Professional Documents

Culture Documents

55

Uploaded by

sebaversaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

55

Uploaded by

sebaversaCopyright:

Available Formats

Model CBLE 100-800 HP Boilers

Table A1-23. Minimum Required Regulated Gas Pressure Altitude Conversion

ALTITUDE CORRECTION ALTITUDE CORRECTION

(FT) FACTOR (FT) FACTOR

1000 1.04 6000 1.25

2000 1.07 7000 1.30

3000 1.11 8000 1.35

4000 1.16 9000 1.40

5000 1.21 - -

To obtain minimum required gas pressure at altitudes

above 700 feet, multiply the pressure by the listed factors:

Inches WC x 0.577 = oz/sq-in.

Oz/sq-in x 1.732 = Inches WC

Inches WC x 0.0361= psig.

Oz/sq-in x 0.0625 = psig.

Psig x 27.71 = Inches WC

Psig x 16.0 = Oz/sq-in.

Table A1-24. Maximum Gas Consumption (CFH) for Natural Gas and Propane Vapor

TYPE OF GAS AND HEAT CONTENT

BOILER

HP NATURAL GAS PROPANE GAS

1000 (Btu/cu-ft) 2550 (Btu/cu-ft)

125 5103 2000

150 6124 2402

200 8165 3202

250 10206 4002

300 12247 4802

350 14280 5600

400 16329 6404

500 20415 8006

600 24494 9605

700 28576 11206

750 30618 12007

800 32659 12807

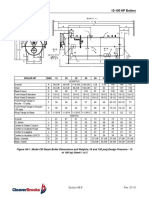

A

MODEL CB

BOILER HP CONNECTION LOCATION

SIZE DIMENSION

(IN. NPT) A (IN.) BOILER

125-200 1-1/2 52 FRONT

250-350 2 56

400 2 58

500 2-1/2 60

PLAN VIEW

600 2-1/2 - 3 71

700-800 3 65

Figure A1-12. Standard Gas Train Connection Size and Location

Section A1-32 Rev. 09-09

Model CBLE 100-800 HP Boilers

Oil-Fired Burners

Fuel oil consumption information is shown on the boiler rating sheets in the Dimensions

and Rating Section.

Figure A1-15 shows the oil connection sizes and locations for Model CB Boilers firing No.

2 oil.

Figure A1-16 through Figure A1-18 show typical oil systems and layouts.

Figure A1-19 and Figure A1-20 show the detail of an oil transfer tank (day tank) typically

utilized to provide a storage reservoir between the oil system supply pump and the boiler

oil pump.

General Boiler Information

Table A1-24 shows blowdown tank sizing information.

Table A1-25 provides heating surface information.

Table A1-26 provides steam volume and disengaging area information

Table A1-27 provides recommended steam nozzle sizes.

Table A1-28 provides recommended non-return valve sizes.

Boiler Room Information

Figure A1-21 shows typical boiler room length requirements.

Figure A1-22 shows typical boiler room width requirements.

Figure A1-23 shows typical breeching arrangements.

Stack Support Capabilities

All standard Cleaver-Brooks Firetube Boilers with an LE option can support up to

2,000 lbs without additional support.

LE Boilers 250 hp through 800 hp can be reinforced to support 3,000 lbs.

Stack/Breeching Size Criteria

The design of the stack and breeching must provide the required draft at each boiler flue

gas outlet. Proper draft is critical to burner performance.

Although constant pressure at the flue gas outlet of the Model CB-LE is not required, it is

necessary to size the stack/breeching to limit flue gas pressure variation. The allowable

pressure range is 0.25" W.C. to +0.25" W.C.

For additional information, please review Section I4, General Engineering Data (Stacks)

and Section F, Stacks. Stack and breeching sizes should always be provided by a

reputable stack supplier who will design the stack and breeching system based on the

above criteria. Your local Cleaver-Brooks authorized representative is capable of

assisting in your evaluation of the stack/breeching design.

Boiler Room Combustion Air

When determining boiler room air requirements, the size of the room, air flow, and

velocity of air must be reviewed as follows:

1. Size (area) and location of air supply openings in boiler room.

A. Two (2) permanent air supply openings in the outer walls of the boiler room are

recommended. Locate (1) at each end of the boiler room, preferably below a

height of 7 feet. This allows air to sweep the length of the boiler.

Section A1-33 Rev. 09-09

Model CBLE 100-800 HP Boilers

B. Air supply openings can be louvered for weather protection, but they should not

be covered with fine mesh wire, as this type of covering has poor air flow

qualities and is subject to clogging by dust or dirt.

C. A vent fan in the boiler room is not recommended, as it could create a slight

vacuum under certain conditions and cause variations in the quantity of

combustion air. This can result in unsatisfactory burner performance.

D. Under no condition should the total area of the air supply openings be less than

(1) square foot.

E. Size the openings by using the formula: Area (sq-ft) = CFM/FPM

2. Amount of air required (cfm).

A. Combustion Air = Rated bhp x 8 cfm/bhp.

B. Ventilation Air = Maximum bhp x 2 cfm/bhp

C. Total recommended air = 10 cfm/bhp - up to 1000 feet elevation. Add 3 percent

more per 1000 feet of added elevation.

3. Acceptable air velocity in Boiler Room (fpm).

A. From floor to (7) foot height - 250 fpm

B. Above (7) foot height - 500 fpm

Example: Determine the area of the boiler room air supply openings for (1)

300 hp boiler at 800 feet altitude. The air openings are to be 5 feet above floor

level.

Air required: 300 x 10 = 3000 cfm (from 2B above).

Air velocity: Up to 7 feet = 250 fpm (from 3 above).

Area Required: Area = cfm = 3000/250 = 12 sq-ft total.

Area/Opening: 12/2 = 6 sq-ft/opening (2 required).

Notice

Consult local codes, which may supersede these requirements.

Section A1-34 Rev. 09-09

Model CBLE 100-800 HP Boilers

This figure illustrates the basic gas valve arrangement on Cleaver-Brooks Model CB

boiler and shows the contractor's connection point. The valves and controls between the

contractor connection point and the gas main in the street are representative of a typical

installation. Actual requirements may vary depending on local codes or local gas

company requirements which should be investigated prior to preparation of specifications

and prior to construction.

MODEL MODEL

CB-LE CB-LE

BOILERS BOILERS

A. Utilities service valve.

B. Utilities service regulator.

C. Gas meter.

D. Piping from meter to boiler.

The size of the gas line from the meter to the gas pressure regulator at the boiler can be

very important if gas pressures are marginal. The gas line sizing is dependent on:

1. Gas pressure at outlet of gas meter (C)

2. Rate of gas flow required, CFH

3. Length of pipe run (D)

4. Pressure required at contractor connection point.

The local gas utility will advise the pressure that is available at the outlet of their meter.

Figure A1-13. Typical Gas Piping Layout

Section A1-35 Rev. 09-09

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaNo ratings yet

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Technical Manual - C&C08 Digital Switching System Chapter 2 OverviewDocument19 pagesTechnical Manual - C&C08 Digital Switching System Chapter 2 OverviewSamuel100% (2)

- DBMS Architecture FeaturesDocument30 pagesDBMS Architecture FeaturesFred BloggsNo ratings yet

- 2018 NAMCYA CHILDREN'S RONDALLA ENSEMBLE GuidelinesDocument3 pages2018 NAMCYA CHILDREN'S RONDALLA ENSEMBLE GuidelinesJohn Cedrick JagapeNo ratings yet

- Ofper 1 Application For Seagoing AppointmentDocument4 pagesOfper 1 Application For Seagoing AppointmentNarayana ReddyNo ratings yet

- Bad DayDocument3 pagesBad DayLink YouNo ratings yet

- Equilibruim of Forces and How Three Forces Meet at A PointDocument32 pagesEquilibruim of Forces and How Three Forces Meet at A PointSherif Yehia Al MaraghyNo ratings yet

- New Hire WorkbookDocument40 pagesNew Hire WorkbookkNo ratings yet

- Cover Letter PDFDocument1 pageCover Letter PDFAli EjazNo ratings yet

- Pulse Width ModulationDocument13 pagesPulse Width Modulationhimanshu jainNo ratings yet

- Prasads Pine Perks - Gift CardsDocument10 pagesPrasads Pine Perks - Gift CardsSusanth Kumar100% (1)

- HP HP3-X11 Exam: A Composite Solution With Just One ClickDocument17 pagesHP HP3-X11 Exam: A Composite Solution With Just One ClicksunnyNo ratings yet

- Business Case PresentationDocument27 pagesBusiness Case Presentationapi-253435256No ratings yet

- Oxgen Sensor Cat WEBDocument184 pagesOxgen Sensor Cat WEBBuddy Davis100% (2)

- BenchmarkDocument4 pagesBenchmarkKiran KumarNo ratings yet

- The Smith Generator BlueprintsDocument36 pagesThe Smith Generator BlueprintsZoran AleksicNo ratings yet

- How To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Document31 pagesHow To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Myster HighNo ratings yet

- Simba s7d Long Hole Drill RigDocument2 pagesSimba s7d Long Hole Drill RigJaime Asis LopezNo ratings yet

- Price List PPM TerbaruDocument7 pagesPrice List PPM TerbaruAvip HidayatNo ratings yet

- Techniques in Selecting and Organizing InformationDocument3 pagesTechniques in Selecting and Organizing InformationMylen Noel Elgincolin ManlapazNo ratings yet

- Nokia CaseDocument28 pagesNokia CaseErykah Faith PerezNo ratings yet

- Arta Kelmendi's resume highlighting education and work experienceDocument2 pagesArta Kelmendi's resume highlighting education and work experienceArta KelmendiNo ratings yet

- PeopleSoft Security TablesDocument8 pagesPeopleSoft Security TablesChhavibhasinNo ratings yet

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 pagesStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141No ratings yet

- Prlude No BWV in C MinorDocument3 pagesPrlude No BWV in C MinorFrédéric LemaireNo ratings yet

- 3d Control Sphere Edge and Face StudyDocument4 pages3d Control Sphere Edge and Face Studydjbroussard100% (2)

- Rubric 5th GradeDocument2 pagesRubric 5th GradeAlbert SantosNo ratings yet

- Strategies For StartupDocument16 pagesStrategies For StartupRoshankumar BalasubramanianNo ratings yet

- Gapped SentencesDocument8 pagesGapped SentencesKianujillaNo ratings yet

- SEC QPP Coop TrainingDocument62 pagesSEC QPP Coop TrainingAbdalelah BagajateNo ratings yet

- Jesd8 15aDocument22 pagesJesd8 15aSridhar PonnurangamNo ratings yet