Professional Documents

Culture Documents

Kimray H - 50.2

Uploaded by

smnizamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kimray H - 50.2

Uploaded by

smnizamCopyright:

Available Formats

TEMPERATURE CONTROLLERS

INDIRECT HIGH TEMPERATURE SHUT-DOWN

ACTION: OPERATION:

Indirect; Pilot Output Pressure (Yellow) decreases with tem- These Thermostats consist of Base Assemblies sending an

perature rise. Indirect Throttle signal to a 3 PGM Pilot. The 3 PGM pilot is

connected so that once the Output Pressure (Yellow) is vented,

it must be manually reset to resume service.

APPLICATION: Assume the set temperature of the Thermostat is above the

For temperature controlled system shutdown until manually temperature of the system being controlled and Pilot Output

reset. Pressure (Yellow) is being sent to any Pilot or Motor Valve.

As the system temperature rises, the STAINLESS TUBE

increases in length to move the Thermostat Diaphragm (or

Bellows) Assembly in a direction to first close the seat at

WORKING PRESSURE (sensing element): BALL 1 (Yellow to Red) and open the seat at BALL 2 (Red to

psig kg/cm2 Atmosphere). As Variable Pressure (Red) decreases, the 3 PGM

500 35.15 max. without Separable Socket Pilot Diaphragm Assembly moves upward to close the seat at

4000 281.23 max. with Separable Socket BALL 4 (Violet to Yellow) and open the seat at Ball 3 (Yellow to

7000 492.15 max. with Special Separable Socket Atmosphere). Output Pressure (Yellow) decreases to cause the

desired Pilot or Motor Valve action.

Separable Socket is an extra price item and must be ordered Once the Output Pressure (Yellow) has been vented, the

separately, if desired. To order Separable Sockets refer to Table Thermostat is shut down until the temperature of the system is

of Contents. below the set temperature and the RESET LEVER is used to

reset the Pilot. If desired the RESET LEVER can also be used

to manually vent Output Pressure (Yellow) and shut-down the

TEMPERATURE RANGE: thermostat.

T 12M, T 18M -30F minimum to 400F maximum The 112 SMT-T is the recommended Motor valve for this

-34C minimum to 204C maximum thermostat configuration. Refer to Burner Valves in Table of

HT 12M, HT 18M -30F minimum to 750F maximum Contents for more information.

-34C minimum to 399C maximum

SUPPLY PRESSURE:

5 to 30 psig

.35 to 2.11 kg/cm2

RESPONSE RANGE:

T 12M - 3F, (1.7C) Above control point

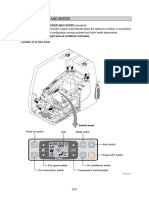

Thermostat Diaphragm Assembly

T 18M - 2F, (1.1C) Above control point

HT 12M - 2F, (1.1C) Above control point

3PS Pilot Diaphragm Assembly HT 18M - 1.5F, ( .8C) Above control point

Variable Pressure

Supply Pressure

Pilot Output Pressure

Thermostat Diaphragm

or Bellows Assembly

1/2 NPT

Stainless Tube

Low Expansion Alloy

Control Knob

2 1

Manual Reset Lever

(Push up to reset)

Pilot Diaphragm

3 PGM Pilot

Kimray is an ISO 9001- certified manufacturer.

Current Revision: H:50.1

Add numbers to Pilot Plugs www.kimray.com Issued 8/13

TEMPERATURE CONTROLLERS

INDIRECT HIGH TEMPERATURE SHUT-DOWN

DUCTILE IRON or STEEL

Upper Plate 597 *

* Diaphragm 601 Screw 693, 4 Reqd.

Ell 204 Housing 595 Bonnet 2728

Seat 111

Spring 108 O Ring 265, 2 Reqd. *

O Ring 265 *

* Lower Plate 763 Plug 112 1743, T-12S

Dial 1744, T-18S

Base 1627, T-12S

1628, T-18S

Set Screw 264

Pointer 600SS6

Seat 1621

Drive Screw

Nipple 648

602, 3 Reqd.

Tubing 5437

Gauge 603

Screw 573, 6 Reqd.

Cover 577

* Diaphragm 582

Diaphragm Plate 579 Bushing 539

Tee 6973 Spring 108

Housing 578 Reset Lever 1396

Breather Plug 147

Seat 113

* Diaphragm 583

Spool 580 Pilot Plug 112

Spacer 581 Gasket 118 *

* Diaphragm 584

1/4 F30 Filter

Plug 699

Nipple 648

Spring 566

Seat 565 Spring 585

Body 587

DIMENSIONS

3 7/8" 3 1/4" H/T 12S 11 3/4"

4 1/4" H/T 18S 17 3/4"

1 1/8"

5 7/16"

3/8" DIA.

1/2" NPT

1 3/8"

1 3/16"

2 1/4"

H/T 12S 5 15/16"

H/T 18S 5 7/16"

ALL TAPPED OPENINGS ARE 1/4" NPT EXCEPT AS NOTED.

THERMOSTATS AVAILABLE: NOTES:

CAT. BASE MAX. TEMP. MAX. TEMP. REPAIR *These are recommended spare parts and are stocked as

NO. ASSEMBLY F C KIT repair kits.

HAM T 12 IAM 400 204 RLF

Separable Sockets are available at extra cost, refer to Table of

HAN T 18 IAM 400 204 RLF

Contents for ordering.

HBM HT 12 IAM 750 399 RLT

HBN HT 18 IAM 750 399 RLT

For HT 12M and HT 18M High Temperature Base Assembly parts,

refer to Base Assemblies in Table of Contents.

Kimray is an ISO 9001- certified manufacturer.

H:50.2 Current Revision:

Issued 6/16 www.kimray.com Remove 1/8 NPT callout from dimension view

TEMPERATURE CONTROLLERS

GAS CAPACITY CHARTS

3 PG CAPACITY CHART

*For gravity correction multiply above capacities by .65

Gas capacities are based on the SUPPLY PRESSURE taken G

immediately upstream the pilot in a wide open position. :where G equals specific gravity of gas.

HOW TO USE THE CHART: Locate SUPPLY PRESSURE

at left of chart. Project the SUPPLY PRESSURE horizontally to

the curve and read the VOLUME directly below.

Current Revision: H:70.1

Change Logo www.kimray.com Issued 1/13

You might also like

- Fast Track Troubleshooting: Downloaded From Manuals Search EngineDocument6 pagesFast Track Troubleshooting: Downloaded From Manuals Search EngineIsir isirNo ratings yet

- Service Manual Daikin FTXN LDocument54 pagesService Manual Daikin FTXN LQasir MughalNo ratings yet

- Room Air Conditioner: Service ManualDocument84 pagesRoom Air Conditioner: Service ManualMustafaNo ratings yet

- Samsung DvmsDocument88 pagesSamsung DvmsGingubaNo ratings yet

- Esp ManualDocument12 pagesEsp Manualjaikolangaraparambil100% (3)

- Portugal Espacial PT Space Catalog 2011 Screen VersionDocument86 pagesPortugal Espacial PT Space Catalog 2011 Screen Versionpmjafonso100% (1)

- Option N Modbus TCP IPDocument32 pagesOption N Modbus TCP IPJosé Miguel Echeverria HerediaNo ratings yet

- ASTM 6365 - 99 - Spark TestDocument4 pagesASTM 6365 - 99 - Spark Testjudith_ayala_10No ratings yet

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pages050-Itp For Installation of Air Intake Filter PDFKöksal PatanNo ratings yet

- Maanual Service Ac LGDocument75 pagesMaanual Service Ac LGMustafaNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Business ListingDocument16 pagesBusiness ListingSarika YadavNo ratings yet

- What Is PackagingDocument10 pagesWhat Is PackagingAdnan ButtNo ratings yet

- NS0 157Document42 pagesNS0 157Muthu LNo ratings yet

- Checkpoint R65 QoS Admin GuideDocument220 pagesCheckpoint R65 QoS Admin GuidePradeep_KNVPNo ratings yet

- T12 Das KimrayDocument2 pagesT12 Das KimrayWendel Soares CorreiaNo ratings yet

- Temperature Controllers: Action: OperationDocument3 pagesTemperature Controllers: Action: OperationfedemochileroNo ratings yet

- 1operating and Service Manual ATF 110G-5 - 12.2004 - Air Condition Heater Ventilation - 25Document12 pages1operating and Service Manual ATF 110G-5 - 12.2004 - Air Condition Heater Ventilation - 25Mochamad fandi DharmawanNo ratings yet

- ThermoelectricDocument6 pagesThermoelectricsyNo ratings yet

- Xe70 Series T6372/T6373: Fan-Coil Thermostats 2-Pipe Fan-Coil ControlDocument4 pagesXe70 Series T6372/T6373: Fan-Coil Thermostats 2-Pipe Fan-Coil Controlmuhammad FikriNo ratings yet

- Termostat (Thermostat) Siemens RAB31Document6 pagesTermostat (Thermostat) Siemens RAB31IONUT PRISECARUNo ratings yet

- Honeywell Fcu Thermostat t6374 t6375Document4 pagesHoneywell Fcu Thermostat t6374 t6375Ahmed MohyNo ratings yet

- Refrigerated Dryer Troubleshooting Guide: More Than Air. AnswersDocument32 pagesRefrigerated Dryer Troubleshooting Guide: More Than Air. AnswersMiguel NavarreteNo ratings yet

- Custom Control Sensors, Inc.: Iae ApprovedDocument6 pagesCustom Control Sensors, Inc.: Iae ApprovedjordiNo ratings yet

- Room Air Conditioner: Service ManualDocument79 pagesRoom Air Conditioner: Service ManualPablosoNo ratings yet

- Klima Panasonic UputstvoDocument62 pagesKlima Panasonic UputstvoKukiNo ratings yet

- Technical Manual For Air-Cooled Split Ducted R22-R407C (FDXA05-202021) - MinDocument52 pagesTechnical Manual For Air-Cooled Split Ducted R22-R407C (FDXA05-202021) - MinJason NguyenNo ratings yet

- 1098 EgrDocument44 pages1098 EgrPat AuffretNo ratings yet

- Termostat Ventiloconvector - Siemens - RAB31 - Modificat PDFDocument5 pagesTermostat Ventiloconvector - Siemens - RAB31 - Modificat PDFpriseNo ratings yet

- Termostat Ventiloconvector - Siemens - RAB31 - Modificat PDFDocument5 pagesTermostat Ventiloconvector - Siemens - RAB31 - Modificat PDFpriseNo ratings yet

- Operating Procedure For Compressed Air SystemDocument5 pagesOperating Procedure For Compressed Air SystemsubscruNo ratings yet

- COMANDA TERMOSTAT - T6374-T6375 - Fisa TehnicaDocument4 pagesCOMANDA TERMOSTAT - T6374-T6375 - Fisa TehnicaMihai MitreaNo ratings yet

- Multi Type Room Air Conditioner: Service ManualDocument132 pagesMulti Type Room Air Conditioner: Service ManualoribataNo ratings yet

- Bradford White Heat Pump Error CodesDocument6 pagesBradford White Heat Pump Error CodesMichael David DuffNo ratings yet

- Samsung Air Conditioner ManualDocument36 pagesSamsung Air Conditioner ManualoriginaljohnboyNo ratings yet

- Service Manual PAC9041Document64 pagesService Manual PAC9041Mumba Martin ChikomboNo ratings yet

- AC System On Bus RoofDocument33 pagesAC System On Bus Roofkingtiger.bkNo ratings yet

- Manual de Serv. TNSC24Document42 pagesManual de Serv. TNSC24sbkhalilNo ratings yet

- System Flow Pattern: IstatDocument18 pagesSystem Flow Pattern: IstatgenuineswedeNo ratings yet

- 299H Series Pressure Reducing RegulatorsDocument32 pages299H Series Pressure Reducing RegulatorsmokbelNo ratings yet

- Cs/Cu-Re9Gke Cs/Cu-Re12Gke: Air ConditionerDocument17 pagesCs/Cu-Re9Gke Cs/Cu-Re12Gke: Air ConditionerNikolai_Dimitr_7781No ratings yet

- Sea Breeze Mini-Split Troubleshooting Guide 9A23YGX, 12A23YGX, 12A23ZGX 18A23ZGX 9H43YCX, 12H43YCX 12H43ZGX, 18H43ZGX 24H43ZCX, 24A43ZCXDocument38 pagesSea Breeze Mini-Split Troubleshooting Guide 9A23YGX, 12A23YGX, 12A23ZGX 18A23ZGX 9H43YCX, 12H43YCX 12H43ZGX, 18H43ZGX 24H43ZCX, 24A43ZCXMNo ratings yet

- SERVICE MANUAL - lg+L1204RDocument35 pagesSERVICE MANUAL - lg+L1204Raless2056100% (1)

- AOU48RLXFZ1 (SI) SMDocument145 pagesAOU48RLXFZ1 (SI) SMAllan BuenoNo ratings yet

- RIS Comem 2Document8 pagesRIS Comem 2tanniayulianaNo ratings yet

- Manual Termostato Digitall t6812 FancoilDocument4 pagesManual Termostato Digitall t6812 FancoilaarroyofNo ratings yet

- Room Air Conditioner: Service ManualDocument73 pagesRoom Air Conditioner: Service Manualpaolo ciacciNo ratings yet

- TempDocument1 pageTempFBFDNNo ratings yet

- Xe70 Series T6370/T6371: Fan-Coil Thermostats Fan Only ControlDocument4 pagesXe70 Series T6370/T6371: Fan-Coil Thermostats Fan Only ControlISMAEL ENRIQUE VALENCIA JURADONo ratings yet

- 4MCW15-4TTK15 Service ManualDocument37 pages4MCW15-4TTK15 Service ManualJesus Andres SuarezNo ratings yet

- Filtrine Medical & Process Water Chiller 60+: Options/Accessories To Meet Your Specific RequirementsDocument2 pagesFiltrine Medical & Process Water Chiller 60+: Options/Accessories To Meet Your Specific RequirementsTaisto HernándezNo ratings yet

- 5.2 Z 1239085 Test Report - ENDocument7 pages5.2 Z 1239085 Test Report - ENUlises Rumiche ChungaNo ratings yet

- Stg-2 Turbine - Fast - Cooling CHECKLISTDocument7 pagesStg-2 Turbine - Fast - Cooling CHECKLISTscentpcbarauni BARAUNINo ratings yet

- T-Reg300 EngDocument12 pagesT-Reg300 EngFlorin BocanetNo ratings yet

- MTS-SUPER MTSC-SUPER - Operating ManualDocument40 pagesMTS-SUPER MTSC-SUPER - Operating ManualhectorNo ratings yet

- Thermostat Manual - Siemens RDF310.2Document14 pagesThermostat Manual - Siemens RDF310.2sebarm86No ratings yet

- AT249PD - L'hermomatic Dimpling Control Unit - Operating and Maintenance ManualDocument8 pagesAT249PD - L'hermomatic Dimpling Control Unit - Operating and Maintenance ManualMARTY CARTERNo ratings yet

- Aire W182 W242 W121 W091 W092 Seccion 2Document30 pagesAire W182 W242 W121 W091 W092 Seccion 2AlbertoMoralesNo ratings yet

- 48 50tj-2wDocument64 pages48 50tj-2wsclstc89No ratings yet

- PRO 1000 Vertical Non Programmable Thermostat Operating ManualDocument52 pagesPRO 1000 Vertical Non Programmable Thermostat Operating ManualEnrique EspinosaNo ratings yet

- Danuhm Bush Air Cooled Condensing UnitsDocument24 pagesDanuhm Bush Air Cooled Condensing UnitsFalak KhanNo ratings yet

- Manual de Serviço Ar Sala LG CBN181QLA PDFDocument64 pagesManual de Serviço Ar Sala LG CBN181QLA PDFYuri GodoyNo ratings yet

- TBA0166Document26 pagesTBA0166Jose Angel Morillo BelloNo ratings yet

- SH 07 12 As Service ManualDocument46 pagesSH 07 12 As Service Manualanon_329876928No ratings yet

- Omron E5cj-Q2hb DatasheetDocument6 pagesOmron E5cj-Q2hb Datasheet王俊發No ratings yet

- Installation Manual RecessedDocument40 pagesInstallation Manual RecessedDICEA DANNo ratings yet

- 3-5 Aire AcondicionadoDocument7 pages3-5 Aire AcondicionadoJorge RojasNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Different Types of Fuse TerminalDocument3 pagesDifferent Types of Fuse TerminalsmnizamNo ratings yet

- Generator Sizing CalculatorDocument2 pagesGenerator Sizing CalculatorsmnizamNo ratings yet

- Hipower Load CalculatorDocument8 pagesHipower Load CalculatorsmnizamNo ratings yet

- Siren + Hooter BBJ81Document2 pagesSiren + Hooter BBJ81smnizamNo ratings yet

- Hammer Union 2018Document1 pageHammer Union 2018smnizamNo ratings yet

- FlareVIEW For Flare Stack Monitoring Rev01Document7 pagesFlareVIEW For Flare Stack Monitoring Rev01smnizamNo ratings yet

- Parker Valve Ball Three Way B SeriesDocument3 pagesParker Valve Ball Three Way B SeriessmnizamNo ratings yet

- Litografia Soft LithographyDocument33 pagesLitografia Soft Lithographyrfm147No ratings yet

- Week 03 Network Concepts and Network Media PDFDocument63 pagesWeek 03 Network Concepts and Network Media PDFikonNo ratings yet

- Ivd Symbols FinalDocument14 pagesIvd Symbols FinalDennis ChenNo ratings yet

- GNP-GAP Installation InstructionsDocument10 pagesGNP-GAP Installation InstructionsLeonardo ValenciaNo ratings yet

- Kerjaya MatematikDocument20 pagesKerjaya MatematikRoszelan Majid100% (1)

- KW Tedder LeafletDocument32 pagesKW Tedder Leafletinfo4826No ratings yet

- Engineering and Ginning: Dust Cyclone Technology - A Literature ReviewDocument12 pagesEngineering and Ginning: Dust Cyclone Technology - A Literature ReviewviettiennguyenNo ratings yet

- Upgrading A P - SupplyDocument7 pagesUpgrading A P - SupplyDrift GeeNo ratings yet

- Accenture Global Pharmaceutical and Company Planning Forecasting With Oracle HyperionDocument2 pagesAccenture Global Pharmaceutical and Company Planning Forecasting With Oracle HyperionparmitchoudhuryNo ratings yet

- 032 Wire Rope Sling 76.5 TonDocument4 pages032 Wire Rope Sling 76.5 TonHario PramuditoNo ratings yet

- Logitech Mouse M505 ManualDocument2 pagesLogitech Mouse M505 ManualbmmanualsNo ratings yet

- Canvas Integration GuideDocument27 pagesCanvas Integration GuideValerie BossNo ratings yet

- JDocument4 pagesJapi-299173937No ratings yet

- Lesson 3 Solid Pressure Osunero, Kim John S. BSED 2D SCIE 4Document6 pagesLesson 3 Solid Pressure Osunero, Kim John S. BSED 2D SCIE 4Kim John OsuneroNo ratings yet

- Requirements For Transferees FinalDocument29 pagesRequirements For Transferees FinalKaren GedalangaNo ratings yet

- The Effectiveness of Acceptance and Commitment-BasDocument18 pagesThe Effectiveness of Acceptance and Commitment-BasRaphaele ColferaiNo ratings yet

- GSM BSS Integration For Field Maintenance: ExercisesDocument14 pagesGSM BSS Integration For Field Maintenance: Exercisesswr cluster100% (1)

- Adjustment of Conditions: Contents: Procedure Adjustment Methods Country-Specific Methods in Austria and SwitzerlandDocument41 pagesAdjustment of Conditions: Contents: Procedure Adjustment Methods Country-Specific Methods in Austria and Switzerlandtushar2001No ratings yet

- India International Centre India International Centre QuarterlyDocument15 pagesIndia International Centre India International Centre QuarterlySruti UNo ratings yet

- Oil Checks On Linde Reach Stacker Heavy TrucksDocument2 pagesOil Checks On Linde Reach Stacker Heavy TrucksmliugongNo ratings yet

- Peach TreeDocument36 pagesPeach TreeSana MeerNo ratings yet

- UNIC Jakarta Internship ApplicationDocument4 pagesUNIC Jakarta Internship ApplicationMuhammad IkhsanNo ratings yet