Professional Documents

Culture Documents

Job Safety Analysis Identifying Hazards Checklist: SN Hazards YES NO N/A 1 2 3 4 5 6 7

Uploaded by

abdulgafoor540 ratings0% found this document useful (0 votes)

29 views3 pagesq

Original Title

q

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentq

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views3 pagesJob Safety Analysis Identifying Hazards Checklist: SN Hazards YES NO N/A 1 2 3 4 5 6 7

Uploaded by

abdulgafoor54q

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

JOB SAFETY ANALYSIS

IDENTIFYING HAZARDS CHECKLIST

SN HAZARDS YES NO N/A

Is there a danger of striking against, being struck by, or otherwise ✔

1

making harmful contact with an object?

2 Can the employee be caught in, by, or between objects? ✔

Is there a potential for a slip or trip? Can the employee fall on the same ✔

3

level or to another?

4 Can pushing, pulling, lifting, bending, or twisting cause strain? ✔

Is the area hazardous to safety or health? For example, are there ✔

5

concentrations of toxic gas, vapor, mist, fume, dust, heat, or radiation?

Is it possible for a person to come in contact with any moving piece of ✔

6

machine or equipment?

Are rotating equipment exposed where they can strike at or snag a ✔

7

worker’s clothing?

Is it possible to be drawn into the running nip point between two moving ✔

8 parts, such as belt and sheave, chain and sprocket, pressure rolls, rack

and gear, or gear train?

Do machines or equipment have reciprocating movement or any ✔

9 motion where workers can be caught on or between a moving part and

a fixed object?

Is it possible for a worker’s hands or arms to make contact with moving ✔

10 parts at the point of operation where milling, shaping, punching,

shearing, bending, grinding, or other work is being done?

Is it possible for material to be kicked back or ejected from the point of ✔

11

operation, injuring someone nearby?

Are machine controls safeguarded to prevent unintended or ✔

12

inadvertent operation?

Are machine controls located to provide immediate access in the event ✔

13

of an emergency?

14 Do machines vibrate or move while in operation? ✔

Is it possible for parts to become loose during operation, injuring ✔

15

operators or others?

Are guards positioned or adjusted to correspond with the permissible ✔

16

openings?

Is it possible for workers to bypass the guard, thereby making it ✔

17

ineffective?

Do machines, equipment, and appurtenances receive regular ✔

18

maintenance?

Are machines placed so operators have sufficient room to safely work ✔

19

with no exposure to aisle traffic?

Is there sufficient room to accommodate incoming and finished work ✔

20

as well as scrap that may be generated?

Are the materials handling methods adequate for the work in process ✔

21

and the tooling associated with it?

If tools, jigs, and other work fixtures are required, are they stored ✔

22

conveniently, where they will not interfere with the work?

Is the work area well illuminated with specific point-of-operation lighting ✔

23

where necessary?

Is ventilation adequate, particularly for those operations that create ✔

24

dusts, mists, vapors, and gases?

25 Is the operator using personal protective equipment? ✔

Is housekeeping satisfactory with no debris or tripping hazards or spills ✔

26

on the floor?

SHEM-P-08.10.09-B

You might also like

- Machine Guarding Safety ChecklistDocument2 pagesMachine Guarding Safety ChecklistSirley Sanmartín RestrepoNo ratings yet

- RDC Fall Protection SystemDocument27 pagesRDC Fall Protection SystemChristian Eric UntalanNo ratings yet

- Draft Report SRIKAR LABS Annual Safety Review & Safety AuditDocument16 pagesDraft Report SRIKAR LABS Annual Safety Review & Safety AuditL JayanthiNo ratings yet

- Fire Safety Training Dos and Don'tsDocument11 pagesFire Safety Training Dos and Don'tssweety1188No ratings yet

- Rental Manbasket Meets Safety StandardsDocument2 pagesRental Manbasket Meets Safety StandardsJuanV VeraNo ratings yet

- Manbasket Unsafe SIRDocument4 pagesManbasket Unsafe SIRRagalagNo ratings yet

- BSS Guide Chap7Document38 pagesBSS Guide Chap7handoyo_eko20017573No ratings yet

- Spill CleanupDocument1 pageSpill CleanuptomiNo ratings yet

- RIGGING SAFETY TrainingDocument43 pagesRIGGING SAFETY TrainingBG REDDYNo ratings yet

- Ballarpur Industries Limited Unit - A.P.Rayons, Kamalapuram, Warangal, (AP)Document18 pagesBallarpur Industries Limited Unit - A.P.Rayons, Kamalapuram, Warangal, (AP)monish147852No ratings yet

- Check List (Pre Entry) For Gas Cutting SetDocument2 pagesCheck List (Pre Entry) For Gas Cutting SetAli KaziNo ratings yet

- Fire Extinguisher Training: Health, Safety & Environment DeptDocument33 pagesFire Extinguisher Training: Health, Safety & Environment DeptRosano D. ManamtamNo ratings yet

- Control of Hazardous EnergiesDocument15 pagesControl of Hazardous EnergiesMika PelagioNo ratings yet

- Scaffolding Safety Procedure for Sulphate Removal PlantDocument32 pagesScaffolding Safety Procedure for Sulphate Removal PlantOws AnishNo ratings yet

- Water Tanker 1Document1 pageWater Tanker 1Arjun SatheesanNo ratings yet

- JSA STEEL ERECTIONDocument4 pagesJSA STEEL ERECTIONCherry BetonioNo ratings yet

- Checklist Fire PDFDocument1 pageChecklist Fire PDFMadan TiwariNo ratings yet

- SFPC B.tech III Year 2021Document328 pagesSFPC B.tech III Year 2021ruban sNo ratings yet

- Safe Journey Management WorkshopDocument28 pagesSafe Journey Management WorkshopRamadan KareemNo ratings yet

- National Safety Council, India: Overview of Indian Standard and Statutes Related To Occupational Health & Safety AuditDocument26 pagesNational Safety Council, India: Overview of Indian Standard and Statutes Related To Occupational Health & Safety AuditGyanendra Narayan NayakNo ratings yet

- Basic Safety Orientation TrainingDocument57 pagesBasic Safety Orientation Trainingrambabukomati3179No ratings yet

- JUST Safety Audit ReportDocument3 pagesJUST Safety Audit ReportMohammad LiftawiNo ratings yet

- Spill Containment SOPDocument2 pagesSpill Containment SOPW. GayuhNo ratings yet

- Safety Abrasive WheelDocument32 pagesSafety Abrasive WheelMohamed Hichem GuesmiNo ratings yet

- Ambulance ChecklistDocument43 pagesAmbulance ChecklistRatnaSuryatiNo ratings yet

- Eot TrainingDocument16 pagesEot TrainingShariqNo ratings yet

- Safety Induction: Presented By: Rizky RamadhanDocument10 pagesSafety Induction: Presented By: Rizky RamadhanMuhammad Rizky RamadhanNo ratings yet

- Integrated HSE Management and Permit To WorkDocument75 pagesIntegrated HSE Management and Permit To WorkKamakshi JoshiNo ratings yet

- Mr. R. M. Desai NOCILDocument50 pagesMr. R. M. Desai NOCILhariNo ratings yet

- Daily HSE observations at IOCL Barauni siteDocument2 pagesDaily HSE observations at IOCL Barauni siteSUDHIR KUMARNo ratings yet

- Ladder Safety Check ListDocument1 pageLadder Safety Check ListjoesuhreNo ratings yet

- EHS PlanDocument37 pagesEHS PlanVishal TiwariNo ratings yet

- Sharing of Industry Best Practice - Straits ConstructionDocument79 pagesSharing of Industry Best Practice - Straits Construction88sanNo ratings yet

- Heat Stress Training & CampaignDocument11 pagesHeat Stress Training & CampaigndammyNo ratings yet

- Hot Works Permit: HSE Manual Ref. No.: HSEM GF04039 Location: Site ID: Sub Contractor Details (If Any) : DateDocument2 pagesHot Works Permit: HSE Manual Ref. No.: HSEM GF04039 Location: Site ID: Sub Contractor Details (If Any) : DateTonmay MajumderNo ratings yet

- Saline Water Desalination Electrical Work ChecklistDocument1 pageSaline Water Desalination Electrical Work ChecklistBRC HSE Dept.No ratings yet

- Al Asab Hse Presentation June-14Document15 pagesAl Asab Hse Presentation June-14Sri DharanNo ratings yet

- M TechDocument24 pagesM Techdeep1625No ratings yet

- 49 Roofing safety-JOB PROCEDUREDocument2 pages49 Roofing safety-JOB PROCEDUREmalimsaidi_160040895No ratings yet

- 30-Hour Construction Safetey - Updated (2017 - 09 - 04 12 - 51 - 06 UTC)Document393 pages30-Hour Construction Safetey - Updated (2017 - 09 - 04 12 - 51 - 06 UTC)nuhNo ratings yet

- Gas Welding ComponentsDocument57 pagesGas Welding ComponentsJoseph Magbanua Dato-onNo ratings yet

- Basics of FireDocument2 pagesBasics of FireMr. XNo ratings yet

- Presentation On Safety For E1 E2 PDFDocument84 pagesPresentation On Safety For E1 E2 PDFdalalanup90No ratings yet

- Machine Guarding BasicsDocument30 pagesMachine Guarding BasicsAjay meena Ajay meenaNo ratings yet

- Defensive DrivingDocument26 pagesDefensive DrivingMarc Louie S. SanchezNo ratings yet

- Hse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationDocument61 pagesHse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationJinadNo ratings yet

- Safety Park BungeDocument37 pagesSafety Park BungeRavi Sankar VenkatesanNo ratings yet

- Job Hazard AnalysisDocument19 pagesJob Hazard AnalysisCharlyn FloresNo ratings yet

- Gail: Safety Culture ChangeDocument9 pagesGail: Safety Culture ChangeShreyansi Singhal0% (1)

- Forklift Inspection StsDocument30 pagesForklift Inspection Stsvineeth kNo ratings yet

- Ppe Method StatementDocument1 pagePpe Method StatementNaga RajanNo ratings yet

- Machineguardingsoptech 12Document1 pageMachineguardingsoptech 12api-200253170No ratings yet

- CGS Weekly Safety & Health Inspection ReportDocument1 pageCGS Weekly Safety & Health Inspection Reportတိုး ေဝ ေအာင္No ratings yet

- ARC Flash / Blast SafetyDocument89 pagesARC Flash / Blast SafetyRobert LopezNo ratings yet

- The Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8TDocument3 pagesThe Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8Tpyrolysisoil100% (1)

- Safety Audit Plan and ProceduresDocument3 pagesSafety Audit Plan and ProceduresDwitikrushna RoutNo ratings yet

- Machine Safety in ConstructionDocument27 pagesMachine Safety in ConstructionSawyu Nandar100% (1)

- Safety Resume Without Certificate PDFDocument4 pagesSafety Resume Without Certificate PDFSAFETY RNo ratings yet

- Mine Rescue and Recovery WorkDocument48 pagesMine Rescue and Recovery WorkPramod Kumar MaheshwariNo ratings yet

- SNT-TC-IA and ANSI CP-189 RefresherDocument19 pagesSNT-TC-IA and ANSI CP-189 RefreshermohamedNo ratings yet

- Exam Attend-Sheet Bgas March 09 Rev 1Document1 pageExam Attend-Sheet Bgas March 09 Rev 1abdulgafoor54No ratings yet

- Bevel Pre (PDocument1 pageBevel Pre (Pabdulgafoor54No ratings yet

- Gerard B. Hawkins Managing DirectorDocument37 pagesGerard B. Hawkins Managing Directorabdulgafoor54No ratings yet

- Straight Tees Inches / Pounds: Schedule 160Document1 pageStraight Tees Inches / Pounds: Schedule 160abdulgafoor54No ratings yet

- Flat Bed Reactor Loading& UnloadingDocument12 pagesFlat Bed Reactor Loading& Unloadingabdulgafoor54No ratings yet

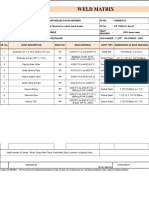

- Weld Matrix - PAGE 1&2Document4 pagesWeld Matrix - PAGE 1&2abdulgafoor54No ratings yet

- Bevel PreparationDocument2 pagesBevel Preparationabdulgafoor54No ratings yet

- Quality QuoteDocument1 pageQuality Quoteabdulgafoor54No ratings yet

- Tubesheet LayoutDocument1 pageTubesheet Layoutabdulgafoor54No ratings yet

- Quality Management System (Qms Iso 9001:2008) Department Log of FilesDocument2 pagesQuality Management System (Qms Iso 9001:2008) Department Log of Filesabdulgafoor54No ratings yet

- Datasheet Penguard TopcoatDocument5 pagesDatasheet Penguard Topcoatabdulgafoor54No ratings yet

- Piping Q.C Ag& UgDocument12 pagesPiping Q.C Ag& UgGokulPrasad88% (8)

- Weld Matrix - PAGE 1&2Document20 pagesWeld Matrix - PAGE 1&2abdulgafoor54No ratings yet

- Weld Matrix - PAGE 1&2Document20 pagesWeld Matrix - PAGE 1&2abdulgafoor54No ratings yet

- PendingDocument1 pagePendingabdulgafoor54No ratings yet

- Purchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With SpecificationDocument6 pagesPurchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With Specificationabdulgafoor54No ratings yet

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- Industrial Cadre For Operation and Maintenance: 15-Jan-18 25-Feb-18Document2 pagesIndustrial Cadre For Operation and Maintenance: 15-Jan-18 25-Feb-18abdulgafoor54No ratings yet

- Industrial Cadre For Operation and Maintenance: Date: 1/3/2018Document1 pageIndustrial Cadre For Operation and Maintenance: Date: 1/3/2018abdulgafoor54No ratings yet

- FP-Projects Status SheetDocument1 pageFP-Projects Status Sheetabdulgafoor54No ratings yet

- Ik MFC T CJ DJ CM 2174 PDFDocument1 pageIk MFC T CJ DJ CM 2174 PDFabdulgafoor54No ratings yet

- RTDocument4 pagesRTabdulgafoor54No ratings yet

- Chemanol-PRJ-17096: 18-Dec-17 25-Dec-17Document762 pagesChemanol-PRJ-17096: 18-Dec-17 25-Dec-17abdulgafoor54No ratings yet

- Industrial Cadre For Operation and MaintenanceDocument1 pageIndustrial Cadre For Operation and Maintenanceabdulgafoor54No ratings yet

- ListDocument1 pageListabdulgafoor54No ratings yet

- Astm A335 PDFDocument2 pagesAstm A335 PDFTeoTyJayNo ratings yet

- Astm A335 PDFDocument2 pagesAstm A335 PDFTeoTyJayNo ratings yet

- Purchase Request Form TemplateDocument6 pagesPurchase Request Form Templateabdulgafoor54No ratings yet

- Mathematics - 2Document5 pagesMathematics - 2Bharat & CompanyNo ratings yet

- Fenner Keyless DrivesDocument56 pagesFenner Keyless DrivesroytamaltanuNo ratings yet

- ELEK Cable HV ReportDocument6 pagesELEK Cable HV ReportJayson PatrickNo ratings yet

- What Is Telecommunication TransmissionDocument26 pagesWhat Is Telecommunication TransmissionmyotezaNo ratings yet

- 00hydr Fundamentals PDFDocument298 pages00hydr Fundamentals PDFpcalver2000No ratings yet

- 14 Case Study Shanghai World Financial CenterDocument6 pages14 Case Study Shanghai World Financial CenterElvin Michaels100% (1)

- Universal Law of GravitationDocument6 pagesUniversal Law of GravitationKrish AggrawalNo ratings yet

- Ijoaem 202109Document20 pagesIjoaem 202109Sahadev RoyNo ratings yet

- Unit 03 NocDocument42 pagesUnit 03 NocSaba HashmiNo ratings yet

- Workshop 16 Thermal Stress Analysis of A Bi-Metalic PlateDocument40 pagesWorkshop 16 Thermal Stress Analysis of A Bi-Metalic Plateaiyubi2No ratings yet

- (Dislocations in Solids 1) F.R.N. Nabarro - Dislocations in Solids - Elastic Theory (1979, North-Holland Publishing Co)Document179 pages(Dislocations in Solids 1) F.R.N. Nabarro - Dislocations in Solids - Elastic Theory (1979, North-Holland Publishing Co)Hariom PrakashNo ratings yet

- Math-6 Demo-LPDocument4 pagesMath-6 Demo-LPREZANo ratings yet

- Syllabus (402050B) Finite Element Analysis (Elective IV)Document3 pagesSyllabus (402050B) Finite Element Analysis (Elective IV)shekhusatavNo ratings yet

- Control Systems - Lecture NoteDocument190 pagesControl Systems - Lecture NoteAbenezer AchamyelehNo ratings yet

- Solucionario de Problemas de Momento de InerciaDocument23 pagesSolucionario de Problemas de Momento de InerciaEsteban Huacasi VargasNo ratings yet

- Tutorial8 RelationDocument4 pagesTutorial8 RelationAkhmal HaziqNo ratings yet

- Power Estimation Methods For Sequential Logic Circuits: Pedram, M. DespainDocument13 pagesPower Estimation Methods For Sequential Logic Circuits: Pedram, M. DespainHeejung SoNo ratings yet

- Quality Assurance of Computed and Digital Radiography SystemsDocument6 pagesQuality Assurance of Computed and Digital Radiography SystemsYuda FhunkshyangNo ratings yet

- Graflex xl Cameras Lenses Accessories GuideDocument12 pagesGraflex xl Cameras Lenses Accessories GuideDocNo ratings yet

- Telpro Data Sheets 2014 PDFDocument26 pagesTelpro Data Sheets 2014 PDFrakacyuNo ratings yet

- Module: Electromagnetism Activity: 3.2 R, C&L CircuitsDocument10 pagesModule: Electromagnetism Activity: 3.2 R, C&L CircuitsJun YamamotoNo ratings yet

- GuideToProtectiveCoatingsInspectionMaintenance2012 508Document177 pagesGuideToProtectiveCoatingsInspectionMaintenance2012 508nourhenNo ratings yet

- Finding the Area of Circular Sectors and their Real-World ApplicationsDocument4 pagesFinding the Area of Circular Sectors and their Real-World ApplicationsPaula Jan100% (5)

- Ieee STD c37.06.1 - Guide For High-Voltage Circuit BreakersDocument12 pagesIeee STD c37.06.1 - Guide For High-Voltage Circuit Breakerstatacps100% (2)

- PDS Nynas Nytro LibraDocument2 pagesPDS Nynas Nytro LibraGilbert Pineda100% (1)

- Marginal and Internal Adaptation of Zirconia CrownDocument7 pagesMarginal and Internal Adaptation of Zirconia CrownAndrei AvîrvareiNo ratings yet

- Axfa14g PDFDocument12 pagesAxfa14g PDFhenryhariyadiNo ratings yet

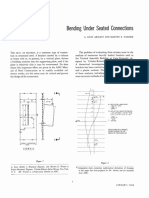

- BENDING CONNECTIONSDocument5 pagesBENDING CONNECTIONScmkohNo ratings yet

- A Cheat Sheet of MathsDocument1 pageA Cheat Sheet of MathsaadoyeNo ratings yet

- Advanced Control Strategies WordDocument6 pagesAdvanced Control Strategies WordGrazel MDNo ratings yet