Professional Documents

Culture Documents

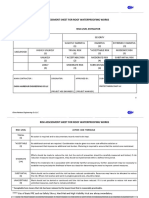

Weakness Spotting Is Made in These Areas

Uploaded by

Vidya SagarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weakness Spotting Is Made in These Areas

Uploaded by

Vidya SagarCopyright:

Available Formats

1308 Legislation in Indian Mines Safety, Health, and Sanitation in Mines 1309

2. Accident vulnerability increases when the seam is having lower STAGE OF COAL EXTRACTION

incubation period, and lower crossing point. Development workings have lower accident vulnerability as corn-

3. Accident vulnerability increases when there is a higher inci- pared to depillaring areas. Depillaring with stowing has lower accident

dence of geological disturbances such as faults, dykes, etc. vulnerability as compared to depillaring with caving. Mechanised caving

areas have still higher accident vulnerability as compared to manual caving

4. Accident vulnerability is highest when the immediate roof is

districts, as the man-machine system , when worked with close roof

shale, medium when it is mixed (sandstone and shale), and the lowest when

support in the restricted working area, exposes men to higher degree of

the roof is of sandstone.

accident risk.

5. Accident vulnerability is highest with a steep seam, and lowest AGE OF THE MINE

with a flat seam.

An old mine has more accident vulnerability than a new mine, as the

6. Accident vulnerability is highest when the gassiness dgree is total area, which has to be kept free from unsafe occurrence, is relatively

larger.

7. Accident vulerability is highest when the seam density is high. GENERAL LOCATION OF MINE

SYSTEM PARAMETERS A far-flung mine, located in a remote area, with scant infrastructural

facilities around, is more vulnerable to accidents, as, in case of any unsafe

Following basic assumptions are made with regard to the effect of

occurrence, the risk factor of accident casuality is more, as the casuality and

each of the system parameters over the accident vulnerability. occurrence may not be attended with the speed and efficiency it deserves.

1. Accident vulnerability is high for a high capacity mine. AVALIABILITY OF BASIC SAFETY HARDWARE AND SOFTWARE

2. Accident vulnerability is low for a low OMS mine, as the

Non-availability of the basic safety hardware and software increases

manpower deployment in the mine is of comparatively lower order.

the accident vulnerability.

3. Accident vulnerability is high when the production growth rate STATUS OF SAFETY DEVICES IN THE PRODUCTION SYSTEM

is high.

Following areas of operation under production are identified, and

4. Accident vulnerability is high when there is any new technology weakness spotting is made in these areas :

envisaged/applied for the operation of the mine system. Accident potentiallity

(a)Shaft.

is comparatively low for a planned/new mine/project.

(b) Haulage road way.

SYSTEM OF MINING

( c ) Travelling roadway.

OCP (Open Cost Project) mines are presumed to be of low accident

vulnerability as compared to UG (Underground) mines. (d) Lighting.

METHOD OF MINING ( e ) Stone dusting and stone dust barrier.

Bord and pillar method of mining, compared to longwall method, has (0 Water spraying.

comparatively higher accident vulnerability, as the method exposes a larger Availability to the full satisfaction of the above mentioned sub-

working area, more manpower, and less concentration of work. systems, in terms of safety provision, indicate a lower degree of vulnera-

SYSTEM OF MECHANISATION bility.

STATUS OF SAFETY DEVICES AS PER STATUTE AND SAFETY

Fully mechanised workings have lower accident vulnerability as

REQUIREMENTS

compared to manual workings, as the working area and manpower deploy=

ment level is comparatively lower. Following functional areas are considered :

You might also like

- U.S. Critical Infrastructure: Its Importance and Vulnerabilities to Cyber and Unmanned SystemsFrom EverandU.S. Critical Infrastructure: Its Importance and Vulnerabilities to Cyber and Unmanned SystemsNo ratings yet

- Of The: Prevention"Document1 pageOf The: Prevention"Vidya SagarNo ratings yet

- Safety Light Curtains - OMRONDocument11 pagesSafety Light Curtains - OMRONnarshihNo ratings yet

- Methods For Determining Roof Fall Risk in Underground Mines: A. Iannacchione, L. Prosser, G. Esterhuizen and T. BajpayeeDocument7 pagesMethods For Determining Roof Fall Risk in Underground Mines: A. Iannacchione, L. Prosser, G. Esterhuizen and T. BajpayeeSushantNo ratings yet

- Mechanical Study Chapter2Document30 pagesMechanical Study Chapter2Amiel MonsantoNo ratings yet

- BOWTIEDocument5 pagesBOWTIEjulio cesar borjas celisNo ratings yet

- Risk Managment Swot AnalysisDocument2 pagesRisk Managment Swot Analysisapi-491553418No ratings yet

- Lightning Damage Probability Assessment Model for Process EquipmentDocument9 pagesLightning Damage Probability Assessment Model for Process EquipmentENRIQUENo ratings yet

- Volkmann Technical Exclusive Vacuum ConveyingDocument3 pagesVolkmann Technical Exclusive Vacuum ConveyingMarkNo ratings yet

- ANCOLD 2015-Anomalies in Design For Mining Dams-HERZA PHILLIPSDocument6 pagesANCOLD 2015-Anomalies in Design For Mining Dams-HERZA PHILLIPSFlávia GomesNo ratings yet

- Natural Gas Pipelines: "Safety and Risk Management in Highly Populated AreasDocument29 pagesNatural Gas Pipelines: "Safety and Risk Management in Highly Populated AreasdakidofdaboomNo ratings yet

- 2024 Emerging Space Brief Counter-Unmanned Aerial SystemsDocument7 pages2024 Emerging Space Brief Counter-Unmanned Aerial SystemsNointingNo ratings yet

- Blasting Without Wires in Surface and UndergroundDocument3 pagesBlasting Without Wires in Surface and UndergroundJoseph buluguNo ratings yet

- Leveraging Jamming To Help Drones Complete Their MDocument16 pagesLeveraging Jamming To Help Drones Complete Their MAlexandra TrtdNo ratings yet

- Need of Low-Cost Lightning Protection SchemesDocument5 pagesNeed of Low-Cost Lightning Protection SchemesChandima GomesNo ratings yet

- Bhandari 2015Document13 pagesBhandari 2015Ad ILNo ratings yet

- Offshore System Safety and Operational Challen 2022 Journal of Safety SciencDocument16 pagesOffshore System Safety and Operational Challen 2022 Journal of Safety SciencIVAN EFRAIN CHEVARRIA LAZONo ratings yet

- RoofWaterProofing - Risk Assessment SheetDocument7 pagesRoofWaterProofing - Risk Assessment SheetYash Sharma100% (2)

- Health and Safety Hazards in Tunnel ConstructionDocument2 pagesHealth and Safety Hazards in Tunnel ConstructionZainab FaisalNo ratings yet

- Goffart-VasilEv2019 Article PracticalIssuesOfSafetyInCoalMDocument7 pagesGoffart-VasilEv2019 Article PracticalIssuesOfSafetyInCoalMAlexandru SimonNo ratings yet

- ALEC MethodDocument15 pagesALEC Methodwalter7tauroNo ratings yet

- Machine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsDocument9 pagesMachine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsKhurram AzizNo ratings yet

- SRAS ChemicalDocument22 pagesSRAS ChemicalArjun Chitradurga RamachandraRaoNo ratings yet

- Marine2017-Effect Wave in DeckDocument9 pagesMarine2017-Effect Wave in Deckmar ezaNo ratings yet

- Land Mines Detection, Mapping and Clearance Using Quadcopter in Yemen: A Perspective StudyDocument5 pagesLand Mines Detection, Mapping and Clearance Using Quadcopter in Yemen: A Perspective StudyShawqi AlwatiriNo ratings yet

- Airbus TurbulenceDocument13 pagesAirbus TurbulenceokyNo ratings yet

- CORESafety InfographicJanuary 13 2019 Five Safety Hazards Technology FINAL NewbackgroundDocument1 pageCORESafety InfographicJanuary 13 2019 Five Safety Hazards Technology FINAL NewbackgroundDUCE FUHRERNo ratings yet

- Busbar Protection Guide for Energy and Voltage TransformersDocument38 pagesBusbar Protection Guide for Energy and Voltage TransformersmubarakkirkoNo ratings yet

- Excavation SafetyDocument11 pagesExcavation SafetyKenneth Jade OrocayNo ratings yet

- Application Oil and Gas REV001 (1) 2Document4 pagesApplication Oil and Gas REV001 (1) 2Mohamed ElsayadNo ratings yet

- (Asce) 0733-9364 (2003) 129 4Document6 pages(Asce) 0733-9364 (2003) 129 4v.kasu16No ratings yet

- Management of Health and Safety in TunneDocument10 pagesManagement of Health and Safety in TunneMahmood AliNo ratings yet

- AERO Q308 Article4Document9 pagesAERO Q308 Article4Eliana FLT100% (1)

- JAM-ME Exploiting Jamming To AccomplishDocument7 pagesJAM-ME Exploiting Jamming To AccomplishzcNo ratings yet

- Roof Work Risk Assessment Group 2Document9 pagesRoof Work Risk Assessment Group 2Rome GentaNo ratings yet

- Duty Motor WhitePaper-finalDocument8 pagesDuty Motor WhitePaper-finalHarryBouterNo ratings yet

- Blast Furnace RisksDocument7 pagesBlast Furnace RisksRafael Do CarmoNo ratings yet

- Lightning 20protection 20systems 202005 PDFDocument55 pagesLightning 20protection 20systems 202005 PDFNgocTien BuiNo ratings yet

- Fotta, B., Peters, R. and Mallett, L. 1999. Safety Challenges at Thin Seam Mines, HAS BulletinDocument17 pagesFotta, B., Peters, R. and Mallett, L. 1999. Safety Challenges at Thin Seam Mines, HAS Bulletin1844030No ratings yet

- Living With SCC: Stress CorrosionDocument1 pageLiving With SCC: Stress CorrosionTasmanijskaNemaNo ratings yet

- Downloadload - Petrochemical-White-PaperDocument10 pagesDownloadload - Petrochemical-White-PaperDanny BoysieNo ratings yet

- VIII Paper 16Document16 pagesVIII Paper 16hamza laribiNo ratings yet

- Monte Cal Ro SimulationDocument21 pagesMonte Cal Ro SimulationRubens JuniorNo ratings yet

- Electrical Safety Risk Assessment for Wind Turbine WorkshopDocument7 pagesElectrical Safety Risk Assessment for Wind Turbine Workshopmha BakerNo ratings yet

- Earthing System Design - Moving From Worst Case To The Big Picture PDFDocument10 pagesEarthing System Design - Moving From Worst Case To The Big Picture PDFHung nguyen manhNo ratings yet

- Airport Safety AwarenessDocument19 pagesAirport Safety AwarenessAdhitya Octavianie100% (1)

- Application of dynamic risk analysis in offshore drilling processesDocument9 pagesApplication of dynamic risk analysis in offshore drilling processesAmal ZakirNo ratings yet

- s42797-022-00057-1Document17 pagess42797-022-00057-1Yakubu WagajaNo ratings yet

- DroneShield CUAS BriefDocument6 pagesDroneShield CUAS Briefmaruka33No ratings yet

- Security Architecture for SubstationsDocument6 pagesSecurity Architecture for SubstationsSofyan AndikaNo ratings yet

- An Offshore Risk Analysis Method Using Fuzzy Bayesian NetworkDocument12 pagesAn Offshore Risk Analysis Method Using Fuzzy Bayesian NetworkDenis TsoupisNo ratings yet

- Safe - Work - Method - Statement - Roof - Truss - Installation V1.0Document8 pagesSafe - Work - Method - Statement - Roof - Truss - Installation V1.0hurairamughal666No ratings yet

- 1 s2.0 S0950705124000480 MainDocument21 pages1 s2.0 S0950705124000480 MainZhang WeiNo ratings yet

- ZTV-InG, Part 1-10 ARS 13 - 2012 Status - 2012 - 03.PDF EngDocument5 pagesZTV-InG, Part 1-10 ARS 13 - 2012 Status - 2012 - 03.PDF EngSahiduj Jaman SajuNo ratings yet

- Threshold Blasting: The Renaissance of Explosives in Narrow Reef MiningDocument8 pagesThreshold Blasting: The Renaissance of Explosives in Narrow Reef Miningmatias79No ratings yet

- Topic: Blasting SafetyDocument2 pagesTopic: Blasting SafetySanil KuriakoseNo ratings yet

- Accuracy Estimation of Probabilistic Wake Vortex Prediction Considering Weather Information ErrorsDocument5 pagesAccuracy Estimation of Probabilistic Wake Vortex Prediction Considering Weather Information ErrorsalvoronNo ratings yet

- JHA For Mobile Crane 1 PDFDocument6 pagesJHA For Mobile Crane 1 PDFSethu MathanNo ratings yet

- Workplace Accidents & Its PreventionsDocument11 pagesWorkplace Accidents & Its PreventionsDimple BorahNo ratings yet

- Convair Traveler Vol - Xvii 1965-66Document92 pagesConvair Traveler Vol - Xvii 1965-66TateNo ratings yet

- Excavation Safety Dos and DontsDocument4 pagesExcavation Safety Dos and DontsVidya SagarNo ratings yet

- Knowledge Session 06-21 - Crèche Facilities & POCSODocument10 pagesKnowledge Session 06-21 - Crèche Facilities & POCSOVidya SagarNo ratings yet

- What Is 5SDocument13 pagesWhat Is 5SVidya SagarNo ratings yet

- Present at The Place of Accident) - Such Photographs, WhereDocument2 pagesPresent at The Place of Accident) - Such Photographs, WhereVidya SagarNo ratings yet

- Cost Models of Theoretical Mining Operations - CostMine PDFDocument5 pagesCost Models of Theoretical Mining Operations - CostMine PDFVidya Sagar0% (1)

- Commercial Blasting Compounds ClassifiedDocument18 pagesCommercial Blasting Compounds ClassifiedBenjamin AmoahNo ratings yet

- D85ESS-2A: With Steering Clutch/Brake SystemDocument8 pagesD85ESS-2A: With Steering Clutch/Brake SystemVidya SagarNo ratings yet

- 5S VWM Assessment - Guidelines 2021-22Document43 pages5S VWM Assessment - Guidelines 2021-22Vidya SagarNo ratings yet

- Comparative Study of Blasting Techniques in Dimension AlstonDocument10 pagesComparative Study of Blasting Techniques in Dimension AlstonVidya SagarNo ratings yet

- Portable MagazineDocument1 pagePortable MagazineVidya SagarNo ratings yet

- 03Document1 page03Vidya SagarNo ratings yet

- Open Pit Blast Design Rules of ThumbDocument14 pagesOpen Pit Blast Design Rules of ThumbVidya SagarNo ratings yet

- Max Charge Per DelayDocument6 pagesMax Charge Per DelayVidya SagarNo ratings yet

- Max Charge Per DelayDocument6 pagesMax Charge Per DelayVidya SagarNo ratings yet

- Comparative Study of Blasting Techniques in Dimension AlstonDocument10 pagesComparative Study of Blasting Techniques in Dimension AlstonVidya SagarNo ratings yet

- Raising Methods in Metal MinesDocument4 pagesRaising Methods in Metal MinesVidya Sagar83% (6)

- Hours Within 48 Hours Accidents.: EveryDocument1 pageHours Within 48 Hours Accidents.: EveryVidya SagarNo ratings yet

- Mine Legislation Assignment - I (Knowledge Based Test)Document2 pagesMine Legislation Assignment - I (Knowledge Based Test)Vidya SagarNo ratings yet

- Hardgrove Grindability IndexDocument1 pageHardgrove Grindability IndexVidya Sagar100% (1)

- Accident Costs: To Employer (B) To Employee 1Document1 pageAccident Costs: To Employer (B) To Employee 1Vidya SagarNo ratings yet

- Safety,: Health, and Sanita-Tion in MinesDocument1 pageSafety,: Health, and Sanita-Tion in MinesVidya SagarNo ratings yet

- High Angle Conveyor Offers Mine Haulage SavingsDocument27 pagesHigh Angle Conveyor Offers Mine Haulage SavingsJDNo ratings yet

- PT51 09Document8 pagesPT51 09walterloliNo ratings yet

- Sandwich Belt Conveyors ExplainedDocument11 pagesSandwich Belt Conveyors ExplainedVidya SagarNo ratings yet

- Sandwich Belt Conveyors ExplainedDocument11 pagesSandwich Belt Conveyors ExplainedVidya SagarNo ratings yet

- Soil Nailing For Slope StabilityDocument2 pagesSoil Nailing For Slope StabilityVidya SagarNo ratings yet

- Coal Mines Regulation 2011Document233 pagesCoal Mines Regulation 2011Vidya SagarNo ratings yet

- New Statutory ProvisionsDocument9 pagesNew Statutory ProvisionsVidya SagarNo ratings yet

- Classification of FluidDocument29 pagesClassification of FluidAbdur RehmanNo ratings yet

- Nichrome60 Wire Data SheetDocument2 pagesNichrome60 Wire Data SheetvvingtsabtaNo ratings yet

- IEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000VDocument104 pagesIEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000Valex100% (4)

- Engine & Transmission ToolsDocument45 pagesEngine & Transmission Toolsabduallah muhammad100% (1)

- Antena Eh para 10 MetrosDocument3 pagesAntena Eh para 10 Metros10sd156No ratings yet

- Cotta Transfer Case Lube PlanDocument3 pagesCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichNo ratings yet

- Module 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite SealDocument18 pagesModule 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite Sealbansalmohit01No ratings yet

- Mixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Document84 pagesMixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Masayu MYusoffNo ratings yet

- Fem Question PaperDocument4 pagesFem Question PaperARSNo ratings yet

- 8 Ways To Achieve Efficient Combustion in Marine EnginesDocument10 pages8 Ways To Achieve Efficient Combustion in Marine EnginestomNo ratings yet

- GENG 8000 Final Project Memo - W19 FinalDocument2 pagesGENG 8000 Final Project Memo - W19 Finalஇலக்கியா ராஜாNo ratings yet

- Propeller DesignDocument74 pagesPropeller DesignBambang Teguh Setiawan75% (4)

- 1986 Lobel RobinsonDocument18 pages1986 Lobel RobinsonNathallia SalvadorNo ratings yet

- Oksd Icwh 1993 RoisumDocument40 pagesOksd Icwh 1993 RoisumKamalam CloudsoftNo ratings yet

- Specifications: 3516C - SS Marine PropulsionDocument5 pagesSpecifications: 3516C - SS Marine PropulsionAidel MustafaNo ratings yet

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDocument1 pageBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalNo ratings yet

- Civil 3 8sem PDFDocument43 pagesCivil 3 8sem PDFG0utham100% (1)

- Ornl 2465Document101 pagesOrnl 2465jesusNo ratings yet

- Mobiltech (Textile Used in Transportation, Automotive & Aerospace)Document12 pagesMobiltech (Textile Used in Transportation, Automotive & Aerospace)cario galleryNo ratings yet

- Operating Instructions, FormulaDocument35 pagesOperating Instructions, FormulaandymulyonoNo ratings yet

- Physics ExamDocument30 pagesPhysics Examjomar bolasocNo ratings yet

- VisiLogic Software Manual-LadderDocument158 pagesVisiLogic Software Manual-LadderEduardo Vasquez CastroNo ratings yet

- 01chapter 5-1Document55 pages01chapter 5-1AhmNo ratings yet

- Acsomega 9b01541Document9 pagesAcsomega 9b01541Benedictus EduardoNo ratings yet

- NTP35N15 Power MOSFET Features and SpecificationsDocument7 pagesNTP35N15 Power MOSFET Features and SpecificationsChristine GomezNo ratings yet

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- Pressure Vessel Rivets Welded Joints MDSP PrimeDocument16 pagesPressure Vessel Rivets Welded Joints MDSP PrimeIvanNo ratings yet

- Ultrasonic Testing Level 2 MCQsDocument8 pagesUltrasonic Testing Level 2 MCQspandab BkNo ratings yet

- Woodson Property Group's Conditional Use Permit ApplicationDocument108 pagesWoodson Property Group's Conditional Use Permit ApplicationShannon GeisenNo ratings yet

- Aso Airfield Standards Quick ReferenceDocument66 pagesAso Airfield Standards Quick ReferenceRahul RanaNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)