Professional Documents

Culture Documents

Risk Assessment For Installation of Cooling Towers

Uploaded by

Girithar M SundaramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For Installation of Cooling Towers

Uploaded by

Girithar M SundaramCopyright:

Available Formats

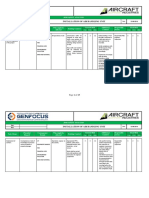

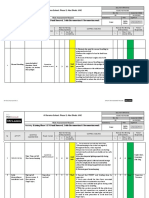

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 1 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

· TBT/DSTI shall be conducted by the

foreman/

· Unauthorized, untrained · Cuts safety officer prior to work commencement Low

1. Prepare work area workers · Abrasions 2 A L · Task specific safety training to be provided (ALARP)

· Authorized personnel to undertake the job

· Daily safety inspection should be carried

and

eliminate the hazard.

• Prior to start obtain all relevant approval from

traffic department in connection to the use of

road.

• Collision with vehicles/ • Trained and experienced operator/ driver and

fixed installations. • Fatality banks men shall be appointed for the activity. Low

Traffic and road • Poor identification • Property damage 4 B M • Public vehicles and transport to be restrict to (ALARP)

2. management • Unauthorized/ untrained • Fracture enter the work area and proper alternative way

operator/ driver, banks men • Penalty/ to be provided.

• Poor access for vehicle compensation • Flagman to be positioned to the areas wherever

• Public movement required.

• Close supervision to be done at all times.

• Restricted to unauthorized and public to enter

the area.

• Warning sign boards to be placed and area to

be well barricaded.

• High visibility vest to be provided to flagman

to increase visibility.

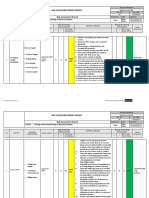

• Unauthorized, Untrained •Pre check to be carried out by the operator prior

Workers • Fatality to start the work to ensure that no hydraulic

Unloading and shifting • Lifting failure. • Fractures leaks, or other visible damages seen. M

3. of cooling tower unit • Unsafe lifting. • Property damage 4 C H • Ensure the crane, forklift, lifting equipment’s, (ALARP)

and accessories with • Swinging of material • Injury to personal lifting tools and tackles shall have valid third

using crane or forklift • Damaged sling/wire rope or • Sprain and strain party certificates and the operators has valid

a chain • Crush license and approved 3rd party certificate.

• Poor maintenance of vehicle • Cuts • Trained and third party certified riggers shall be

• Over turn provided.

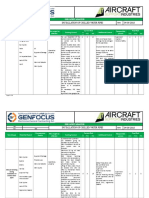

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 2 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Over load • Unit offloading and shifting procedure shall

• Poor communication be followed by as per manufacturer

• Poor lighting recommendation.

• Spreader bar shall be used for lifting of cooling

tower as recommended by manufacturer.

• Colour coded system shall be implemented to

all lifting gears as per the month.

• Use taglines to control the loads.

• The crane must be stopped when the wind

speed exceeds 38km/hr.

• Never exceed the SWL marked on the crane.

• All loads shall be secured prior to lifting.

·Vehicle not to be left unattended at site (ie,to

be switch off mode if required and keys

removed)

·Vehicle routes kept free of obstructions (with

spillages being cleaned up promptly)

• Ensure that there is no obstruction around the

lifting radius.

• The crane and trucks inspection shall be

conducted periodically and record maintained.

• Weather conditions shall be forecasted prior to

start of lifting of chiller units.

• Adequate lighting shall be provided for the

work location.

• Barrication and warning signs shall be

provided for the area where lifting operation is

carried out restrict to unauthorized entry.

• Appropriate PPE shall be worn (Reflective

vest, cover all, helmet, shoe.)

Installation of cooling • Untrained, unauthorized • Cut and abrasion · Authorized personnel to undertake the job Low

4. tower unit and Workers • Back Injuries 3 C M ∙Work location shall be inspected by (ALARP)

accessories • Sharp edges • Fatigue concerned supervisor / foreman.

• Unsafe posture • Fractures

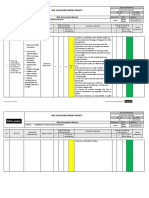

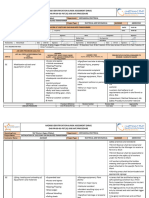

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 3 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Crush • Musculoskeletal • Close supervision to be done at all times

• Slip, trip and fall Injuries • Materials shall not be kept in walkways and to

the edges.

· Deploy enough number of personnel for

material lifting shall be appointed to the task

depending upon the distance.

• Manufacturer recommendation shall be

followed during the installation

•Proper communication to be maintained

between the workers while doing the

installation

• Maintain a good housekeeping to prevent from

slip, trip, and fall hazards.

• Emergency procedure shall be briefed to all

personnel prior to start the activity.

• Emergency evacuation plan shall be readily

available according to site condition and briefed

to the workforce prior to start.

• Safe and obstruction free access for working

personnel’s shall be maintained all the time

during the activity.

• Trained first aider, fire warden and emergency

vehicle to be available at the site during the

activity.

• Emergency contact numbers shall be displayed

at work location for easy communication

• PPE to be worn at all times( Gloves, goggles,

mask, helmet, shoe, vest, overall)

∙ Unauthorized, untrained • Crush · If the material is too heavy, use hydraulic

workers · Cut and abrasion trolley to shift the material. Low

5. Stacking and Storing · Material fall from height · Damage to 3 B M · All materials shall be stored below 2 meters (ALARP)

• Improper stacking property height.

• Collapse of materials

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 4 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• No materials shall be stored at work place, only

required quantity to be taken for the job.

• Personnel protective equipment must be worn

at all time during the activity. (Helmet, shoe,

vest, coverall, gloves, goggles, mask.)

·Use mechanical aids such as trolley etc.

· Any lifting tasks shall be carried out by

persons those physically capable to do so.

· Incorrect lifting of loads · Back Injuries · Deploy enough number of personnel for

· Sharp edges. · Cut to finger lifting

6. Manual Handling · Placing the object while · Strain depending upon the type of load to be lifted. Low

fingers underneath. • Musculoskeletal 3 C M • Load not to be lifted above your shoulder (ALARP)

• Slip/trip/fall ( same level ) Injuries height

• Unsafe posture • Keep your fingers away from pinch point

while placing the load.

• Materials shall not be carried through

Pedestrian access.

• Area shall be illuminated with adequate

lighting.

· Appropriate personal protective equipment’s

shall be used while manual handling of

materials and loads.

• Openings in the roof must be securely covered

or guarded.

• Unauthorized/ • Keep walkways free of obstacles, tools and

Untrained workers • Fatality equipment Low

7. Working on roofs • Slip, trip and fall • Fracture 4 B M • Trained rigger shall be appointed to control the (ALARP)

• Material Fall from • Sprain and strain lifting operation at roof.

height • Rigger to be observe and note other activities

• Abnormal weather within the crane operating area.

• Poor communication • Rigger shall be given alert by whistle that no

person are below the load whilst lifting is in

progress.

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 5 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Covering or guarding may be removed to allow

the passage of men or material, it must be

replaced immediately after that operation.

• Restricted to work on roof in abnormal weather

condition. ( ie., wet, windy and hot )

· Close supervision shall be done at all times.

• Area shall be barricaded and provide signage

• Appropriate PPE shall be worn at all times.

• Use right tools for the job

• Defective tools should not be issued or used

to perform the task, to be checked by store

• Slip, trip and fall keeper

Use of Hand tools • Damaged / worn out hand • Fatigue • Don’t extend the spanner by using a pipe as Low

8. ( Hack saw, torch tools • Trigger finger 3 C M an extension bar (ALARP)

wrench, hammer ) • Flying objects • Cuts and abrasions •Hand tools shall be free from oil, grease & etc.

∙ Mushroom Heads • Chisel’s head shall have safety cap to avoid

• Using incorrect type finger injury.

• Never use a file as a lever

• Never use a screw driver as a chisel

• Use eye/ face protection when there is flying

materials hazard, wear gloves while required to

protect the hands

• Defective equipment Hearing losses • PTW shall be applied and obtained prior to

Electricity Eye injury start, If spark producing activity is performed.

9. Use of power tools Improper use of Crushing • Operators must be having their training card.

(Grinder, Pipe cutter, equipment Back injury · Defective tools should not be issued or used to M

drill ) Poor maintenance Burns 3 C M perform a task. (ALARP)

Untrained workers Electrocution • Monthly inspection should be carried out by the

Flying object Ringing in the electrician and record to be kept at the store.

Noise and vibration ear / Deafness · All portable power tools should be fitted with

Fire adequate fuse protection either in the tool body

Dust or in its electrical plug.

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 6 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Don’t lay the cables around the access way, it

should be routed properly.

• Industrial distribution board and socket only

shall be used at site.

• No joints shall be made in electrical cable.

• Cable hangers shall be used to avoid the

direct contact of power tools cable with the

scaffolding members.

• Electrical connection shall be routed through

ELCB only ( Eg. 30ma )

· Tools should be stored and maintained in

good working condition.

· Appropriate PPE Should be use ( Goggles,

Mask, Ear plug, Gloves, Shoe, Helmet, Overall,

Vest )

• PTW to be applied and obtained prior to start,

If spark producing activity is performed

• Certified person only undertake the welding

job.

• Fire •Electric Shock • Calibrated gauges only to be used.

• Untrained, Unauthorized •Burns • All Flammable /combustible materials should Low

10. Welding/ brazing work Worker •Skin Effect 4 C H be removed from the area where welding & gas (ALARP)

• Improper lighting •Eye Injury cutting operations are carried out.

• Inadequate ventilation •Property damage • Fire blankets should be used to contain sparks

and molten metal’s within the floor and should

not be allowed to fall from height.

• Close supervision to be done at all times.

•Flash back arrestor to be installed for the

cylinder

• Gauges of cylinders to be functional to ensure

the pressure variation inside the cylinder.

• Hoses should be of approved type and should

be free and hose checklist to be maintained.

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 7 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

•Empty cylinder to be identified and stored

separately.

•Fire extinguishers to be made available.

∙Area to be restricted to unauthorized personnel.

• Adequate lighting and ventilation to be

Provided.

• Warning signs and boards should be provided

And area to be well barricaded

·Appropriate PPE Should use ( Face shield,

Dust

mask, Goggles, Gloves, Shoe, Helmet, Overall,

Vest )

• Visual inspection should be carried out before

use (i.e., hand rails, toe board, on the platform

and any opening are there).

• Only trained scaffolders shall be involved in

• Person/ material falling from • Sprain and strain erection & dismantling activities. Low

height • Fracture 3 C M • The ladder should extend minimum one meter (ALARP)

11. Use of ladder/ scaffold • Over reaching • Spinal cord damage from the top for safe movement

• Over loading • Musculoskeletal • Do not erect in slippery, uneven surface

• Obstructing the access way Injury • Should be set up with a 4 vertical to 1

• Slippery or uneven surface • Fatality horizontal slope ( 4:1 )

• Overhead structure and cable • Step ladder must fully open and lock the

• Untrained, unauthorized devices as per manufacturer recommendations.

Workers • Do not work from the top of two rungs of step

• Collapse of scaffold ladders.

• Remember the 3 point contact.

• Ladder shall be used for short duration works

Only limited to 15 min.

• Colour code system shall be implemented.

• Do not stack materials on to the scaffold.

• Keep walkways free of obstacles, tools and

equipment.

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 8 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Work at height is restricted during adverse

weather condition.

• Adequate lighting shall be provided while

working at night.

• Safety harness shall be used above 2mtr height

and anchored in above shoulder height at all

time.

∙ Dehydration ∙ Employees shall be trained about heat Low

12. Working in hot ∙ Heat Stress · Sunburn 2 B M stress symptoms & first aid measures. (ALARP)

weather · Skin Cancer · Avoid highly physical tasks during the hottest

part of the day.

· Isotonic drinks to be provided.

• Provide sufficient rest breaks based on the

humidity & temperature conditions

• Heat stress management plan shall developed

and implement during the activity.

· Work notification to be applied and obtained

∙ Poor illumination ∙ Fatality prior to start the night work from contractor. Low

13. While working at night · Slip/trip/fall • Cuts 3 B M · Proper illumination to be provided (ALARP)

shift · light post to be secured from fall

· Proper cable management system to be

Followed

· All materials to be staged in proper manner

without obstacles

· General housekeeping, Remove all surface,

· Poor housekeeping unwanted waste materials from the building Low

14. Work Completion · Slip/trip/fall · Fire 2 A L · All necessary precautions will be adopted to (ALARP)

prevent fire

PROJECT NAME

Ref No:

ACTIVITY– INSTALLATION OF COOLING TOWER Rev.No:0

Page 9 of 9

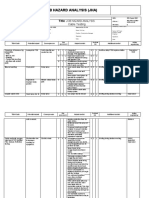

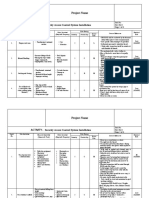

RISK MATRIX

Probability

A B C D E

Improbable Remote Occasional

Probable Frequent

Severity People Assets Environment Reputation 1 in 100,000 1 in 10,000 1 in 1000

1 in 100 years 1 in 10 years

Years Years years

Multiple

fatalities or

Extensive International

5-Catatrophic permanent Massive effect

damage impact

total

disabilities

Single

fatalities or

4-Severe permanent

Major

Major effect National impact

High Risk

damage

total

disabilities

Major injury

Local Considerable

Medium Risk

3-critical or health Localised effect

effects

damage impact (ALARP)

Minor

Minor

2-Marginal injury or Minor effect Minor impact

damage

health effects

Slight injury

Slight

1-Negligble or health

Damage

Slight effect Slight impact Low Risk

effects

3-E

HIGH 4-C,D,E

5-B,C,D,E

1-D,E

2-B,C,D,E

3-A,B,C,D

MEDIUM 4-A,B

5-A

LOW 1-A,B,C

2A

You might also like

- Behavior Intervention MenuDocument56 pagesBehavior Intervention Menuapi-479527084100% (4)

- Heavy Lifting Risk AssessmentsDocument9 pagesHeavy Lifting Risk AssessmentsSayed Darwish100% (6)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Installation of Air Handling UnitDocument15 pagesInstallation of Air Handling UnitAnandu Ashokan100% (2)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment Work at HeightDocument3 pagesRisk Assessment Work at HeightSathi sh0% (1)

- Replacement of Flowmeter - Risk AssessmentDocument3 pagesReplacement of Flowmeter - Risk Assessmentanishdev660% (5)

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 pagesHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Risk Assessment For MEP Isolation WorksDocument8 pagesRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Risk Assessment For Installation of Air Handling UnitsDocument19 pagesRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- Risk Assessment For CABLE TRAYDocument11 pagesRisk Assessment For CABLE TRAYAnandu Ashokan86% (14)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (2)

- Man Machine InterfaceDocument22 pagesMan Machine Interfaceamdarrif3723100% (1)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- Risk Assessment For Air BlowingDocument8 pagesRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- RA For Man Lift OperationDocument6 pagesRA For Man Lift Operationalla malikNo ratings yet

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- AFA HIRA - Electrical Control PanelDocument30 pagesAFA HIRA - Electrical Control PaneljavedNo ratings yet

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (2)

- Chiller Plant RADocument2 pagesChiller Plant RAarifzakir67% (9)

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroNo ratings yet

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- JSA GC-5 Mobile ScaffoldingDocument6 pagesJSA GC-5 Mobile Scaffoldinggrande100% (2)

- RISK ASSES-106-Erection of Steel Structure BuildinDocument4 pagesRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Document12 pagesRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- Charles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)Document441 pagesCharles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)joan82% (17)

- 005 Risk Assessment T&C Fire Suppression SystemDocument10 pages005 Risk Assessment T&C Fire Suppression SystemJohn RazaNo ratings yet

- The Other Twelve Part 1Document5 pagesThe Other Twelve Part 1vv380100% (2)

- 1en 02 PDFDocument96 pages1en 02 PDFAndrey100% (2)

- Working at Height Risk AssessmentDocument7 pagesWorking at Height Risk AssessmentAshish100% (3)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentNii Ashiii100% (1)

- TRA-Installation of Cathodic ProtectionDocument9 pagesTRA-Installation of Cathodic ProtectionGilbert Gill100% (4)

- Risk Assessment (Electric Works)Document4 pagesRisk Assessment (Electric Works)Raza Muhammad Soomro100% (3)

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Risk Assessment For Tank BaseDocument5 pagesRisk Assessment For Tank Baseramod100% (2)

- Jsa - Earthing SystemDocument4 pagesJsa - Earthing SystemAkash Shukla75% (4)

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Risk Assessment For Water Heaters InstallationDocument6 pagesRisk Assessment For Water Heaters Installationfidgety100% (1)

- HIRA & EAI For Installation of LT Supply StationDocument12 pagesHIRA & EAI For Installation of LT Supply StationDEBASISH KHADANGA100% (1)

- Installation of Chilled Water PipesDocument6 pagesInstallation of Chilled Water PipesAnandu Ashokan0% (1)

- Risk Assessment For Piping ErectionDocument6 pagesRisk Assessment For Piping ErectionAzhar MushtaqNo ratings yet

- Risk Assessment - FM 200Document5 pagesRisk Assessment - FM 200Nangyal KhanNo ratings yet

- Data Mining in IoTDocument29 pagesData Mining in IoTRohit Mukherjee100% (1)

- 01 HIRA Lifting & RiggingDocument3 pages01 HIRA Lifting & RiggingMudhyn MI75% (4)

- HIRA For Laying of PipelineDocument33 pagesHIRA For Laying of PipelineVineet Agrawal100% (4)

- Operator's ManualDocument110 pagesOperator's ManualAdam0% (1)

- BIOLOGY Notes PDFDocument5 pagesBIOLOGY Notes PDFGirithar M SundaramNo ratings yet

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNo ratings yet

- JSA For Hydro Test Activites (Generic)Document4 pagesJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- Risk Assessment For Erection of Boiler Steam DrumDocument4 pagesRisk Assessment For Erection of Boiler Steam DrumQuynh Tao100% (1)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- Confined Spaces Risk Assessment TemplateDocument1 pageConfined Spaces Risk Assessment Templatemkashkooli_scribdNo ratings yet

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanNo ratings yet

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- Wall Painting Risk AssesmentDocument3 pagesWall Painting Risk AssesmentJacob ChirayilNo ratings yet

- Risk Assessment For Structural Cabling System Testing and CommissioningDocument5 pagesRisk Assessment For Structural Cabling System Testing and CommissioningInfas YahyaNo ratings yet

- OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesDocument11 pagesOHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesRAI AHTESHAM HaiderNo ratings yet

- Risk Assessment For Access Control System InstallationDocument6 pagesRisk Assessment For Access Control System InstallationRommel Espinosa ParasNo ratings yet

- Patron Pelele Lino Rayas PDFDocument9 pagesPatron Pelele Lino Rayas PDFGirithar M SundaramNo ratings yet

- JANUARY - TNPSC Current Affairs - English - 2017 - WWW - Tnpsc.academy PDFDocument37 pagesJANUARY - TNPSC Current Affairs - English - 2017 - WWW - Tnpsc.academy PDFGirithar M SundaramNo ratings yet

- DECEMBER - TNPSC Current Affairs - English - 2016 - WWW - Tnpsc.academy PDFDocument44 pagesDECEMBER - TNPSC Current Affairs - English - 2016 - WWW - Tnpsc.academy PDFGirithar M SundaramNo ratings yet

- AUGUST - TNPSC Current Affairs in English - 2017 - WWW - Tnpsc.academyDocument47 pagesAUGUST - TNPSC Current Affairs in English - 2017 - WWW - Tnpsc.academyTnpsc TargetNo ratings yet

- APRIL - TNPSC Current Affairs 2017Document54 pagesAPRIL - TNPSC Current Affairs 2017Raja SekarNo ratings yet

- JUNE - TNPSC Current Affairs in English - 2017 - WWW - Tnpsc.academyDocument66 pagesJUNE - TNPSC Current Affairs in English - 2017 - WWW - Tnpsc.academyjeyainbox2000No ratings yet

- Key Changes in SharePoint Designer 2013 - 4sysopsDocument21 pagesKey Changes in SharePoint Designer 2013 - 4sysopsGirithar M SundaramNo ratings yet

- Modern India PDFDocument16 pagesModern India PDFSE Works-IINo ratings yet

- LTA Reimbursement PDFDocument1 pageLTA Reimbursement PDFGirithar M SundaramNo ratings yet

- List of Airports in IndiaDocument10 pagesList of Airports in IndiasagrvNo ratings yet

- List of Governors General & Viceroys of India PDF For UPSC, Banking & SSC ExamsDocument7 pagesList of Governors General & Viceroys of India PDF For UPSC, Banking & SSC ExamsGirithar M SundaramNo ratings yet

- Top 6 New Features For Designers in SharePoint 2013 Randy DrisgillDocument12 pagesTop 6 New Features For Designers in SharePoint 2013 Randy DrisgillGirithar M SundaramNo ratings yet

- Create A Community - Office SupportDocument9 pagesCreate A Community - Office SupportGirithar M SundaramNo ratings yet

- Collaboration Services - SharePoint OverviewDocument4 pagesCollaboration Services - SharePoint OverviewGirithar M SundaramNo ratings yet

- Overview of Business Connectivity Services in SharePoint 2013Document17 pagesOverview of Business Connectivity Services in SharePoint 2013Girithar M SundaramNo ratings yet

- New Features in SharePoint Designer 2013 - Things To ShareDocument15 pagesNew Features in SharePoint Designer 2013 - Things To ShareGirithar M SundaramNo ratings yet

- Business Connectivity Services in SharePoint 2013Document3 pagesBusiness Connectivity Services in SharePoint 2013Girithar M SundaramNo ratings yet

- A Guide To Quick SharePoint 2013 Branding - BLKSTHLDocument25 pagesA Guide To Quick SharePoint 2013 Branding - BLKSTHLGirithar M SundaramNo ratings yet

- 8 Best Reasons To Migrate To SharePoint 2013 & Office 365 - SharegateDocument12 pages8 Best Reasons To Migrate To SharePoint 2013 & Office 365 - SharegateGirithar M SundaramNo ratings yet

- Social and Collaboration Features in SharePoint 2013Document2 pagesSocial and Collaboration Features in SharePoint 2013Girithar M SundaramNo ratings yet

- Things To Be LearnedDocument2 pagesThings To Be LearnedGirithar M SundaramNo ratings yet

- The Community Portal Template Versus The Community Site Template - Overview of SharePoint 2013's Social Computing Capabilities - InformITDocument2 pagesThe Community Portal Template Versus The Community Site Template - Overview of SharePoint 2013's Social Computing Capabilities - InformITGirithar M SundaramNo ratings yet

- Overview of Communities in SharePoint Server 2013Document6 pagesOverview of Communities in SharePoint Server 2013Girithar M SundaramNo ratings yet

- Changes From SharePoint 2010 To SharePoint 2013Document19 pagesChanges From SharePoint 2010 To SharePoint 2013Girithar M SundaramNo ratings yet

- What's Changed in SharePoint Designer 2013Document3 pagesWhat's Changed in SharePoint Designer 2013Girithar M SundaramNo ratings yet

- Ways To Brand SharePoint 2013 Sites - Blog - Cardinal SolutionsDocument11 pagesWays To Brand SharePoint 2013 Sites - Blog - Cardinal SolutionsGirithar M SundaramNo ratings yet

- What's New For Business Connectivity Services in SharePoint 2013Document7 pagesWhat's New For Business Connectivity Services in SharePoint 2013Girithar M SundaramNo ratings yet

- What Is A SharePoint 2013 Community Site - NothingButSharePointDocument15 pagesWhat Is A SharePoint 2013 Community Site - NothingButSharePointGirithar M SundaramNo ratings yet

- What's Changed in SharePoint Designer 2013nnDocument3 pagesWhat's Changed in SharePoint Designer 2013nnGirithar M SundaramNo ratings yet

- 3DS 2017 GEO GEMS Brochure A4 WEBDocument4 pages3DS 2017 GEO GEMS Brochure A4 WEBlazarpaladinNo ratings yet

- Dress Code19sepDocument36 pagesDress Code19sepapi-100323454No ratings yet

- The Limits of The Sectarian Narrative in YemenDocument19 pagesThe Limits of The Sectarian Narrative in Yemenهادي قبيسيNo ratings yet

- Lecture BouffonDocument1 pageLecture BouffonCarlos Enrique GuerraNo ratings yet

- Lab 1Document51 pagesLab 1aliNo ratings yet

- PID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDocument7 pagesPID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDenisNo ratings yet

- Bullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceDocument174 pagesBullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceAlexandre AndréNo ratings yet

- 1 AlarmvalveDocument9 pages1 AlarmvalveAnandNo ratings yet

- CHAPTER I Lesson II Seven Environmental PrinciplesDocument17 pagesCHAPTER I Lesson II Seven Environmental PrinciplesTrixie jade DumotNo ratings yet

- 2nd Second Sun of Advent (B)Document4 pages2nd Second Sun of Advent (B)Max PolakNo ratings yet

- Chapter 9Document28 pagesChapter 9Aniket BatraNo ratings yet

- ENSC1001 Unit Outline 2014Document12 pagesENSC1001 Unit Outline 2014TheColonel999No ratings yet

- Effects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionDocument5 pagesEffects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionJasmine EffendiNo ratings yet

- Random Questions From Various IIM InterviewsDocument4 pagesRandom Questions From Various IIM InterviewsPrachi GuptaNo ratings yet

- 한국항만 (영문)Document38 pages한국항만 (영문)hiyeonNo ratings yet

- LP Pe 3Q - ShaynevillafuerteDocument3 pagesLP Pe 3Q - ShaynevillafuerteMa. Shayne Rose VillafuerteNo ratings yet

- Oracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JDocument10 pagesOracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JLuis YañezNo ratings yet

- Gandhi and The Non-Cooperation MovementDocument6 pagesGandhi and The Non-Cooperation MovementAliya KhanNo ratings yet

- Krishna TejaDocument71 pagesKrishna TejaHimanshu GaurNo ratings yet

- DADTCO Presentation PDFDocument34 pagesDADTCO Presentation PDFIngeniería Industrias Alimentarias Itsm100% (1)

- X Lube Bushes PDFDocument8 pagesX Lube Bushes PDFDavid TurnerNo ratings yet

- University of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSDocument3 pagesUniversity of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSPhilip Pearce-PearsonNo ratings yet

- Chromatographic Separation PDFDocument7 pagesChromatographic Separation PDFNicolle CletoNo ratings yet

- NamalDocument5 pagesNamalAyusnab KarkiNo ratings yet