Professional Documents

Culture Documents

38i-Ties Axial Tension and Moments - PNG

Uploaded by

Parthiban ArivazhaganOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

38i-Ties Axial Tension and Moments - PNG

Uploaded by

Parthiban ArivazhaganCopyright:

Available Formats

xc

g Proj: Admin

Ref :

Tel:d Date: 24/08/17

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

Tie section

Calculations for timber ties in accordance with BS5268:Pt 2:2002

Tie shaft - 150 wide x 200 deep

Timber type - Sawn Softwood as Table NA.2 of BS EN 336

Length of tie = 3000 mm

Strength class from Table 8 (service classes 1 & 2) - C16

Service class - 2 (Covered and heated or unheated)

Design axial tension = 10 kN

Design moment - about x-x axis = 1.5 kNm

- about y-y axis = 0.5 kNm

Grade stresses - from Tables 8 and 9

Bending parallel to grain = 5.3 N/mm2

Tension parallel to grain = 3.2 N/mm2

Modification factors

For service class 2 - moment K =1

2M

- tension K =1

2T

For load duration - long K =1

3

For depth between 72 and 300mm K = (300/h)0.11

7

= (300/200)0.11

= 1.05

For load sharing system K = 1.1

8

For maximum dimension >72mm

- size factor K = (300/h)0.11

14

= (300/200)0.11

= 1.05

Determine Axial Stresses

The allowable tensile stress is

= *K *K *K *K

tenall ten 2T 3 8 14

= 3.2*1*1*1.1*1.05

= 3.70 N/mm2

The applied tensile stress is

= N*103/A

tenapp

= 10*103/30000

= 0.33 N/mm2

Determine Bending Stresses

The allowable bending stress

= *K *K *K *K

bpall bp 2M 3 7 8

= 5.3*1*1*1.05*1.1

= 6.12 N/mm2

The applied bending stress about the x-x axis is

= M *106/Z

bpappx xx xx

= 1.5*106/1000000

= 1.50 N/mm2

The applied bending stress about the y-y axis is

= M *106/Z

bpappy yy yy

= 0.5*106/750000

= 0.67 N/mm2

Combining Axial and Bending Stresses

Using the interaction formula described in clause 2.12.3, the combined effect of axial load and bending is

IFC = ( / )+( / )+( / )

bpappy bpall bpappx bpall tenapp tenall

= (0.67/6.12)+(1.5/6.12)+(0.33/3.7)

= 0.44

NOTE: The effect of connections on the net area of the section should be checked manually.

The combined effect does not exceed 1.0, section PASSES.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Welding For Design EngineersDocument518 pagesWelding For Design EngineersHumberto Magno FukeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-TrapezoidalDocument3 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-TrapezoidalParthiban ArivazhaganNo ratings yet

- Lab Report - Tensile TestingDocument19 pagesLab Report - Tensile Testingapi-404653452100% (1)

- Towards Recycling of Textile FibersDocument75 pagesTowards Recycling of Textile FibersMusa EltayebNo ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Parthiban ArivazhaganNo ratings yet

- Air Quality MonitoringDocument43 pagesAir Quality MonitoringTulika GalaniNo ratings yet

- Cavitation and Pipe DetailsDocument34 pagesCavitation and Pipe DetailsSANDIP ROYNo ratings yet

- Web Content - Monorail-R2Document2 pagesWeb Content - Monorail-R2Parthiban ArivazhaganNo ratings yet

- 22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedDocument2 pages22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedParthiban Arivazhagan100% (1)

- UI Reinforcement DetailsDocument3 pagesUI Reinforcement DetailsParthiban ArivazhaganNo ratings yet

- Isolated Foundation Design PunchingDocument2 pagesIsolated Foundation Design PunchingParthiban ArivazhaganNo ratings yet

- 38a-Columns Axial Compression and Moments - PNGDocument3 pages38a-Columns Axial Compression and Moments - PNGParthiban ArivazhaganNo ratings yet

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocument2 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganNo ratings yet

- 13a-Building Near Trees To NHBC STANDARDSDocument1 page13a-Building Near Trees To NHBC STANDARDSParthiban ArivazhaganNo ratings yet

- 45a-Columns Axial Force and Bending - PNGDocument5 pages45a-Columns Axial Force and Bending - PNGParthiban ArivazhaganNo ratings yet

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocument2 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganNo ratings yet

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocument2 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganNo ratings yet

- 22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedDocument2 pages22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedParthiban Arivazhagan100% (1)

- 45b-Floor Joits Type 01.PngDocument7 pages45b-Floor Joits Type 01.PngParthiban ArivazhaganNo ratings yet

- 37a-Colums Axial Compression and Moments Type 03.PngDocument4 pages37a-Colums Axial Compression and Moments Type 03.PngParthiban ArivazhaganNo ratings yet

- 39b-Columns Axial Compression Only - PNGDocument2 pages39b-Columns Axial Compression Only - PNGParthiban ArivazhaganNo ratings yet

- 34e Trussed Beam - PNGDocument3 pages34e Trussed Beam - PNGParthiban ArivazhaganNo ratings yet

- 34d-Rafter or Sloping Beam-Roller at Lower Lever - PNGDocument3 pages34d-Rafter or Sloping Beam-Roller at Lower Lever - PNGParthiban ArivazhaganNo ratings yet

- 34e Trussed Beam - PNGDocument3 pages34e Trussed Beam - PNGParthiban ArivazhaganNo ratings yet

- 34d-Rafter or Sloping Beam-Roller at Lower Lever-With Depth and Width - PNGDocument3 pages34d-Rafter or Sloping Beam-Roller at Lower Lever-With Depth and Width - PNGParthiban ArivazhaganNo ratings yet

- 38j-Ties Axial Tension Only - PNGDocument2 pages38j-Ties Axial Tension Only - PNGParthiban ArivazhaganNo ratings yet

- 37b-Columns Axial Compression Only Type 02.PngDocument2 pages37b-Columns Axial Compression Only Type 02.PngParthiban ArivazhaganNo ratings yet

- 37b-Columns Axial Compression Only Type 03.PngDocument2 pages37b-Columns Axial Compression Only Type 03.PngParthiban ArivazhaganNo ratings yet

- 38i-Ties Axial Tension and Moments - PNGDocument2 pages38i-Ties Axial Tension and Moments - PNGParthiban ArivazhaganNo ratings yet

- 35c Floor Joists Long No Notch Dry - PNGDocument5 pages35c Floor Joists Long No Notch Dry - PNGParthiban ArivazhaganNo ratings yet

- 37c Floor Joists No Notch - PNGDocument4 pages37c Floor Joists No Notch - PNGParthiban ArivazhaganNo ratings yet

- 35c Floor Joists Medium Type A Notch Both Wet - PNGDocument5 pages35c Floor Joists Medium Type A Notch Both Wet - PNGParthiban ArivazhaganNo ratings yet

- 30F-I Stability Check Bending Simply Supported Beams-On Bottom Flange - PNGDocument3 pages30F-I Stability Check Bending Simply Supported Beams-On Bottom Flange - PNGParthiban ArivazhaganNo ratings yet

- 35b Columns Axial Compression Only Spaced Screws or Bolts Wet Load Sharing - PNGDocument3 pages35b Columns Axial Compression Only Spaced Screws or Bolts Wet Load Sharing - PNGParthiban ArivazhaganNo ratings yet

- 35b Columns Axial Compression Only Single Nails Dry No Load Sharing - PNGDocument2 pages35b Columns Axial Compression Only Single Nails Dry No Load Sharing - PNGParthiban ArivazhaganNo ratings yet

- Cheetham Salt BrochureDocument8 pagesCheetham Salt BrochureSamscribdingNo ratings yet

- Chemistry Viva QuestionsDocument3 pagesChemistry Viva QuestionsShivamNo ratings yet

- Bio Assignmnet 1Document15 pagesBio Assignmnet 1api-535572482No ratings yet

- Mole Concept (Scholar Paper)Document4 pagesMole Concept (Scholar Paper)Rudraksh AhujaNo ratings yet

- مثال فصل 3Document10 pagesمثال فصل 3mohammadNo ratings yet

- Material Safety Data Sheet - NITRIC ACID PDFDocument9 pagesMaterial Safety Data Sheet - NITRIC ACID PDFJunaid AhmadNo ratings yet

- Researchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFDocument4 pagesResearchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFTran Huynh NamNo ratings yet

- Friction Welding Usage TodayDocument15 pagesFriction Welding Usage Todaycule93No ratings yet

- 08-SM412-1-Refrigeration SystemDocument54 pages08-SM412-1-Refrigeration SystemTunaNo ratings yet

- Spectroscopic Techniques For Pharmaceutical and Biopharmaceutical Industries - Unit 9 - Week 8 PDFDocument1 pageSpectroscopic Techniques For Pharmaceutical and Biopharmaceutical Industries - Unit 9 - Week 8 PDFantony bevanNo ratings yet

- AlSi12Fe MS, Props Under VacuumDocument14 pagesAlSi12Fe MS, Props Under VacuumRishabh MenonNo ratings yet

- API PILOT WorkbookVideoOrderSheetDocument1 pageAPI PILOT WorkbookVideoOrderSheetAhmed YehiaNo ratings yet

- Arcebido, GwynnDocument4 pagesArcebido, GwynnGwynnNo ratings yet

- Pooml Ghting: Contract Collection 2010Document218 pagesPooml Ghting: Contract Collection 2010Lori ChiriacNo ratings yet

- Biosuite Qd10 Ghs Sds - Us v04Document6 pagesBiosuite Qd10 Ghs Sds - Us v04izzybjNo ratings yet

- 8.2 (B) Identification of GasesDocument20 pages8.2 (B) Identification of GasesFidree AzizNo ratings yet

- Joint Universities Preliminary Examinations Board 2015 Examinations Chemistry: Sci-J153 Multiple Choice Questions: Answer All QuestionsDocument11 pagesJoint Universities Preliminary Examinations Board 2015 Examinations Chemistry: Sci-J153 Multiple Choice Questions: Answer All QuestionsDeborahNo ratings yet

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Document12 pagesLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonNo ratings yet

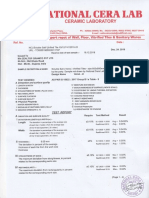

- 12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Document3 pages12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Shaikh MohammedHanifSultanNo ratings yet

- Balancing Equations and Stoichiometric CalculationsDocument4 pagesBalancing Equations and Stoichiometric CalculationsNikoh Anthony EwayanNo ratings yet

- Thermal Isolation of AccelerometersDocument4 pagesThermal Isolation of AccelerometersLake HouseNo ratings yet

- A Proven Cleaner For Acetone ReplacementDocument4 pagesA Proven Cleaner For Acetone ReplacementhuahmeduaeNo ratings yet

- Ampoule Filling Line BDocument4 pagesAmpoule Filling Line BRahul JainNo ratings yet

- Nuclear T-2 CH 7Document5 pagesNuclear T-2 CH 7Yashashree GedamNo ratings yet

- Spectrofluorimetry: Minia University Faculty of Pharmacy Department of Analytical ChemistryDocument35 pagesSpectrofluorimetry: Minia University Faculty of Pharmacy Department of Analytical ChemistryAhmed Zaghloul100% (2)