Professional Documents

Culture Documents

VA1-BSWS-00100-M-M3-SPC-0011 Rev B Piping Material%2

Uploaded by

Tam Huynh ThanhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VA1-BSWS-00100-M-M3-SPC-0011 Rev B Piping Material%2

Uploaded by

Tam Huynh ThanhCopyright:

Available Formats

DOCUMENT SUBMISSION STATUS: FOR APPROVAL

B 29/04/2011 General Revision SY Tan JJ Lee HSW

A 31/03/2010 First Submission SY Tan JJ Lee HSW

REV DATE DESCRIPTION PREPD CHKD APPD

OWNER OWNER’S CONSULTANT

POYRY ENERGY LTD

VIETNAM OIL AND GAS GROUP (PVN)

EPC CONTRACTOR EPC CONTRACTOR’S CONSULTANT

VIETNAM MACHINERY INSTALLATION

CORPORATION (LILAMA) FICHTNER GmbH & Co. KG

PROJECT TITLE

VUNG ANG 1 THERMAL POWER PLANT 2 x 600MW

WATER TREATMENT AND WASTE WATER TREATMENT PLANT

CONTRACT No.120110\LILAMA-BOUSTEAD SALCON

DOCUMENT TITLE:

PIPING MATERIAL SPECIFICATION

SUB-CONTRACTOR: FUNCTION NAME SIGN DATE

BOUSTEAD SALCON PREPARED BY SY Tan 29/04/2011

WATER SOLUTIONS PTE. LTD. CHECKED BY JJ Lee 29/04/2011

APPROVED BY SW Hooi 29/04/2011

DOCUMENT No. : VA1-BSWS-00100-M-M3-SPC-0011 SCALE: REV:

NA B

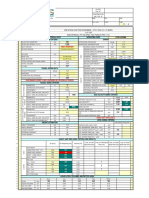

PIPING MATERIAL SPECIFICATION PIPING CLASS JOB NO: 162003

DOC NO:

Carbon Steel CS VA1-BSWS-00100-M-M3-

SPC-0011

TYPICAL i) Oily waste water treatment system pipeline (Note 1) Pressure Rating CL 150 General Material

SERVICE Corrosion Allowance (mm) 0 Carbon steel

Operating temperature (oC) Ambient

SCH/

ITEM SIZE (DN) RATIN END DESCRIPTION REMARKS

G

PIPE 15 ~ 50 40 PE A53-B-E SMLS PE ASME-B36.10M

60 ~ 250 40 BE A53-B-E ERW BE ASME-B36.10M

ELBOWS 15 ~ 50 3000# SW A105, FORGED, B16.11

60 ~ 250 40 BW A234 WPB, SMLS, B16.9

FITTINGS 15 ~ 50 3000# SW A105, FORGED, B16.11

60 ~ 250 40 BW A234 WPB, SMLS, B16.9

TEES & 15 ~ 50 3000# SW A105, FORGED, B16.11

REDUCERS 60 ~ 250 40 BW A234 WPB, SMLS, B16.9

FLANGE 15 ~ 50 150# SW A105, RF, B16.5, SCH 40

60 ~ 250 150# SO A105, RF, B16.5

BLIND FLANGE 15 ~ 50 150# - A105, RF, B16.5

60 ~ 250 150# - A105, RF, B16.5

-

VALVE - - - AS PER VALVE LIST

STUD BOLTS & NUTS GALVANIZED A193 B7 BOLT C/W A194-2H HH NUTS

- - -

GASKET 15 ~ 250 150# RF EPDM 3.0mm

Note: 1. kindly refer to P & ID for process piping material

PIPING MATERIAL SPECIFICATION PIPING CLASS JOB NO: 162003

DOC NO:

STAINLESS STEEL 304 SS304 VA1-BSWS-00100-M-M3-

SPC-0011

TYPICAL i. Pipeline carrying demin water Pressure Rating CL 150 General Material

SERVICE ii. Pipeline carrying NaOH solution Corrosion Allowance (mm) 0

(Note 1) Operating temperature (oC) Ambient

Stainless steel 304

SCH/

ITEM SIZE (DN) RATIN END DESCRIPTION REMARKS

G

PIPE 15 ~ 50 40S PE A312 TP304, SMLS, B36.19M

60 ~ 250 10S BE A312 TP304, WLD, B36.19M

ELBOWS 15 ~ 50 3000# SW A182 Gr. F304, FORGED, B16.11

60 ~ 250 10S BW A403Gr.WP304, WLD, B16.9

FITTINGS 15 ~ 50 3000# SW A182 Gr. F304, FORGED, B16.11

60 ~ 250 10S BW A403Gr.WP304, WLD, B16.9

TEES & 15 ~ 50 3000# SW A182 Gr. F304, FORGED, B16.11

REDUCERS 60 ~ 250 10S BW A403Gr.WP304, WLD, B16.9

FLANGE 15 ~ 50 150# SW A182 Gr. F304, RF, B16.5 SCH 40S

60 ~ 250 150# WN A182 Gr. F304, RF, B16.5 SCH 10S

BLIND FLANGE 15 ~ 50 150# - A182 Gr. F304, RF, B16.5

60 ~ 250 150# - A182 Gr. F304, RF, B16.5

-

VALVE - - - AS PER VALVE LIST

STUD BOLTS & NUTS A193 SS316 BOLTS C/W A194 SS316 HH NUTS

- - -

GASKET 15 ~ 250 150# RF EPDM, 3.0mm - NaOH pipeline

- Demin Water

Note: 1. kindly refer to P & ID for process piping material

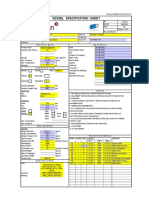

PIPING MATERIAL SPECIFICATION PIPING CLASS JOB NO: 162003

DOC NO:

Carbon Steel (Galvanized) GALV VA1-BSWS-00100-M-M3-

SPC-0011

TYPICAL i. Process air line, instrument air line (Note 1) Pressure Rating CL 150 General Material

SERVICE Corrosion Allowance (mm) 0

Operating temperature (oC) Ambient

Galvanized Carbon Steel

SCH/

ITEM SIZE (DN) RATIN END DESCRIPTION REMARKS

G

PIPE 15 ~ 50 40 NPT AP1 5L/ A53 Gr.B- E GALV SMLS, B36.10M

60 ~ 250 40 BE AP1 5L/ A53 Gr.B-E GALV ERW, B36.10M

ELBOWS 15 ~ 50 3000# NPT A105 GALV NPT B 16.11

60 ~ 250 40 BW A234 WPB, GALV, B16.9

FITTINGS 15 ~ 50 3000# NPT A105 GALV NPT B 16.11

60 ~ 250 40 BW A234 WPB, GALV, B16.9

TEES & 15 ~ 50 3000# NPT A105 GALV NPT B 16.11

REDUCERS 60 ~ 250 40 BW A234 WPB, GALV, B16.9

FLANGE 15 ~ 50 150# NPT A105N, GALV, RF, B16.5

60 ~ 250 150# SO A105N, GALV, RF, B16.5

BLIND FLANGE 15 ~ 50 150# - A105N, GALV, RF, B16.5

60 ~ 250 150# - A105N, GALV, RF, B16.5

VALVE - - - - AS PER VALVE LIST

STUD BOLTS & NUTS GALVANIZED A193 B7 BOLT C/W A194-2H HH NUTS

- - -

GASKET 15 ~ 250 150# RF EPDM 3.0mm

Note: 1. kindly refer to P & ID for process piping material

PIPING MATERIAL SPECIFICATION PIPING CLASS JOB NO: 162003

DOC NO:

UPVC UPVC VA1-BSWS-00100-M-M3-

SPC-0011

TYPICAL i. Pipeline carrying PAC & Polymer solution Pressure Rating 7 bar General Material

SERVICE ii. Indoor pipeline Corrosion Allowance (mm) 0

(Note 1) Operating temperature (oC) Ambient

Polyvinyl Chloride

SCH/

ITEM SIZE (DN) RATIN END DESCRIPTION REMARKS

G

PIPE 15 ~ 200 80 PE ASTM D 1785 SCH 80

ELBOWS 15 ~ 200 80 SW ASTM D 2467, SOCKET SCH 80

FITTINGS 15 ~ 200 80 SW ASTM D 2467, SOCKET SCH 80

TEES & 15 ~ 200 80 SW ASTM D 2467, SOCKET SCH 80

REDUCERS

FLANGE 15 ~ 200 150# SW ASTM F 1970, FF, ANSI B16.5, Van Stone flange

VALVE - - - - AS PER VALVE LIST

STUD BOLTS & NUTS A193 SS316 BOLTS C/W A194 SS316 HH NUTS

- - -

GASKET 15 ~ 200 150# RF EPDM, 3.0mm - Coagulant (PAC)

- Polymer

- Others

Note: 1. kindly refer to P & ID for process piping material

PIPING MATERIAL SPECIFICATION PIPING CLASS JOB NO: 162003

DOC NO:

CPVC CPVC VA1-BSWS-00100-M-M3-

SPC-0011

TYPICAL i. Pipeline carrying NaOCl solution Pressure Rating 7 bar General Material

SERVICE ii.Pipeline carrying HCl Corrosion Allowance (mm) 0

(Note 1) Operating temperature (oC) Ambient

Chlorinated Polyvinyl Chloride

SCH/

ITEM SIZE (DN) RATIN END DESCRIPTION REMARKS

G

PIPE 15 ~ 200 80 PE ASTM F441/ ASTM D 1784 SCH 80

ELBOWS 15 ~ 200 80 SW ASTM F 439, SOCKET SCH 80

FITTINGS 15 ~ 200 80 SW ASTM F 439, SOCKET SCH 80

TEES & 15 ~ 200 80 SW ASTM F 439, SOCKET SCH 80

REDUCERS

FLANGE 15 ~ 200 150# SW ASTM F 1970 , FF, ANSI B16.5, Van Stone flange

VALVE - - - - AS PER VALVE LIST

STUD BOLTS & NUTS A193 SS316 BOLTS C/W A194 SS316 HH NUTS

- - -

GASKET 15 ~ 200 150# RF Viton, 3.0mm - NaOCl, HCl

Note: 1. kindly refer to P & ID for process piping material

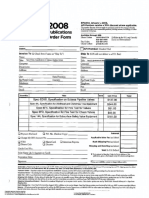

PIPING MATERIAL SPECIFICATION PIPING CLASS JOB NO: 162003

DOC NO:

HDPE PE VA1-BSWS-00100-M-M3-

SPC-0011

TYPICAL Outdoor pipeline for the entire plant except NaOH Pressure Rating PN 16/ PN 10 General Material

SERVICE Corrosion Allowance (mm) 0

Operating temperature (oC) Ambient

High Density Polyethylene

SCH/

ITEM SIZE (DN) RATIN END DESCRIPTION (Note 2) REMARKS

G

PIPE 15 ~ 50 PN 16 PE PE 100, SDR 11, DIN8074 Note 3

60 ~ 250 PN 10 PE PE 100, SDR 17.6, DIN8074

ELBOWS/ BEND 15 ~ 50 PN16 BF/ EF PE100, SDR 11 Note 3

60 ~ 250 PN 10 BF/ EF PE100, SDR 17.6

FITTINGS 15 ~ 50 PN16 BF/ EF PE100, SDR 11 Note 3

60 ~ 250 PN 10 BF/ EF PE100, SDR 17.6

TEES & 15 ~ 50 PN16 BF/ EF PE100, SDR 11 Note 3

REDUCERS 60 ~ 250 PN 10 BF/ EF PE100, SDR 17.6

FLANGE

ADAPTOR 15 ~ 50 PN16 BF/ EF PE100, SDR 11, Serated face Note 3

BACKING RING 15 ~ 50 PN16 BF/ EF PP-V ASME B16.5, ASTM D 4024

ADAPTOR 60 ~ 250 PN10 BF/EF PE100, SDR 17.6, Serated face Note 3

BACKING RING 60 ~ 250 PN10 BF/EF PP-V ASME B16.5, ASTM D 4024

VALVE - - - - AS PER VALVE LIST

STUD BOLTS & NUTS GALVANIZED A193 B7 BOLT C/W A194-2H HH NUTS

- - -

GASKET 15 ~ 200 150# RF Viton, 3.0mm NaOCl, HCl

EPDM, 3.0mm Others

Note: 1. kindly refer to P & ID for process piping material

2. description is with referencens to GF piping specification

3. SDR 11 (PN16) was chosen for 2" and below pipe size as SDR 17.6 (PN10) fitting or pipe is not available/ common for small pipe size

You might also like

- 094135-PE-SPC-001 Piping Material Specification-REV 4Document76 pages094135-PE-SPC-001 Piping Material Specification-REV 4thongpvgas100% (1)

- Astm C78Document3 pagesAstm C78avrajan100% (3)

- A Teaching Guide For Structural Steel ConnectionsDocument85 pagesA Teaching Guide For Structural Steel Connectionsv97% (65)

- A Teaching Guide For Structural Steel ConnectionsDocument85 pagesA Teaching Guide For Structural Steel Connectionsv97% (65)

- Aws B1.10Document41 pagesAws B1.10Tam Huynh Thanh100% (1)

- Branch Calculation Sample - B31.1a-2008Document2 pagesBranch Calculation Sample - B31.1a-2008Tam Huynh ThanhNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Long - Guide To Storage Tanks - Part2Document296 pagesLong - Guide To Storage Tanks - Part2Raúl León Medina100% (2)

- Plastic FormingDocument11 pagesPlastic FormingAngeloLorenzoSalvadorTamayoNo ratings yet

- Engineers Handbooks Aci Aisc 17Document311 pagesEngineers Handbooks Aci Aisc 17Tam Huynh ThanhNo ratings yet

- Welding Pipeline HandbookDocument63 pagesWelding Pipeline Handbookchanchai T100% (9)

- Column Base Plates DesignDocument19 pagesColumn Base Plates Designccbserialk80% (5)

- Exp. (3) Determination of Adsorption Isotherm of Acetic Acid On Activated Charcoal.Document21 pagesExp. (3) Determination of Adsorption Isotherm of Acetic Acid On Activated Charcoal.soran najeb100% (1)

- Bolting and WeldingDocument73 pagesBolting and Weldinggerrydimayuga100% (2)

- KPD-TAY Integrated Development Project Phase-II DatasheetDocument2 pagesKPD-TAY Integrated Development Project Phase-II Datasheetm.shehreyar.khanNo ratings yet

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Document11 pagesDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanNo ratings yet

- 0420 - 118T3440 - Cooling WaterDocument2 pages0420 - 118T3440 - Cooling WaterfaisalnadimNo ratings yet

- Crane Operators ManualDocument34 pagesCrane Operators ManualTam Huynh ThanhNo ratings yet

- CCPP Operating BehaviorDocument32 pagesCCPP Operating BehaviorphamquanghieuNo ratings yet

- Technical Bid No 1Document235 pagesTechnical Bid No 1kaushalNo ratings yet

- CB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.DDocument1 pageCB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.Dari wibowoNo ratings yet

- Equipment ListDocument8 pagesEquipment ListLakshman RaoNo ratings yet

- Breakaways enDocument20 pagesBreakaways enAcid HadiNo ratings yet

- Panamax Cargo Hold Cleaning Manual Rev00Document36 pagesPanamax Cargo Hold Cleaning Manual Rev00Cenk ÇobanNo ratings yet

- Astm A530 PDFDocument9 pagesAstm A530 PDFTam Huynh Thanh100% (1)

- Chemical Injection System (Construct)Document2 pagesChemical Injection System (Construct)Raj Mohan100% (1)

- SWS Process Flow DiagramDocument1 pageSWS Process Flow DiagramNKNo ratings yet

- Sov - 1Document1 pageSov - 1biswasdipankar05No ratings yet

- Astm C612Document5 pagesAstm C612GLADYS2714100% (2)

- Dictionar Tehnic General / General Technical Dictionary: Romana/RomanianDocument62 pagesDictionar Tehnic General / General Technical Dictionary: Romana/RomanianAma81100% (17)

- MQ SP M 4033 PDFDocument16 pagesMQ SP M 4033 PDFjaseelNo ratings yet

- Open Rack Vaporizer Mass and Energy BalanceDocument12 pagesOpen Rack Vaporizer Mass and Energy BalanceMuhammad Nanda100% (1)

- Vv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationDocument30 pagesVv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationPhong ĐỗNo ratings yet

- Dodsal Engineering P&ID TransmittalDocument2 pagesDodsal Engineering P&ID TransmittalPriyam KmNo ratings yet

- Et 0000 0 000 04 750Document83 pagesEt 0000 0 000 04 750RenatoNo ratings yet

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDNo ratings yet

- Exp 6 Phase Equilibrium Eutectic SystemDocument6 pagesExp 6 Phase Equilibrium Eutectic SystemNur Fadhilah33% (3)

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Document10 pagesDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182No ratings yet

- NT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemDocument15 pagesNT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemHuynh Thanh TamNo ratings yet

- TurboDocument8 pagesTurboKorichiKarimNo ratings yet

- Rei Vol IiDocument142 pagesRei Vol IiDineshNo ratings yet

- General Perlite Filling ProcedureDocument17 pagesGeneral Perlite Filling ProcedureWilfredo Porco Estrada100% (1)

- De MisterDocument2 pagesDe MisterLaxman G GalipelliNo ratings yet

- Specification for Pressure Vessel MechanicalDocument17 pagesSpecification for Pressure Vessel MechanicalBukhory TajudinNo ratings yet

- HRSG Equipment ListDocument20 pagesHRSG Equipment ListManuel Jesus Perez MelgarNo ratings yet

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083No ratings yet

- Vg216a 109 A 001 - 0 - 0001Document18 pagesVg216a 109 A 001 - 0 - 0001Phuoc PhuNo ratings yet

- VA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Document1 pageVA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Anonymous JtYvKt5XENo ratings yet

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNo ratings yet

- Air, Steam Vent Silencer - Enquiry Data SheetDocument1 pageAir, Steam Vent Silencer - Enquiry Data Sheetkishore1214No ratings yet

- Uong Bi 300 MW Extension Power Plant: OwnerDocument29 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- Technical Documents of The BoilerDocument20 pagesTechnical Documents of The BoilerMatias Mancilla0% (1)

- PP Aaa PP1 145Document13 pagesPP Aaa PP1 145Rabah AmidiNo ratings yet

- Design of Incinerator Plant For Vasai-Virar RegionDocument4 pagesDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRINo ratings yet

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayNo ratings yet

- PZ D CS Pi SP 015 02Document60 pagesPZ D CS Pi SP 015 02epbamdadNo ratings yet

- Skikda Training CDU (Basis - Process.EQ Modi. Interlock)Document48 pagesSkikda Training CDU (Basis - Process.EQ Modi. Interlock)Mohamed OuichaouiNo ratings yet

- Va1 Dec 00100 I M1D Pid 8301 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XENo ratings yet

- Modelling of A Coil Steam Generator For CSP ApplicationsDocument10 pagesModelling of A Coil Steam Generator For CSP ApplicationsAnonymous 3fTYXaW7WNo ratings yet

- PHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow DiagramsDocument54 pagesPHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow Diagramsmashari budiNo ratings yet

- Requisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)Document206 pagesRequisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)ThiruppathirajanNo ratings yet

- Uong Bi 300 MW Extension Power Plant: OwnerDocument32 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- 9112 575 Opr 704 00046 - 01Document16 pages9112 575 Opr 704 00046 - 01Anonymous qT80dF24dNo ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- Eil Spec For Architechture-6-75-0051 - Rev 0Document14 pagesEil Spec For Architechture-6-75-0051 - Rev 0innovativekarthiNo ratings yet

- Paint Specification Package CDocument32 pagesPaint Specification Package CMohammedNo ratings yet

- Safet Valve Data SheetDocument3 pagesSafet Valve Data SheetMathivanan AnbazhaganNo ratings yet

- Standard Procedure For Vacuum Decay Test (Advisory Procedure)Document7 pagesStandard Procedure For Vacuum Decay Test (Advisory Procedure)Jonathan MoralesNo ratings yet

- Compressors How To Achieve High Reliability & Availability (Electronics)Document55 pagesCompressors How To Achieve High Reliability & Availability (Electronics)Anonymous IGtWHoi0No ratings yet

- Vessel Specification SheetDocument2 pagesVessel Specification Sheetangel gabriel perez valdezNo ratings yet

- Iso-Propanol Production Report: Student Name: Course Name: Submission DateDocument18 pagesIso-Propanol Production Report: Student Name: Course Name: Submission DateAmir Javed official100% (1)

- TA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8Document1 pageTA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8mohsen_cumminsNo ratings yet

- Saes A 102Document21 pagesSaes A 102Ziyad ShaathNo ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043Document62 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- STD 118Document29 pagesSTD 118intelashok100% (1)

- D-1100-Pid-004 Cause and Effect ProcessDocument17 pagesD-1100-Pid-004 Cause and Effect ProcessRizky Perdana PutraNo ratings yet

- SMR Hydrogen Generators-Technologies and Producers 2009Document28 pagesSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricNo ratings yet

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- CMPC Pulp: Valve Metallurgy Under RevisionDocument4 pagesCMPC Pulp: Valve Metallurgy Under RevisionCesar Eugenio Sanhueza ValdebenitoNo ratings yet

- 102001-Crn-Pip-Pms-001 04202021Document3 pages102001-Crn-Pip-Pms-001 04202021Karl CaudalNo ratings yet

- B31.3 Process Piping Course - 02 Metallic Pipe & Fitting SelectionDocument44 pagesB31.3 Process Piping Course - 02 Metallic Pipe & Fitting SelectionAnonymous cuOIjrLINo ratings yet

- S-00-ULF-M-46-001-002 A Commented - 14.04.2015Document40 pagesS-00-ULF-M-46-001-002 A Commented - 14.04.2015Tam Huynh ThanhNo ratings yet

- 600 Essential Words For The TOEIC Test PDFDocument187 pages600 Essential Words For The TOEIC Test PDFLeda Maria Backes67% (6)

- How To Tighena Bolt CorectlyDocument14 pagesHow To Tighena Bolt CorectlyTam Huynh ThanhNo ratings yet

- Appendix 1 - Attachment b1 - Book 1 of 1Document21 pagesAppendix 1 - Attachment b1 - Book 1 of 1Tam Huynh ThanhNo ratings yet

- Preparing the Foundation for Steel ErectionDocument25 pagesPreparing the Foundation for Steel ErectionTam Huynh ThanhNo ratings yet

- API 6A 19th Edition 2004 PDFDocument444 pagesAPI 6A 19th Edition 2004 PDFTam Huynh ThanhNo ratings yet

- MD1 0 V 111 02 00001 A - STGDocument31 pagesMD1 0 V 111 02 00001 A - STGTam Huynh ThanhNo ratings yet

- Determination of Carbon in Fly AshDocument5 pagesDetermination of Carbon in Fly AshTam Huynh ThanhNo ratings yet

- ASTM A 672 - 96 Reaproved 2001Document6 pagesASTM A 672 - 96 Reaproved 2001bgdaniel07No ratings yet

- API 6a 19th Edition 2004 - Annex ADocument24 pagesAPI 6a 19th Edition 2004 - Annex ATam Huynh ThanhNo ratings yet

- Installation Manual (350VZM)Document39 pagesInstallation Manual (350VZM)Tam Huynh ThanhNo ratings yet

- Piping Material Specification - Rev. BDocument39 pagesPiping Material Specification - Rev. BTam Huynh ThanhNo ratings yet

- Aws D14.5 PDFDocument157 pagesAws D14.5 PDFTam Huynh ThanhNo ratings yet

- Astm A335 PDFDocument2 pagesAstm A335 PDFTeoTyJayNo ratings yet

- A 0234 01 Conexiones Acero Moderada & Alta Temp PDFDocument8 pagesA 0234 01 Conexiones Acero Moderada & Alta Temp PDFIvan Gonzalez MoralesNo ratings yet

- Emcompress Newsl 051027Document4 pagesEmcompress Newsl 051027Cesar Rodolfo Angulo DelgadoNo ratings yet

- Aluminium Cookware To MinimizeDocument7 pagesAluminium Cookware To MinimizeKeep CalmNo ratings yet

- Contentpage Tafssp 157 17Document77 pagesContentpage Tafssp 157 17prabs20069178No ratings yet

- Titraver Titration Method Method 8214 10-1000 MG/L As Fe Digital TitratorDocument6 pagesTitraver Titration Method Method 8214 10-1000 MG/L As Fe Digital Titratoralexis villalobosNo ratings yet

- Masterseal 622 TdsDocument3 pagesMasterseal 622 TdsMahmoud SaeedNo ratings yet

- AITECH Accredited October 2015Document17 pagesAITECH Accredited October 2015Jiane NavalNo ratings yet

- Geot 2007 57 3 289 PDFDocument13 pagesGeot 2007 57 3 289 PDFDaniel Felipe Ruiz RestrepoNo ratings yet

- PF2579EN00EMDocument2 pagesPF2579EN00EMVinoth KumarNo ratings yet

- Depithers For Efficient Preparation of Sugar Cane Bagasse Fibers in Pulp and Paper IndustryDocument8 pagesDepithers For Efficient Preparation of Sugar Cane Bagasse Fibers in Pulp and Paper IndustryAlphonse SambranoNo ratings yet

- Llautó M38 CuZn37Document2 pagesLlautó M38 CuZn37Josep TanuNo ratings yet

- Beam Design ReportDocument22 pagesBeam Design Reportkwoshaba pidsonNo ratings yet

- HyperLite Data SheetDocument2 pagesHyperLite Data Sheetbiomedical_com_brNo ratings yet

- Naffco-Psv-Pc Application ProcedureDocument5 pagesNaffco-Psv-Pc Application Procedureimad qaissouniNo ratings yet

- PROCESS PLANNING FOR CONTROL JOINT PURCHASE ORDERDocument4 pagesPROCESS PLANNING FOR CONTROL JOINT PURCHASE ORDERVarunn VelNo ratings yet

- Quantitative Techniques in Textile EngineeringDocument26 pagesQuantitative Techniques in Textile EngineeringRAGHUL MNo ratings yet

- 05 - Boat Building MaterialsDocument8 pages05 - Boat Building MaterialsPhong TuanNo ratings yet

- SSC Resistance of QT-900 and QT-1000 Coiled TubingDocument11 pagesSSC Resistance of QT-900 and QT-1000 Coiled TubingSeçkin ÖztelNo ratings yet

- Aisi 9254 - Spring SteelDocument2 pagesAisi 9254 - Spring SteelSergio100% (1)

- Tle 6 (Industrial Arts) Week 8 Day 2Document3 pagesTle 6 (Industrial Arts) Week 8 Day 2Krisna HundosNo ratings yet

- Umc Technical SpecsDocument3 pagesUmc Technical SpecsMunir AhmadNo ratings yet

- Clinical Success of Zirconia in Dental Applications: KeywordsDocument5 pagesClinical Success of Zirconia in Dental Applications: KeywordsJulio TorresNo ratings yet

- 18474IAT - VHB Tapes - US A4 SIZE - BroDocument4 pages18474IAT - VHB Tapes - US A4 SIZE - BroGeorge OnashsNo ratings yet

- Awareness of Domestic Solid Waste ManagementDocument6 pagesAwareness of Domestic Solid Waste ManagementJenemarNo ratings yet