Professional Documents

Culture Documents

Bridge Print16

Uploaded by

Husen GhoriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bridge Print16

Uploaded by

Husen GhoriCopyright:

Available Formats

IS 1343:2007

0.088 for R.C bridges & 0.154 for steel bridges. The impact stages, re-stressing for adjustment of force or

% for highway bridges can also be directly obtained from for monitoring of force, if required, etc.

the curves of IRC code. b) Calculated amount of tensile force and

IRC Class AA or 70R loadings. Less than 9m span- for corresponding expected elongation of each tendon

tracked vehicle 25% for span up 5m linearly reduced to 10% when methods described in (a) are followed.

for span of 9m. c) Minimum requirements of strength of concrete at

For span 9m & more, tracked vehicle- for RC bridges, 10% transfer (see also 16.2), stressing sequence with

up to a span of 40m & in accordance with spans exceeding respect to age of concrete or stage of construction,

40m. for steel bridges,25% for span up to 23m & as per span requirements with respect to grouting operations of

exceeding 23m. neighbouring tendons.

13.1.3 Detailed note on Beam and slab Deck bridges. d) Method(s) of measuring force and elongation. e)

Beam bridge: Is consist of a horizontal beam supported at Tolerances/limits of variation from design

each end by piers.(a)when the load pushes down on the requirements stated in (a) and (b) beyond which

beam the top edge is push together or compressed ,while the reference should be made to the designer (In the

bottom of the beam is stretched or is under tension.(b)The absence of any specified provision provided by the

beam must be strong enough so that it doesn't bend under its designer, method described in 13.2.1.3 may be

own weight and the added weight. adopted for acceptance).

13.1.4 Slab deck bridge: A bridge deck is the roadway or f) Assumptions made in calculation of

the pedestrian walkway, surface of bridge and is one forceelongation relationship should be given. These

structural element of the superstructure of the bridge. The include effective ‘E’ value of tendon, crosssectional

Deck may be constructed of concrete, steel, open granting or area of tendon, co-efficient of friction and wobble

wood. Sometimes the Deck is covered with the Asphalt factor between tendon and duct, assumed slip in

concrete or other pavement. When bridge Deck is installed anchoring devices, if any, efficiency of prestressing

in through Truss, it is sometimes called as Floor system. jacks where force is measured indirectly by

Some bridges such as Tide Arch or a Cable stayed, the deck pressure gauges on jacks, corrections to elongation

is primary structural element, carrying tension or due to changes in gripping length beyond

compression to support span. anchorages during stressing and any other relevant

13.1.4.3 The anchorage shall transfer effectively and information.

distribute, as evenly as possible, the entire force from the 13.2.1.2 Any slack in the prestressing tendon shall

prestressing tendon to the concrete without inducing first be taken up by applying a small initial tension.

undesirable secondary or local stresses. The initial tension required to remove slackness

13.1.4.4 The anchorage shall be safe and secure against both shall be taken as the starting point for measuring

dynamic and static loads as well as against impact (see elongation.

Annex C). Further increase of tension shall be carried out in

13.1.4.5 The anchorage shall have provision for the suitable steps and corresponding elongations noted.

introduction of a suitable protective medium, such as cement The ‘force-elongation’ relationship shall be

grout, for the protection of the prestressing steel unless recorded in tabular and/or graphical form. The

alternative arrangements are made. magnitude of initiatial effective elongation

13.2 Procedure for Tensioning and Transfer corresponding to initial tension applied to remove

13.2.1 Stressing slackness shall be obtained from the recorded and

13.2.1.1 The tensioning of prestressing tendons shall be linearized portion of measured tensione longation

carried out in a manner that will induce a smooth and even relationship and added to the measured elongation

rate of increase of stress in the tendons. The prestressing to give the total elongation. Alternatively, the same

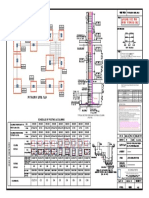

shall be controlled by measuring both the force applied to correction can be carried out graphically as shown

the tendon and the elongation of the tendon. Stressing in Fig. 1.

schedule shall be incorporated in the design, which may 13.2.1.3 In practice, the force and elongation of

include the following: tendon may not exactly match with the expected

a) Details of equipment and procedure for applying values given in stressing schedule. In such cases

prestress, specification of one end or simultaneous either the force (or the elongation) will be achieved

stressing from both ends of tendons, stressing in first and the other value lag behind. In such cases

single stage or multiple the force (or elongation) shall be further increased,

but not exceeding 5 percent of the design value till

the elongation (or force), which

16

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Astm D3689 PDFDocument13 pagesAstm D3689 PDFhalil can100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Base Plate Design (Pin) Asd For CompressionDocument54 pagesBase Plate Design (Pin) Asd For CompressionEmdadul HuqNo ratings yet

- Burns and MacDocument34 pagesBurns and MacGreg DaileyNo ratings yet

- Reverse L Shaped Cantilever RETAINING WALLDocument6 pagesReverse L Shaped Cantilever RETAINING WALLHusen Ghori100% (2)

- Fe Ce 511 Prestressed ConcreteDocument6 pagesFe Ce 511 Prestressed ConcreteJeana Rick GallanoNo ratings yet

- End Plate DesignDocument4 pagesEnd Plate Designsiva0% (1)

- Week 1 Reinforced Concrete PDFDocument18 pagesWeek 1 Reinforced Concrete PDFmuhammad ridNo ratings yet

- Two Way Slab Design (DRAFT)Document72 pagesTwo Way Slab Design (DRAFT)ابو عمر الأسمريNo ratings yet

- Final Year ProjectDocument71 pagesFinal Year ProjectAayush Adhikari100% (1)

- Delivery InvoiceDocument1 pageDelivery InvoiceHusen GhoriNo ratings yet

- Sakib Ismail Naikwadi: ObjectiveDocument2 pagesSakib Ismail Naikwadi: ObjectiveHusen GhoriNo ratings yet

- Construction Pass (10) - 01-18Document1 pageConstruction Pass (10) - 01-18Husen GhoriNo ratings yet

- Delivery PassDocument1 pageDelivery PassHusen GhoriNo ratings yet

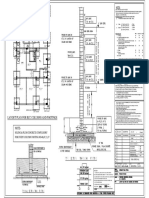

- Service Kitchen Quartz Drawings-06-03-2024Document1 pageService Kitchen Quartz Drawings-06-03-2024Husen GhoriNo ratings yet

- Deck Profile SheetDocument20 pagesDeck Profile SheetHusen GhoriNo ratings yet

- Layout Plan For RCC Columns and FootingsDocument1 pageLayout Plan For RCC Columns and FootingsHusen GhoriNo ratings yet

- Ajit Gijare - Structural Engineer: Job ConfirmationDocument2 pagesAjit Gijare - Structural Engineer: Job ConfirmationHusen GhoriNo ratings yet

- Venkateshwara Hatcheries PVT LTDDocument3 pagesVenkateshwara Hatcheries PVT LTDHusen GhoriNo ratings yet

- C2 Footing DetailsDocument1 pageC2 Footing DetailsHusen GhoriNo ratings yet

- Design Data-As Per Received From Aniket SirDocument3 pagesDesign Data-As Per Received From Aniket SirHusen GhoriNo ratings yet

- Design By: Saadam Ghori Mobile: 08793596857Document3 pagesDesign By: Saadam Ghori Mobile: 08793596857Husen GhoriNo ratings yet

- C11 Pillar: Round Pipe. OD 152, 12thkDocument1 pageC11 Pillar: Round Pipe. OD 152, 12thkHusen GhoriNo ratings yet

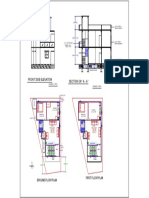

- Existing Building Existing Building: Ground Floor Plan 1St Floor PlanDocument1 pageExisting Building Existing Building: Ground Floor Plan 1St Floor PlanHusen GhoriNo ratings yet

- C11 Pillar: Schedule of R.C. Columns & FootingsDocument1 pageC11 Pillar: Schedule of R.C. Columns & FootingsHusen GhoriNo ratings yet

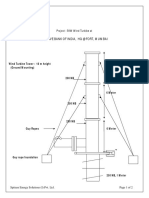

- Tower & Foundation - RBI - 5KW WT - 2020Document2 pagesTower & Foundation - RBI - 5KW WT - 2020Husen GhoriNo ratings yet

- Back Side: SHS 50X50X4mmDocument1 pageBack Side: SHS 50X50X4mmHusen GhoriNo ratings yet

- First Floor Plan: Owner'S NameDocument1 pageFirst Floor Plan: Owner'S NameHusen GhoriNo ratings yet

- Section On ' A - A ' Front Side Elevation: First Floor Plan Ground Floor PlanDocument1 pageSection On ' A - A ' Front Side Elevation: First Floor Plan Ground Floor PlanHusen GhoriNo ratings yet

- Pay Slip For The Month of October-2018: School Transport ServicesDocument1 pagePay Slip For The Month of October-2018: School Transport ServicesHusen GhoriNo ratings yet

- Rent A FlatDocument2 pagesRent A FlatHusen GhoriNo ratings yet

- N S W E: Ground Floor Plan First Floor PlanDocument1 pageN S W E: Ground Floor Plan First Floor PlanHusen GhoriNo ratings yet

- 1 - Ga - Drawing of Renuka SugarDocument1 page1 - Ga - Drawing of Renuka SugarHusen GhoriNo ratings yet

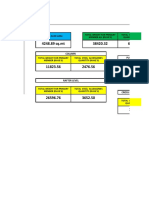

- 4248.89 SQ - MT 38420.32 66613.29: Column Purlin DetailsDocument2 pages4248.89 SQ - MT 38420.32 66613.29: Column Purlin DetailsHusen GhoriNo ratings yet

- 02.R3 - FOUNDATION LEVEL PLAN-ModelDocument1 page02.R3 - FOUNDATION LEVEL PLAN-ModelHusen GhoriNo ratings yet

- Bank of India Branch: Rajarampuri: Bank of India, Star HOUSE, C - 5, G Block, Bandra Kurla Complex, Mumbai 400 051Document1 pageBank of India Branch: Rajarampuri: Bank of India, Star HOUSE, C - 5, G Block, Bandra Kurla Complex, Mumbai 400 051Husen GhoriNo ratings yet

- Proposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IDocument27 pagesProposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IHusen GhoriNo ratings yet

- Barchip Technical Note: Best Practice For Testing Fibre Reinforced ShotcreteDocument12 pagesBarchip Technical Note: Best Practice For Testing Fibre Reinforced ShotcreteMauro GelmiNo ratings yet

- Long Span StructuresDocument8 pagesLong Span Structures1707 Bhitale SiddharthNo ratings yet

- TorsionDocument18 pagesTorsionRenganayagi BalajiNo ratings yet

- Pile Cap DesignDocument3 pagesPile Cap Designravi4paperNo ratings yet

- Solid Slab For Three Lane Bridge by Using Irc Codal ProvisionDocument1 pageSolid Slab For Three Lane Bridge by Using Irc Codal ProvisionChandra Prakash JyotiNo ratings yet

- BSL cp7Document7 pagesBSL cp7Tj AtienzaNo ratings yet

- Analysis and Design of A Multi Storey Building With Flat Slab (C+G+9) Using ETABSDocument8 pagesAnalysis and Design of A Multi Storey Building With Flat Slab (C+G+9) Using ETABSTurnitin ReportNo ratings yet

- Cover & Table of Contents - Fundamentals of Structural Analysis (2nd Edition)Document14 pagesCover & Table of Contents - Fundamentals of Structural Analysis (2nd Edition)braveknight940% (1)

- Astm D7460-10Document14 pagesAstm D7460-10tantai2004No ratings yet

- Structural Calculation For Gl1 Beam: 1. DescriptionDocument13 pagesStructural Calculation For Gl1 Beam: 1. DescriptionAndrei BobuNo ratings yet

- Seismic Evaluation of Buildings & RetrofittingDocument17 pagesSeismic Evaluation of Buildings & RetrofittingHage Tajang100% (1)

- Test-Paper-6: Physics Time: 1hr Date: 23-12-2020 Multi-Choice Single Correct (+3,0,-1)Document12 pagesTest-Paper-6: Physics Time: 1hr Date: 23-12-2020 Multi-Choice Single Correct (+3,0,-1)NdjskaNo ratings yet

- 05 Erection ChecklistDocument8 pages05 Erection ChecklistAnonymous cG5MyHMNo ratings yet

- MPSC Civil (Mes) Main Exam Subjectwise Previous Year Question Paper With Detail ExplanationDocument29 pagesMPSC Civil (Mes) Main Exam Subjectwise Previous Year Question Paper With Detail ExplanationvishalNo ratings yet

- Project 2 - Preliminary ProjectDocument6 pagesProject 2 - Preliminary ProjectajdarkobejNo ratings yet

- Aerodynamic and Structural Design of A 2022 F1 Front WingDocument23 pagesAerodynamic and Structural Design of A 2022 F1 Front Winglorenzo19No ratings yet

- Modul 3 Beton Prategang UMBDocument13 pagesModul 3 Beton Prategang UMBhandayaniafriNo ratings yet

- Evaluation of Ultimate Ship Hull Strength: Po@.-Collapse Loss F10@Document16 pagesEvaluation of Ultimate Ship Hull Strength: Po@.-Collapse Loss F10@maaathanNo ratings yet

- ASTM TestingDocument7 pagesASTM TestingMarina Bock MonteroNo ratings yet

- Steel Construction - New Development & ChalengesDocument62 pagesSteel Construction - New Development & ChalengesNIBEDITA DEYNo ratings yet

- A Critical Analysis of The Design and Construction of Boyne Bridge, IrelandDocument10 pagesA Critical Analysis of The Design and Construction of Boyne Bridge, Irelandahmed55No ratings yet

- Short Course Mechanical-TestingDocument35 pagesShort Course Mechanical-TestingAndrei CostacheNo ratings yet