Professional Documents

Culture Documents

Lo-Driv: A Superior Thread-Former For Steel

Uploaded by

SquidwardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lo-Driv: A Superior Thread-Former For Steel

Uploaded by

SquidwardCopyright:

Available Formats

LO-DRIV

A Superior Thread-Former for Steel

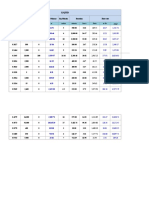

Low In-Place Cost 100 Assembly costs

In-place joint cost savings can be realized through the Operation costs

elimination of all costs associated with the tapping 80 Material costs

costs [%]

operation, including:

direct labor (setup, run, and inspection time) 60

thread taps, fixtures, and gages

40

in-process moving and storage

cleaning oil and chips from a tapped hole

20

required capital

scrap 0

machine screw LO-DRIV

Quality Improvement thread-former

Utilizing a LO-DRIV fastener improves supply-chain quality by eliminating

secondary tapping operations and all associated quality issues including:

cross-threading and assembly problems

oil and chip contamination

missing or improperly tapped holes

Superior Installation Characteristics

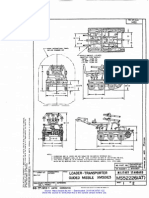

The unique LO-DRIV screw design incorporates three distinct sections. The first

section is an initial sharp crested thread. The second section is a tapered area

having numerous thread relief indentations. The third section is a completely round

bodied area. The sharp lead thread provides quick starting using a minimum

amount of end load force. The tapered relief section allows thread forming at very

low torque values. The fully round body provides the highest possible resistance to

thread stripping. The combination of these features provides for fast, easy screw

installation requiring minimum operator exertion and high reliability against screw

failures and all of their associated costs.

Excellent Joint Stability

The circular cross section maximizes flank engagement compared to trilobular

designs, providing high stripping torque, consistent vibration resistance, and

superior clamp load. In addition, the large cross sectional area provides

increased axial and torsional strength.

LO-DRIV Fastener Standards

External thread diameter 2.5 3.0 3.5 4.0 5.0 6.0 8.0 10.0 12.0

Thread pitch 0.45 0.50 0.60 0.70 0.80 1.00 1.25 1.50 1.75

Thread run-out X max. 0.45 0.50 0.60 0.70 0.80 1.00 1.25 1.50 1.75

Indented Hex Flange Head

max. 5.40 6.40 7.50 8.50 10.60 12.80 16.80 21.00 24.80

Flange diameter D

min. 5.00 5.90 6.90 7.80 9.80 11.80 15.50 19.30 23.30

max. 3.20 4.00 5.00 5.50 7.00 8.00 10.00 13.00 15.00

Width across flats W

min. 3.04 3.84 4.82 5.32 6.78 7.78 9.78 12.72 14.72

Width across corners E min. 3.39 4.27 5.36 5.92 7.55 8.66 10.89 14.16 16.38

Head height K max. 2.70 3.20 3.80 4.30 5.40 6.70 8.60 10.70 13.70

Hex height H min. 1.60 1.90 2.40 2.80 3.50 4.20 5.60 7.00 8.40

Flange edge thickness s min. 0.30 0.40 0.50 0.60 0.70 1.00 1.20 1.40 1.80

Radius R min. 0.10 0.10 0.10 0.20 0.20 0.30 0.40 0.40 0.40

Torx Plus Round Washer Head

max. 6.00 7.50 9.00 10.00 11.50 14.50 19.00

Washer diameter D

min. 5.52 6.92 8.42 9.42 10.80 13.80 18.16

max. 2.12 2.37 2.62 3.02 3.55 4.55 5.85

Head height K

min. 1.88 2.13 2.38 2.78 3.25 4.25 5.55

max. 0.70 0.80 0.90 1.10 1.30 1.70 2.10

Washer thickness s

min. 0.50 0.60 0.70 0.90 1.10 1.50 1.90 on request

Radius R min. 0.10 0.10 0.10 0.20 0.20 0.30 0.40

Torx Plus size 8IP 10IP 15IP 20IP 25IP 30IP 40IP

Recess width A ref. 2.40 2.80 3.35 3.95 4.50 5.60 6.75

max. 1.10 1.30 1.40 1.65 1.85 2.30 3.10

Recess penetration depth t

min. 0.90 1.00 1.10 1.30 1.50 1.90 2.60

Material: Plating:

Case Hardened (up to M6): 1022 or 10B21 steel, Zinc, bake, and trivalent chromate with wax dip

RC 28-38 core hardness, RC 45 min. case hardness

Through Hardened: 4037 steel, Different materials and platings, and special designs

RC 28-38, tip induction hardened to RC 45 min available upon request

Joint Design

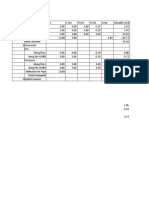

Thread Engagement Guidelines Hole Sizes (mm)

Percent Thread Engagement 2.5 3.0 3.5 4.0 5.0 6.0 8.0 10.0 12.0

Application Percent Thread Engagement 50 2.35 2.84 3.31 3.77 4.74 5.68 7.59 9.51 11.43

Powdered Metal 50-65 55 2.34 2.82 3.29 3.75 4.71 5.64 7.55 9.46 11.37

Cast Iron 50-65 60 2.33 2.81 3.27 3.73 4.69 5.61 7.51 9.42 11.32

Cold Rolled Steel 65-70 65 2.31 2.79 3.25 3.70 4.66 5.58 7.47 9.37 11.26

Thin Sheet Metal 80-95 70 2.30 2.77 3.23 3.68 4.64 5.55 7.43 9.32 11.20

Punch Extrusion 85-90 75 2.28 2.76 3.21 3.66 4.61 5.51 7.39 9.27 11.15

80 2.27 2.74 3.19 3.64 4.58 5.48 7.35 9.22 11.09

Optimum hole sizes and tightening torques for specific 85 2.25 2.72 3.17 3.61 4.56 5.45 7.31 9.17 11.03

applications can be determined through experimentation 90 2.24 2.71 3.15 3.59 4.53 5.42 7.27 9.12 10.98

in the ATF Applications Lab 95 2.22 2.69 3.13 3.57 4.51 5.38 7.23 9.07 10.92

LO-DRIV (Patent No. 5,088,869) is a registered trademark of Greenslade Co,

Fort Worth, TX

Torx, Torx Plus and Autosert are registered trademarks of Camcar, Div. of

Textron, Rockford, IL

ATF, Inc.

Corporate Headquarters Tel (847) 677-1300

3550 West Pratt Avenue Fax (847) 677-9335

Lincolnwood, Illinois 60712 USA www.atf-inc.com

You might also like

- Manual Balanceadora HunterDocument19 pagesManual Balanceadora HunterAriel MercochaNo ratings yet

- TICS Resistance For MITSUBISHI InddDocument31 pagesTICS Resistance For MITSUBISHI InddBradley Lodder92% (13)

- 88-02 Cummins Exhaust BrakeDocument24 pages88-02 Cummins Exhaust Brakemark_dayNo ratings yet

- Torque Details-Hex Bolt DIN 933Document2 pagesTorque Details-Hex Bolt DIN 933coolkaisy100% (2)

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Document4 pagesProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNo ratings yet

- SF6 Circuit Breaker Up To 17.5 KV: 2018 CatalogDocument52 pagesSF6 Circuit Breaker Up To 17.5 KV: 2018 Catalogjean Gilbert NoutamoNo ratings yet

- DRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CDocument2 pagesDRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CBimal DeyNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Din 933Document2 pagesDin 933Sugumar0% (1)

- Sieve Analysis Data Sheet: ASTM D422-63 (2007)Document2 pagesSieve Analysis Data Sheet: ASTM D422-63 (2007)Noor MohdNo ratings yet

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan Aranyawat100% (1)

- Relay and Contactor in DetailDocument12 pagesRelay and Contactor in DetailSafen Bakr SiwailyNo ratings yet

- Torque de Trepanos Smith (PDC - Tricono) PDFDocument1 pageTorque de Trepanos Smith (PDC - Tricono) PDFPither ZuritaNo ratings yet

- XT225 TTR225 1992-2004Document392 pagesXT225 TTR225 1992-2004Barryc100% (2)

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YDocument2 pagesHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuNo ratings yet

- The Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- PLATE BEARING TEST (Acc. DIN 18134) - Part - 1 (Field Data)Document2 pagesPLATE BEARING TEST (Acc. DIN 18134) - Part - 1 (Field Data)EMANUELINo ratings yet

- Comparison of PSFB and FB-LLC For High Power DCDCDocument49 pagesComparison of PSFB and FB-LLC For High Power DCDCNhật Đào QuốcNo ratings yet

- The World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionDocument2 pagesThe World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionSquidwardNo ratings yet

- Bar Bending Schedule BBS FormatDocument8 pagesBar Bending Schedule BBS FormatvijkingNo ratings yet

- Socket Countersunk Screws Din7991Document2 pagesSocket Countersunk Screws Din7991Gökhan AnliNo ratings yet

- 1 - ATF EJOT DELTA - PT - Thread-Former For PlasticsDocument8 pages1 - ATF EJOT DELTA - PT - Thread-Former For PlasticsCamiLeaNo ratings yet

- Altracs: A Superior Thread-Former For Light AlloysDocument8 pagesAltracs: A Superior Thread-Former For Light AlloysSquidwardNo ratings yet

- Tse 708 B420C 2Document1 pageTse 708 B420C 2ihsankeskinnNo ratings yet

- Screw, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDocument1 pageScrew, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDerekNo ratings yet

- WFF - FlangesDocument5 pagesWFF - Flangesbaskaran vNo ratings yet

- 7MPa Concrete Blocks TDS - v2Document7 pages7MPa Concrete Blocks TDS - v2Slinky BillNo ratings yet

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 pagesNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaNo ratings yet

- Data NYAF 4mm SupremeDocument1 pageData NYAF 4mm SupremeHans JayaNo ratings yet

- Jis C 3406Document2 pagesJis C 3406Chul Woong SonNo ratings yet

- SUPREME-flexible Cable PDFDocument12 pagesSUPREME-flexible Cable PDFRobert BudiwijayaNo ratings yet

- K-511-V, FLW SWTDocument2 pagesK-511-V, FLW SWTamir shokrNo ratings yet

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringNitin SharmaNo ratings yet

- Well Tube 1050514Document12 pagesWell Tube 1050514Mustafa AlhoubaniNo ratings yet

- Rates AnalysisDocument867 pagesRates AnalysisChauhan UjjvalNo ratings yet

- 5.dhegale Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesDocument5 pages5.dhegale Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesAbi DemeNo ratings yet

- Ejot Data Sheet jt2 5.50x 25Document2 pagesEjot Data Sheet jt2 5.50x 25Vengatesh HariNo ratings yet

- SPH4U - Investigating Circular Motion (Data) - Ananya AdityaxlsxDocument7 pagesSPH4U - Investigating Circular Motion (Data) - Ananya AdityaxlsxAnanya AdityaNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Area of SteelDocument26 pagesArea of Steelaqib.syed1011No ratings yet

- Product List Under SWR Fittings Standard IS 14735: 1999: MinimumDocument2 pagesProduct List Under SWR Fittings Standard IS 14735: 1999: MinimumPrakash KumarNo ratings yet

- WENDYEDocument12 pagesWENDYEDawit BirhanNo ratings yet

- Metric DIN 404 Slotted Capstan Screws: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 404 Slotted Capstan Screws: Visit Our For Product AvailabilityPaulo Henrique NascimentoNo ratings yet

- Slip On Flanges ANSI B16.5 300lbsDocument1 pageSlip On Flanges ANSI B16.5 300lbskannu19802550No ratings yet

- Measurement of The Drag Coefficients of Spherical ParticlesDocument10 pagesMeasurement of The Drag Coefficients of Spherical Particlessr3shNo ratings yet

- Weight CalculationDocument22 pagesWeight Calculationkamaldhar007No ratings yet

- SieveAnalysis Data For CADocument1 pageSieveAnalysis Data For CAraju_420034520No ratings yet

- Diam. (MM) A (CM) (MM)Document12 pagesDiam. (MM) A (CM) (MM)telnajjarNo ratings yet

- Penthor 964: External StandardDocument2 pagesPenthor 964: External StandardAnjani kumarNo ratings yet

- Astm A325m PDFDocument1 pageAstm A325m PDFFrose KhanNo ratings yet

- Jack. Pump Head CalculationDocument3 pagesJack. Pump Head CalculationAbarajithan RajendranNo ratings yet

- Design of Rising MainDocument1 pageDesign of Rising MainRaju SainiNo ratings yet

- MB Book RAwDocument4 pagesMB Book RAwDeep AceNo ratings yet

- Cylinder Name Lift Cylinder Bucket Cylinder: Tube FosDocument11 pagesCylinder Name Lift Cylinder Bucket Cylinder: Tube FosSandipTakalikarNo ratings yet

- Air Bending Force Chart PDFDocument1 pageAir Bending Force Chart PDFAbraham Aguado0% (1)

- Reduksi BebanDocument7 pagesReduksi BebanFariz Hikmatyar AzzamNo ratings yet

- Quotation ForDocument4 pagesQuotation ForAnsaf AskyNo ratings yet

- ASC Groove Specifications v01Document6 pagesASC Groove Specifications v01Pape DiopNo ratings yet

- D265T063Document6 pagesD265T063adhyharmonypngNo ratings yet

- ANSI B16.5 Flanges - JMVDocument24 pagesANSI B16.5 Flanges - JMVJMVNo ratings yet

- The Book 5.0: Lifting Load Securing Light Material Handling Application EngineeringDocument10 pagesThe Book 5.0: Lifting Load Securing Light Material Handling Application EngineeringirinaNo ratings yet

- ASME B16.47 - Serie ADocument1 pageASME B16.47 - Serie Ajose2192No ratings yet

- Plumbing FinalDocument118 pagesPlumbing FinalGino Paolo ObsiomaNo ratings yet

- ACI Estimates 11111Document228 pagesACI Estimates 11111Gino Paolo ObsiomaNo ratings yet

- Untitled1 PDFDocument36 pagesUntitled1 PDFJulius OgowewoNo ratings yet

- En Ag1000htDocument2 pagesEn Ag1000hteloy marroquinNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Nascc2015 DurasquirtDocument2 pagesNascc2015 DurasquirtSquidwardNo ratings yet

- Aerospace Products Brochure PDFDocument15 pagesAerospace Products Brochure PDFArjun PanditNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2015-06-03T08:50Z Check The Source To Verify That This Is The Current Version Before UseDocument14 pagesSource: Https://assist - Dla.mil - Downloaded: 2015-06-03T08:50Z Check The Source To Verify That This Is The Current Version Before UseSquidwardNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2015-04-28T07:48Z Check The Source To Verify That This Is The Current Version Before UseDocument19 pagesSource: Https://assist - Dla.mil - Downloaded: 2015-04-28T07:48Z Check The Source To Verify That This Is The Current Version Before UseSquidwardNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2015-06-03T08:38Z Check The Source To Verify That This Is The Current Version Before UseDocument23 pagesSource: Https://assist - Dla.mil - Downloaded: 2015-06-03T08:38Z Check The Source To Verify That This Is The Current Version Before UseSquidwardNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2015-06-03T08:23Z Check The Source To Verify That This Is The Current Version Before UseDocument4 pagesSource: Https://assist - Dla.mil - Downloaded: 2015-06-03T08:23Z Check The Source To Verify That This Is The Current Version Before UseSquidwardNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2015-04-28T07:12Z Check The Source To Verify That This Is The Current Version Before UseDocument2 pagesSource: Https://assist - Dla.mil - Downloaded: 2015-04-28T07:12Z Check The Source To Verify That This Is The Current Version Before UseSquidwardNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2015-04-28T07:00Z Check The Source To Verify That This Is The Current Version Before UseDocument6 pagesSource: Https://assist - Dla.mil - Downloaded: 2015-04-28T07:00Z Check The Source To Verify That This Is The Current Version Before UseSquidwardNo ratings yet

- DIN513 3锯齿形螺纹Document8 pagesDIN513 3锯齿形螺纹SquidwardNo ratings yet

- Failures of Bolts in Helicopter Main Rotor Drive Plate Assembly Due To Improper Application of LubricantDocument9 pagesFailures of Bolts in Helicopter Main Rotor Drive Plate Assembly Due To Improper Application of LubricantSquidwardNo ratings yet

- The Communist ManifestoDocument20 pagesThe Communist ManifestoSquidwardNo ratings yet

- Growatt 8000tl3 S ManualDocument30 pagesGrowatt 8000tl3 S Manualletuananh122No ratings yet

- TL5000 RM - En674144Document413 pagesTL5000 RM - En674144Алексей МироновNo ratings yet

- Rincian Estimasi Instalasi CCTV CabangDocument11 pagesRincian Estimasi Instalasi CCTV CabangAhmad AstajibNo ratings yet

- Measuring Instruments: Multimeter Electrical ResistanceDocument14 pagesMeasuring Instruments: Multimeter Electrical ResistancescarlettNo ratings yet

- RCV Flyer DF Engines A4 Size Air CooledDocument2 pagesRCV Flyer DF Engines A4 Size Air CooledJohn WickNo ratings yet

- Spare Part CatalogueDocument178 pagesSpare Part Cataloguethinewill_bedone8055No ratings yet

- Understanding Complete Test Performed To Induction MotorDocument5 pagesUnderstanding Complete Test Performed To Induction MotorFirmanJohannesNo ratings yet

- 1vcp000931 Rev e CA DcbreakDocument26 pages1vcp000931 Rev e CA DcbreakMouth GoonieNo ratings yet

- Motherboard The Common MOSFET (FET) Substitution TableDocument3 pagesMotherboard The Common MOSFET (FET) Substitution TableDhruv Gonawala100% (3)

- High Pressure Cast Steel: Sempell Dewrance Parallel Slide Gate ValvesDocument20 pagesHigh Pressure Cast Steel: Sempell Dewrance Parallel Slide Gate ValvesbagusNo ratings yet

- Bulletin 136Document39 pagesBulletin 136Константин ГусевNo ratings yet

- Scross Service Bill at 67K+Document2 pagesScross Service Bill at 67K+Anil GuptaNo ratings yet

- Vicinity Map: Waterline, Plumbing and Storm Drainage Layout SCALE: 1:100 MTSDocument1 pageVicinity Map: Waterline, Plumbing and Storm Drainage Layout SCALE: 1:100 MTSLou PotesNo ratings yet

- NOM 003 SCFI 2014 Electrical Products Safety RequirementsDocument6 pagesNOM 003 SCFI 2014 Electrical Products Safety Requirements2357131270No ratings yet

- Electrical ElectronicsDocument92 pagesElectrical ElectronicstechNo ratings yet

- Kalkulimi Për NXDocument6 pagesKalkulimi Për NXGazmend NixhaNo ratings yet

- Dp1100i t3 Specification Sheet EnglishDocument4 pagesDp1100i t3 Specification Sheet EnglishRAFTAMA JAYA ABADINo ratings yet

- DB 01 SubstationDocument1 pageDB 01 Substationfahamida joyaNo ratings yet

- ZG Starting Systems 8B - 1Document14 pagesZG Starting Systems 8B - 1ensmartisNo ratings yet

- BA Maxicat-GB Juni 2015 PDFDocument14 pagesBA Maxicat-GB Juni 2015 PDFKheiro BelhadiaNo ratings yet

- New NC Report FormatDocument24 pagesNew NC Report FormatNitish SinghNo ratings yet