Professional Documents

Culture Documents

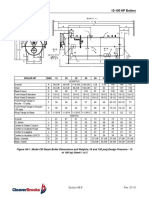

Model ICB 100-800 HP Boilers: Illustrations

Uploaded by

sebaversaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model ICB 100-800 HP Boilers: Illustrations

Uploaded by

sebaversaCopyright:

Available Formats

Model ICB 100-800 HP Boilers

ILLUSTRATIONS

Figure A4-1. Model ICB Steam Boiler Dimensions, 4-Pass and 3-Pass (Optional) .................................................. 9

Figure A4-2. Model ICB Hot Water Boiler Dimensions, 4-Pass and 3-Pass (Optional) .......................................... 11

Figure A4-3. Model ICB-LE Steam Boiler Dimensions, 4-Pass and 3-Pass (Optional) .......................................... 13

Figure A4-4. Model ICB-LE Hot Water Boiler Dimensions, 4-Pass and 3-Pass (Optional) .................................... 15

Figure A4-5. Space Required to Open Rear Head on Model ICB Boilers............................................................... 17

Figure A4-6. Model ICB Boilers Lifting Lug Location............................................................................................... 17

Figure A4-7. Model ICB Boiler Mounting Piers ........................................................................................................ 18

Figure A4-8. Typical Fuel Oil Supply Arrangement ................................................................................................. 27

Figure A4-9. Boiler Room Length (Typical Layouts) Model ICB ......................................................................... 28

Figure A4-10. Boiler Room Width (Typical Layout) Model ICB .......................................................................... 28

TABLES

Table A4-1. Model ICB Steam Boiler Ratings, 4-Pass .............................................................................................. 5

Table A4-2. Model ICB Steam Boiler Ratings, 3-Pass .............................................................................................. 5

Table A4-3. Model ICB Hot Water Boiler Ratings, 4-Pass ........................................................................................ 6

Table A4-4. Model ICB Hot Water Boiler Ratings, 3-Pass ........................................................................................ 6

Table A4-5. Model ICB-LE Steam Boiler Ratings, 4-Pass ........................................................................................ 7

Table A4-6. Model ICB-LE Steam Boiler Ratings, 3-Pass ........................................................................................ 7

Table A4-7. Model ICB-LE Hot Water Ratings, 4-Pass ............................................................................................. 8

Table A4-8. Model ICB-LE Hot Water Ratings, 3-Pass ............................................................................................. 8

Table A4-9. Model ICB Steam Boiler Dimensions, 4-Pass and 3-Pass .................................................................. 10

Table A4-10. Model ICB Hot Water Boiler Dimensions, 4-Pass and 3-Pass .......................................................... 12

Table A4-11. Model ICB-LE Steam Boiler Dimensions, 4-Pass and 3-Pass .......................................................... 14

Table A4-12. Model ICB-LE Hot Water Boiler Dimensions, 4-Pass and 3-Pass..................................................... 16

Table A4-13. Model ICB Steam Volume and Disengaging Areas ........................................................................... 21

Table A4-14. Model ICB Steam Boiler Safety Valve Outlet Size ............................................................................ 22

Table A4-15. Model ICB Hot Water Boiler Relief Valve Outlet Size........................................................................ 22

Table A4-16. Model ICB Recommended Steam Nozzle Size ................................................................................. 23

Table A4-17. Model ICB Recommended Non-Return Valve Size ........................................................................... 23

Table A4-18. Model ICB Blowdown Tank Sizing Information .................................................................................. 24

Table A4-19. Altitude Correction for Gas ................................................................................................................ 24

Table A4-20. Sound Levels in dBA for 4-Pass ICB Boilers at High Fire ................................................................. 24

Table A4-21. Model ICB, Standard Emissions, Minimum Required Gas Pressure at Entrance to Standard, FM &

IRI Gas Trains (Upstream of Gas Pressure Regulator)........................................................................................... 25

Table A4-22. Model ICB, Low NOx, Minimum Required Gas Pressure at Entrance to Standard, FM & IRI Gas

Trains (Upstream of Gas Pressure Regulator) ........................................................................................................ 26

The following information applies to the Cleaver-Brooks Model ICB Boiler.

Section A4-2 Rev. 02-08

Model ICB 100-800 HP Boilers

FEATURES AND BENEFITS

The Cleaver-Brooks Model ICB Boiler line provides a quality product utilizing a baseline

boiler/burner design. Additionally, the boiler/burner package is UL compliant. The

following features apply:

Four-Pass Intercooled Design:

Four-pass design provides high flue gas velocities and low stack temperatures to

maximize efficiency.

Three-Pass Intercooled Design (optional):

Versatile design offered with choice of three or four-pass construction to meet

application needs.

Intercooled Rear Turnaround:

Rear furnace turnaround area is fluid cooled and has a davited access opening for

full accessibility to 2nd pass tubes and furnace. It eliminates confined space issues

and provides for ease of maintenance. All tubes can be removed from either the front

or rear of the boiler.

Front and Rear Doors:

Davit, front and rear doors, all sizes.

Provides access to front and rear tube sheet.

Rear door completely covers and insulates rear tube sheet.

Natural Gas, No. 2 Oil, or Combination Burners Available:

Combination gas/oil burners provide quick fuel changeover without burner

adjustment.

Ultra low NOx emissions (<9ppm), consult factory.

PRODUCT OFFERING

Cleaver-Brooks Model ICB Boilers are available in low pressure steam, high pressure

steam, and hot water designs. Burners are available to fire natural gas, No. 2 oil, or a

combination of oil and gas. Standard product offering is:

100 800 hp.

30 and 125 psig hot water.

15 300 psig steam.

Full modulation, all sizes.

Available options include the following (contact your local Cleaver-Brooks Authorized

Representative for option details).

Boiler Options:

Three-pass design.

Drain valves.

Additional screwed or flanged tappings.

Blowdown valves.

Non-return valves.

Feedwater valves and regulators.

Surface blowdown systems.

Blend pump.

Section A4-3 Rev. 02-08

Model ICB 100-800 HP Boilers

Surge load baffles.

Seismic design.

Burner/Control Options:

Flame safeguard controllers.

Lead/lag system.

High altitude design.

Special insurance and code requirements (e.g., IRI, FM, CSD-1).

Alarm bell/silence switch.

Special motor requirements (TEFC, high efficiency).

Special indicating lights.

Elapsed time meter.

Voltmeter/micro-ammeter.

NEMA enclosures.

Low-fire hold control.

Remote emergency shut-off (115V).

Circuit breakers.

Day/night controls.

Special power requirements.

Stack thermometer.

Fuel Options

Air atomizing oil burner, 200 800 hp.

Pressure atomizing oil burner, 100 150 hp.

Gas strainer.

Gas pressure gauge.

Future gas conversion.

Oversized/undersized gas trains.

DIMENSIONS AND RATINGS

Dimensions and ratings for the Model ICB Boilers are shown in the following tables and

illustrations. The information is subject to change without notice.

Table A4-1 Model ICB Steam Boiler Ratings, 4-Pass

Table A4-2 Model ICB Steam Boiler Ratings, 3-Pass (Optional)

Table A4-3 Model ICB Hot Water Boiler Ratings, 4-Pass

Table A4-4 Model ICB Hot Water Boiler Ratings, 3-Pass (Optional)

Figure A4-1 Model ICB Steam Boiler Dimensions, 4-Pass and 3-Pass (Optional)

Table A4-9 Model ICB Steam Boiler Dimensions, 4-Pass and 3-Pass (Optional)

Figure A4-6 Model ICB Hot Water Boiler Dimensions, 4-Pass and 3-Pass (Optional)

Table A4-10 Model ICB Hot Water Boiler Dimensions, 4-Pass and 3-Pass (Optional)

Figure A4-5 Space Required to Open Rear Head on Model ICB Boilers

Figure A4-6 Model ICB Boilers Lifting Lug Location

Figure A4-7 Model ICB Boiler Mounting Piers

Section A4-4 Rev. 02-08

Model ICB 100-800 HP Boilers

Table A4-1. Model ICB Steam Boiler Ratings, 4-Pass

BOILER H.P. 100 125 150 200 250 300 350 400 500 600 700 800

BURNER MODEL Model ICB FP-3 FP-3 FP-3 FP-4 FP-4 D145P D175P D210P D252P D300P D336P D378P

RATINGS SEA LEVEL TO 700 FT.

Rated Capacity (lbs-steam/hr.

3450 4313 5175 6900 8625 10350 12075 13800 17250 20700 24150 27600

from and at 212F)

Btu Output (1000 Btu/hr.) 3348 4184 5021 6695 8369 10043 11716 13390 16738 20085 23433 26780

APPROXIMATE FUEL CONSUMPTION AT RATED CAPACITY BASED ON NOMINAL 82% EFFICIENCY

Light Oil gph (140,000 Btu/gal) 29.2 36.4 43.7 58.3 72.9 87.5 102.1 116.6 145.8 175.0 204.1 233.3

Gas CFH (1000 Btu) 4082 5103 6124 8165 10206 12247 14280 16329 20415 24494 28576 32659

Gas (Therm/hr.) 40.8 51.0 61.2 81.7 102.1 122.5 142.8 163.3 204.2 245.0 285.8 326.6

POWER REQUIREMENTS SEA LEVEL TO 700 FT. (60 HZ)

Blower Motor hp 3 5 7-1/2 7-1/2 7-1/2 15 20 25 30 40 60 60

Separate Compressor Motor

** ** ** 3 3 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 15

hp (Oil only)

Integral Oil/Air Motor hp

2

(Oil only)

Oil Metering Pump Motor hp

1/2 3/4 3/4 3/4 3/4 1

(Oil only)

Circulating Oil Pump Motor hp

* * * 1/2 1/2 3/4 3/4 3/4 3/4 3/4 1 1

(Oil only)

BOILER DATA

Heating Surface sq.-ft.

353 438 555 729 885 1055 1384 1522 1734 2094 3244 3641

(Fireside)

* = Integral oil pump

** = No air compressor required (pressure atomized system)

NOTE: All fractional hp motors will be single phase voltage except oil metering pump motor (3-phase); integral motors will be

3-phase voltage.

Table A4-2. Model ICB Steam Boiler Ratings, 3-Pass

BOILER H.P. 100 125 150 200 250 300 350 400 500 600 700 800

BURNER MODEL Model ICB FP-3 FP-3 FP-3 FP-4 FP-4 FP-4 FP-4 D175P D210P D252P D300P D336P

RATINGS SEA LEVEL TO 700 FT.

Rated Capacity (lbs-steam/hr.

3450 4313 5175 6900 8625 10350 12075 13800 17250 20700 24150 27600

from and at 212F)

Btu Output (1000 Btu/hr.) 3348 4184 5021 6695 8369 10043 11716 13390 16738 20085 23433 26780

APPROXIMATE FUEL CONSUMPTION AT RATED CAPACITY BASED ON NOMINAL 80% EFFICIENCY

Light Oil gph (140,000 Btu/gal) 29.9 37.5 45.0 60.0 74.5 89.5 104.5 119.5 149.5 179.5 209 239

Gas CFH (1000 Btu) 4184 5230 6280 8370 10460 12555 14650 16750 20925 25100 29300 33500

Gas (Therm/hr.) 41.8 52.3 62.8 83.7 104.6 125.5 146.5 167.5 209.3 251.0 293.0 335.0

POWER REQUIREMENTS SEA LEVEL TO 700 FT. (60 HZ)

Blower Motor hp 2 3 5 7-1/2 7-1/2 10 10 20 25 30 40 60

Separate Compressor Motor

** ** ** 3 3 33 5 5 7-1/2 7-1/2 7-1/2

hp (Oil only)

Integral Oil/Air Motor hp (Oil

only)

Oil Metering Pump Motor hp

1/2 3/4 3/4 3/4 3/4

(Oil only)

Circulating Oil Pump Motor hp

* * * 1/2 1/2 3/4 3/4 3/4 3/4 3/4 1 1

(Oil only)

BOILER DATA

Heating Surface sq.-ft.

353 438 555 729 885 1055 1384 1522 1734 2094 3244 3641

(Fireside)

* = Integral oil pump

** = No air compressor required (pressure atomized system)

NOTE: All fractional hp motors will be single phase voltage except oil metering pump motor (3-phase); integral motors will be

3-phase voltage.

Section A4-5 Rev. 02-08

You might also like

- ICB Boiler Book PDFDocument28 pagesICB Boiler Book PDFfauzi endraNo ratings yet

- BB CB Icb Boiler BookDocument26 pagesBB CB Icb Boiler BookedjiniNo ratings yet

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Boiler Book 2005 PDFDocument1,014 pagesBoiler Book 2005 PDFYul Ramon Paradas HernandezNo ratings yet

- CB-OS Boiler BookDocument20 pagesCB-OS Boiler Bookfauzi endraNo ratings yet

- Boiler Book CBEX Premium 100-800Document19 pagesBoiler Book CBEX Premium 100-800fauzi endraNo ratings yet

- CBL Boiler BookDocument18 pagesCBL Boiler Bookfauzi endraNo ratings yet

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaNo ratings yet

- The Boiler BookDocument1,140 pagesThe Boiler BookJose Lorenzo ToralNo ratings yet

- Claver Brooks General Boiler InformationDocument10 pagesClaver Brooks General Boiler Informationnecio77No ratings yet

- A7 CBE CleaverDocument34 pagesA7 CBE Cleaverjoseluis83No ratings yet

- Model ICB 100-800 HP Boilers: Performance DataDocument4 pagesModel ICB 100-800 HP Boilers: Performance DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Paquete Landmark KCA 2-7.5Document60 pagesPaquete Landmark KCA 2-7.5Carlos EafNo ratings yet

- CBEX-P 900-1200 Boiler BookDocument16 pagesCBEX-P 900-1200 Boiler Bookfauzi endraNo ratings yet

- CEW Boiler BookDocument16 pagesCEW Boiler Bookfauzi endraNo ratings yet

- CB ICB Boiler BookDocument26 pagesCB ICB Boiler BookMohamed SaadNo ratings yet

- SPEC ModelCBR Steam Mar4Document10 pagesSPEC ModelCBR Steam Mar4Jason PoloNo ratings yet

- Cleaver Brooks - Boiler Book 2011Document1,140 pagesCleaver Brooks - Boiler Book 2011kennnyp1100% (1)

- Thermax IR-CFBC Conference Rajavel - DistributionDocument32 pagesThermax IR-CFBC Conference Rajavel - Distributionchada1971100% (4)

- Mcquay Chiller CondDocument28 pagesMcquay Chiller CondScott DahlNo ratings yet

- AFV1600Document24 pagesAFV1600Roger AklNo ratings yet

- BFS Boiler Book PDFDocument4 pagesBFS Boiler Book PDFfauzi endraNo ratings yet

- CB Model CB Boiler Book PDFDocument29 pagesCB Model CB Boiler Book PDFBarney Paradox100% (1)

- Cbex Elite: Boiler Book 09/2019Document22 pagesCbex Elite: Boiler Book 09/2019Luis Miguel Rios CuentasNo ratings yet

- Selection Guide 11Document44 pagesSelection Guide 11lynnlynn23No ratings yet

- Steam/Hot Water Unit Heaters: Model HSB/HC Model V/VN Model PT/PTNDocument32 pagesSteam/Hot Water Unit Heaters: Model HSB/HC Model V/VN Model PT/PTNeeeNo ratings yet

- Goodman CPLE Series Spec SheetDocument8 pagesGoodman CPLE Series Spec SheetkarlbaumannNo ratings yet

- CP LeftletDocument4 pagesCP LeftletSiang LingNo ratings yet

- 25KVA Greaves DG GeneratorDocument3 pages25KVA Greaves DG GeneratorVikaas JainNo ratings yet

- Flash Tank Heat Recovery Boiler BookDocument6 pagesFlash Tank Heat Recovery Boiler Bookfauzi endraNo ratings yet

- 2009 Ajax CatalogDocument88 pages2009 Ajax Cataloglemiis93No ratings yet

- KeepRite 8P BrocherDocument8 pagesKeepRite 8P BrochergoodtiNo ratings yet

- Especificacion Caldera 700 BHP E-704Document2 pagesEspecificacion Caldera 700 BHP E-704AlejandroMuñozNo ratings yet

- Rheem Package Unit ManualDocument76 pagesRheem Package Unit ManualyingwenNo ratings yet

- APCYDocument61 pagesAPCYsumitsharma2010No ratings yet

- Untitled - FHP ManufacturingDocument52 pagesUntitled - FHP ManufacturingAbdulSattarNo ratings yet

- Dunhm-Bush PRODUCT GUIDEDB Global Product GuideDocument19 pagesDunhm-Bush PRODUCT GUIDEDB Global Product GuideFalak KhanNo ratings yet

- Caterpillar Genset Prime 400 EkW 500kvaDocument6 pagesCaterpillar Genset Prime 400 EkW 500kvaYusuf Isman Wibowo100% (1)

- SPEC Model CB Steam Jan11Document12 pagesSPEC Model CB Steam Jan11Stanford BrownNo ratings yet

- 3516B, 1600 kW-2000 kVA PDFDocument6 pages3516B, 1600 kW-2000 kVA PDFbambangNo ratings yet

- 438d8b4c-9d3a-4e95-be60-0b3a7dd96f1eDocument4 pages438d8b4c-9d3a-4e95-be60-0b3a7dd96f1eCristian Jhair PerezNo ratings yet

- Conventional Surface WellheadsDocument21 pagesConventional Surface WellheadsMohammad Reza Najafi100% (1)

- XQ Trailer Spec SheetDocument6 pagesXQ Trailer Spec Sheetmohammad hazbehzadNo ratings yet

- Directive056 ConversionCalculatorDocument16 pagesDirective056 ConversionCalculatorAnonymous KpVxNXsNo ratings yet

- Electric Boiler BrochureDocument4 pagesElectric Boiler BrochuredeztruktorNo ratings yet

- AH AV CatalogDocument16 pagesAH AV CatalognomurapreNo ratings yet

- Caldera Agua Caliente Alta Temperatura 350 HP Dual GNC DieselDocument11 pagesCaldera Agua Caliente Alta Temperatura 350 HP Dual GNC DieselEnrique RafaelNo ratings yet

- CST Boiler BookDocument4 pagesCST Boiler Bookfauzi endraNo ratings yet

- Chiller-6CHW3-01B (1) LGDocument59 pagesChiller-6CHW3-01B (1) LGHernan Hoyos100% (1)

- 9002Document2 pages9002bioarquitecturaNo ratings yet

- Lube Oil Coller DesignDocument8 pagesLube Oil Coller DesignBabar Manzoor GhauriNo ratings yet

- 4WI Boiler Book 05 2018 PDFDocument28 pages4WI Boiler Book 05 2018 PDFEury Dario PuelloNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Circulating Fluidized Bed Boilers: Design and OperationsFrom EverandCirculating Fluidized Bed Boilers: Design and OperationsRating: 4.5 out of 5 stars4.5/5 (6)

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Research ArticleDocument9 pagesResearch ArticlesebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizeDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizesebaversaNo ratings yet

- Case Study in Industrial Plant EngineeringDocument11 pagesCase Study in Industrial Plant EngineeringRenz Gabrielle Montalbo SomatizaNo ratings yet

- Sensair Manual 1.0 en PDFDocument104 pagesSensair Manual 1.0 en PDFPaul KinsellaNo ratings yet

- HIPOT TestingDocument4 pagesHIPOT Testingparuchurivenkat5272100% (1)

- Lamp Ba t302Document16 pagesLamp Ba t302Yeni EkaNo ratings yet

- Reb 670 Manul PDFDocument508 pagesReb 670 Manul PDFchandrakant patelNo ratings yet

- Loop Diagram Analog OutputDocument1 pageLoop Diagram Analog Outputteguh perkasaNo ratings yet

- Energy Conversion Experiment No. 3Document5 pagesEnergy Conversion Experiment No. 3multisporkyNo ratings yet

- Ahmad Hamidd IzomerizationDocument6 pagesAhmad Hamidd Izomerizationاحمد حمید کارسول عزیزNo ratings yet

- Axial ThrustDocument2 pagesAxial ThrustمحمدعبداللهNo ratings yet

- ABS Anglo Belgian CorporationDocument6 pagesABS Anglo Belgian CorporationDammiam GaticaNo ratings yet

- Understanding and Tuning The Injection Pump of ... - Land Rover WebDocument8 pagesUnderstanding and Tuning The Injection Pump of ... - Land Rover Webamp divisionNo ratings yet

- Diffraction Grating: BackgroundDocument10 pagesDiffraction Grating: BackgroundShahzad ahamadNo ratings yet

- Green Star Buildings-Guidance On Credit Substitution r1Document10 pagesGreen Star Buildings-Guidance On Credit Substitution r1Chetan SakharkarNo ratings yet

- Catalog - RCCB - Acti9 RCCB Katalog Indonesia PDFDocument3 pagesCatalog - RCCB - Acti9 RCCB Katalog Indonesia PDFNelyana UnoNo ratings yet

- Sour Water Stripper: Our ExperienceDocument2 pagesSour Water Stripper: Our Experiencevarsha PrajapatiNo ratings yet

- Antractica Ozone Layer: Gudied ByDocument33 pagesAntractica Ozone Layer: Gudied ByRohit AgarwalNo ratings yet

- Aspen Polymers+Vol1V7 1-UsrDocument560 pagesAspen Polymers+Vol1V7 1-Usraftentea100% (2)

- Cause and Effect EassyDocument11 pagesCause and Effect EassyMrito ManobNo ratings yet

- Fast Facts: Masdar's Core MessagingDocument3 pagesFast Facts: Masdar's Core MessagingHari SreyasNo ratings yet

- Specification of Each Machine:: SDT-800 Non-Woven Box Bag Making MachineDocument7 pagesSpecification of Each Machine:: SDT-800 Non-Woven Box Bag Making MachineMILADNo ratings yet

- Part Winding Motor PDFDocument4 pagesPart Winding Motor PDFBj Valdez100% (2)

- Direct To HomeDocument22 pagesDirect To HomeShashank DubeyNo ratings yet

- 管線腐蝕案例Document12 pages管線腐蝕案例Tzu Huan PengNo ratings yet

- Gradually Varied Flow and Rapidly Varied FlowDocument3 pagesGradually Varied Flow and Rapidly Varied FlowCourtneyNo ratings yet

- Raychem MWTM Medium Wall PDFDocument4 pagesRaychem MWTM Medium Wall PDFLeo TopacioNo ratings yet

- 07-Electricity v5Document113 pages07-Electricity v5Data TécnicaNo ratings yet

- 8.yanmar 6HYM WET DatasheetDocument2 pages8.yanmar 6HYM WET Datasheetপরীক্ষামূলক হিসাবNo ratings yet

- Anon 30-40TPD Rice Mill Details With CIF Douala, Cameroon-2Document10 pagesAnon 30-40TPD Rice Mill Details With CIF Douala, Cameroon-2ousmaneNo ratings yet

- Review of The Shear-Stress Transport Turbulence Model Experience From An Industrial PerspectiveDocument13 pagesReview of The Shear-Stress Transport Turbulence Model Experience From An Industrial PerspectiveVyssionNo ratings yet

- 3303.0002 Micropack FDS303 Multi Spectrum IR Flame Detector - Datasheet Rev 1.4Document2 pages3303.0002 Micropack FDS303 Multi Spectrum IR Flame Detector - Datasheet Rev 1.4Landi ManusNo ratings yet