Professional Documents

Culture Documents

Shutdown Maintenance July 2017

Uploaded by

vinodsnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shutdown Maintenance July 2017

Uploaded by

vinodsnCopyright:

Available Formats

UNITED CEMENTS PVT. LTD.

NAUBISE-4, DHADING, NEPAL

SHUT-DOWN MAINTENANCE AND PENDING JOB LIST

(MAN POWER REQUIREMENT & COSTINGS)

EXPECTED SHUTDOWN PERIOD = 14 DAYS

SR.NO. MAN POWER REQ. NOS. MAN POWER RATE/NOS TOTAL COST (INR) REMARKS

1 Fitter 5.77 6.00 450.00 37800

2 Welder 5.77 6.00 350.00 29400

3 Rigger 5.77 6.00 300.00 25200

4 Khalashi 5.77 6.00 280.00 23520

ABOVE SUB TOTAL = 24.00 115920.00

UNITED CEMENTS PVT. LTD.

NAUBISE-4, DHADING, NEPAL

SHUT-DOWN MAINTENANCE AND PENDING JOB LIST

(FOR RAW MIL SECTION-MONTH: JULY-2017)

DATE: 24TH JULY-2017

SR.

TAG. MAN POWER CONSUMABLE MATERIAL MATERIAL / SPARES USED EXPECTED TIME

JOB

DESCRIPTION OF ACTIVITY REMARKS

PRIORITY F W R KH DETAIL AVAILABILITY DETAIL AVAILABILITY DAYS HOURS

NO.

NO.

TRUCK TIPPLER TO L/S STOCK PILE AREA

Lime Stone Truck Tippler middle plate strengthening work by

1 100 TT1 providing extra angle supports; also maintenance work for

tippler ratchets, holding the rear wheels of tipper.

Lime Stone Truck Tippler foundation strengthening work by This work is required to accomplish

2 100 TT1 dismantling and re-grouting work. with civil dept.

Lime Stone hopper discharge mouth and bottom face RCC

beams have been damaged. Welding of TMT bars & stiffner The work is required to execute as

3 100HP1 plates followed by shuttering and concreting work by Civil per instruction of civil department.

Dept.

Lime Stone Apron Conveyor, pan bolt tightening and tag

4 100 AC1 welding and jam clearing work for supporting guide rollers & to

provide locking arrangement.

Apron Conveyor grease line & grease point cleaning and

5 100 AC1 necessary maintenance work.

Lime Stone Crusher discharge chute and liner plates

6 100CR1 maintenance work.

L/S Crusher discharge belt conveyor, replacement by new one

7 100 BC8 followed by belt jointing work. Fixing of new type of scrapers

for head & tail pulleys.

Belt conveyor tippler trolley rail aligning & welding work. The

8 100 BC2 existing rail supports strengthening work, by providing extra

supports.

Temporary fixing of a de-watering pump behind the spillage

9 Misc. conveyor 100SX1 at L/S crusher floor level.

10 Misc. Fixing of a de-watering at 100BC1 tail end side.

Belt conveyor 100BC2 open platform area, hand rail fixing

11 Misc. work.

L/S STOCK PILE TO RAW MILL FEED AREA

Under ground tunnel belt replacement and jointing work after

12 100 BC3 removal of jointed piece of rubber belt.

Fixing of scrappers at head and tail pulleys along with re-setting

13 100 BC3 of side skirts at different feed chutes for belt 100BC3.

Replacement of 100VF1 & discharge chute complete assembly

14 100 BC3 by MS pipe chute, as per process requirement.

As this rubber belt is slightly damaged at several places;

15 100BC4 required patching with solution laying work.

Modification of stepped discharge chute, conveying to hopper

16 100 BC5 nos-3&4, by enhancing its slope.

Fixing of new type scrapers at head & tail pulleys and

17 200 BC3 adjustment of side skirts for all weigh feeders discharge chutes.

200 TCR1 Maintenance work for tertiary crusher side liner plates and

18 discharge chute.

Fixing of toe guards at Raw Material Hopper floor level along

19 Misc. with handrailing.

Fixing of a de-watering at 100BC3 tail end side area, as the rain

20 Misc. water causes movement problem at tunnel belt conveyor.

Fixing of a de-watering at 100BC4 tail end side area, as the rain

21 Misc. water causes movement problem at tunnel belt conveyor.

RAW MILL TO BLENDING SILO TOP AREA

300 RM1 Raw Mill inlet mounting flange inspection followed by required

22 bolt tightening work.

300 RM1 Inspection of all bolts of Raw mill diaphragm, shell liner bolts &

23 girth gear followed by required tightening work.

Removal of collected grease from Raw Mill girth gear guard by

24 300 RM1 taping it from the point. Fixing & tightening of sealing felt at

raw mill inlet & outlet.

300 RM1 Internal inspection of raw mill diaphragm liners and required

25 bolt tightening work.

Both the trunion bearings pre-jacking oil line checking and

26 300 LQ1 & 2 required maintenance work. (This is due to unhealthy pressure

comes at sometime)

300 LQ1, 2 Cleaning of all oil filters and strainers alongwith arresting oil

27 &3 leakages from oil lines.

Grease Cleaning of all spraying nozzles followed by inspection for

28 Spray smooth operation with taking spray pattern. Also, cleaning of

System air filters and FRL fixed in compressed air line.

Bag House inspection for all puppet valve pneumatic cylinders

29 Bag House and fixing of bottom limits for pneumatics cylinders for hopper

no. 6, 8, 12 & 13.

Bag House Inspection for alignment of both screw conveyors 300SC1 & 2 ,

30 all the hanging bearing & its greasing point.

Bag House discharge air slide, required to connect to CA fan

31 Bag House suction line for venting the air slide & screw conveyors 300SC1

&2.

Proper sealing arrangement of boot casing; and provision of

32 400 BE-1 bucket safety plate during the failure of BDS, avoiding any

contact to boot casing.

400 BE-1 Inspection of condition for belt, belt joint, buckets and bucket

33 bolts. Also discharge chute tounge plate gap inspection.

34 Misc. Blending Silo top floor handrail fixing work.

Blending Silo bucket elevator staircase top portion handrail

35 Misc. fixing work.

RAW MILL COMPRESSORS AND DUST COLLECTORS

300CP1-2 Sorting out the problems of dryer during the visit of Service

36 Engineer. Although the refrigerant (R410A) level is Ok.

Provision of fixing individual duct line from compressor's heat

300 CP1-2 exchanger to out side of the building, in order to avoid

37 overheating of the compressor room alongwith fixing a exhaust

fan (Electrical scope)

Provision of valves at the bending points of compressed air line

38 300 CP1-2 at Raw mill 1st floor and bag house 2nd floor level, to drain

moistures as and when desired.

TOTAL MEN POWER =

UNITED CEMENTS PVT. LTD.

NAUBISE-4, DHADING, NEPAL

SHUT-DOWN MAINTENANCE AND PENDING JOB LIST

(FOR RAW MIL SECTION-MONTH: JULY-2017)

SR. DATE: 24TH JULY-2017

TAG.

DESCRIPTION OF ACTIVITY STATUS REMARKS

NO.

NO. TRUCK TIPPLER TO L/S STOCK PILE AREA

Lime Stone Truck Tippler middle plate strengthening work by

1 100 TT1 providing extra angle supports; also maintenance work for

tippler ratchets, holding the rear wheels of tipper.

This work is

Lime Stone Truck Tippler foundation strengthening work by required to

2 100 TT1 dismantling and re-grouting work. accomplish with civil

dept.

Lime Stone hopper discharge mouth and bottom face RCC The work is required

beams have been damaged. Welding of TMT bars & stiffner to execute as per

3 100HP1 plates followed by shuttering and concreting work by Civil instruction of civil

Dept. department.

Lime Stone Apron Conveyor, pan bolt tightening and tag

4 100 AC1 welding and jam clearing work for supporting guide rollers & to

provide locking arrangement.

Apron Conveyor grease line & grease point cleaning and

5 100 AC1 necessary maintenance work.

Lime Stone Crusher discharge chute and liner plates

6 100CR1 maintenance work.

L/S Crusher discharge belt conveyor, replacement by new one

7 100 BC8 followed by belt jointing work. Fixing of new type of scrapers

for head & tail pulleys.

Belt conveyor tippler trolley rail aligning & welding work. The

8 100 BC2 existing rail supports strengthening work, by providing extra

supports.

9 Misc. 100TT1 side, handrail damaged; required repairing work.

Temporary fixing of a de-watering pump behind the spillage

10 Misc. conveyor 100SX1 at L/S crusher floor level.

11 Misc. Fixing of a de-watering at 100BC1 tail end side.

Belt conveyor 100BC2 open platform area, hand rail fixing

12 Misc. work.

L/S STOCK PILE TO RAW MILL FEED AREA

Under ground tunnel belt replacement and jointing work after

13 100 BC3 removal of jointed piece of rubber belt.

Fixing of scrappers at head and tail pulleys along with re-setting

14 100 BC3 of side skirts at different feed chutes for belt 100BC3.

Replacement of 100VF1 & discharge chute complete assembly

15 100 BC3 by MS pipe chute, as per process requirement.

As this rubber belt is slightly damaged at several places;

16 100BC4 required patching with solution laying work.

Modification of stepped discharge chute, conveying to hopper

17 100 BC5 nos-3&4, by enhancing its slope.

Fixing of new type scrapers at head & tail pulleys and

18 200 BC3 adjustment of side skirts for all weigh feeders discharge chutes.

200 TCR1 Maintenance work for tertiary crusher side liner plates and

19 discharge chute.

20 200 TCR1 All V-belt replacement work by new spare V-belts.

Fixing of toe guards at Raw Material Hopper floor level along

21 Misc. with handrailing.

Fixing of a de-watering at 100BC3 tail end side area, as the rain

22 Misc. water causes movement problem at tunnel belt conveyor.

Fixing of a de-watering at 100BC4 tail end side area, as the rain

23 Misc. water causes movement problem at tunnel belt conveyor.

RAW MILL TO BLENDING SILO TOP AREA

300 RM1 Raw Mill inlet mounting flange, drives and G/B's base bolts

24 tightening work.

300 RM1 Raw Mill torsion shaft bolt tightness and coupling greasing

25 work.

300 RM1 Inspection of all bolts of Raw mill diaphragm, shell liner bolts &

26 girth gear followed by required tightening work.

Removal of collected grease from Raw Mill girth gear guard by

27 300 RM1 taping it from the point. Fixing of a 4'' ball valve for grease

removal work.

300 RM1 Internal inspection of raw mill diaphragm liners and required

28 bolt tightening work.

Both the trunion bearings pre-jacking oil line checking and

29 300 LQ1 & 2 required maintenance work. (This is due to unhealthy pressure

comes at sometime)

300 LQ1, 2 Cleaning of all oil filters and strainers alongwith arresting oil

30 &3 leakages from oil lines.

Grease Cleaning of all spraying nozzles followed by inspection for

31 Spray smooth operation with taking spray pattern. Also, cleaning of

System air filters and FRL fixed in compressed air line.

Bag House inspection for all puppet valve pneumatic cylinders

32 Bag House and fixing of bottom limits for pneumatics cylinders for hopper

no. 6, 8, 12 & 13.

Bag House Inspection for alignment of both screw conveyors 300SC1 & 2 ,

33 all the hanging bearing & its greasing point.

Bag House discharge air slide, required to connect to CA fan

34 Bag House suction line for venting the air slide & screw conveyors 300SC1

&2.

Proper sealing arrangement of boot casing; and provision of

35 400 BE-1 bucket safety plate during the failure of BDS, avoiding any

contact to boot casing.

400 BE-1 Inspection of condition for belt, belt joint, buckets and bucket

36 bolts. Also discharge chute tounge plate gap inspection.

37 Misc. Blending Silo top floor handrail fixing work.

Blending Silo bucket elevator staircase top portion handrail

38 Misc. fixing work.

Prepared By--- Checked By

Joydeep Das Vinod Kumar Verma

(Engineer) (Section In-Charge)

You might also like

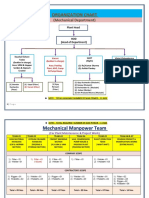

- ORGANIZATION CHARTDocument3 pagesORGANIZATION CHARTvinodsn100% (1)

- Sop For Cleaning & HousekeepingDocument4 pagesSop For Cleaning & HousekeepingvinodsnNo ratings yet

- Lime Stone Cleaning Station - Project Proposal-03Document4 pagesLime Stone Cleaning Station - Project Proposal-03vinodsnNo ratings yet

- Lime Stone Cleaning Station - Project Proposal-03Document4 pagesLime Stone Cleaning Station - Project Proposal-03vinodsnNo ratings yet

- Belt Conveyor Operation & Cleaning SOPDocument2 pagesBelt Conveyor Operation & Cleaning SOPvinodsn100% (2)

- Daily Stoppage ReportDocument2 pagesDaily Stoppage ReportvinodsnNo ratings yet

- 3.20 Removal of Conveyor Belt With New BeltDocument2 pages3.20 Removal of Conveyor Belt With New Beltvinodsn100% (1)

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDocument2 pagesBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNo ratings yet

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDocument1 pageBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNo ratings yet

- Pending Job of CPWDocument2 pagesPending Job of CPWvinodsnNo ratings yet

- Coal Crushing Sec. Drg. List Fo ErectionDocument1 pageCoal Crushing Sec. Drg. List Fo ErectionvinodsnNo ratings yet

- Sop For Ls CrusherDocument5 pagesSop For Ls CrusherVinod Kumar VermaNo ratings yet

- Transmital of Assly. Drgs. of Equipments of Coal Crusher & Storage Sec. & Coal Mill Sec.Document2 pagesTransmital of Assly. Drgs. of Equipments of Coal Crusher & Storage Sec. & Coal Mill Sec.vinodsnNo ratings yet

- Nov 15 Daily MeetingDocument2 pagesNov 15 Daily MeetingvinodsnNo ratings yet

- Offer Letter-Manpower Supply & Project WorkDocument10 pagesOffer Letter-Manpower Supply & Project WorkvinodsnNo ratings yet

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Document1 pageEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnNo ratings yet

- Sop Working at High Noise AreaDocument5 pagesSop Working at High Noise AreavinodsnNo ratings yet

- Org ChartDocument1 pageOrg ChartvinodsnNo ratings yet

- Safe Lifting Guide for Chain Pulley Blocks & SlingsDocument5 pagesSafe Lifting Guide for Chain Pulley Blocks & SlingsvinodsnNo ratings yet

- Sop For Bag FilterDocument5 pagesSop For Bag FiltervinodsnNo ratings yet

- Sop For Safe Working at HeightDocument6 pagesSop For Safe Working at HeightvinodsnNo ratings yet

- Operation & Maintenance of Cement Ball MillDocument7 pagesOperation & Maintenance of Cement Ball MillvinodsnNo ratings yet

- Sop Welding & Gas CuttingDocument9 pagesSop Welding & Gas CuttingvinodsnNo ratings yet

- 1-SOP For Raw Mill StartDocument2 pages1-SOP For Raw Mill Startvinodsn100% (2)

- Costing Details E & I (2074-75)Document8 pagesCosting Details E & I (2074-75)vinodsnNo ratings yet

- Sop Ls CrusherDocument2 pagesSop Ls Crushervinodsn100% (1)

- HR CircularDocument4 pagesHR CircularvinodsnNo ratings yet

- Gist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalDocument1 pageGist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalvinodsnNo ratings yet

- HR CircularDocument2 pagesHR CircularvinodsnNo ratings yet

- Sukh Raj Sigh ResignationDocument1 pageSukh Raj Sigh ResignationvinodsnNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Electro 3 Lab ResearchDocument6 pagesElectro 3 Lab ResearchJuan Miguel TorresNo ratings yet

- ABB Single Phase MotorsDocument30 pagesABB Single Phase MotorsErvin BošnjakNo ratings yet

- Irf3207 MOSFETDocument12 pagesIrf3207 MOSFETKennedy IruNo ratings yet

- DsPIC33FJ32MC204 PIM Information SheetDocument6 pagesDsPIC33FJ32MC204 PIM Information SheetGerman Mauricio Neira VargasNo ratings yet

- M.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksDocument3 pagesM.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksMariyath Muraleedharan KiranNo ratings yet

- Genelec 6010A Data SheetDocument2 pagesGenelec 6010A Data SheetDušan StojanovičNo ratings yet

- Service Manual Spe160l 7SLL12.5 - 20F Sn.924454aaDocument216 pagesService Manual Spe160l 7SLL12.5 - 20F Sn.924454aaMarc BralNo ratings yet

- Display TechnologyDocument63 pagesDisplay Technologyanalog changeNo ratings yet

- Bobkat 435 6902331 enUSDocument1,537 pagesBobkat 435 6902331 enUSviktorNo ratings yet

- Solid Rivets ComparisonDocument3 pagesSolid Rivets ComparisonManoj ManoharanNo ratings yet

- AT400T41T M.Y. 2013 Cursor 13 Euro ViDocument16 pagesAT400T41T M.Y. 2013 Cursor 13 Euro ViCesar MartinezNo ratings yet

- BOQ 1x80 MW Dariba HZL Captive Power PlantDocument8 pagesBOQ 1x80 MW Dariba HZL Captive Power Plantm 418No ratings yet

- Service Manual: EPSON Stylus Pro 7600/9600Document322 pagesService Manual: EPSON Stylus Pro 7600/9600Luis Miguel Martinez PerezNo ratings yet

- Sam Wall Chart Epa 07 and Epa 2010Document2 pagesSam Wall Chart Epa 07 and Epa 2010Jose Luis Calla Huanca94% (18)

- DS Special Purpose Fuse Links HelioProtection Photovoltaic Fuses NH 800VAC GR ENDocument14 pagesDS Special Purpose Fuse Links HelioProtection Photovoltaic Fuses NH 800VAC GR ENFiras ouhichiNo ratings yet

- Coa Unit-3Document35 pagesCoa Unit-3Revanth RavikantiNo ratings yet

- Replacement Parts List: Built On InnovationDocument108 pagesReplacement Parts List: Built On InnovationMatthew PorrittNo ratings yet

- LG 50pj250r-Ta Chassis Pp01aDocument34 pagesLG 50pj250r-Ta Chassis Pp01aNICHOLASNo ratings yet

- Draka Mobile Networks Cables 2010-10Document33 pagesDraka Mobile Networks Cables 2010-10dieters_uaNo ratings yet

- Kixx Atf Dx-Iii: GM Dexron - Iii, Mercon, Allison C-4Document1 pageKixx Atf Dx-Iii: GM Dexron - Iii, Mercon, Allison C-4jack sliverNo ratings yet

- Reduce RsDocument73 pagesReduce RsbangpaiNo ratings yet

- Echometer Acoustic Wellhead Parts List: Part Number Part Name PictureDocument4 pagesEchometer Acoustic Wellhead Parts List: Part Number Part Name PictureBoyke SaptaNo ratings yet

- M24256-BW M24256-BR M24256-BF M24256-DR M24256-DF: 256-Kbit Serial I C Bus EEPROMDocument47 pagesM24256-BW M24256-BR M24256-BF M24256-DR M24256-DF: 256-Kbit Serial I C Bus EEPROMNguyễn Thế MạnhNo ratings yet

- BT Synergy 4500 ManualDocument100 pagesBT Synergy 4500 Manualkamzid12335No ratings yet

- Ej800clfph - W800 Cafe 2019-20 PDFDocument89 pagesEj800clfph - W800 Cafe 2019-20 PDFAlbert DepanoNo ratings yet

- E74h IbmDocument37 pagesE74h IbmJose BerrospiNo ratings yet

- Suzuki Jimny Flyer FinalDocument2 pagesSuzuki Jimny Flyer FinalZeeshan0% (1)

- Kumax: (1000 V / 1500 V) Cs3U-375 - 380 - 385 - 390 - 395MsDocument2 pagesKumax: (1000 V / 1500 V) Cs3U-375 - 380 - 385 - 390 - 395Mspatricio marin guerraNo ratings yet

- 416b Elec - TransDocument9 pages416b Elec - TransFelix CruzNo ratings yet