Professional Documents

Culture Documents

Oooooooooo Oooooooooo

Uploaded by

gebreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oooooooooo Oooooooooo

Uploaded by

gebreCopyright:

Available Formats

A column should be designed with a specific wall thickness to ensure it has sufficient rigidity to

be able to cope with the maximum amount of pressure which it is expected to be susceptible to in

operation. The minimum column wall thickness needed to withstand the vessel weight itself as

well as other incidental loads such as internal pressure is calculated and shown in the following

calculation section The design pressure for vessels under internal pressure is conventionally

taken as the pressure where the relief device is set. This is usually about 5-10 % above the

regular working pressure. This is done to avoid spurious operation during minor process upsets.

A cylindrical pressure vessel shell must be enclosed at both ends by heads. Flat plates, formed

flatheads, hemispherical heads, torispherical heads and ellipsoidal heads are several principal

types of heads used . Hemispherical, torispherical and ellipsoidal are categorised as domed heads

where the formation is by pressing or spinning with large diameters fabricated from formed

sections.Torispherical heads, on the other hand also referred to as dished ends. Pressure vessels

can theoretically be almost any shape, but shapes made of sections of spheres, cylinders and

cones are usually employed. More complicated shapes have historically been much harder to

analyse for safe operation and are usually far harder to construct. Theoretically a sphere would

be the optimal shape of a pressure vessel. Unfortunately the sphere shape is difficult to

manufacture, therefore more expensive, so most of the pressure vessels are cylindrical shape

with 2:1 semi elliptical heads or end caps on each end. Smaller pressure vessels are arranged

from a pipe and two covers. Disadvantage of these vessels is the fact that larger diameters make

them relatively more expensive. Many pressure vessels are made of steel. To manufacture a

spherical pressure vessel, forged parts would have to be welded together. The design of pressure

vessels is an important and practical topic which has been explored for decades. Optimization

techniques have been extensively applied to design structures in general; few pieces of work can

be found which are directly related to optimal pressure vessel design. These few references are

mainly related to the design optimization of homogeneous and composite pressure vessels.

The pressure vessel meets international safety standards, carefully selected steel with a high

impact resistance & corrosion resistant material.

1.2 Statement of Problem

Vessels failure can be grouped into the following major categories, which describe why a vessel

failure occurs. Failures also grouped into types of failures, which describe how the failure occurs

mean each failure contains its failure history, why and how it occurs. There are many reasons of

vessels failure such as:

Improper material selection, defected material.

You might also like

- FDDZBHDocument1 pageFDDZBHgebreNo ratings yet

- RefrvvDocument32 pagesRefrvvgebreNo ratings yet

- Uuuuuuu UuuuuuuDocument23 pagesUuuuuuu UuuuuuugebreNo ratings yet

- RefrvvDocument34 pagesRefrvvgebreNo ratings yet

- Uuuuuuu UuuuuuuDocument23 pagesUuuuuuu UuuuuuugebreNo ratings yet

- FDDZBHDocument1 pageFDDZBHgebreNo ratings yet

- FDDZBHDocument2 pagesFDDZBHgebreNo ratings yet

- Uuuuuuu UuuuuuuDocument24 pagesUuuuuuu UuuuuuugebreNo ratings yet

- ExamineDocument113 pagesExaminegebreNo ratings yet

- ExamineDocument6 pagesExaminegebreNo ratings yet

- Chapter 04Document3 pagesChapter 04gebreNo ratings yet

- ExamineDocument114 pagesExaminegebreNo ratings yet

- GGGGG GGGGG GGGGG GGGGGDocument13 pagesGGGGG GGGGG GGGGG GGGGGgebreNo ratings yet

- ET Tut5 AUT2016-17Document4 pagesET Tut5 AUT2016-17gebreNo ratings yet

- 3, Design Pressure: B.S.Thakkar, S.A.Thakkar, 2012Document1 page3, Design Pressure: B.S.Thakkar, S.A.Thakkar, 2012gebreNo ratings yet

- ExamineDocument6 pagesExaminegebreNo ratings yet

- Basic Economic ProblemsDocument4 pagesBasic Economic ProblemsgebreNo ratings yet

- Im Ic: Current. It Comprises A Fundamental Component Lagging The Counter Emf by 90 °, TogetherDocument2 pagesIm Ic: Current. It Comprises A Fundamental Component Lagging The Counter Emf by 90 °, TogethergebreNo ratings yet

- Eeee EeeeeeDocument1 pageEeee EeeeeegebreNo ratings yet

- FFFFFFF FFFFFFF FFFFFFF FFFFFFFDocument77 pagesFFFFFFF FFFFFFF FFFFFFF FFFFFFFgebreNo ratings yet

- If The Machine Is Separating A SolidDocument2 pagesIf The Machine Is Separating A SolidgebreNo ratings yet

- DD DDDD DDDD DDDDDocument1,692 pagesDD DDDD DDDD DDDDgebreNo ratings yet

- 7 Magnetic Circuits: B, and State Their Units A H L ADocument10 pages7 Magnetic Circuits: B, and State Their Units A H L AgebreNo ratings yet

- WWWWWWWWWDocument38 pagesWWWWWWWWWgebreNo ratings yet

- Introduction Sieve Plate Column Is One of The Distillation Columns With CrossDocument1 pageIntroduction Sieve Plate Column Is One of The Distillation Columns With CrossgebreNo ratings yet

- The Advertising DebateDocument2 pagesThe Advertising DebategebreNo ratings yet

- Introduction Sieve Plate Column Is One of The Distillation Columns With CrossDocument1 pageIntroduction Sieve Plate Column Is One of The Distillation Columns With CrossgebreNo ratings yet

- Introduction Sieve Plate Column Is One of The Distillation Columns With CrossDocument1 pageIntroduction Sieve Plate Column Is One of The Distillation Columns With CrossgebreNo ratings yet

- FFDocument1 pageFFgebreNo ratings yet

- FGVDocument1 pageFGVgebreNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

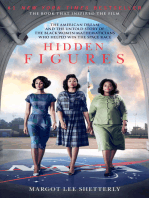

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SuperTuff R Tuff R SellSheetDocument2 pagesSuperTuff R Tuff R SellSheetZainuddinNo ratings yet

- Advanced Quality ManualDocument15 pagesAdvanced Quality ManualPhilip AnomnezeNo ratings yet

- CZ120 (CW612N) : Technical DatasheetDocument1 pageCZ120 (CW612N) : Technical DatasheetAmrut KanungoNo ratings yet

- API RP 1109 4th Ed. Oct. 2010 - Marking Liquid Petroleum Pipeline Facilities - Compilation - Part2Document8 pagesAPI RP 1109 4th Ed. Oct. 2010 - Marking Liquid Petroleum Pipeline Facilities - Compilation - Part2FranckNo ratings yet

- Drilling Attachment: CPA Range OverviewDocument3 pagesDrilling Attachment: CPA Range OverviewPablo NarváezNo ratings yet

- Zn4 Rust Preventives Line Card 100529Document2 pagesZn4 Rust Preventives Line Card 100529Manoel Caetano DamascenoNo ratings yet

- Welding of Nickel AlloysDocument4 pagesWelding of Nickel AlloysMuhammed SulfeekNo ratings yet

- Physical DistributionDocument19 pagesPhysical DistributionLoveleen Santosh100% (2)

- ENVIRO GUARD - Pipe End CoversDocument2 pagesENVIRO GUARD - Pipe End CoversadalghusaNo ratings yet

- Petroleum Refinery Engg. - SyllabusDocument7 pagesPetroleum Refinery Engg. - SyllabusPradeep MunnaNo ratings yet

- Practical No. 1:: Food Processing EquipmentsDocument3 pagesPractical No. 1:: Food Processing EquipmentsHamza HafeezNo ratings yet

- JJ104 Workshop Technology Chapter6 Milling MachineDocument27 pagesJJ104 Workshop Technology Chapter6 Milling MachineAh Tiang100% (3)

- Mount Kenya UniversityDocument4 pagesMount Kenya Universitybrian samNo ratings yet

- Overview On Kanban Methodology and Its Implementation: July 2015Document5 pagesOverview On Kanban Methodology and Its Implementation: July 2015prajwal upadhyayNo ratings yet

- Application of Lean Principle in New Product DevelopmentDocument39 pagesApplication of Lean Principle in New Product DevelopmentGyandeep TripathiNo ratings yet

- Machine Design Elements03 - : God BlessDocument101 pagesMachine Design Elements03 - : God BlessReynald de VeraNo ratings yet

- Letter of Complaint of Truckers Vs Asian Terminals IncDocument3 pagesLetter of Complaint of Truckers Vs Asian Terminals IncPortCallsNo ratings yet

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument19 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNo ratings yet

- Introduction To CIM & Manufacturing EnterpriseDocument53 pagesIntroduction To CIM & Manufacturing Enterprisesabtrex0% (1)

- Sikadur 52 - PDSDocument2 pagesSikadur 52 - PDS231340No ratings yet

- Assignment No 1 - Cost ClassificationDocument7 pagesAssignment No 1 - Cost ClassificationJitesh Maheshwari100% (1)

- Slab-On-Grade Reinforcing DesignDocument9 pagesSlab-On-Grade Reinforcing DesignAdam GreenlawNo ratings yet

- UL Traceability RequirementsDocument5 pagesUL Traceability RequirementsvintecomNo ratings yet

- CoatedDocument3 pagesCoatedmatteo2009No ratings yet

- 1Document17 pages1Saurabh Saran100% (1)

- Unit Costing and Cost SheetDocument15 pagesUnit Costing and Cost SheetAyush100% (1)

- Answers To Summer 2010 Perfect Competition QuestionsDocument7 pagesAnswers To Summer 2010 Perfect Competition QuestionsNikhil Darak100% (1)

- Welding Code IndexDocument6 pagesWelding Code IndexAkhilesh KumarNo ratings yet

- Warisan - 2020 LivingDocument73 pagesWarisan - 2020 LivingJose Mejia CaveroNo ratings yet

- Position Paper Outline SampleDocument3 pagesPosition Paper Outline SampleRenee Louise CoNo ratings yet