing & CNCumesh vishwakarmaNo ratings yet

- Dummy PDFDocument1 pageDummy PDFumesh vishwakarmaNo ratings yet

- Finite Element Method Simulation of Drilling Process On Metal-Matrix CompositesDocument5 pagesFinite Element Method Simulation of Drilling Process On Metal-Matrix Compositesumesh vishwakarmaNo ratings yet

- AKTU Proposed Evaluation Scheme For Mechanical Engg Related Branches 2020-21Document7 pagesAKTU Proposed Evaluation Scheme For Mechanical Engg Related Branches 2020-21umesh vishwakarmaNo ratings yet

- A Gear Cutting Predictive Model Using The Finite Element MethodDocument6 pagesA Gear Cutting Predictive Model Using The Finite Element Methodumesh vishwakarmaNo ratings yet

- After 60 Years of EDM The Discharge Process Remains Still DisputedDocument6 pagesAfter 60 Years of EDM The Discharge Process Remains Still Disputedumesh vishwakarmaNo ratings yet

- Experimental and Finite Element Analysis of EDM Process and Investigation of Material Removal Rate by Response Surface MethodologyDocument18 pagesExperimental and Finite Element Analysis of EDM Process and Investigation of Material Removal Rate by Response Surface Methodologyumesh vishwakarmaNo ratings yet

- Untitled 1Document1 pageUntitled 1umesh vishwakarmaNo ratings yet

- B.tech Ec Ei 2nd Year 2018-19Document17 pagesB.tech Ec Ei 2nd Year 2018-19umesh vishwakarmaNo ratings yet

- Epass Summative Week 1 &2Document2 pagesEpass Summative Week 1 &2ANA REIZA ZAFRANo ratings yet

- Fatiguetesting 170304225349 PDFDocument26 pagesFatiguetesting 170304225349 PDFEngr.Hamid Ismail CheemaNo ratings yet

- Catalysts: Sio @tio Composite Synthesis and Its Hydrophobic Applications: A ReviewDocument17 pagesCatalysts: Sio @tio Composite Synthesis and Its Hydrophobic Applications: A ReviewAngelina GultomNo ratings yet

- Miller IndexDocument5 pagesMiller IndexKamenriderNo ratings yet

- Flocculation PDFDocument5 pagesFlocculation PDFSunilNo ratings yet

- Equivalences Between Different Designations: Chemical CompositionDocument2 pagesEquivalences Between Different Designations: Chemical CompositionSuleman KhanNo ratings yet

- Norman C. Lee Blow Molding Design Guide ISBN: 978-3-446-41264-4Document8 pagesNorman C. Lee Blow Molding Design Guide ISBN: 978-3-446-41264-4PrabakaranNo ratings yet

- Fe2o3 Trên CNTDocument96 pagesFe2o3 Trên CNTlumineurNo ratings yet

- Comparison of The Effectiveness of Deep Soil Mix ColumnsDocument3 pagesComparison of The Effectiveness of Deep Soil Mix Columnsvickneshj9406No ratings yet

- EE-106 UNIT 5 NotesDocument12 pagesEE-106 UNIT 5 Notesece gptplptNo ratings yet

- Beam To Column Flange Connection-ASDDocument7 pagesBeam To Column Flange Connection-ASDAnonymous YDwBCtsNo ratings yet

- Carbon CompositesDocument30 pagesCarbon CompositesVIbhav GuptaNo ratings yet

- Stable Pure-Iodide Wide-Band-Gap Perovskites For Efficient Si Tandem Cells Via Kinetically Controlled Phase EvolutionDocument17 pagesStable Pure-Iodide Wide-Band-Gap Perovskites For Efficient Si Tandem Cells Via Kinetically Controlled Phase EvolutionPeter GuoNo ratings yet

- Reformer Furnaces - Material, Damage Mechanism and AssessmentDocument21 pagesReformer Furnaces - Material, Damage Mechanism and AssessmentMuhammad Noor FadhliNo ratings yet

- General Organic ChemistryDocument153 pagesGeneral Organic ChemistrydfafsasdNo ratings yet

- Bonding RefresherDocument28 pagesBonding RefresherPierce TaylorNo ratings yet

- Rec9 - Force On Wires - V2Document5 pagesRec9 - Force On Wires - V2joshuarroldanNo ratings yet

- Ipc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDocument9 pagesIpc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDietmar WengerNo ratings yet

- EE143 - Four-Point Probe ManualDocument3 pagesEE143 - Four-Point Probe ManualJoseline1No ratings yet

- Bhavishya Chowrira ManuscriptDocument265 pagesBhavishya Chowrira ManuscriptDaniel LacourNo ratings yet

- BASF - Admixtures PresentationDocument37 pagesBASF - Admixtures PresentationДанило ГадайчукNo ratings yet

- Bphys102 Mod1 5@azdocuments - inDocument95 pagesBphys102 Mod1 5@azdocuments - inmokshayinidrNo ratings yet

- SuperconductivityDocument5 pagesSuperconductivityShruti ChakrabortyNo ratings yet

- 115 Terram 700 and Ekotex 06 Comparison v1 PDFDocument1 page115 Terram 700 and Ekotex 06 Comparison v1 PDFStefan CioaraNo ratings yet

- 3RD Floor: Flat Oval Duct - Joint Measurment SheetDocument3 pages3RD Floor: Flat Oval Duct - Joint Measurment Sheetsaquib715No ratings yet

- Wind Loads UK - Portal Frame WEDocument31 pagesWind Loads UK - Portal Frame WEjohnsmith198083% (6)

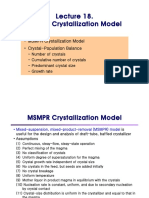

- MSMPR Crystallization ModelDocument9 pagesMSMPR Crystallization ModelAbou Tebba SamNo ratings yet

- Revised Profile Capacity-UpdateDocument2 pagesRevised Profile Capacity-UpdateRitwick BhattacharyaNo ratings yet

- Inspection Certificate: Ensa de Traccion I Tensile TestDocument8 pagesInspection Certificate: Ensa de Traccion I Tensile TestАнна КокоеваNo ratings yet

- 4 Powder Preparation by Chemical Methods 2Document59 pages4 Powder Preparation by Chemical Methods 2andrreaskinzNo ratings yet