Professional Documents

Culture Documents

The Physical Behaviors of The Organic Solid Waste Inside The Static Water Tank

Uploaded by

IJAMTESOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Physical Behaviors of The Organic Solid Waste Inside The Static Water Tank

Uploaded by

IJAMTESCopyright:

Available Formats

International Journal of Advanced in Management, Technology and Engineering Sciences ISSN NO : 2249-7455

The Physical Behaviors of the Organic Solid Waste inside the Static Water

Tank

1

Kirki Ori , 2Dr.Ajay Bharti and 3Kilu Ori

1

PhD Scholar NERIST(Arunachal), Associate Professor(NERIST) and 2B.Tech(UG)- KTU(Kerela)

Email:-1kirkiori@yahoo.com, 2ajaybharti123@rediffmail.com and 3kiluori@gmail.com

Abstract :

Difficulties in disposal of the organic solid waste from the high rise building are increasing with the advent of housing sector in the

modern city. To mitigate the vertical transportation problems of the organic waste from the high rise building, water aided transportation system

is being conceived. Hence water and the waste are required to store temporarily in the tanks at ground level before further treatment and

disposal. Further the vermicomposting technique is another interesting composting technique popularly prevailing now a day for environment

friendly waste stabilization process. But the animal waste, the rice wastes, citric food and other oily matters are restricted in vermicomposting.

Therefore, heterogeneous mixture of the organic solid waste which contains above restricted items are partially stabilized in a digestion tanks

and made fit to use as feed for the earthworm. Hence, the facts on the behavior of the Organic Waste inside the Water are vital and requiring for

design of the Waste Digestion Tank and the data will be useful for further study by the researcher.

Key words: Static Water Tank, Hydrolysis, Organic Solid Waste, Vermicompoting, Disintegrated Waste.

.

1. INTRODUCTION

Organic Solid Waste is a material that is biodegradable and comes from either a plant or animal. Organic Solid Waste is usually broken

down by other organisms over time and may also be referred to as wet waste. Most of the time, it is made up of vegetable and fruit debris, paper,

bones and human waste which quickly disintegrate. The Organic Solid Waste comprises the majority of Municipal Solid Waste (MSW),

followed by paper, metal, other wastes, plastic, and glass. Out of all the waste, the composition of the organic waste varies from 28% (High

Income group) to 64% (Low income group) of the total solid waste. The organic waste is a potential source of methane and other Greenhouse

Gas (GHG) emissions. Methane is a highly polluting GHG with a global warming potential of 21 times that of carbon dioxide.

As per the Municipal Solid Waste Management Manual by Central Public Health and Environmental Engineering Organisation (CPHEEO),

Ministry of Urban Development (2016), the average per capita waste generation in India is 0.110 Kg/Capita/day. [CPHEEO]1. Again as per the

study by NEERI, in developed countries it is normally observed to vary between 0.2-0.6 kg/capita/day. Value upto 0.6 kg/capita/day are

observed in metropolitan cities.

Since India is the 2nd largest populous nation, its Organic Solid Waste generation will be immense and the cost for handling such large

quantities of Organic Solid Waste will be unbearable at some point of time. Therefore the efforts are being made to minimize the organic solid

waste at generation points and the research works on organic waste management are given due encouragement in many institution. The

hydrolysis in the tank is one technique to disintegrate organic waste and to stabilize the waste. Hence to know the behavior of the organic solid

waste in the static water tank the study has been done and this paper is an effort to present it.

2. THE OBJECTIVES

The objective of this paper is to study the followings;

1. To know the quantities of waste floated on the surface, the quantities of the waste settled down, the waste dissolved and suspended in the

water by volume.

2. To know the Carbon and Nitrogen losses during the hydrolysis.

Volume 7 Issue 11 2017 104 http://ijamtes.org/

International Journal of Advanced in Management, Technology and Engineering Sciences ISSN NO : 2249-7455

3. THE MATERIALS & METHOD

The prototype transparent glass tank of 8mm thick size 60cm length, 20cm breadth and 20 cm depth were made for experimental purpose.

The tank was kept on steel frame stand 45 cm above the ground in an open shed. The inlet hole were made on one side of the tank to allow the

water with the waste to enter into the tank and outlet arrangement were kept at another end of the tank at the same level for discharge of the

organic dissolved waste from the tank. Inlet collection funnel was made of PVC pipe reducer socket and outlet pipe was fitted with the valves.

There are three nos of outlet pipe. One is for regular and routine discharge of pipe, another for de-sludging of settled waste at the bottom and

third one at the centre is for regulating water level. The section of the prototype experiment tanks is shown in FIGURE-1.

The photograph of the prototype experiment glass tank is shown in FIGURE-2

Volume 7 Issue 11 2017 105 http://ijamtes.org/

International Journal of Advanced in Management, Technology and Engineering Sciences ISSN NO : 2249-7455

4. EXPERIMENT

The heterogeneous mixtures of the organic solid wastes were shredded into pieces manually. The wastes were chopped down to the size of

less than 10mm. The shredded Organic Solid Waste was added into the tank daily. Before the wastes were put into the tank, the tank was kept

full of water upto the routine inlet and outlet level. The daily 500 grams of shredded waste was added into the tank in the ratio of 20% Waste

with 80% Water.

The approximate composition of the waste was Green Vegetable Waste 40 %, Food Waste 30%, Fruit Wastes 10% and other waste 20%. The

experiment was done for 60 days during the month of November and December. The temperatures were varied from 9 to 23 Degree Celsius

during the experiment period. The photograph of putting Waste into the tank is shown in FIGURE-3.

After 60 days of putting waste into the tank, the physical behavior of the waste in the tank was observed. The shape of the shredded organic

waste in the tank is shown in FIGURE-4. The sectional area of the waste was measured to know the space covered by the waste inside the tank.

Volume 7 Issue 11 2017 106 http://ijamtes.org/

International Journal of Advanced in Management, Technology and Engineering Sciences ISSN NO : 2249-7455

The details of the measurement are shown in FIGURE-5 and the cross section area was also worked out as under:

Floated waste:

(11+10)/2 X 20 =210.00 Sqcm

X10X17 = 85.00 Sqcm

X 3X 37 = 55.50 Sqcm

Total= 350.5 Sqcm

The space cover=350.5X20=7010 Cucm =63%

The settled waste:

(5+4+3)/3 X 40 =160.00 Sqcm

X20X3 = 45.00 Sqcm

Total= 205 Sqcm

The space cover=205X20=4100 Cucm =37%

Further the sample of the settled waste was taken from the bottom of the tank and the Carbon contents and the Nitrogen contents were

determined to assess carbon utilized during the hydrolysis and to know the potential of the residue waste to released Methane Gas.

Determination of the Organic Carbon Contents:-

The Organic Carbon Contents of the Raw waste and the settled waste was determined by Loss on Ignition Method [Al-Selwi A and Joshi M[2],

Tenzing Norbu[3]. And LOI standard operating procedur4].The calculation and the test results are tabulated in TABLE-1.

Volume 7 Issue 11 2017 107 http://ijamtes.org/

International Journal of Advanced in Management, Technology and Engineering Sciences ISSN NO : 2249-7455

Determination of the Nitrogen %

The % Nitrogen Contents of the Organic Raw Waste and the settled waste after 60 days has been determined with the help of Kjaldehl Method

(A Guide To Kjeldahl[5])

The % Nitrogen contents of Raw and 60 Days settled waste are tabulated in TABLE-

Volume 7 Issue 11 2017 108 http://ijamtes.org/

International Journal of Advanced in Management, Technology and Engineering Sciences ISSN NO : 2249-7455

5. RESULT AND DISCUSSION

1. After 60 days of addition of the waste in the tanks it was observed that the 63% of the waste by volume were found floated on the surface of the

Tank and 37% of the waste by volume were found settled down at the bottom of the tanks. The dissolved wastes were not assessed as it is

negligible. Therefore the outlet pipe is fitted such that its mouth is in the suspended zone.

2. The volume and the depth of the substrate inside the water were found more near the inlet side and the depth was found gradually reducing

towards the outlet side.

3. It was also observed that when new waste is added into the digestion tank, then the new waste joins at the bottom of the already floated waste

and it tends to come up by the force of buoyant. As a result the upper part of the already floated waste is exposed to air and decomposed by

aerobic bacteria.

4. The worms were found survived on the floated waste, which need further study and improvement of the tank design for Vermicomposting of the

floated waste inside the digestion tanks while it is in use.

5. It was found that the Carbon Losses of the settled waste during 60 days of experiment was 6.21% and Nitrogen variation was found to be

14.71%(TABLE-2). The variation may depend on waste to waste and climate of the area. But less losses indicates less microbes activities and

less methane generation.

6. When the surface waste is under aerobic decomposition and the surface layer is not disturbed, then no foul smell was notice during the entire

experiment.

7. After the surface waste are decomposed and disintegrated due to aerobic microbes, the disintegrated waste are either suspended or settled down

in the bottom of the digestion tank at the end.

8. The fatty matters in the tanks are found floated on surface of the water in the tank.

9. The plants like fungus also grow on the surface of the tank.

10. The residue sludge can be put into the Vermicomposting after pre-treatment.

Conclusion and Recommendations:

It can be concluded that the information found in this study will be useful for design of the waste digestion tank and it will be a useful data for

the researcher for future study on the subjects. Further study can be done for vermicomposting of the surface waste inside the tank.

Volume 7 Issue 11 2017 109 http://ijamtes.org/

International Journal of Advanced in Management, Technology and Engineering Sciences ISSN NO : 2249-7455

REFERENCES:

1. Municipal Solid Waste Management Manual by Central Public Health and Environmental Engineering Organization (CPHEEO),

Ministry of Urban Development, Government of India-2016.

2. Al-Selwi A and Joshi M Source Rock Evaluation using Total Organic Carbon (TOC) and the Loss-On-Ignition (LOI) Techniques

3. Tenzing Norbu ,Pretreatment of Municipal Solid Waste by Windrow Composting and Vermicomposting

4. Loss-on-Ignition Standard Operating Procedure. Lac Core, National Lacustrine Core Facility, University of Minnesota

5. The Guide to Kjeldahl Method.

Volume 7 Issue 11 2017 110 http://ijamtes.org/

You might also like

- Experimentation and Optimization of Sugar Cane Bagasse (SCB) Dust Reinforced Epoxy Based CompositeDocument10 pagesExperimentation and Optimization of Sugar Cane Bagasse (SCB) Dust Reinforced Epoxy Based CompositeIJAMTESNo ratings yet

- Purification of Biogas at Domestic LevelDocument2 pagesPurification of Biogas at Domestic LevelIJAMTESNo ratings yet

- Effects of Reinforcement of Sugarcane Fiber and Wheat Straw Fiber On Flexural and Dynamic Mechanical Properties of Corn Starch BiocompositesDocument10 pagesEffects of Reinforcement of Sugarcane Fiber and Wheat Straw Fiber On Flexural and Dynamic Mechanical Properties of Corn Starch BiocompositesIJAMTESNo ratings yet

- Building Simulation and Energy ModelingDocument8 pagesBuilding Simulation and Energy ModelingIJAMTESNo ratings yet

- Solar-Driven Refrigeration SystemDocument7 pagesSolar-Driven Refrigeration SystemIJAMTESNo ratings yet

- A Study of Smart Materials, Classification and Applications: A ReviewDocument6 pagesA Study of Smart Materials, Classification and Applications: A ReviewIJAMTES0% (1)

- Atomic & Nuclear BatteryDocument6 pagesAtomic & Nuclear BatteryIJAMTESNo ratings yet

- Floating ConcreteDocument5 pagesFloating ConcreteIJAMTESNo ratings yet

- Hydrogen: Fue of FutureDocument8 pagesHydrogen: Fue of FutureIJAMTESNo ratings yet

- Divestment of Air CarDocument4 pagesDivestment of Air CarIJAMTESNo ratings yet

- Solar Water Purification Using Evacuated TubesDocument4 pagesSolar Water Purification Using Evacuated TubesIJAMTESNo ratings yet

- Fuel Cell:-Future of Energy SourceDocument3 pagesFuel Cell:-Future of Energy SourceIJAMTESNo ratings yet

- Automated Bottle Filling System by Using PLCDocument4 pagesAutomated Bottle Filling System by Using PLCIJAMTESNo ratings yet

- Review Paper On Technology and Tool of Lean Manufacturing HTTP://WWW - Ijamtes.orgDocument5 pagesReview Paper On Technology and Tool of Lean Manufacturing HTTP://WWW - Ijamtes.orgIJAMTESNo ratings yet

- Best Fit Probability Distributions For Monthly Radiosonde Weather DataDocument8 pagesBest Fit Probability Distributions For Monthly Radiosonde Weather DataIJAMTESNo ratings yet

- A Study On Role of Bit Coin in Global Asset Class PortfolioDocument11 pagesA Study On Role of Bit Coin in Global Asset Class PortfolioIJAMTESNo ratings yet

- A Review Paper On Anti-Lock Braking System (Abs) and Its AdvancementDocument5 pagesA Review Paper On Anti-Lock Braking System (Abs) and Its AdvancementIJAMTESNo ratings yet

- A Poet of Eternal RelevanceDocument5 pagesA Poet of Eternal RelevanceIJAMTESNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- What Are The Good Research QuestionDocument26 pagesWhat Are The Good Research Questionkavindukarunarathna100% (2)

- LG W4320S Service ManualDocument24 pagesLG W4320S Service ManualeleandrorobertoNo ratings yet

- STR Mpa-MpmDocument8 pagesSTR Mpa-MpmBANGGANo ratings yet

- Introduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsDocument53 pagesIntroduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsShanti Swaroop ChauhanNo ratings yet

- Homework 1&2 Report EE440Document19 pagesHomework 1&2 Report EE440Võ Hoàng Chương100% (1)

- Dodge Journey 2017 - Owner's ManualDocument510 pagesDodge Journey 2017 - Owner's Manualandres camachin100% (1)

- MclogitDocument19 pagesMclogitkyotopinheiroNo ratings yet

- Patrick C Hall@yahoo - com-TruthfinderReportDocument13 pagesPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithNo ratings yet

- Nvidia CompanyDocument4 pagesNvidia CompanyaaaNo ratings yet

- Dehp 780 MPDocument104 pagesDehp 780 MPVitorNo ratings yet

- Ansi C29.2aDocument22 pagesAnsi C29.2afecasNo ratings yet

- 1 Pre-Lab: Lab 07: Sampling, Convolution, and FIR FilteringDocument12 pages1 Pre-Lab: Lab 07: Sampling, Convolution, and FIR Filteringdemetrickn0% (1)

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresNo ratings yet

- D-1967 (Clean) Quilting Machine ManualDocument33 pagesD-1967 (Clean) Quilting Machine Manualvalter craccoNo ratings yet

- Patrol For Unix and Linux Unix Get StartedDocument112 pagesPatrol For Unix and Linux Unix Get StartedRamesh SharmaNo ratings yet

- Applies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)Document5 pagesApplies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)apletonprinceNo ratings yet

- Module Tes Answer Key: Student B Student ADocument2 pagesModule Tes Answer Key: Student B Student AKremena KoevaNo ratings yet

- Sample Detailed Estimates PDFDocument9 pagesSample Detailed Estimates PDFJj Salazar Dela CruzNo ratings yet

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Document10 pagesSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- Global Cardiac Catheters - 2012-2018Document4 pagesGlobal Cardiac Catheters - 2012-2018Axis Research MindNo ratings yet

- DBMS-LM Kavi With MinipjtDocument56 pagesDBMS-LM Kavi With Minipjtkavi_mithuNo ratings yet

- Case StudyDocument2 pagesCase StudyAyeng 1502100% (1)

- Workover Kill Fluid Density CalculationDocument3 pagesWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- Dialogues in French and EnglishDocument62 pagesDialogues in French and Englishmiki1222No ratings yet

- Commodity Sourcing Strategy ProjectDocument5 pagesCommodity Sourcing Strategy ProjectMohit TalwarNo ratings yet

- Diseño de Tuberías C-10 Y C-40Document1 pageDiseño de Tuberías C-10 Y C-40samuelcordova36No ratings yet

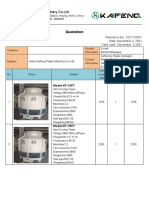

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyNo ratings yet

- Overboard Dump ValveDocument3 pagesOverboard Dump ValveekabudiartiNo ratings yet

- Poly BoreDocument2 pagesPoly BoreMarian OpreaNo ratings yet