Professional Documents

Culture Documents

Wda Rubrics

Uploaded by

api-313716520Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wda Rubrics

Uploaded by

api-313716520Copyright:

Available Formats

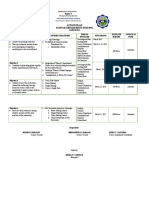

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3401: TOOLS & EQUIPMENT

Level: First Period Apprenticeship

Prerequisite: WDA3900: Apprenticeship Safety

Description: Students use workshop hand and power tools and develop proper material handling techniques.

Parameters: Access to a materials work centre, complete with basic hand and power tools, and to instruction from an individual with

journeyperson certification as a welder.

ILM Resources: Hand Tools 120101f; Power Tools 120101g; Materials Handling 120101k

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3401: TOOLS & EQUIPMENT

Checklist

Welder Apprenticeship Assessment CTS, TMT: WDA3401 / 1

Alberta Education, Alberta, Canada 2015

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. use hand tools

2. use power tools

1. apply materials handling

procedures

Teacher Signature Date

2 / CTS, TMT: WDA3401 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE WDA3401: TOOLS & EQUIPMENT

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. use hand tools

1.1 describe safety I can consistently I can usually describe I sometimes need I often need assistance I have not yet

precautions for hand tools describe safety safety precautions for assistance to describe to describe safety provided evidence of

precautions for hand hand tools. safety precautions for precautions for hand this performance task.

tools. hand tools. tools.

1.2 identify layout and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

measuring tools and their identify layout and layout and measuring assistance to identify to identify layout and provided evidence of

uses measuring tools and tools and their uses. layout and measuring measuring tools and this performance task.

their uses. tools and their uses. their uses.

1.3 identify clamping tools I can consistently I can usually identify I sometimes need I often need assistance I have not yet

and their uses identify clamping tools clamping tools and assistance to identify to identify clamping provided evidence of

and their uses. their uses. clamping tools and their tools and their uses. this performance task.

uses.

1.4 identify cutting tools and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

their uses identify cutting tools cutting tools and their assistance to identify to identify cutting tools provided evidence of

and their uses. uses. cutting tools and their and their uses. this performance task.

uses.

1.5 identify other hand tools I can consistently I can usually identify I sometimes need I often need assistance I have not yet

used by welders identify other hand other hand tools used assistance to identify to identify other hand provided evidence of

tools used by welders. by welders. other hand tools used tools used by welders. this performance task.

by welders.

Welder Apprenticeship Assessment CTS, TMT: WDA3401 / 3

Alberta Education, Alberta, Canada 2015

2. use power tools

2.1 demonstrate the operation I can consistently I can usually I sometimes need I often need assistance I have not yet

of bench and pedestal demonstrate the demonstrate the assistance to to demonstrate the provided evidence of

grinders, angle grinders operation of bench and operation of bench demonstrate the operation of bench and this performance task.

and straight grinders pedestal grinders, angle and pedestal grinders, operation of bench and pedestal grinders, angle

grinders and straight angle grinders and pedestal grinders, angle grinders and straight

grinders. straight grinders. grinders and straight grinders.

grinders.

2.2 demonstrate the operation I can consistently I can usually I sometimes need I often need assistance I have not yet

of portable power drills, demonstrate the demonstrate the assistance to to demonstrate the provided evidence of

drill presses and twist operation of portable operation of portable demonstrate the operation of portable this performance task.

drills power drills, drill power drills, drill operation of portable power drills, drill

presses and twist drills. presses and twist power drills, drill presses and twist drills.

drills. presses and twist drills.

2.3 describe the operation of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

metal forming and describe the operation the operation of metal assistance to describe to describe the provided evidence of

shaping tools of metal forming and forming and shaping the operation of metal operation of metal this performance task.

shaping tools. tools. forming and shaping forming and shaping

tools. tools.

2.4 describe the operation of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

metal cutting tools describe the operation the operation of metal assistance to describe to describe the provided evidence of

of metal cutting tools. cutting tools. the operation of metal operation of metal this performance task.

cutting tools. cutting tools.

2.5 describe the use of power I can consistently I can usually describe I sometimes need I often need assistance I have not yet

positioners describe the use of the use of power assistance to describe to describe the use of provided evidence of

power positioners. positioners. the use of power power positioners. this performance task.

positioners.

4 / CTS, TMT: WDA3401 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3. apply materials handling procedures

3.1 identify procedures for I can consistently I can usually identify I sometimes need I often need assistance I have not yet

handling and storing identify procedures for procedures for assistance to identify to identify procedures provided evidence of

materials handling and storing handling and storing procedures for handling for handling and storing this performance task.

materials. materials. and storing materials. materials.

3.2 determine weight and I can consistently I can usually I sometimes need I often need assistance I have not yet

centre of gravity of loads determine weight and determine weight and assistance to determine to determine weight and provided evidence of

centre of gravity loads. centre of gravity weight and centre of centre of gravity loads. this performance task.

loads. gravity loads.

3.3 identify the load limits of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

wire rope and synthetic identify the load limits the load limits of wire assistance to identify to identify the load provided evidence of

slings of wire rope and rope and synthetic the load limits of wire limits of wire rope and this performance task.

synthetic slings. slings. rope and synthetic synthetic slings.

slings.

3.4 describe the use of plate I can consistently I can usually describe I sometimes need I often need assistance I have not yet

clamps and cable clips describe the use of plate the use of plate assistance to describe to describe the use of provided evidence of

clamps and cable clips. clamps and cable the use of plate clamps plate clamps and cable this performance task.

clips. and cable clips. clips.

Teacher feedback and

assessment.

Welder Apprenticeship Assessment CTS, TMT: WDA3401 / 5

Alberta Education, Alberta, Canada 2015

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3403: OXYFUEL & PLASMA ARC

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge, skills and attitudes to use oxyfuel heating and cutting equipment as well as plasma arc

and gouging equipment and tools.

Parameters: Access to a materials work centre, complete with oxyfuel heating and cutting equipment as well as plasma arc equipment,

and to instruction from an individual with journeyperson certification as a welder.

ILM Resources: Oxy-fuel Equipment 120101h; Oxy-fuel Cutting120101i; Plasma Arc Cutting and Gouging 120101j

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3403: OXYFUEL & PLASMA ARC

Checklist

6 / CTS, TMT: WDA3403 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. assemble oxyfuel equipment

2. perform oxyfuel cutting

3. cut and gouge using the

plasma arc and carbon arc

cutting processes

Teacher Signature Date

Welder Apprenticeship Assessment CTS, TMT: WDA3403 / 7

Alberta Education, Alberta, Canada 2015

COURSE WDA3403: OXYFUEL & PLASMA ARC

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. assemble oxyfuel equipment

1.1 describe the I can consistently I can usually describe I sometimes need I often need assistance I have not yet

characteristics and describe the the characteristics and assistance to describe to describe the provided evidence of

handling procedures for characteristics and handling procedures the characteristics and characteristics and this performance task.

oxygen and fuel gases handling procedures for for oxygen and fuel handling procedures for handling procedures for

oxygen and fuel gases. gases. oxygen and fuel gases. oxygen and fuel gases.

1.2 describe the functions of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

oxyfuel equipment describe the functions the functions of assistance to describe to describe the provided evidence of

components of oxyfuel equipment oxyfuel equipment the functions of oxyfuel functions of oxyfuel this performance task.

components. components. equipment components. equipment components.

1.3 demonstrate the use, care I can consistently I can usually I sometimes need I often need assistance I have not yet

and maintenance of demonstrate the use, demonstrate the use, assistance to to demonstrate the use, provided evidence of

oxyfuel equipment care and maintenance care and maintenance demonstrate the use, care and maintenance of this performance task.

components of oxyfuel equipment of oxyfuel equipment care and maintenance of oxyfuel equipment

components. components. oxyfuel equipment components.

components.

1.4 explain the procedure for I can consistently I can usually explain I sometimes need I often need assistance I have not yet

placement, set-up and explain the procedure the procedure for assistance to explain the to explain the procedure provided evidence of

shutdown of oxyfuel for placement, set-up placement, set-up and procedure for for placement, set-up this performance task.

equipment and shutdown of shutdown of oxyfuel placement, set-up and and shutdown of

oxyfuel equipment. equipment. shutdown of oxyfuel oxyfuel equipment.

equipment.

8 / CTS, TMT: WDA3403 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

1.5 identify causes and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

preventive measure for identify causes and causes and preventive assistance to identify to identify causes and provided evidence of

backfires, flashbacks and preventive measure for measure for backfires, causes and preventive preventive measure for this performance task.

burn backs backfires, flashbacks flashbacks and burn measure for backfires, backfires, flashbacks

and burn backs. backs. flashbacks and burn and burn backs.

backs.

1.6 describe pressure and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

flame adjustments describe pressure and pressure and flame assistance to describe to describe pressure and provided evidence of

flame adjustments. adjustments. pressure and flame flame adjustments. this performance task.

adjustments.

2. perform oxyfuel cutting

2.1 describe how to operate a I can consistently I can usually describe I sometimes need I often need assistance I have not yet

hand-held oxyfuel cutting describe how to operate how to operate a assistance to describe to describe how to provided evidence of

torch on mild steel plate a hand-held oxyfuel hand-held oxyfuel how to operate a operate a hand-held this performance task.

and structural shapes cutting torch on mild cutting torch on mild hand-held oxyfuel oxyfuel cutting torch on

steel plate and steel plate and cutting torch on mild mild steel plate and

structural shapes. structural shapes. steel plate and structural structural shapes.

shapes.

2.2 perform straight line, I can consistently I can usually perform I sometimes need I often need assistance I have not yet

bevel and shape cutting on perform straight line, straight line, bevel and assistance to perform to perform straight line, provided evidence of

mild steel bevel and shape cutting shape cutting on mild straight line, bevel and bevel and shape cutting this performance task.

on mild steel. steel. shape cutting on mild on mild steel.

steel.

2.3 pierce and cut holes in I can consistently pierce I can usually pierce I sometimes need I often need assistance I have not yet

mild steel plate and cut holes in mild and cut holes in mild assistance to pierce and to pierce and cut holes provided evidence of

steel plate. steel plate. cut holes in mild steel in mild steel plate. this performance task.

plate.

2.4 cope 9.6 mm () mild I can consistently cope I can usually cope a I sometimes need I often need assistance I have not yet

steel to fit a 100 mm (4) a 9.6 mm () mild 9.6 mm () mild assistance to cope a to cope a 9.6 mm () provided evidence of

channel member steel to fit a 100 mm steel to fit a 100 mm 9.6 mm () mild steel mild steel to fit a 100 this performance task.

(4) channel member. (4) channel member. to fit a 100 mm (4) mm (4) channel

channel member. member.

2.5 perform cuts on structural I can consistently I can usually perform I sometimes need I often need assistance I have not yet

shapes perform cuts on cuts on structural assistance to perform to perform cuts on provided evidence of

structural shapes. shapes. cuts on structural structural shapes. this performance task.

Welder Apprenticeship Assessment CTS, TMT: WDA3403 / 9

Alberta Education, Alberta, Canada 2015

shapes.

2.6 operate a machine oxyfuel I can consistently I can usually operate a I sometimes need I often need assistance I have not yet

cutting torch on mild steel operate a machine machine oxyfuel assistance to operate a to operate a machine provided evidence of

plate and pipe oxyfuel cutting torch on cutting torch on mild machine oxyfuel cutting oxyfuel cutting torch on this performance task.

mild steel plate and steel plate and pipe. torch on mild steel plate mild steel plate and

pipe. and pipe. pipe.

3. cut and gouge using the plasma arc and carbon arc cutting processes

3.1 describe the plasma arc I can consistently I can usually describe I sometimes need I often need assistance I have not yet

cutting process and describe the plasma arc the plasma arc cutting assistance to describe to describe the plasma provided evidence of

equipment cutting process and process and the plasma arc cutting arc cutting process and this performance task.

equipment. equipment. process and equipment. equipment.

3.2 observe plasma arc cutting I can consistently I can usually observe I sometimes need I often need assistance I have not yet

observe plasma arc plasma arc cutting. assistance to observe to observe plasma arc provided evidence of

cutting. plasma arc cutting. cutting. this performance task.

3.3 describe the carbon arc I can consistently I can usually describe I sometimes need I often need assistance I have not yet

cutting process describe the carbon arc the carbon arc cutting assistance to describe to describe the carbon provided evidence of

cutting process. process. the carbon arc cutting arc cutting process. this performance task.

process.

3.4 gouge using the carbon arc I can consistently gouge I can usually gouge I sometimes need I often need assistance I have not yet

cutting process using the carbon arc using the carbon arc assistance to gouge to gouge using the provided evidence of

cutting process. cutting process. using the carbon arc carbon arc cutting this performance task.

cutting process. process.

Teacher feedback and

assessment.

10 / CTS, TMT: WDA3403 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3406: ELECTRICITY & METALS

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge, skills and attitudes in the practice of workshop safety, communication and the use of

specialty hand tools, measuring tools and fasteners.

Parameters: Access to a materials work centre, complete with basic measuring tools, specialty hand tools and fastening devices, and to

instruction from an individual with specialized training as a heavy duty mechanic or trailer mechanic and/or a heavy

equipment technician.

ILM Resources: Electricity 120102b; Metal Identification 120101c; Heat Treatment 120102d

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3406: ELECTRICITY & METALS

Checklist

Welder Apprenticeship Assessment CTS, TMT: WDA3406 / 11

Alberta Education, Alberta, Canada 2015

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. describe electrical concepts

2. identify types of metals and

their characteristics

3. identify the effects of heat

treatment on carbon steels

Teacher Signature Date

12 / CTS, TMT: WDA3406 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE WDA3406: ELECTRICITY & METALS

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. describe electrical concepts

1.1 define electrical terms I can consistently I can usually define I sometimes need I often need assistance I have not yet

define electrical terms. electrical terms. assistance to define to define electrical provided evidence of

electrical terms. terms. this performance task.

1.2 describe electron flow I can consistently I can usually describe I sometimes need I often need assistance I have not yet

describe electron flow. electron flow. assistance to describe to describe electron provided evidence of

electron flow. flow. this performance task.

1.3 describe single-phase and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

three-phase power describe single-phase single-phase and assistance to describe to describe provided evidence of

and three-phase power. three-phase power. single-phase and single-phase and this performance task.

three-phase power. three-phase power.

1.4 describe AC (alternating I can consistently I can usually describe I sometimes need I often need assistance I have not yet

current) and DC (direct describe AC and DC AC and DC rectified assistance to describe to describe AC and DC provided evidence of

current) rectified power rectified power sources. power sources. AC and DC rectified rectified power sources. this performance task.

sources power sources.

1.5 describe AC and DC I can consistently I can usually describe I sometimes need I often need assistance I have not yet

generator power sources describe AC and DC AC and DC generator assistance to describe to describe AC and DC provided evidence of

generator power power sources. AC and DC generator generator power this performance task.

sources. power sources. sources.

1.6 describe multi-purpose I can consistently I can usually describe I sometimes need I often need assistance I have not yet

inverter power sources describe multi-purpose multi-purpose inverter assistance to describe to describe provided evidence of

inverter power sources. power sources. multi-purpose inverter multi-purpose inverter this performance task.

power sources. power sources.

1.7 describe welding power I can consistently I can usually describe I sometimes need I often need assistance I have not yet

source installation and describe welding power welding power source assistance to describe to describe welding provided evidence of

Welder Apprenticeship Assessment CTS, TMT: WDA3406 / 13

Alberta Education, Alberta, Canada 2015

maintenance source installation and installation and welding power source power source this performance task.

maintenance. maintenance. installation and installation and

maintenance. maintenance.

2. identify types of metals and their characteristics

2.1 identify metals by visual I can consistently I can usually identify I sometimes need I often need assistance I have not yet

appearance, colour, identify metals by metals by visual assistance to identify to identify metals by provided evidence of

relative weight, typical visual appearance, appearance, colour, metals by visual visual appearance, this performance task.

shape and texture colour, relative weight, relative weight, appearance, colour, colour, relative weight,

typical shape and typical shape and relative weight, typical typical shape and

texture. texture. shape and texture. texture.

2.2 describe chip, spark, file I can consistently I can usually describe I sometimes need I often need assistance I have not yet

hardness and flame tests describe chip, spark, chip, spark, file assistance to describe to describe chip, spark, provided evidence of

file hardness and flame hardness and flame chip, spark, file file hardness and flame this performance task.

tests. tests. hardness and flame tests.

tests.

2.3 interpret information I can consistently I can usually interpret I sometimes need I often need assistance I have not yet

supplied on mill test interpret information information supplied assistance to interpret to interpret information provided evidence of

reports supplied on mill test on mill test reports. information supplied on supplied on mill test this performance task.

reports. mill test reports. reports.

2.4 describe the mechanical I can consistently I can usually describe I sometimes need I often need assistance I have not yet

properties of metals describe the mechanical the mechanical assistance to describe to describe the provided evidence of

properties of metals. properties of metals. the mechanical mechanical properties this performance task.

properties of metals. of metals.

2.5 describe the physical I can consistently I can usually describe I sometimes need I often need assistance I have not yet

properties of metals describe the physical the physical properties assistance to describe to describe the physical provided evidence of

properties of metals. of metals. the physical properties properties of metals. this performance task.

of metals.

14 / CTS, TMT: WDA3406 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3. identify the effects of heat treatment on carbon steels

3.1 define heat-affected zones I can consistently I can usually define I sometimes need I often need assistance I have not yet

in metals define heat-affected heat-affected zones in assistance to define to define heat-affected provided evidence of

zones in metals. metals. heat-affected zones in zones in metals. this performance task.

metals.

3.2 explain the difference I can consistently I can usually explain I sometimes need I often need assistance I have not yet

between heat and explain the difference the difference between assistance to explain the to explain the difference provided evidence of

temperature between heat and heat and temperature. difference between heat between heat and this performance task.

temperature. and temperature. temperature.

3.3 explain the three forms of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

heat transfer explain the three forms the three forms of heat assistance to explain the to explain the three provided evidence of

of heat transfer. transfer. three forms of heat forms of heat transfer. this performance task.

transfer.

3.4 describe the effects of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

expansion and contraction describe the effects of the effects of assistance to describe to describe the effects provided evidence of

expansion and expansion and the effects of expansion of expansion and this performance task.

contraction. contraction. and contraction. contraction.

3.5 describe the purpose and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

effects of pre-heating and describe the effects of the effects of assistance to describe to describe the effects provided evidence of

post-heating pre-heating and pre-heating and the effects of of pre-heating and this performance task.

post-heating. post-heating. pre-heating and post-heating.

post-heating.

3.6 describe the practices of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

heat treatment describe the practices of the practices of heat assistance to describe to describe the practices provided evidence of

heat treatment. treatment. the practices of heat of heat treatment. this performance task.

treatment.

3.7 explain the principle of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

temperature indicating explain the principle of the principle of assistance to explain the to explain the principle provided evidence of

devices temperature indicating temperature indicating principle of temperature of temperature this performance task.

devices. devices. indicating devices. indicating devices.

Teacher feedback and

assessment.

Welder Apprenticeship Assessment CTS, TMT: WDA3406 / 15

Alberta Education, Alberta, Canada 2015

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3407: SYMBOLS & DRAWINGS

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge and skills to identify blueprint symbols and interpret drawings related to the welding

trade.

Parameters: Access to a materials work centre, complete with drawings and blueprints, and to instruction from an individual with

journeyperson certification as a welder.

ILM Resources: Joint and Weld Types 120102e; Welding Symbols 120102f; Drawing Interpretation 120102a

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3407: SYMBOLS & DRAWINGS

Checklist

16 / CTS, TMT: WDA3407 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. identify joints and weld

types

2. interpret welding symbols

3. read and interpret drawings

Teacher Signature Date

Welder Apprenticeship Assessment CTS, TMT: WDA3407 / 17

Alberta Education, Alberta, Canada 2015

COURSE WDA3407: SYMBOLS & DRAWINGS

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. identify joints and weld types

1.1 identify the five basic I can consistently I can usually identify I sometimes need I often need assistance I have not yet

joints identify the five basic the five basic joints. assistance to identify to identify the five basic provided evidence of

joints. the five basic joints. joints. this performance task.

1.2 describe the types of welds I can consistently I can usually describe I sometimes need I often need assistance I have not yet

and their dimensions describe the types of the types of welds and assistance to describe to describe the types of provided evidence of

welds and their their dimensions. the types of welds and welds and their this performance task.

dimensions. their dimensions. dimensions.

1.3 identify joint and weld I can consistently I can usually identify I sometimes need I often need assistance I have not yet

type variations identify joint and weld joint and weld type assistance to identify to identify joint and provided evidence of

type variations. variations. joint and weld type weld type variations. this performance task.

variations.

1.4 outline the considerations I can consistently I can usually outline I sometimes need I often need assistance I have not yet

in the design of a joint for outline the the considerations in assistance to outline the to outline the provided evidence of

welding considerations in the the design of a joint considerations in the considerations in the this performance task.

design of a joint for for welding. design of a joint for design of a joint for

welding. welding. welding.

18 / CTS, TMT: WDA3407 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2. interpret welding symbols

2.1 explain the purpose of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

welding symbols explain the purpose of the purpose of assistance to explain the to explain the purpose provided evidence of

welding symbols. welding symbols. purpose of welding of welding symbols. this performance task.

symbols.

2.2 define weld symbol, I can consistently I can usually define I sometimes need I often need assistance I have not yet

welding symbol and define weld symbol, weld symbol, welding assistance to define to define weld symbol, provided evidence of

supplementary symbols welding symbol and symbol and weld symbol, welding welding symbol and this performance task.

supplementary symbols. supplementary symbol and supplementary symbols.

symbols. supplementary symbols.

2.3 interpret weld symbols I can consistently I can usually interpret I sometimes need I often need assistance I have not yet

and welding symbols interpret weld symbols weld symbols and assistance to interpret to interpret weld provided evidence of

and welding symbols. welding symbols. weld symbols and symbols and welding this performance task.

welding symbols. symbols.

2.4 identify the dimensioning I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of weld symbols identify the the dimensioning of assistance to identify to identify the provided evidence of

dimensioning of weld weld symbols. the dimensioning of dimensioning of weld this performance task.

symbols. weld symbols. symbols.

2.5 identify non-destructive I can consistently I can usually identify I sometimes need I often need assistance I have not yet

testing symbol identify non-destructive testing assistance to identify to identify provided evidence of

non-destructive testing symbols. non-destructive testing non-destructive testing this performance task.

symbols. symbols. symbols.

3. read and interpret drawings

3.1 identify the alphabet of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

lines identify the alphabet of the alphabet of lines. assistance to identify to identify the alphabet provided evidence of

lines. the alphabet of lines. of lines. this performance task.

3.2 explain the purpose of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

drawings explain the purpose of the purpose of assistance to explain the to explain the purpose provided evidence of

drawings. drawings. purpose of drawings. of drawings. this performance task.

Welder Apprenticeship Assessment CTS, TMT: WDA3407 / 19

Alberta Education, Alberta, Canada 2015

3.3 identify elements and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

information found on identify elements and elements and assistance to identify to identify elements and provided evidence of

drawings information found on information found on elements and information found on this performance task.

drawings. drawings. information found on drawings.

drawings.

3.4 interpret symbols, views I can consistently I can usually interpret I sometimes need I often need assistance I have not yet

and sections used on interpret symbols, symbols, views and assistance to interpret to interpret symbols, provided evidence of

drawings views and sections used sections used on symbols, views and views and sections used this performance task.

on drawings. drawings. sections used on on drawings.

drawings.

3.5 identify metric and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

imperial dimensioning identify metric and metric and imperial assistance to identify to identify metric and provided evidence of

imperial dimensioning. dimensioning. metric and imperial imperial dimensioning. this performance task.

dimensioning.

Teacher feedback and

assessment.

20 / CTS, TMT: WDA3407 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3408: WELD FAULTS

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge and skills to understand the concept of distortion, identify weld faults and understand the

use of hardfacing as related to the welding trade.

Parameters: Access to a materials work centre, complete with welding equipment, and to instruction from an individual with

journeyperson certification as a welder.

ILM Resources: Distortion 120102g; Weld Faults 120102h; Hardfacing 120102i

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3408: WELD FAULTS

Checklist

Welder Apprenticeship Assessment CTS, TMT: WDA3408 / 21

Alberta Education, Alberta, Canada 2015

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. identify distortion and

methods of control

2. identify weld faults

3. observe hardfacing of steel

Teacher Signature Date

22 / CTS, TMT: WDA3408 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE WDA3408: WELD FAULTS

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. identify distortion and methods of control

1.1 identify how heat and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

temperature relate to identify how heat and how heat and assistance to identify to identify how heat and provided evidence of

distortion temperature relate to temperature relate to how heat and temperature relate to this performance task.

distortion. distortion. temperature relate to distortion.

distortion.

1.2 identify the three types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

distortion, their causes and identify the three types the three types of assistance to identify to identify the three provided evidence of

control of each type of distortion, their distortion, their causes the three types of types of distortion, their this performance task.

causes and control of and control of each distortion, their causes causes and control of

each type. type. and control of each each type.

type.

1.3 describe the mechanical, I can consistently I can usually describe I sometimes need I often need assistance I have not yet

procedural and design describe the the mechanical, assistance to describe to describe the provided evidence of

methods of controlling mechanical, procedural procedural and design the mechanical, mechanical, procedural this performance task.

distortion and design methods of methods of controlling procedural and design and design methods of

controlling distortion. distortion. methods of controlling controlling distortion.

distortion.

Welder Apprenticeship Assessment CTS, TMT: WDA3408 / 23

Alberta Education, Alberta, Canada 2015

2. identify weld faults

2.1 define the classifications I can consistently I can usually define I sometimes need I often need assistance I have not yet

of weld faults define the the classifications of assistance to define the to define the provided evidence of

classifications of weld weld faults. classifications of weld classifications of weld this performance task.

faults. faults. faults.

2.2 define the notching effect I can consistently I can usually define I sometimes need I often need assistance I have not yet

define the notching the notching effect. assistance to define the to define the notching provided evidence of

effect. notching effect. effect. this performance task.

2.3 identify weld faults, their I can consistently I can usually identify I sometimes need I often need assistance I have not yet

causes and methods of identify weld faults, weld faults, their assistance to identify to identify weld faults, provided evidence of

prevention their causes and causes and methods of weld faults, their causes their causes and this performance task.

methods of prevention. prevention. and methods of methods of prevention.

prevention.

3. observe hardfacing of steel

3.1 describe the hardfacing I can consistently I can usually describe I sometimes need I often need assistance I have not yet

process and applications describe the hardfacing the hardfacing process assistance to describe to describe the provided evidence of

process and and applications. the hardfacing process hardfacing process and this performance task.

applications. and applications. applications.

3.2 identify types of wear I can consistently I can usually identify I sometimes need I often need assistance I have not yet

identify types of wear. types of wear. assistance to identify to identify types of provided evidence of

types of wear. wear. this performance task.

3.3 identify filler metals for I can consistently I can usually identify I sometimes need I often need assistance I have not yet

hardfacing identify filler metals for filler metals for assistance to identify to identify filler metals provided evidence of

hardfacing. hardfacing. filler metals for for hardfacing. this performance task.

hardfacing.

3.4 identify the problems I can consistently I can usually identify I sometimes need I often need assistance I have not yet

associated with hardfacing identify the problems the problems assistance to identify to identify the problems provided evidence of

and how to avoid them associated with associated with the problems associated associated with this performance task.

hardfacing and how to hardfacing and how to with hardfacing and hardfacing and how to

avoid them. avoid them. how to avoid them. avoid them.

3.5 describe the procedures for I can consistently I can usually describe I sometimes need I often need assistance I have not yet

applying hardfacing describe the procedures the procedures for assistance to describe to describe the provided evidence of

materials with filler wires for applying hardfacing applying hardfacing the procedures for procedures for applying this performance task.

materials with filler materials with filler applying hardfacing hardfacing materials

24 / CTS, TMT: WDA3408 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

wires. wires. materials with filler with filler wires.

wires.

Teacher feedback and

assessment.

Welder Apprenticeship Assessment CTS, TMT: WDA3408 / 25

Alberta Education, Alberta, Canada 2015

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3411: WIRE-FEED WELDING

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students use wire-fed welding machines.

Parameters: Access to a materials work centre, complete with wire-feed welding equipment, and to instruction from an individual with

journeyperson certification as a welder.

ILM Resources: Wire Feed Welding Equipment Power Sources 120103a; Wire Feed Welding Filler Metals and Feeders 120103b

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3411: WIRE-FEED WELDING

26 / CTS, TMT: WDA3411 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. select wire-feed welding

equipment

2. select wire-feed welding

consumables

Teacher Signature Date

Welder Apprenticeship Assessment CTS, TMT: WDA3411 / 27

Alberta Education, Alberta, Canada 2015

COURSE WDA3411: WIRE-FEED WELDING

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. select wire-feed welding equipment

1.1 describe the principals of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

operation of wire-feed describe the principals the principals of assistance to describe to describe the provided evidence of

welding equipment of operation of operation of the principals of principals of operation this performance task.

wire-feed welding wire-feed welding operation of wire-feed of wire-feed welding

equipment. equipment. welding equipment. equipment.

1.2 identify the components I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of a wire-feed welding identify the components the components of assistance to identify to identify the provided evidence of

equipment set-up of wire-feed welding wire-feed welding the components of components of this performance task.

equipment set-up. equipment set-up. wire-feed welding wire-feed welding

equipment set-up. equipment set-up.

1.3 describe wire-process I can consistently I can usually describe I sometimes need I often need assistance I have not yet

welding equipment power describe wire-process wire-process welding assistance to describe to describe wire-process provided evidence of

sources and wire feeders welding equipment equipment power wire-process welding welding equipment this performance task.

power sources and wire sources and wire equipment power power sources and wire

feeders. feeders. sources and wire feeders.

feeders.

1.4 identify advantages and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

disadvantages of identify advantages and advantages and assistance to identify to identify advantages provided evidence of

wire-feed processes disadvantages of wire- disadvantages of advantages and and disadvantages of this performance task.

feed processes. wire-feed processes. disadvantages of wire-feed processes.

wire-feed processes.

28 / CTS, TMT: WDA3411 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2. select wire-feed welding consumables

2.1 identify wire-feed welding I can consistently I can usually identify I sometimes need I often need assistance I have not yet

equipment filler metals identify wire-feed wire-feed welding assistance to identify to identify wire-feed provided evidence of

welding equipment equipment filler wire-feed welding welding equipment this performance task.

filler metals. metals. equipment filler metals. filler metals.

2.2 describe the modes of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

metal transfer describe the modes of the modes of metal assistance to describe to describe the modes provided evidence of

metal transfer. transfer. the modes of metal of metal transfer. this performance task.

transfer.

2.3 describe wire-feed drive I can consistently I can usually describe I sometimes need I often need assistance I have not yet

systems and gun and cable describe wire-feed drive wire-feed drive assistance to describe to describe wire-feed provided evidence of

accessories systems and gun and systems and gun and wire-feed drive systems drive systems and gun this performance task.

cable accessories. cable accessories. and gun and cable and cable accessories.

accessories.

2.4 describe wire-feed I can consistently I can usually describe I sometimes need I often need assistance I have not yet

operating variables describe wire-feed wire-feed operating assistance to describe to describe wire-feed provided evidence of

operating variables. variables. wire-feed operating operating variables. this performance task.

variables.

Teacher feedback and

assessment.

Welder Apprenticeship Assessment CTS, TMT: WDA3411 / 29

Alberta Education, Alberta, Canada 2015

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3413: GASES & MAINTENANCE

Level: First Period Apprenticeship, Section One

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge and skills to select shielding gases and to maintain and troubleshoot wire-fed welding

machines.

Parameters: Access to a materials work centre, complete with wire-feed welding equipment, and to instruction from an individual with

journeyperson certification as a welder.

ILM Resources: Wire Feed Welding Equipment Power Sources 120103a; Wire Feed Welding Filler Metals and Feeders 120103b

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3413: GASES & MAINTENANCE

Checklist

30 / CTS, TMT: WDA3413 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. select shielding gases for the

wire-feed process

2. set-up, maintain and

troubleshoot wire welding

equipment

Teacher Signature Date

Welder Apprenticeship Assessment CTS, TMT: WDA3413 / 31

Alberta Education, Alberta, Canada 2015

COURSE WDA3413: GASES & MAINTENANCE

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. select shielding gases for wire-feed process

1.1 identify shielding gases I can consistently I can usually identify I sometimes need I often need assistance I have not yet

for wire-feed processes identify shielding gases shielding gases for assistance to identify to identify shielding provided evidence of

for wire-feed processes. wire-feed processes. shielding gases for gases for wire-feed this performance task.

wire-feed processes. processes.

1.2 identify shielding gas I can consistently I can usually identify I sometimes need I often need assistance I have not yet

supply systems identify shielding gas shielding gas supply assistance to identify to identify shielding gas provided evidence of

supply systems. systems. shielding gas supply supply systems. this performance task.

systems.

2. set-up, maintain and troubleshoot wire welding equipment

2.1 demonstrate the set-up I can consistently I can usually I sometimes need I often need assistance I have not yet

and maintenance required demonstrate the set-up demonstrate the assistance to to demonstrate the provided evidence of

for wire-drive systems and and maintenance for set-up and demonstrate the set-up set-up and maintenance this performance task.

gun assemblies wire-drive systems and maintenance for and maintenance for for wire-drive systems

gun assemblies. wire-drive systems wire-drive systems and and gun assemblies.

and gun assemblies. gun assemblies.

2.2 perform corrective I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measures for perform corrective corrective measures assistance to perform to perform corrective provided evidence of

malfunctioning measures for for malfunctioning corrective measures for measures for this performance task.

wire-process equipment malfunctioning wire-process malfunctioning malfunctioning

wire-process equipment. wire-process wire-process

equipment. equipment. equipment.

Teacher feedback and

32 / CTS, TMT: WDA3413 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

assessment.

Welder Apprenticeship Assessment CTS, TMT: WDA3413 / 33

Alberta Education, Alberta, Canada 2015

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3415: GMAW ON MILD STEEL

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge and skills to use gas metal arc welding (GMAW) equipment.

Parameters: Access to a materials work centre, complete with GMAE equipment, and to instruction from an individual with

journeyperson certification as a welder.

ILM Resources: GMAW on Mild Steel 120103e

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3415: GMAW ON MILD STEEL

34 / CTS, TMT: WDA3415 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. perform fillet and groove

welds on mild steel

Teacher Signature Date

Welder Apprenticeship Assessment CTS, TMT: WDA3415 / 35

Alberta Education, Alberta, Canada 2015

COURSE WDA3415: GMAW ON MILD STEEL

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. perform fillet and groove welds on mild steel

1.1 weld stringer/weave beads I can consistently weld I can usually weld I sometimes need I often need assistance I have not yet

in the flat and horizontal stringer/weave beads in stringer/weave beads assistance to weld to weld stringer/weave provided evidence of

positions the flat and horizontal in the flat and stringer/weave beads in beads in the flat and this performance task.

positions. horizontal positions. the flat and horizontal horizontal positions.

positions.

1.2 weld in the 1F, 2F and 3F I can consistently weld I can usually weld in I sometimes need I often need assistance I have not yet

positions in the 1F, 2F and 3F the 1F, 2F and 3F assistance to weld in the to weld in the 1F, 2F provided evidence of

positions. positions. 1F, 2F and 3F positions. and 3F positions. this performance task.

1.3 weld in the 1G, 2G, 3G I can consistently weld I can usually weld in I sometimes need I often need assistance I have not yet

and 4G positions in the 1G, 2G, 3G and the 1G, 2G, 3G and assistance to weld in the to weld in the 1G, 2G, provided evidence of

4G positions. 4G positions. 1G, 2G, 3G and 4G 3G and 4G positions. this performance task.

positions.

1.4 weld a 1GR I can consistently weld I can usually weld a I sometimes need I often need assistance I have not yet

a 1GR. 1GR. assistance to weld a to weld a 1GR. provided evidence of

1GR. this performance task.

1.5 use CWB test procedures I can consistently use I can usually use I sometimes need I often need assistance I have not yet

CWB test procedures. CWB test procedures. assistance to use CWB to use CWB test provided evidence of

test procedures. procedures. this performance task.

1.6 weld the 1GF, 2G, 3GF, I can consistently weld I can usually weld the I sometimes need I often need assistance I have not yet

and 4GF joint the 1GF, 2G, 3GF and 1GF, 2G, 3GF and assistance to weld the to weld the 1GF, 2G, provided evidence of

configurations with a 4GF joint 4GF joint 1GF, 2G, 3GF and 4GF 3GF and 4GF joint this performance task.

6.35 mm () backing configurations with a configurations with a joint configurations configurations with a

6.35 mm () backing 6.35 mm () backing with a 6.35 mm () 6.35 mm () backing

plate

plate. plate. backing plate. plate.

36 / CTS, TMT: WDA3415 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

1.7 weld on structural shapes I can consistently weld I can usually weld on I sometimes need I often need assistance I have not yet

on structural shapes. structural shapes. assistance to weld on to weld on structural provided evidence of

structural shapes. shapes. this performance task.

Teacher feedback and

assessment.

Welder Apprenticeship Assessment CTS, TMT: WDA3415 / 37

Alberta Education, Alberta, Canada 2015

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3420: FCAW & MCAW ON MILD STEEL

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge and skills to use flux core arc welding (FCAW) and metal core arc welding (MCAW)

equipment.

Parameters: Access to a materials work centre, complete with FCAW and MCAW equipment, and to instruction from an individual

with journeyperson certification as a welder

ILM Resources: FCAW and MCAW on Mild Steel 120103f

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3420: FCAW & MCAW ON MILD STEEL

Checklist

38 / CTS, TMT: WDA3420 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. perform specific welding

operations in multiple

positions

Teacher Signature Date

Welder Apprenticeship Assessment CTS, TMT: WDA3420 / 39

Alberta Education, Alberta, Canada 2015

COURSE WDA3420: FCAW & MCAW ON MILD STEEL

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. perform specific welding operations in multiple positions

1.1 weld stringer/weave beads I can consistently weld I can usually weld I sometimes need I often need assistance I have not yet

in the flat and horizontal stringer/weave beads in stringer/weave beads assistance to weld to weld stringer/weave provided evidence of

positions on mild steel the flat and horizontal in the flat and stringer/weave beads in beads in the flat and this performance task.

plate positions on mild steel horizontal positions on the flat and horizontal horizontal positions on

plate. mild steel plate. positions on mild steel mild steel plate.

plate.

1.2 weld in the 1F, 2F and 3F I can consistently weld I can usually weld in I sometimes need I often need assistance I have not yet

positions using the FCAW in the 1F, 2F and 3F the 1F, 2F and 3F assistance to weld in the to weld in the 1F, 2F provided evidence of

process positions using the positions using the 1F, 2F and 3F positions and 3F positions using this performance task.

FCAW process. FCAW process. using the FCAW the FCAW process.

process.

1.3 weld using the MCAW I can consistently weld I can usually weld I sometimes need I often need assistance I have not yet

process using the MCAW using the MCAW assistance to weld using to weld using the provided evidence of

process. process. the MCAW process. MCAW process. this performance task.

1.4 weld in the 1GF, 2G, 3GF I can consistently weld I can usually weld in I sometimes need I often need assistance I have not yet

and 4GF joint in the 1GF, 2G, 3GF the 1GF, 2G, 3GF and assistance to weld in the to weld in the 1GF, 2G, provided evidence of

configurations using the and 4GF joint 4GF joint 1GF, 2G, 3GF and 4GF 3GF and 4GF joint this performance task.

FCAW process with a configurations using the configurations using joint configurations configurations using the

FCAW process with a the FCAW process using the FCAW FCAW process with a

6.35 mm () backing

6.35 mm () backing with a 6.35 mm () process with a 6.35 mm 6.35 mm () backing

plate plate. backing plate. () backing plate. plate.

1.5 use CWB testing I can consistently use I can usually use I sometimes need I often need assistance I have not yet

procedures CWB testing CWB testing assistance to use CWB to use CWB testing provided evidence of

procedures. procedures. testing procedures. procedures. this performance task.

40 / CTS, TMT: WDA3420 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

1.6 weld on structural shapes I can consistently weld I can usually weld on I sometimes need I often need assistance I have not yet

on structural shapes. structural shapes. assistance to weld on to weld on structural provided evidence of

structural shapes. shapes. this performance task.

Teacher feedback and

assessment.

Welder Apprenticeship Assessment CTS, TMT: WDA3420 / 41

Alberta Education, Alberta, Canada 2015

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3423: MILD STEEL WELDS

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge and skills to use GMAW, FCAW and MCAW equipment in various positions and

configurations.

Parameters: Access to a materials work centre, complete with GMAW, FCAW and MCAW, and to instruction from an individual with

journeyperson certification as a welder.

ILM Resources: GMAW, FCAW and MCAW Groove Welds on Mild Steel 120103g

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3423: MILD STEEL WELDS

Checklist

42 / CTS, TMT: WDA3423 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. perform GMAW, FCAW

and MCAW welds on mild

steel

Teacher Signature Date

Welder Apprenticeship Assessment CTS, TMT: WDA3423 / 43

Alberta Education, Alberta, Canada 2015

COURSE WDA3423: MILD STEEL WELDS

Rubrics

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. perform GMAW, FCAW and MCAW welds on mild steel

1.1 weld butt joints in the 1G, I can consistently weld I can usually weld butt I sometimes need I often need assistance I have not yet

2G and 3G positions on butt joints in the 1G, joints in the 1G, 2G assistance to weld butt to weld butt joints in the provided evidence of

mild steel using GMAW 2G and 3G positions on and 3G positions on joints in the 1G, 2G and 1G, 2G and 3G this performance task.

for the root bead and mild steel using mild steel using 3G positions on mild positions on mild steel

GMAW for the root GMAW for the root steel using GMAW for using GMAW for the

FCAW or MCAW for fill

bead and FCAW or bead and FCAW or the root bead and root bead and FCAW or

and cap MCAW for fill and cap. MCAW for fill and FCAW or MCAW for MCAW for fill and cap.

cap. fill and cap.

1.2 weld with MCAW on I can consistently weld I can usually weld I sometimes need I often need assistance I have not yet

various joint with MCAW on various with MCAW on assistance to weld with to weld with MCAW on provided evidence of

configurations joint configurations. various joint MCAW on various joint various joint this performance task.

configurations. configurations. configurations.

Teacher feedback and

assessment.

44 / CTS, TMT: WDA3423 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

WELDER APPRENTICESHIP ASSESSMENT

COURSE WDA3427: MILD STEEL PIPE WELDS

Level: First Period Apprenticeship

Prerequisites: WDA3900: Apprenticeship Safety

WDA3401: Tools & Equipment

Description: Students develop knowledge and skills to use GMAW, FCAW and MCAW equipment in various positions and

configurations on steel pipe.

Parameters: Access to a materials work centre, complete with GMAW, FCAW and MCAW equipment, and to instruction from an

individual with journeyperson certification as a welder.

ILM Resources: GMAW, FCAW and MCAW on Mild Steel Pipe 120103j

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE WDA3427: MILD STEEL PIPE WELDS

Checklist

Welder Apprenticeship Assessment CTS, TMT: WDA3427 / 45

Alberta Education, Alberta, Canada 2015

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. perform GMAW, FCAW

and MCAW welds on mild

steel pipe

Teacher Signature Date

46 / CTS, TMT: WDA3427 Welder Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE WDA3427: MILD STEEL PIPE WELDS

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. perform GMAW, FCAW and MCAW welds on mild steel pipe

1.1 weld in the 2G position on I can consistently weld I can usually weld in I sometimes need I often need assistance I have not yet

pipe using GMAW in the 2G position on the 2G position on assistance to weld in the to weld in the 2G provided evidence of

pipe using GMAW. pipe using GMAW. 2G position on pipe position on pipe using this performance task.

using GMAW. GMAW.

1.2 weld in the 1G-rotated I can consistently weld I can usually weld in I sometimes need I often need assistance I have not yet

positions on pipe using in the 1G-rotated the 1G-rotated assistance to weld in the to weld in the provided evidence of

GMAW for root pass and positions on pipe using positions on pipe 1G-rotated positions on 1G-rotated positions on this performance task.

FCAW for fill and cap GMAW for root pass using GMAW for root pipe using GMAW for pipe using GMAW for

and FCAW for fill and pass and FCAW for root pass and FCAW for root pass and FCAW for

cap. fill and cap. fill and cap. fill and cap.

1.3 weld in the 2G position on I can consistently weld I can usually weld in I sometimes need I often need assistance I have not yet

pipe using GMAW for in the 2G position on the 2G position on assistance to weld in the to weld in the 2G provided evidence of

root pass and FCAW for pipe using GMAW for pipe using GMAW for 2G position on pipe position on pipe using this performance task.

fill and cap root pass and FCAW root pass and FCAW using GMAW for root GMAW for root pass

for fill and cap. for fill and cap. pass and FCAW for fill and FCAW for fill and

and cap. cap.

1.4 weld with GMAW in the I can consistently weld I can usually weld I sometimes need I often need assistance I have not yet

5G position on pipe using with GMAW in the 5G with GMAW in the 5G assistance to weld with to weld with GMAW in provided evidence of

a root downhill pass, an position on pipe using a position on pipe using GMAW in the 5G the 5G position on pipe this performance task.

uphill fill pass and an root downhill pass, an a root downhill pass, position on pipe using a using a root downhill

uphill fill pass and an an uphill fill pass and root downhill pass, an pass, an uphill fill pass

uphill cap pass

uphill cap pass. an uphill cap pass. uphill fill pass and an and an uphill cap pass.

uphill cap pass.

Welder Apprenticeship Assessment CTS, TMT: WDA3427 / 47

Alberta Education, Alberta, Canada 2015

Teacher feedback and