Professional Documents

Culture Documents

Humidity Sensor: A Review

Uploaded by

iaetsdiaetsdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Humidity Sensor: A Review

Uploaded by

iaetsdiaetsdCopyright:

Available Formats

IAETSD JOURNAL FOR ADVANCED RESEARCH IN APPLIED SCIENCES ISSN NO: 2394-8442

Humidity Sensor: A Review

Ravindra Kumar

Department of Applied Sciences and Humanities, IIMT group of Colleges, Greater Noida, U.P., India

ravindra.kumar101@gmail.com

Abstract- The review presents a distinct classification pursuant to latest humidity sensor types, principles of work,

production technologies and their applications in day to day life. Furthermore, performance characteristics of the different

humidity sensors such as electrical and statistical data will be detailed and gives an added value to the report. Significant

developments of humidity sensors are critically reviewed and the advantages of thin film composites have been discussed

in detail. The main objectives and brief outline of the present investigations carried out in this review are presented in

brief.

Keywords— humidity sensors, relative humidity, capacitive/resistive sensor, relative humidity, fabrication

technologies

I. INTRODUCTION

Humidity refers to the water vapor content in air or other gases. A humidity sensor (HS) senses, determines and states

the relative humidity in the air. It, therefore, measures both moisture and air temperature. The warmer the air temperature

is the more moisture it can hold. Humidity measurement instruments usually rely on measurements of some other quantity

such as temperature, pressure, mass or a mechanical or electrical change in a substance as moisture is absorbed [1]. By

calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices

use temperature of condensation (the dew point), or changes in electrical capacitance or resistance to measure humidity

differences [2]. The first crude hygrometer was invented by Leonardo da Vinci in 1480 and a more modern version was

created by polymath Johann Heinrich Lambert in 1755 [3].

II. ABSOLUTE HUMIDTY SENSORS (HYGROMETERS)

In early years, meteorologists were interested in an instrument capable of measuring the water content of the upper air

latitudes where the water concentration was less than 10 ppmv at air temperature of −56 C. In 1948, a dew/frost

hygrometer based on moisture condensation on a mirror was developed to measure the absolute humidity in extremely dry

air of stratosphere with the lowest detectable humidity level of 90 ºC frost point [4]. In 1967, a fully automated dew/frost

point hygrometer based on a mirror with much better performance was developed with much faster response. In 1978, a

solid-state moisture sensor based on porous anodic aluminum oxide was developed with fast response and wide

measurement range (−110 C to +50C). In following two sections, we will review the mirror-based hygrometers and solid-

based moisture sensors [5].

III. REQUIREMENT OF HUMIDITY SENSORS

The most important specifications to keep in mind when selecting a robust humidity sensor are:

The material should have high sensitivity over a wide range of humidity and temperature.

The device should also have good stability and reversibility.

There should not be any hysteresis in the characteristics.

The sensitivity should be independent of the ambient temperature.

The reliability of humidity sensors is affected by many environmental factors such as contamination due to oil,

dust and other materials in the air.

VOLUME 4, ISSUE 7, DEC/2017 235 http://iaetsdjaras.org/

IAETSD JOURNAL FOR ADVANCED RESEARCH IN APPLIED SCIENCES ISSN NO: 2394-8442

It should have a short response and recovery times.

It should be less portable.

It should be resistive to contaminants.

It should have good mechanical properties and durability.

Humidity measurements can be stated in a variety of terms and units. Few of them are given as under:

A. Saturation Humidity

Saturation Humidity is defined as the ratio of the mass of water vapour at saturation to the volume of air [6]:

SH= ………………………………………...………….(1)

where, SH is the saturation humidity (g/m3), mws is mass of water vapor at saturation (g) and v is the volume of air (m3).

The saturation humidity is a function of temperature and can provide the maximum amount of moisture content (mass) in

a unit volume of gas at a given temperature.

B. Relative Humidity

Relative humidity (RH) refers to the ratio of the moisture content of air compared to the saturated moisture level at the

same temperature and pressure. In the early 1900, RH was derived from measuring a physical change that moisture

absorption caused in certain natural materials such as silk or human hair. Nylon and other synthetics were subsequently

used [7]. Since the 1940s, more mechanical methods have been replaced by electronic RH sensors due to their greater

accuracy and dependability and their lower cost. In the fairly recent past, specialized polymer-based resistive and laser-

trimmed capacitive sensors with monolithic signal conditioners have been introduced. RH is defined as below:

%RH = X 100 .............................................................................................(2)

where, Pw is water vapor pressure and Psw is saturated water vapor pressure at the gas temperature.

C. Dew/Frost Point

Dew point is the temperature and pressure at which a gas begins to condense into a liquid. It is also used as an

indicator of water vapor in high-temperature processes, such as industrial drying. It is the function of the pressure of the

gas, but is independent of temperature and therefore defined as the absolute humidity measurement. Calibration data for

each specific sensor are stored in nonvolatile memory for improved accuracy. When the dew point is at or below freezing,

it is called the frost point.

D. Part Per million

Part per million (PPM) is equal to a volume of a given gas mixed in a million volumes of air. It is also an absolute

measurement and given in Eqn. in 3.

PPM = ………………………………………………….(3)

VOLUME 4, ISSUE 7, DEC/2017 236 http://iaetsdjaras.org/

IAETSD JOURNAL FOR ADVANCED RESEARCH IN APPLIED SCIENCES ISSN NO: 2394-8442

IV. TYPES OF HUMIDITY SENSORS

A. Sensors based on Capacitive Effect

Humidity sensors relying on this principle consist of a hygroscopic dielectric material sandwiched between a pair of

electrodes forming a small capacitor. Most capacitive sensors use a plastic or polymer as the dielectric material, with a

typical dielectric constant ranging from 2 to 15. In the absence of moisture, the dielectric constant of the hygroscopic

dielectric material and the sensor geometry determine the value of capacitance. The basic structure of capacitive type

humidity sensor is shown in Fig. 1.

Fig. 1 The basic structure of capacitance based humidity sensor

At normal room temperature, the dielectric constant of water vapor has a value of about 80, a value much larger than

the constant of the sensor dielectric material. Therefore, absorption of water vapor by the sensor results in an increase in

sensor capacitance. At equilibrium conditions, the amount of moisture present in a hygroscopic material depends on both

the ambient temperature and the ambient water vapor pressure. This is true also for the hygroscopic dielectric material

used on the sensor.

By definition, relative humidity is a function of both the ambient temperature and water vapor pressure. Therefore,

there is a relationship between relative humidity, the amount of moisture present in the sensor and sensor capacitance.

This relationship governs the operation of a capacitive humidity instrument. On Alumina substrate, the lower electrode is

formed using gold, platinum or other material. A polymer layer such as PVA is deposited on the electrode and these layers

senses humidity. On top of this polymer film, a gold layer is deposited which acts as a top electrode. The top electrode also

allows water vapor to pass through it, into the sensing layer. The vapors enter or leave the hygroscopic sensing layer until

the vapor content is in equilibrium with the ambient air or gas. Thus capacitive type sensor is basically a capacitor with

humidity sensitive polymer film as the dielectric.

B. Sensors based on Resistive Effect

Resistive type humidity sensors pick up changes in the resistance value of the sensor element in response to the change

in the humidity. Thick film conductor of precious metals like gold, ruthenium oxide is printed and calcinated in the shape

of the comb to form an electrode. Then a polymeric film is applied to the electrode; the film acts as a humidity sensing

film due to the existence of movable ions. Change in impedance occurs due to the change in the number of movable ions.

Humidity sensors measure and report the air’s relative humidity. They are used in homes, wine cellars, and working

environments that that are so humid that they negatively impact working conditions.

VOLUME 4, ISSUE 7, DEC/2017 237 http://iaetsdjaras.org/

IAETSD JOURNAL FOR ADVANCED RESEARCH IN APPLIED SCIENCES ISSN NO: 2394-8442

Humidity sensors are also used in vehicles, industrial HVAC systems and meteorological stations to help in the

predicting and reporting of weather conditions. The basic structure of the resistive type humidity sensor is shown in Fig. 2.

HSs are competent for the detection of the relative humidity in different environments with respect to electrical, optical

and other physical parameters [7]. These sensors have drawn huge attention in the industrial and medical fields. The

calculation and control of humidity are crucial in several regions such as food and electronic industry, domestic

atmosphere, medical, etc. Hydrophilic properties of the polymer, polymer composites and modified polymers have been

used in HS devices. Jain et. al studied the behavior of HSs with PANI doped with different weak acids such as CSA,

diphenyl phosphate, and maleic acid blends. Choa et. al showed the influence of temperature and relative humidity of PPY

sensor [8]. The author found that the initial impedance of the PPY sensor was increased with enhancement in the humidity

and decrement of temperature, respectively.

Fig. 2 The basic structure of resistance based humidity sensor

The reproducibility of PPY sensor was outstanding at different humidity circumstances. Parvatikar studied the electrical

and humidity sensing properties of PANI/WO3 nanocomposites. Kulkarni et. al studied the poly(N-methyl aniline) doped

with several acids by a chemical polymerization technique with ammonium persulphate as an oxidizing agent. These

polymers were then effectively developed as HSs. Among the several acids utilized for the doping of polymer, the H3PO4-

doped polymer demonstrated the excellent sensing response and was found to be an excellent applicant for HS. HS based

on PANI nanofibers was synthesized by Zenga and its response to humidity was studied. The sensor responded to low

relative humidity (<50% RH) generally by decreasing electrical resistance with enhancing humidity. Though, at higher

relative humidity the sensor quashed its responses by enhancing the electrical resistance with humidity [8].

E. Effects of Humidity on Ecosystems

At high humidity, there is much water in the air, whereas at low humidity less amount of water vapor is present in the

air. Humidity affects the rate at which water evaporates from the surface of organisms, eg. in transpiration or sweating.

This, in turn, affects their distribution on earth.

V. CONCLUSIONS

The moisture sensing properties, modern technologies and in use mechanisms of several humidity sensors based on

applications and different sensing fundamentals consisting of ceramic, organic polymer and hybrid composites have been

classified and comprehensively explained. Among all humidity sensor patterns, the impedance- (resistive) and capacitive-

based sensors are exposed to be the top suited and most popular ones in advanced applications such as laboratory research.

Recent developed humidity sensors, especially those incorporated with nano-scale elements, provide promising

performance with the high impact role to a development of accuracy, reliability and economic efficiency.

VOLUME 4, ISSUE 7, DEC/2017 238 http://iaetsdjaras.org/

IAETSD JOURNAL FOR ADVANCED RESEARCH IN APPLIED SCIENCES ISSN NO: 2394-8442

ACKNOWLEDGMENT

The support of Nanomaterials and Sensors Research Laboratory, Babasaheb Bhimrao Ambedkar University, Lucknow,

U.P., India is highly acknowledged.

REFERENCES

[1] R. Kumar and B. C..Yadav, “Humidity Sensing Investigation on Nanostructured Polyaniline Synthesized via Chemical

Polymerization,” Mat. Lett. Vol. 167, pp. 300-302, Jan. 2016

[2] R. Kumar, S. Singh and B.C. Yadav, “Conducting Polymers: Synthesis, Properties and Applications,” Int. Adv. Res. Jour. Sci. Engg.

Tech., vol. 2, pp. 110-124, Nov. 2015.

[3] B.C. Yadav, Ritesh Kumar, Ravindra Kumar, S. Chaudhuri, P. Pramnik, “Electrical Behaviour of Chitosan-Silver Nanocomposite in

Presence of Water Vapour,” J. Water Environ. Nanotechnol.,vol. 2, pp. 71-79,Feb. 2017.

[4] R. Kumar and B.C. Yadav, “Fabrication of Polyaniline (PANI)- Tungsten oxide (WO3) Composite for Humidity Sensing

Application,” J. Inorg. Organomet. Polym., vol. 26, pp. 1421-1427, Nov. 2016.

[5] B.C. Yadav, K.S. Chauhan, S. Singh, R.K. Sonker, S. Sikarar and R. Kumar, “Growth and Characterization of sol-gel processed

rectangular shaped nanostructured ferric oxide thin film followed by humidity and gas sensing, “J. Mater. Sci. Mater. Electron., vol. 28, pp.

5270-5280, April 2017

[6] Anamika D. Katheria, E. Singh, R. Kumar, R. Srivastava and B.C. Yadav, “Polymer Nanocomposite: An overview,” Internat. Jour.

Innovat. Res. Sci. Engg. Tech., vo. 6, pp. 1960-1968, Feb. 2016.

[7] R. Srivastava and B.C. Yadav, “Nanostructured ZnO, ZnO-TiO2 and ZnO-Nb2O5 as solid state humidity sensor,” Adv. Mater.

Lett., vol. 3, pp. 197-203, 2012.

[8] N. Verma, S. Singh and B.C. Yadav, “Experimental investigations on barium titanate nanocomposite thin films as an opto-electronic

humidity sensor, ”J. Exp. Nanosci., vol. 9, pp. 1-9, 2012.

VOLUME 4, ISSUE 7, DEC/2017 239 http://iaetsdjaras.org/

You might also like

- Sediment Classification Using Side Scan SONARDocument5 pagesSediment Classification Using Side Scan SONARiaetsdiaetsdNo ratings yet

- Working Women - A Broader PerspectiveDocument6 pagesWorking Women - A Broader PerspectiveiaetsdiaetsdNo ratings yet

- A Review On Performance Improvement of Induction Motor by DTC TechniqueDocument8 pagesA Review On Performance Improvement of Induction Motor by DTC TechniqueiaetsdiaetsdNo ratings yet

- Slow Intelligence System Based Software TestingDocument6 pagesSlow Intelligence System Based Software TestingiaetsdiaetsdNo ratings yet

- A Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditionDocument4 pagesA Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditioniaetsdiaetsdNo ratings yet

- Duplicated Region in Digital Image Detection Approaches EvaluationDocument7 pagesDuplicated Region in Digital Image Detection Approaches EvaluationiaetsdiaetsdNo ratings yet

- Essence of Soft Skills Proficiency To Foster Mercantile SectorDocument4 pagesEssence of Soft Skills Proficiency To Foster Mercantile SectoriaetsdiaetsdNo ratings yet

- Comparison Study of Related Data Sharing Security Issues in Cloud ComputingDocument5 pagesComparison Study of Related Data Sharing Security Issues in Cloud ComputingiaetsdiaetsdNo ratings yet

- A Survey - Data Security and Privacy Big DataDocument6 pagesA Survey - Data Security and Privacy Big DataiaetsdiaetsdNo ratings yet

- IOT Based Waste Management System For Smart CityDocument7 pagesIOT Based Waste Management System For Smart Cityiaetsdiaetsd100% (2)

- Optimum Sizing and Composition of Agricultural Residue As Biomass Fuel For A Downdraft Gasifier For Efficient Production of Producergas On A Comercial ScaleDocument11 pagesOptimum Sizing and Composition of Agricultural Residue As Biomass Fuel For A Downdraft Gasifier For Efficient Production of Producergas On A Comercial ScaleiaetsdiaetsdNo ratings yet

- A Novel Design Methodology of 1-Bit Hybrid Full Adder Using SVL TechniqueDocument6 pagesA Novel Design Methodology of 1-Bit Hybrid Full Adder Using SVL TechniqueiaetsdiaetsdNo ratings yet

- Structural Change in Composition of India's Export: EraDocument8 pagesStructural Change in Composition of India's Export: EraiaetsdiaetsdNo ratings yet

- A Survey On Detection and Computing The Amount of Plant Diseases Using Image ProcessingDocument10 pagesA Survey On Detection and Computing The Amount of Plant Diseases Using Image ProcessingiaetsdiaetsdNo ratings yet

- Using Word Net For Document Clustering: A Detailed ReviewDocument5 pagesUsing Word Net For Document Clustering: A Detailed ReviewiaetsdiaetsdNo ratings yet

- Sensing Performance of PEO: KClO4 Polymer Electrolyte As Gas SensorDocument5 pagesSensing Performance of PEO: KClO4 Polymer Electrolyte As Gas SensoriaetsdiaetsdNo ratings yet

- Cassandra DB - A Cloud Deployment ToolDocument4 pagesCassandra DB - A Cloud Deployment TooliaetsdiaetsdNo ratings yet

- Cavitation Analysis On Propeller Turbine Through CFDDocument13 pagesCavitation Analysis On Propeller Turbine Through CFDiaetsdiaetsdNo ratings yet

- Influence of Strontium As A Dopant in Hydroxyapatite For Potential Biomedical ApplicationsDocument6 pagesInfluence of Strontium As A Dopant in Hydroxyapatite For Potential Biomedical ApplicationsiaetsdiaetsdNo ratings yet

- An Evaluation of Socio-Legal and Economic Consequences of Benami Act, 2016Document8 pagesAn Evaluation of Socio-Legal and Economic Consequences of Benami Act, 2016iaetsdiaetsdNo ratings yet

- Design of Transformer Peripharals by Computer Aided Design Drafting (Cadd)Document8 pagesDesign of Transformer Peripharals by Computer Aided Design Drafting (Cadd)iaetsdiaetsdNo ratings yet

- Action of Photo Activated Cow Urine With The Different Combination of Neem and Aloe Vera Extracts Against Pathogenic MicroorganismsDocument4 pagesAction of Photo Activated Cow Urine With The Different Combination of Neem and Aloe Vera Extracts Against Pathogenic MicroorganismsiaetsdiaetsdNo ratings yet

- ON LINE FAULTS IN FIFO BUFFERS OF NOC ROUTERS - Http://iaetsdjaras - Org/gallery/2-D130-23 PDFDocument7 pagesON LINE FAULTS IN FIFO BUFFERS OF NOC ROUTERS - Http://iaetsdjaras - Org/gallery/2-D130-23 PDFiaetsdiaetsdNo ratings yet

- The Impact of Partition As Revealed in Bapsi Sidhwa's Ice Candy ManDocument9 pagesThe Impact of Partition As Revealed in Bapsi Sidhwa's Ice Candy ManiaetsdiaetsdNo ratings yet

- In Vitro Propagation of Anisochilus Carnosus (LF.) Wallich - A Medicinal PlantDocument3 pagesIn Vitro Propagation of Anisochilus Carnosus (LF.) Wallich - A Medicinal PlantiaetsdiaetsdNo ratings yet

- ON LINE FAULTS IN FIFO BUFFERS OF NOC ROUTERS - Http://iaetsdjaras - Org/gallery/2-D130-23 PDFDocument7 pagesON LINE FAULTS IN FIFO BUFFERS OF NOC ROUTERS - Http://iaetsdjaras - Org/gallery/2-D130-23 PDFiaetsdiaetsdNo ratings yet

- ON LINE FAULTS IN FIFO BUFFERS OF NOC ROUTERS - Http://iaetsdjaras - Org/gallery/2-D130-23 PDFDocument7 pagesON LINE FAULTS IN FIFO BUFFERS OF NOC ROUTERS - Http://iaetsdjaras - Org/gallery/2-D130-23 PDFiaetsdiaetsdNo ratings yet

- Comparative Analysis of Online Signature Verification Using Hybrid Wavelet Transform (HWT) - 1 and 2 With HMM ClassifierDocument10 pagesComparative Analysis of Online Signature Verification Using Hybrid Wavelet Transform (HWT) - 1 and 2 With HMM ClassifieriaetsdiaetsdNo ratings yet

- Mathematical Model For Marangoni Convection MHD Flow of Carbon Nanotubes Through A Porous MediumDocument7 pagesMathematical Model For Marangoni Convection MHD Flow of Carbon Nanotubes Through A Porous MediumiaetsdiaetsdNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pass Microsoft 74-343 Exam: Number: 74-343 Passing Score: 800 Time Limit: 120 Min File Version: 40.2Document26 pagesPass Microsoft 74-343 Exam: Number: 74-343 Passing Score: 800 Time Limit: 120 Min File Version: 40.2tapera_mangeziNo ratings yet

- Banking Software System Monitoring ToolDocument4 pagesBanking Software System Monitoring ToolSavun D. CheamNo ratings yet

- Cs614-Mid Term Solved MCQs With References by Moaaz PDFDocument30 pagesCs614-Mid Term Solved MCQs With References by Moaaz PDFNiazi Qureshi AhmedNo ratings yet

- S-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Document7 pagesS-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Data Collection ProcedureDocument58 pagesData Collection ProcedureNorjenn BarquezNo ratings yet

- Real-Time Java and ATCDocument44 pagesReal-Time Java and ATCdnk_victon6248No ratings yet

- EasementDocument10 pagesEasementEik Ren OngNo ratings yet

- 2022 Semester 2 Letter To Parents - FinalDocument7 pages2022 Semester 2 Letter To Parents - FinalRomanceforpianoNo ratings yet

- Unit 8 Risk in The WorkplaceDocument11 pagesUnit 8 Risk in The WorkplaceAnonymous WalvB8No ratings yet

- Marantz CD4000 PDFDocument28 pagesMarantz CD4000 PDFboroda2410No ratings yet

- Vaccination Management System of Brgy 6 (Table of Contents)Document8 pagesVaccination Management System of Brgy 6 (Table of Contents)Ryan Christian MenorNo ratings yet

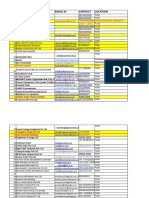

- Company Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDocument65 pagesCompany Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDhruv Parekh100% (1)

- TESA Doorclosers and Door Operators PDFDocument46 pagesTESA Doorclosers and Door Operators PDFDawood Shaik Abdul CadarNo ratings yet

- How To Block Facebook in Mikrotik Using L7 Protocols (Layer 7) - Lazy Geek - )Document11 pagesHow To Block Facebook in Mikrotik Using L7 Protocols (Layer 7) - Lazy Geek - )oscar_198810No ratings yet

- Elegant Tranquil Blue Agency by SlidesgoDocument41 pagesElegant Tranquil Blue Agency by SlidesgoJoana TavaresNo ratings yet

- BurhanresumeDocument1 pageBurhanresumeAbdul Rangwala0% (1)

- In Gov cbse-SSCER-191298202020 PDFDocument1 pageIn Gov cbse-SSCER-191298202020 PDFrishichauhan25No ratings yet

- Frequently Asked Questions (And Answers) About eFPSDocument10 pagesFrequently Asked Questions (And Answers) About eFPSghingker_blopNo ratings yet

- TT1 2lecture SpinningDocument29 pagesTT1 2lecture SpinninghaiNo ratings yet

- Line Sets in Oracle Order ManagementDocument9 pagesLine Sets in Oracle Order ManagementS S PatelNo ratings yet

- Financial Ratios ActivityDocument3 pagesFinancial Ratios ActivityNCF- Student Assistants' OrganizationNo ratings yet

- Alcalel-Lucent WLAN OmniAcces StellarDocument6 pagesAlcalel-Lucent WLAN OmniAcces StellarJBELDNo ratings yet

- Circulation in Vacuum Pans: January 2004Document18 pagesCirculation in Vacuum Pans: January 2004REMINGTON SALAYANo ratings yet

- Data IntegrationDocument7 pagesData IntegrationHan MyoNo ratings yet

- Portfolio Management Banking SectorDocument133 pagesPortfolio Management Banking SectorNitinAgnihotri100% (1)

- 6 Hagonoy V NLRCDocument2 pages6 Hagonoy V NLRCChristiane Marie Bajada0% (1)

- Thesis Statement About Plastic BagsDocument7 pagesThesis Statement About Plastic Bagslyjtpnxff100% (2)

- Kinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide CatalystsDocument9 pagesKinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide Catalysts李国俊No ratings yet

- Office of The Controller of Examinations Anna University:: Chennai - 600 025Document4 pagesOffice of The Controller of Examinations Anna University:: Chennai - 600 025M.KARTHIKEYANNo ratings yet

- GE's Two-Decade Transformation: Jack Welch's Leadership: Amanda Rodriguez Patricia Robledo Brittany Culberson Yue JiangDocument34 pagesGE's Two-Decade Transformation: Jack Welch's Leadership: Amanda Rodriguez Patricia Robledo Brittany Culberson Yue JiangRishendra Singh RathourNo ratings yet