Professional Documents

Culture Documents

Soldering Lead-Free Fittings & Fixtures: Recommended Technique

Uploaded by

AMS0 ratings0% found this document useful (0 votes)

21 views1 pageTorch specs

Original Title

Bernzomatic_LeadFree1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTorch specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 pageSoldering Lead-Free Fittings & Fixtures: Recommended Technique

Uploaded by

AMSTorch specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Soldering Lead-Free

Fittings & Fixtures

Recommended Technique

aggressive MECHANICAL cleaning Frustrated WHEN

Requires an abrasive 120 grit or coarser soldering new

As a result of tenacious surface oxide, aggressive lead-free fittings?

mechanical cleaning is required, including the use

of sandpaper or other abrasive cloth.

Solder doesnt flow as well.

Surface oxide is stubborn.

Fittings dont heat up

2 STANDARD FLUX APPLICATION

For best results, use a water soluble flux with chloride compounds

as easily. Its not your

imagination!

Apply flux immediately after cleaning. To protect newly Recent government

exposed metal and minimize reformation of oxide layer. regulations reduced the

Bernzomatic brand Water Soluble Flux complies with amount of lead in systems

the Reduction of Lead in Drinking Water Act suitable that carry water for human

for use with lead-free brass. Chlorides in the flux consumption.

effectively aid in removal of oxides, providing superior

adhesion of alloy to pipe. New lead-free fittings

require some TLC to get

a leak-free solder joint.

3 Thorough HEATING & TORCH MOVEMENT

As a result of reduced thermal conductivity in lead-free

brass, uniform heating throughout the fitting is critical.

Adjust movement around the joint and heat gradually

to achieve even temperature for soldering.

4 SOLDER CHOICE AND APPLICATION

Use a lead-free compliant solder, ensure NSF/ANSI Std. 61 compliance

After joint is thoroughly heated, apply solder.

5 PROVIDE Adequate TIME FOR Cooling

Because Lead-Free brass retains heat longer, the process

requires more time for solder to solidify, cool and regain

its strength.

For making capillary joints, Bernzomatic recommends

following the techniques found under ASTM standard B828.

1-800-359-9678 www.bernzomatic.com 2015 Worthington Cylinder Corporation

You might also like

- Making Money Online Unlocking SmartphonesDocument7 pagesMaking Money Online Unlocking SmartphonesAMS50% (2)

- Soldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesDocument10 pagesSoldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesChen Zhi ShenNo ratings yet

- National - Criminal DatabaseDocument66 pagesNational - Criminal DatabaseAMSNo ratings yet

- Build Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramDocument21 pagesBuild Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramDanCurtis100% (1)

- SBI - Certificate To Be Submitted by Pensioner - ChandigarhDocument1 pageSBI - Certificate To Be Submitted by Pensioner - ChandigarhMsinghNo ratings yet

- Lines WorksheetDocument3 pagesLines WorksheetJuzef StaljinNo ratings yet

- S6MT 1Q w1 3 MELC1 SLM MIXTURES FinalCopy09082020Document26 pagesS6MT 1Q w1 3 MELC1 SLM MIXTURES FinalCopy09082020Rona Dindang100% (1)

- Chemicals Zetag DATA Powder Magnafloc 351 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc 351 - 0410PromagEnviro.comNo ratings yet

- SolderingDocument18 pagesSolderingMarian MarianNo ratings yet

- LCD Anodizing 2020Document30 pagesLCD Anodizing 2020donny reborn100% (1)

- Isolation and Characterization of Galactomannan From Sugar PalmDocument4 pagesIsolation and Characterization of Galactomannan From Sugar PalmRafaél Berroya Navárro100% (1)

- ALUMINIUMTECHNOLOGIES Week3Document84 pagesALUMINIUMTECHNOLOGIES Week3HaiLuuNo ratings yet

- Soft and Hard Soldering +brazingDocument28 pagesSoft and Hard Soldering +brazingJoseph Magbanua Dato-on67% (3)

- Presentation On Data Integrity in PharmaDocument80 pagesPresentation On Data Integrity in Pharmaskvemula67% (3)

- Silver Brazing GuideDocument8 pagesSilver Brazing GuidegianNo ratings yet

- 6.0 Brazing: 14 - Copper-Nickel Welding and FabricationDocument1 page6.0 Brazing: 14 - Copper-Nickel Welding and FabricationsatnamNo ratings yet

- Pub139 16 PDFDocument1 pagePub139 16 PDFsatnamNo ratings yet

- Tubular Induction Brazing WiresDocument2 pagesTubular Induction Brazing WiresAli HashemiNo ratings yet

- Composition, Testing, and Control of Hot Dip Galvanizing FluxDocument14 pagesComposition, Testing, and Control of Hot Dip Galvanizing FluxdusanNo ratings yet

- Section 12 - Welding Consumables - Silver Brazing AlloysDocument8 pagesSection 12 - Welding Consumables - Silver Brazing AlloysFriedrich SchwimNo ratings yet

- 17A17BDocument10 pages17A17BburaqbarakahsbNo ratings yet

- Plant Engineering Why Absorption Chillers FailDocument5 pagesPlant Engineering Why Absorption Chillers FailUmut Sinan ÇetinbaşNo ratings yet

- mc1696 PDFDocument4 pagesmc1696 PDFBala MuruganNo ratings yet

- ALUMON EN - MIES - NA - 201614 - 16jul18Document7 pagesALUMON EN - MIES - NA - 201614 - 16jul18Sarai Aracely melendez garciaNo ratings yet

- Bronze Wire 01 - 2015 EngDocument2 pagesBronze Wire 01 - 2015 EngMRC WeldingNo ratings yet

- Copper For Refrigeration Pipelines PDFDocument2 pagesCopper For Refrigeration Pipelines PDFBehnam AshouriNo ratings yet

- Oxyfuel Brazing PrimerDocument5 pagesOxyfuel Brazing Primeralfian leoanakNo ratings yet

- CFW 59 W 54 PDFDocument2 pagesCFW 59 W 54 PDFLeonardo LuizNo ratings yet

- Fusing Great Products With Great Service: 100% Made in Italy Product CatalogueDocument20 pagesFusing Great Products With Great Service: 100% Made in Italy Product CatalogueConstantin UdreaNo ratings yet

- Zinc PlatingDocument4 pagesZinc Platingrohitpatil330% (1)

- CW617N - Stång - Eng - Utg 3Document4 pagesCW617N - Stång - Eng - Utg 3Jarco PetrinNo ratings yet

- Copper Nickel AlloysDocument5 pagesCopper Nickel AlloysAditya Agarwal100% (2)

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- High Performance Austenitic Welded Stainless Tubular ProductDocument2 pagesHigh Performance Austenitic Welded Stainless Tubular ProductGuido RuizNo ratings yet

- Anodizing of Aluminum by Charles A. Grubbs: CAG Consulting, Lakeland, FLDocument11 pagesAnodizing of Aluminum by Charles A. Grubbs: CAG Consulting, Lakeland, FLpunkassbobNo ratings yet

- PMP DesignPrinciples 1Document12 pagesPMP DesignPrinciples 1Darren PottsNo ratings yet

- SOLDERING AND BRAZING Presentation #1Document24 pagesSOLDERING AND BRAZING Presentation #1hastavprantoNo ratings yet

- Fluxes in WeldingDocument42 pagesFluxes in Weldingjhas988No ratings yet

- 1 Is 2629 - 1985Document6 pages1 Is 2629 - 1985Sarvesh AhluwaliaNo ratings yet

- Unit IV Unit IV: Industrial Inert GasesDocument19 pagesUnit IV Unit IV: Industrial Inert GasesermiasNo ratings yet

- Ngineering Ulletin: White Rust On Galvanized SteelDocument2 pagesNgineering Ulletin: White Rust On Galvanized SteelAsian Trans PowerNo ratings yet

- Plasma Arc Machining - Lect 3Document26 pagesPlasma Arc Machining - Lect 3sachhpNo ratings yet

- sn995 Lowmaintenance Lowcost Pbfree Soldering Alloy 98572 r3Document2 pagessn995 Lowmaintenance Lowcost Pbfree Soldering Alloy 98572 r3Pako DíazNo ratings yet

- NOCOLOK Brazing Process 2018 02Document8 pagesNOCOLOK Brazing Process 2018 02Pérsio Mozart PintoNo ratings yet

- Aluminum Flyer DistDocument2 pagesAluminum Flyer Distasavari87No ratings yet

- Expt 5,6,7Document15 pagesExpt 5,6,7wocison461No ratings yet

- C PLATE TdsDocument1 pageC PLATE TdsEdwin TacoNo ratings yet

- 5 SawDocument13 pages5 SawKartik BhararaNo ratings yet

- Oasis Handbook - Galvanizing DefectsDocument14 pagesOasis Handbook - Galvanizing DefectsBASKARANNo ratings yet

- BrazingDocument9 pagesBrazingDennis DaleNo ratings yet

- SolderingDocument45 pagesSolderingSushil BodkeNo ratings yet

- Voestalpine - Boehler Cored Wires BrochureDocument6 pagesVoestalpine - Boehler Cored Wires Brochurerusf123No ratings yet

- CBloch ACC CommissioningDocument28 pagesCBloch ACC CommissioningManuel PerezNo ratings yet

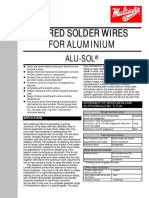

- Cored Solder Wires Cored Solder Wires For Aluminium: Alu-SolDocument4 pagesCored Solder Wires Cored Solder Wires For Aluminium: Alu-Solpaula09No ratings yet

- Zaclon Technical GuideDocument6 pagesZaclon Technical GuideChoice OrganoNo ratings yet

- Mechanisms in The Cleaning of Aluminium Melts With Flux Preparations PDFDocument22 pagesMechanisms in The Cleaning of Aluminium Melts With Flux Preparations PDFafnene1No ratings yet

- 2012v11 - Taking A Dip - Hot-Dip Galvanizing PDFDocument3 pages2012v11 - Taking A Dip - Hot-Dip Galvanizing PDFabcd_iluNo ratings yet

- Braking System in SR20Document12 pagesBraking System in SR20SNEHASIS MOHANTYNo ratings yet

- Industrial Training Presentation: (Cold Rolled Coils)Document21 pagesIndustrial Training Presentation: (Cold Rolled Coils)Gopi BahuNo ratings yet

- HPDC v2 For VIBE ItaDocument10 pagesHPDC v2 For VIBE Itaİsmail Süleyman ŞentürkNo ratings yet

- 3081-1 (4) Stainlesssteel Flux Cored Welding Wire: Shield GASDocument3 pages3081-1 (4) Stainlesssteel Flux Cored Welding Wire: Shield GASArfanAliNo ratings yet

- Mech Mod 4Document82 pagesMech Mod 4brave playerNo ratings yet

- GN - 8-02 - Protective Treatment of FastenersDocument5 pagesGN - 8-02 - Protective Treatment of Fastenersachus2000No ratings yet

- Secondary Steelmaking: Topics To Discuss ..Document11 pagesSecondary Steelmaking: Topics To Discuss ..Mir RafsanNo ratings yet

- Vacuum Oxygen DecarburizationDocument11 pagesVacuum Oxygen DecarburizationSradha Suman100% (1)

- Joining of MetalsDocument5 pagesJoining of MetalsArun PadmanNo ratings yet

- What Does Soldering Flux MeanDocument11 pagesWhat Does Soldering Flux MeanjackNo ratings yet

- Uniform Fine ScheduleDocument115 pagesUniform Fine ScheduleAMSNo ratings yet

- Hensel Recycling HenRy 2017 EnglishDocument20 pagesHensel Recycling HenRy 2017 EnglishAMSNo ratings yet

- 13 Fractional Tap and Drill Bit GuideDocument4 pages13 Fractional Tap and Drill Bit Guidewhitelizard2001No ratings yet

- Haul TruckDocument2 pagesHaul TruckAMSNo ratings yet

- Kennecott Conflict Free Mineral Policy Feb2017Document1 pageKennecott Conflict Free Mineral Policy Feb2017AMSNo ratings yet

- Agaveweb Search: C12345 Doe vs. Doe Doe vs. Doe Doe vs. Doe John DoeDocument3 pagesAgaveweb Search: C12345 Doe vs. Doe Doe vs. Doe Doe vs. Doe John DoeAMSNo ratings yet

- Lit 11626 17 46 - 819Document113 pagesLit 11626 17 46 - 819AMSNo ratings yet

- CSE 127: Computer Security: SQL InjectionDocument35 pagesCSE 127: Computer Security: SQL InjectionAMSNo ratings yet

- Atlas UC & BSPTCL Operational GSS & LinesDocument16 pagesAtlas UC & BSPTCL Operational GSS & LinesSandeep KumarNo ratings yet

- Rundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967Document15 pagesRundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967nixyingboNo ratings yet

- CV Dang Hoang Du - 2021Document7 pagesCV Dang Hoang Du - 2021Tran Khanh VuNo ratings yet

- Concept PaperDocument6 pagesConcept Paperapple amanteNo ratings yet

- Almond Milk Case Study Executive SummaryDocument19 pagesAlmond Milk Case Study Executive Summarygauthamsindia307No ratings yet

- Understanding Empathy and SympathyDocument2 pagesUnderstanding Empathy and SympathyFrinces MarvidaNo ratings yet

- Plant Cell Culture: Genetic Information and Cellular MachineryDocument18 pagesPlant Cell Culture: Genetic Information and Cellular MachineryYudikaNo ratings yet

- Regional Ecology Test ScoringDocument14 pagesRegional Ecology Test Scoringaisyah Wardah201No ratings yet

- 9 Oet Reading Summary 2.0-195-213Document19 pages9 Oet Reading Summary 2.0-195-213Vijayalakshmi Narayanaswami0% (1)

- No.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10Document9 pagesNo.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10William DaslerNo ratings yet

- Seguridad Boltec Cable PDFDocument36 pagesSeguridad Boltec Cable PDFCesar QuintanillaNo ratings yet

- Rajasthan PET Chemistry 1997 Exam with Detailed SolutionsDocument34 pagesRajasthan PET Chemistry 1997 Exam with Detailed SolutionsYumit MorwalNo ratings yet

- Smart Goals ExerciseDocument2 pagesSmart Goals Exerciseapi-594661640No ratings yet

- Heat Transfer Augmentation in Decaying Turbulent Swirl FlowDocument1 pageHeat Transfer Augmentation in Decaying Turbulent Swirl FlowOnkar ChavanNo ratings yet

- ĐỀ THI THU TNTHPT SỐ 17Document4 pagesĐỀ THI THU TNTHPT SỐ 17Nguyên Hà NguyễnNo ratings yet

- Training and Supervision of Health Care WorkersDocument12 pagesTraining and Supervision of Health Care WorkerspriyankaNo ratings yet

- EPF, EPS, Gratuity, Superannuation & Group Life Insurance Nomination FAQsDocument4 pagesEPF, EPS, Gratuity, Superannuation & Group Life Insurance Nomination FAQsHemanth DhananjayNo ratings yet

- TESC CRC Office & Gym Roof Exterior PaintingDocument6 pagesTESC CRC Office & Gym Roof Exterior PaintinghuasNo ratings yet

- Myofascial Release for Piriformis MyalgiaDocument14 pagesMyofascial Release for Piriformis MyalgiaApoorvNo ratings yet

- Carbon Cycle Game Worksheet - EportfolioDocument2 pagesCarbon Cycle Game Worksheet - Eportfolioapi-264746220No ratings yet

- Human Resources Management Article Review On "The 3 Essential Jobs That Most Retention Programs Ignore"Document14 pagesHuman Resources Management Article Review On "The 3 Essential Jobs That Most Retention Programs Ignore"Pang Kok ShengNo ratings yet

- Overhead Set (OBC)Document19 pagesOverhead Set (OBC)MohamedNo ratings yet

- Report Experiment 5 STK1211Document9 pagesReport Experiment 5 STK1211NurAkila Mohd YasirNo ratings yet