Professional Documents

Culture Documents

Volvo Wheel Loader: Steering System Hydraulic System Standard Equipment

Uploaded by

JozefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volvo Wheel Loader: Steering System Hydraulic System Standard Equipment

Uploaded by

JozefCopyright:

Available Formats

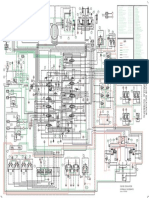

STEERING SYSTEM HYDRAULIC SYSTEM STANDARD EQUIPMENT

Low-effort steering gives short work cycle times. Power- Open centre hydraulics with highly efficient vane pumps Engine Warning & monitoring lights: Brake System Hydraulic System

VOLVO WHEEL LOADER

L90C

Air cleaner, dry type, dual element, • engine oil pressure Wet, internal oil circulation cooled, Main valve, 3-Spool, pilot operated

efficient system provides good fuel economy, good directional allows precision control even at low rpm´s together with quick • engine coolant temperature

exhaust aspirated pre-cleaner disc brakes, 4-wheel, dual circuit Pilot valve, 3-spool

stability and smooth ride. movements thanks to the high capacity pumps. Coolant level, sight gauge • air cleaner restriction Brake system, secondary Vane pump

Engine intake manifold preheater • alternator malfunction Parking brake alarm Bucket lever detent

Steering system: Load-sensing hydrostatic articulated Pump: Vane pump fitted to a power take-off on the transmis- Muffler, spark arresting • working lights Bucket leveler, automatic with posi-

steering. sion. The pilot system is supplied from a combined pilot/brake • high beam driving lights tion indicator, adjustable

• direction indicator, hazard Cab boom lever detents

pump. Electrical System Warning flasher: ROPS (SAE J10400C) (ISO 3471), Boom kickout, automatic, adjustable

System supply: The steering system is supplied from a

24V – prewired for optional • transmission oil pressure FOPS (SAE J 231) (ISO 3449). Hydraulic control lever safety latch

separate steering pump. Valve: Double-acting 3-spool valve. The control valve is accessories • transmission oil temperature Acoustical lining Boom lowering system

actuated by a 3-spool pilot valve. Alternator, 24V, 60 A • brake system pressure Ashtray Hydraulic pressure test ports, Quick

Pump: Variable-flow axial piston pump. Battery disconnect switch • parking brake applied Cigarette lighter connect

Lift function: The valve has four functions: raise, hold, lower Fuel gauge Central warning (with buzzer): Door lockable (left side access) Hydraulic fluid level, sight gauge

Cylinders: Two double-acting cylinders. Hourmeter • engine oil pressure Heater/defroster/pressurizer

and float. Inductive/magnetic automatic boom kickout can be Hydraulic oil cooler

Horn, electric • engine coolant temperature 11 kW, 37 500 Btu/h with four

Steering cylinders ................................ 2 switched on and off and is adjustable to any position between Instrument panel with symbols (buzzer) speed blower fan

Bore .................................................... 70 mm maximum reach and full lift height. Lights: • transmission oil pressure Filtered air External Equipment

• driving (2 front), halogen • transmission oil temperature Floor mat Isolation mounts: cab, engine,

Piston rod diameter ......................... 40 mm Tilt function: The valve has three functions: rollback, hold and with high/low beam • brake system pressure Interior light gearbox

Stroke ................................................. 419 mm dump. Inductive/magnetic automatic bucket positioner that • parking lights Interior rearview mirror Lifting lugs

Relief pressure ..................................... 21 MPa • stop/tail combination Mirrors rearview (2), exterior Side panels, engine hood

can be switched on and off. (2 rear) Drivetrain Openable window, right-hand side Steering frame lock

Max. flow ................................................ 91 l / min Transmission: modulated with single

• turn signals with hazard Safety glass, tinted Vandalism lock, provison for:

Articulation ............................................ ± 40° Cylinders: Double-acting warning switch lever control, Automatic Power Seat belt (SAE J386) batteries, engine oil

• working lights, halogen Shift, and operator controlled Seat, heated, ergonomically desig-

Filter: Full-flow filtration through 20 µm (absolute) filter (2 front, 2 rear) declutch ned, suspension adjustable

cartridge. • instrument lighting Differentials: Storage compartment

Contronic Monitoring System, ECU • front 100 % hydraulic Sun visor

Neutral start feature differential lock Windshield wiper, front & rear

Vane pump Test function for warning & • rear, conventional Intermittent wiper, front

Relief pressure ..................................... 22,5 MPa monitoring lights Tires 20.5 R25* L2 Goodyear Cab access steps and handrails

Flow ..................................................... 202 l/min Fenders, front & rear with anti-skid-

at .......................................................... 10 MPa tape

and engine speed ............................ 35 r/s (2 100 r/min)

CAB Pilot system

Relief pressure .................................. 3,0 MPa

Care Cab with easy entry and wide door opening. Lined with Cycle times

sound-absorbent material. Sound- and vibration-suppressing Raise* .................................................. 5,5 s

suspension. Good all round visibility, large glass areas. Dump* ................................................. 1,9 s OPTIONAL EQUIPMENT (Standard in certain markets)

Curved windshield of laminated, green-tinted glass. Lower, empty ..................................... 2,3 s

Total cycle time ................................. 9,7 s Service and maintenance Shut down to idle at Hydraulic System Tires

Ergonomically located controls and instruments permit a

• high engine coolant temp Hydraulic control, 3rd function 20.5–25

comfortable operating position. * with load as per ISO 5998 and SAE J818

equipment • low engine oil pressure

Tool box Hydraulic control, 4th function 20.5 R25*

• high transm. oil temp Hydraulic single acting lifting

Instrumentation: All information important to the operator is Tool kit Parking brake applied and

Air pressure equipment function

readily visible in front of him. Cab display for Contronic transmission in forward or Boom Suspension System Protective Equipment

Anti-freeze container reverse (buzzer) Protective grids for front running

monitoring system. Wheel nut wrench kit Biodegradable hydraulic fluid

Hydraulic function 3rd, hydraulic light

hoses Protection guard radiator grille

Heater and defroster: Heating element with filtered fresh air Drivetrain Protective grids for rear working

Engine Forward and reverse switch Servo hoses for separate

and four-speed fan. Defroster outlets for all windows. Coolant filter attachment locking lights

Speed limiter, 3-speed version Window guards for side and rear

Extra fuel filter Limited-slip differentials, front/rear Attachment bracket with separate

Operator’s seat: Spring suspended, adjustable operator’s Cold starting aid, engine locking system window

seat with belt. The seat is mounted on a bracket on the rear coolant preheater (220V/1500 W) Windshield guard

Pre-cleaner, oil bath type Cab Fan protection

wall. The force from the belt is absorbed by the seat rails. External Equipment Protective grids for rear lights

Pre-cleaner, turbo type Installation kit for radio

Fenders, extended Bellyguard rear • Engine output SAE J1349: • Volvo transmission with • Care Cab – pressurized cab

Standards: Tested and approved according to the following LIFTARM SYSTEM Radiator, corrosion protected Hand throttle

Counterweight 1 APS II

standards: ROPS (ISO/CD 3471, SAE J1040), FOPS (ISO

Sliding ventilation window gross 118 kW (160 hp) with high comfort and safety

Counterweight 2

Electrical System Speedometer Attachments net 113 kW (153 hp) – 2nd generation Automatic

3449, SAE J231). Complies with ”Overhead guards for rider TP Linkage combines high breakout torque throughout the Air suspended operator's seat Fenders, axle mounted

• Contronic monitoring system

Reverse alarm (SAE J994) Drawbar with pin Buckets Power Shift with mode

lift trucks” (ISO 6055) and ”Operator Restraint System” (SAE working range with nearly exact parallel lift-arm action. These Retractable seat belt Fork equipment • Operating weight: 14,4–16,1 t

Attachment lights Air conditioner 8 kW, selector

J386). features together with high lift height and long reach make Working lights front, extra Material handling arm • Load-sensing steering system

Working lights rear, extra

Dual service brake pedals Other Equipment Timber grapples • Buckets: 2,2–7,0 m3 – optimises performance

the lift-arm system equally as good in bucket loading as in Armrest (left) Comfort Drive Control (CDC) Diagonal snow blade

Rotating beacon, amber with • Wet disc brakes • Pilot-operated working hydraulics

Emergency exits ................................... 2 work with fork attachments and material handling arms. Contronic display Slow moving vehicle emblem Broom

collapsible mount Cab filter for asbetos contaminated • Volvo high performance- – fully sealed oil-circulation

Sound level in cab Alternator, brushless Secondary steering Cutting edge, 3 pc reversible, bolt-on Optional Equipment

as per ISO 6396, Head lights assym. left

environment 50 km/h sign Bucket teeth, bolt-on low emission engine cooled

Lift cylinder ............................................ 2 Instructor seat

Jump-start connector (Nato) Fuel fill strainer Bucket spillguard – with excellent low rpm – outboard mounted • Hydraulic attachment bracket

max fan position ................................ 72 dBA Bore .................................................... 130 mm Noise reduction kit, cab Electro-hydraulic operated park Bale clamp

Light, registration plate Steering wheel, adjustable tilt, lugging performance

fan position 2 .................................... 69 dBA Piston rod diameter ......................... 70 mm brake Drum rotator • Torque Parallel Linkage

Side marker lights telescopic • Boom Suspension System

Ventilation .............................................. 10 m3/min Stroke ................................................. 710 mm Contronic display – meets all known exhaust – high breakout torque through

Windshield washer, front & rear

Heating capacity .................................. 11 kW (37 500 Btu/h) Tilt cylinder ............................................ 1 emission regulations for off- out the working range • Comfort Drive Control

Air conditioning (optional) ................. 8 kW (27 300 Btu/h) Bore .................................................... 190 mm road vehicles until 2002 – excellent parallel lift-arm

Under our policy of continuous product improvement, we reserve the right to change specifications and design

Piston rod diameter ......................... 90 mm without prior notice. The illustrations do not necessarily show the standard version of the machine. action

Stroke ................................................. 430 mm

Volvo Construction Equipment Group

Ref. No. 212 669 2262 English

Printed in Sweden 98.03 – 6,0 WLO

SERVICE REFILL CAPACITIES DRIVETRAIN OPERATIONAL DATA, VOLVO L90C OPERATIONAL DATA & DIMENSIONS

Contronic monitoring system provides information on Drivetrain and working hydraulics well-matched to each other. GENERAL PURPOSE LIGHT MATERIAL Tires: 20.5 R25* L2 Where applicable, specifications and

machine condition, routine maintenance schedules and Dependable design. Quick acceleration boosts productivity. dimensions are in accordance with ISO 7131,

B 6 050 mm SAE J732, ISO 7546, SAE J742, ISO 5998,

minimizes time required for troubleshooting. Volvo system-compatible design facilitates servicing.

SAE J818, ISO 8313.

C 3 000 mm

Service accessibility: Large, easy-to-open engine access Torque converter: Single-stage

doors with gas struts. Hinged radiator grille and radiator. D 410 mm a4

Tires 20.5 R25* Teeth Bolt-on edge Teeth Teeth Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge

Transmission: Volvo Power Shift transmission of countershaft

a1

Fuel tank ............................. 210 l Transmission .......... 33 l type with single-lever control. Fast and smooth forward/ Volume, heaped

F 3 270 mm V

m3 2,2 2,5 2,5 2,5 2,6 2,6 2,7 2,7 4,1 7,0

Engine coolant .................. 53 l Engine oil ................ 16 l reverse shifting. ISO/SAE

G 2 135 mm

Hydraulic tank .................... 130 l Axle front / rear ...... 36/41 l Shifting system: Volvo Automatic Power Shift (APS II) with Actual volume, 110% m3 2,4 2,8 2,8 2,8 2,9 2,9 3,0 3,0 4,5 7,7

J 3 650 mm

mode selector. Static tipping load,

kg 10 180 9 760 9 970 10 550 9 770 10 410 9 720 10 290 9 550 9 270

straight K 3 960 mm

Axles: Volvo, fully floating axle shafts with planetary-type hub a3

reductions. Cast-steel axle housing. Fixed front axle and at 35° turn kg 9 010 8 600 8 800 9 350 8 610 9 210 8 550 9 090 8 400 8 100 O 57˚

a2

oscillating rear axle. 100 % differential lock on front axle. at full turn kg 8 660 8 250 8 450 8 980 8 250 8 850 8 190 8 730 8 050 7 750 P 45˚ (P max 49˚)

ENGINE Transmission ......................................... Volvo HT 131 Breakout force kN 115,1 104,9 108,0 118,2 102,9 112,1 101,0 109,8 82,0 70,4 R 44˚

Torque multiplication ........................... 2,66:1 O

Engine delivers high torque and quick response at low rpm R 1* 48˚ X

Speeds, max forward/reverse A mm 7 610 7 550 7 700 7 600 7 580 7 470 7 610 7 500 7 930 8 230

even under full load. The machine can work at low engine Y

1 ........................................................... 7,1 km/h S 67˚

speeds, which contributes to good fuel economy, less noise, 2 ........................................................... 13,3 km/h E mm 1 130 1 250 1 220 1 100 1 280 1 180 1 300 1 200 1 590 1 860

T 110 mm P

less wear and longer life. 3 ........................................................... 27,7 km/h Z1 L

4 (forward only) ................................ 38,2 km/h H *) mm 2 730 2 770 2 670 2 750 2 750 2 830 2 730 2 810 2 520 2 320

M

Engine: 6-cylinder, in-line, direct-injected, turbocharged, U 450 mm

Measured with tires ............................. 20.5 R25* L2 K

intercooled 4-stroke diesel engine with wet replaceable L mm 5 380 5 430 5 460 5 400 5 460 5 400 5 490 5 430 5 560 5 770 N J

Front axle ............................................... Volvo / AWB 30 X 1 960 mm

cylinder liners. Oscillation, rear axle ........................ ± 15° M*) mm 1 240 1 150 1 300 1 230 1 170 1 100 1 190 1 120 1 440 1 660

F

H

Ground clearance at Y 2 490 mm

Air cleaning: three-stage. R R1 G

15° oscillation ................................... 505 mm N*) mm 1 780 1 720 1 800 1 770 1 730 1 690 1 730 1 690 1 750 1 730 Z 3 060 mm

Engine .................................................. Volvo TD 63 KBE D 15°

U

V mm 2 650 2 650 2 650 2 650 2 650 2 650 2 650 2 650 2 750 3 000 a2 5 370 mm

Flywheel output at ............................. 35 r/s (2 100 r/min)

C

SAE J1349 gross .......................... 118 kW (160 hp) a1 clearance circle mm 12 160 12 060 12 210 12 140 12 080 12 010 12 100 12 030 12 390 12 810 a3 2 880 mm T E

B

SAE J1349 net ............................... 113 kW (153 hp) A

Max. torque at ..................................... 18,3 r/s (1 100 r/min) a4 ± 40˚

Operating weight kg 15 060 15 190 15 140 14 910 15 220 15 000 15 250 15 020 15 300 15 710

S

SAE J1349 gross .......................... 695 Nm * Carry position SAE

SAE J1349 net ............................... 690 Nm *) at dump angle 45° Including counterweight 1

Displacement ...................................... 5,48 l

Nm

700 BUCKET SELECTION CHART

650

BRAKE SYSTEM The choice of bucket is determined by the density of the material and the bucket fill factor. The TP-linkage uses a very open bucket design, has very good roll back in all

600 positions plus fills the bucket very well. This means that the actual volume carried is often larger than the rated capacity of the bucket. Bucket fill factors od different materials and

550 Simple, reliable system with few parts ensures high how they effect the actual bucket volume are shown in the table. Example: Sand and gravel. Fill factor ~105%. Density 1,7 ton/m3. Result: The 2,4 m3 bucket carries 2,5 m3. GRAPPLE (Hook on)

500 availability and safety. Self-adjusting internal oil circulation- For optimum stability always consult the bucket selection chart.

Volvo TD 63 KBE 450 cooled disc brakes give long service intervals. Tires: 20.5 R25* L2

GROSS

400 Material ISO/SAE Type of ISO/SAE L90C Material density (t/m3) A 1,8 m2

NET

Bucket density bucket Actual bucket Bucket Order No: 92 743

Service brakes: Volvo, dual-circuit system with nitrogen- volume 1,0 1,2 1,4 1,6 1,8 2,0

Material fill % ton/m3 volume, m3 volume, m3 B 3 440 mm Operating weight: 15 850 kg (incl. counterweight 1 & 2)

800 1000 1200 1400 1600 1800 2000 2200 r/min charged accumulators for dead engine braking. Fully Earth/Clay ~ 110 ~ 1,8 ~ 2,4 Operating load: 4 800 kg (incl. counterweight 1 & 2)

2,2

r/s hydraulically operated enclosed internal oil circulation-cooled, ~ 1,7 ~ 2,6 2,2 m3 2,4 2,2 C 1 670 mm

General purpose

15 20 25 30 35 2,4 A

2.9 yd3

outboard mounted disc brakes. Transmission declutch during ~ 1,5 2,6 ~ 2,9

D 2 890 mm

ELECTRICAL SYSTEM braking can be preselected by a switch on the instrument Sand/Gravel ~ 105 ~ 1,9

~ 1,7

2,2

2,4

~ 2,3

~ 2,5 2,4 m3 2,6 2,4

panel. Brake performance test by the Contronic system. 3.1 yd3 E 1 310 mm

~ 1,6 2,6 ~ 2,7

Contronic monitoring system with complete information on Aggregate ~ 100 ~ 1,9 2,2 ~ 2,2 1 470 mm

Parking brake: Mechanically operated disc brake on front 2,6 m3 2,9 2,6 F

the status of the machine’s various systems is standard. ~ 1,8 2,4 ~ 2,4 20° I

axle input shaft. ~ 1,6 ~ 2,6

3.4 yd3 45°

Electrical system with circuit board is well protected by fuses. 2,6 G 2 610 mm

≤ 100

material

Rock ~ 1,7 2,2 ~ 2,2

Light-

Prepared for retrofitting of optional equipment. Secondary brake: Either of the service brake circuits or the 4,1m3 4,1 H 4 520 mm H

parking brake fullfills ISO/SAE safety requirements. The size of rock buckets is optimized for optimal penetration andfilling 5.4 yd3 K

Central warning: Central warning lamp for the following capability rather than the density of the material. I 6 260 mm

20° B

J

functions: engine oil pressure, engine coolant temperature Standards: The brake system complies with the requirements Bucket fill D

(with buzzer), hydraulic oil pressure in transmission, transmis- of ISO 3450, SAE J1473 110% 105% 100% 95% J 2 400 mm

sion oil temperature, brake pressure, parking brake (buzzer), F

K 2 590 mm

shut down to idle as standard. Number of discs/wheel ............................................... 1

Number of accumulators ............................................ 2 SUPPLEMENTAL OPERATING DATA L 1 990 mm

E

Voltage ................................................. 24 V Volume, each ............................................................. 1,0 l C

M 8 210 mm L

Batteries .............................................. 2x12 V Excluding Counterweight 2 G

Battery capacity ................................. 2x105 Ah counterweight 1 M

Alternator rating ................................. 1 680 W / 60 A

Starter-motor output ......................... 5,4 kW (7,3 hp) Operating weight kg –300 +500

Tipping Load, full turn kg –500

Counterweight 1 may be used in rehandling and material handling.

+800

Counterweight 2, and combinations of counterweight 1 and 2, may be used within

pallet and material arms handling for stabilizing purposes on firm and level ground.

Counterweight 2 replaces hydroinflation of rear tires and must never be combined

with tire chains.

SERVICE REFILL CAPACITIES DRIVETRAIN OPERATIONAL DATA, VOLVO L90C OPERATIONAL DATA & DIMENSIONS

Contronic monitoring system provides information on Drivetrain and working hydraulics well-matched to each other. GENERAL PURPOSE LIGHT MATERIAL Tires: 20.5 R25* L2 Where applicable, specifications and

machine condition, routine maintenance schedules and Dependable design. Quick acceleration boosts productivity. dimensions are in accordance with ISO 7131,

B 6 050 mm SAE J732, ISO 7546, SAE J742, ISO 5998,

minimizes time required for troubleshooting. Volvo system-compatible design facilitates servicing.

SAE J818, ISO 8313.

C 3 000 mm

Service accessibility: Large, easy-to-open engine access Torque converter: Single-stage

doors with gas struts. Hinged radiator grille and radiator. D 410 mm a4

Tires 20.5 R25* Teeth Bolt-on edge Teeth Teeth Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge

Transmission: Volvo Power Shift transmission of countershaft

a1

Fuel tank ............................. 210 l Transmission .......... 33 l type with single-lever control. Fast and smooth forward/ Volume, heaped

F 3 270 mm V

m3 2,2 2,5 2,5 2,5 2,6 2,6 2,7 2,7 4,1 7,0

Engine coolant .................. 53 l Engine oil ................ 16 l reverse shifting. ISO/SAE

G 2 135 mm

Hydraulic tank .................... 130 l Axle front / rear ...... 36/41 l Shifting system: Volvo Automatic Power Shift (APS II) with Actual volume, 110% m3 2,4 2,8 2,8 2,8 2,9 2,9 3,0 3,0 4,5 7,7

J 3 650 mm

mode selector. Static tipping load,

kg 10 180 9 760 9 970 10 550 9 770 10 410 9 720 10 290 9 550 9 270

straight K 3 960 mm

Axles: Volvo, fully floating axle shafts with planetary-type hub a3

reductions. Cast-steel axle housing. Fixed front axle and at 35° turn kg 9 010 8 600 8 800 9 350 8 610 9 210 8 550 9 090 8 400 8 100 O 57˚

a2

oscillating rear axle. 100 % differential lock on front axle. at full turn kg 8 660 8 250 8 450 8 980 8 250 8 850 8 190 8 730 8 050 7 750 P 45˚ (P max 49˚)

ENGINE Transmission ......................................... Volvo HT 131 Breakout force kN 115,1 104,9 108,0 118,2 102,9 112,1 101,0 109,8 82,0 70,4 R 44˚

Torque multiplication ........................... 2,66:1 O

Engine delivers high torque and quick response at low rpm R 1* 48˚ X

Speeds, max forward/reverse A mm 7 610 7 550 7 700 7 600 7 580 7 470 7 610 7 500 7 930 8 230

even under full load. The machine can work at low engine Y

1 ........................................................... 7,1 km/h S 67˚

speeds, which contributes to good fuel economy, less noise, 2 ........................................................... 13,3 km/h E mm 1 130 1 250 1 220 1 100 1 280 1 180 1 300 1 200 1 590 1 860

T 110 mm P

less wear and longer life. 3 ........................................................... 27,7 km/h Z1 L

4 (forward only) ................................ 38,2 km/h H *) mm 2 730 2 770 2 670 2 750 2 750 2 830 2 730 2 810 2 520 2 320

M

Engine: 6-cylinder, in-line, direct-injected, turbocharged, U 450 mm

Measured with tires ............................. 20.5 R25* L2 K

intercooled 4-stroke diesel engine with wet replaceable L mm 5 380 5 430 5 460 5 400 5 460 5 400 5 490 5 430 5 560 5 770 N J

Front axle ............................................... Volvo / AWB 30 X 1 960 mm

cylinder liners. Oscillation, rear axle ........................ ± 15° M*) mm 1 240 1 150 1 300 1 230 1 170 1 100 1 190 1 120 1 440 1 660

F

H

Ground clearance at Y 2 490 mm

Air cleaning: three-stage. R R1 G

15° oscillation ................................... 505 mm N*) mm 1 780 1 720 1 800 1 770 1 730 1 690 1 730 1 690 1 750 1 730 Z 3 060 mm

Engine .................................................. Volvo TD 63 KBE D 15°

U

V mm 2 650 2 650 2 650 2 650 2 650 2 650 2 650 2 650 2 750 3 000 a2 5 370 mm

Flywheel output at ............................. 35 r/s (2 100 r/min)

C

SAE J1349 gross .......................... 118 kW (160 hp) a1 clearance circle mm 12 160 12 060 12 210 12 140 12 080 12 010 12 100 12 030 12 390 12 810 a3 2 880 mm T E

B

SAE J1349 net ............................... 113 kW (153 hp) A

Max. torque at ..................................... 18,3 r/s (1 100 r/min) a4 ± 40˚

Operating weight kg 15 060 15 190 15 140 14 910 15 220 15 000 15 250 15 020 15 300 15 710

S

SAE J1349 gross .......................... 695 Nm * Carry position SAE

SAE J1349 net ............................... 690 Nm *) at dump angle 45° Including counterweight 1

Displacement ...................................... 5,48 l

Nm

700 BUCKET SELECTION CHART

650

BRAKE SYSTEM The choice of bucket is determined by the density of the material and the bucket fill factor. The TP-linkage uses a very open bucket design, has very good roll back in all

600 positions plus fills the bucket very well. This means that the actual volume carried is often larger than the rated capacity of the bucket. Bucket fill factors od different materials and

550 Simple, reliable system with few parts ensures high how they effect the actual bucket volume are shown in the table. Example: Sand and gravel. Fill factor ~105%. Density 1,7 ton/m3. Result: The 2,4 m3 bucket carries 2,5 m3. GRAPPLE (Hook on)

500 availability and safety. Self-adjusting internal oil circulation- For optimum stability always consult the bucket selection chart.

Volvo TD 63 KBE 450 cooled disc brakes give long service intervals. Tires: 20.5 R25* L2

GROSS

400 Material ISO/SAE Type of ISO/SAE L90C Material density (t/m3) A 1,8 m2

NET

Bucket density bucket Actual bucket Bucket Order No: 92 743

Service brakes: Volvo, dual-circuit system with nitrogen- volume 1,0 1,2 1,4 1,6 1,8 2,0

Material fill % ton/m3 volume, m3 volume, m3 B 3 440 mm Operating weight: 15 850 kg (incl. counterweight 1 & 2)

800 1000 1200 1400 1600 1800 2000 2200 r/min charged accumulators for dead engine braking. Fully Earth/Clay ~ 110 ~ 1,8 ~ 2,4 Operating load: 4 800 kg (incl. counterweight 1 & 2)

2,2

r/s hydraulically operated enclosed internal oil circulation-cooled, ~ 1,7 ~ 2,6 2,2 m3 2,4 2,2 C 1 670 mm

General purpose

15 20 25 30 35 2,4 A

2.9 yd3

outboard mounted disc brakes. Transmission declutch during ~ 1,5 2,6 ~ 2,9

D 2 890 mm

ELECTRICAL SYSTEM braking can be preselected by a switch on the instrument Sand/Gravel ~ 105 ~ 1,9

~ 1,7

2,2

2,4

~ 2,3

~ 2,5 2,4 m3 2,6 2,4

panel. Brake performance test by the Contronic system. 3.1 yd3 E 1 310 mm

~ 1,6 2,6 ~ 2,7

Contronic monitoring system with complete information on Aggregate ~ 100 ~ 1,9 2,2 ~ 2,2 1 470 mm

Parking brake: Mechanically operated disc brake on front 2,6 m3 2,9 2,6 F

the status of the machine’s various systems is standard. ~ 1,8 2,4 ~ 2,4 20° I

axle input shaft. ~ 1,6 ~ 2,6

3.4 yd3 45°

Electrical system with circuit board is well protected by fuses. 2,6 G 2 610 mm

≤ 100

material

Rock ~ 1,7 2,2 ~ 2,2

Light-

Prepared for retrofitting of optional equipment. Secondary brake: Either of the service brake circuits or the 4,1m3 4,1 H 4 520 mm H

parking brake fullfills ISO/SAE safety requirements. The size of rock buckets is optimized for optimal penetration andfilling 5.4 yd3 K

Central warning: Central warning lamp for the following capability rather than the density of the material. I 6 260 mm

20° B

J

functions: engine oil pressure, engine coolant temperature Standards: The brake system complies with the requirements Bucket fill D

(with buzzer), hydraulic oil pressure in transmission, transmis- of ISO 3450, SAE J1473 110% 105% 100% 95% J 2 400 mm

sion oil temperature, brake pressure, parking brake (buzzer), F

K 2 590 mm

shut down to idle as standard. Number of discs/wheel ............................................... 1

Number of accumulators ............................................ 2 SUPPLEMENTAL OPERATING DATA L 1 990 mm

E

Voltage ................................................. 24 V Volume, each ............................................................. 1,0 l C

M 8 210 mm L

Batteries .............................................. 2x12 V Excluding Counterweight 2 G

Battery capacity ................................. 2x105 Ah counterweight 1 M

Alternator rating ................................. 1 680 W / 60 A

Starter-motor output ......................... 5,4 kW (7,3 hp) Operating weight kg –300 +500

Tipping Load, full turn kg –500

Counterweight 1 may be used in rehandling and material handling.

+800

Counterweight 2, and combinations of counterweight 1 and 2, may be used within

pallet and material arms handling for stabilizing purposes on firm and level ground.

Counterweight 2 replaces hydroinflation of rear tires and must never be combined

with tire chains.

SERVICE REFILL CAPACITIES DRIVETRAIN OPERATIONAL DATA, VOLVO L90C OPERATIONAL DATA & DIMENSIONS

Contronic monitoring system provides information on Drivetrain and working hydraulics well-matched to each other. GENERAL PURPOSE LIGHT MATERIAL Tires: 20.5 R25* L2 Where applicable, specifications and

machine condition, routine maintenance schedules and Dependable design. Quick acceleration boosts productivity. dimensions are in accordance with ISO 7131,

B 6 050 mm SAE J732, ISO 7546, SAE J742, ISO 5998,

minimizes time required for troubleshooting. Volvo system-compatible design facilitates servicing.

SAE J818, ISO 8313.

C 3 000 mm

Service accessibility: Large, easy-to-open engine access Torque converter: Single-stage

doors with gas struts. Hinged radiator grille and radiator. D 410 mm a4

Tires 20.5 R25* Teeth Bolt-on edge Teeth Teeth Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge Bolt-on edge

Transmission: Volvo Power Shift transmission of countershaft

a1

Fuel tank ............................. 210 l Transmission .......... 33 l type with single-lever control. Fast and smooth forward/ Volume, heaped

F 3 270 mm V

m3 2,2 2,5 2,5 2,5 2,6 2,6 2,7 2,7 4,1 7,0

Engine coolant .................. 53 l Engine oil ................ 16 l reverse shifting. ISO/SAE

G 2 135 mm

Hydraulic tank .................... 130 l Axle front / rear ...... 36/41 l Shifting system: Volvo Automatic Power Shift (APS II) with Actual volume, 110% m3 2,4 2,8 2,8 2,8 2,9 2,9 3,0 3,0 4,5 7,7

J 3 650 mm

mode selector. Static tipping load,

kg 10 180 9 760 9 970 10 550 9 770 10 410 9 720 10 290 9 550 9 270

straight K 3 960 mm

Axles: Volvo, fully floating axle shafts with planetary-type hub a3

reductions. Cast-steel axle housing. Fixed front axle and at 35° turn kg 9 010 8 600 8 800 9 350 8 610 9 210 8 550 9 090 8 400 8 100 O 57˚

a2

oscillating rear axle. 100 % differential lock on front axle. at full turn kg 8 660 8 250 8 450 8 980 8 250 8 850 8 190 8 730 8 050 7 750 P 45˚ (P max 49˚)

ENGINE Transmission ......................................... Volvo HT 131 Breakout force kN 115,1 104,9 108,0 118,2 102,9 112,1 101,0 109,8 82,0 70,4 R 44˚

Torque multiplication ........................... 2,66:1 O

Engine delivers high torque and quick response at low rpm R 1* 48˚ X

Speeds, max forward/reverse A mm 7 610 7 550 7 700 7 600 7 580 7 470 7 610 7 500 7 930 8 230

even under full load. The machine can work at low engine Y

1 ........................................................... 7,1 km/h S 67˚

speeds, which contributes to good fuel economy, less noise, 2 ........................................................... 13,3 km/h E mm 1 130 1 250 1 220 1 100 1 280 1 180 1 300 1 200 1 590 1 860

T 110 mm P

less wear and longer life. 3 ........................................................... 27,7 km/h Z1 L

4 (forward only) ................................ 38,2 km/h H *) mm 2 730 2 770 2 670 2 750 2 750 2 830 2 730 2 810 2 520 2 320

M

Engine: 6-cylinder, in-line, direct-injected, turbocharged, U 450 mm

Measured with tires ............................. 20.5 R25* L2 K

intercooled 4-stroke diesel engine with wet replaceable L mm 5 380 5 430 5 460 5 400 5 460 5 400 5 490 5 430 5 560 5 770 N J

Front axle ............................................... Volvo / AWB 30 X 1 960 mm

cylinder liners. Oscillation, rear axle ........................ ± 15° M*) mm 1 240 1 150 1 300 1 230 1 170 1 100 1 190 1 120 1 440 1 660

F

H

Ground clearance at Y 2 490 mm

Air cleaning: three-stage. R R1 G

15° oscillation ................................... 505 mm N*) mm 1 780 1 720 1 800 1 770 1 730 1 690 1 730 1 690 1 750 1 730 Z 3 060 mm

Engine .................................................. Volvo TD 63 KBE D 15°

U

V mm 2 650 2 650 2 650 2 650 2 650 2 650 2 650 2 650 2 750 3 000 a2 5 370 mm

Flywheel output at ............................. 35 r/s (2 100 r/min)

C

SAE J1349 gross .......................... 118 kW (160 hp) a1 clearance circle mm 12 160 12 060 12 210 12 140 12 080 12 010 12 100 12 030 12 390 12 810 a3 2 880 mm T E

B

SAE J1349 net ............................... 113 kW (153 hp) A

Max. torque at ..................................... 18,3 r/s (1 100 r/min) a4 ± 40˚

Operating weight kg 15 060 15 190 15 140 14 910 15 220 15 000 15 250 15 020 15 300 15 710

S

SAE J1349 gross .......................... 695 Nm * Carry position SAE

SAE J1349 net ............................... 690 Nm *) at dump angle 45° Including counterweight 1

Displacement ...................................... 5,48 l

Nm

700 BUCKET SELECTION CHART

650

BRAKE SYSTEM The choice of bucket is determined by the density of the material and the bucket fill factor. The TP-linkage uses a very open bucket design, has very good roll back in all

600 positions plus fills the bucket very well. This means that the actual volume carried is often larger than the rated capacity of the bucket. Bucket fill factors od different materials and

550 Simple, reliable system with few parts ensures high how they effect the actual bucket volume are shown in the table. Example: Sand and gravel. Fill factor ~105%. Density 1,7 ton/m3. Result: The 2,4 m3 bucket carries 2,5 m3. GRAPPLE (Hook on)

500 availability and safety. Self-adjusting internal oil circulation- For optimum stability always consult the bucket selection chart.

Volvo TD 63 KBE 450 cooled disc brakes give long service intervals. Tires: 20.5 R25* L2

GROSS

400 Material ISO/SAE Type of ISO/SAE L90C Material density (t/m3) A 1,8 m2

NET

Bucket density bucket Actual bucket Bucket Order No: 92 743

Service brakes: Volvo, dual-circuit system with nitrogen- volume 1,0 1,2 1,4 1,6 1,8 2,0

Material fill % ton/m3 volume, m3 volume, m3 B 3 440 mm Operating weight: 15 850 kg (incl. counterweight 1 & 2)

800 1000 1200 1400 1600 1800 2000 2200 r/min charged accumulators for dead engine braking. Fully Earth/Clay ~ 110 ~ 1,8 ~ 2,4 Operating load: 4 800 kg (incl. counterweight 1 & 2)

2,2

r/s hydraulically operated enclosed internal oil circulation-cooled, ~ 1,7 ~ 2,6 2,2 m3 2,4 2,2 C 1 670 mm

General purpose

15 20 25 30 35 2,4 A

2.9 yd3

outboard mounted disc brakes. Transmission declutch during ~ 1,5 2,6 ~ 2,9

D 2 890 mm

ELECTRICAL SYSTEM braking can be preselected by a switch on the instrument Sand/Gravel ~ 105 ~ 1,9

~ 1,7

2,2

2,4

~ 2,3

~ 2,5 2,4 m3 2,6 2,4

panel. Brake performance test by the Contronic system. 3.1 yd3 E 1 310 mm

~ 1,6 2,6 ~ 2,7

Contronic monitoring system with complete information on Aggregate ~ 100 ~ 1,9 2,2 ~ 2,2 1 470 mm

Parking brake: Mechanically operated disc brake on front 2,6 m3 2,9 2,6 F

the status of the machine’s various systems is standard. ~ 1,8 2,4 ~ 2,4 20° I

axle input shaft. ~ 1,6 ~ 2,6

3.4 yd3 45°

Electrical system with circuit board is well protected by fuses. 2,6 G 2 610 mm

≤ 100

material

Rock ~ 1,7 2,2 ~ 2,2

Light-

Prepared for retrofitting of optional equipment. Secondary brake: Either of the service brake circuits or the 4,1m3 4,1 H 4 520 mm H

parking brake fullfills ISO/SAE safety requirements. The size of rock buckets is optimized for optimal penetration andfilling 5.4 yd3 K

Central warning: Central warning lamp for the following capability rather than the density of the material. I 6 260 mm

20° B

J

functions: engine oil pressure, engine coolant temperature Standards: The brake system complies with the requirements Bucket fill D

(with buzzer), hydraulic oil pressure in transmission, transmis- of ISO 3450, SAE J1473 110% 105% 100% 95% J 2 400 mm

sion oil temperature, brake pressure, parking brake (buzzer), F

K 2 590 mm

shut down to idle as standard. Number of discs/wheel ............................................... 1

Number of accumulators ............................................ 2 SUPPLEMENTAL OPERATING DATA L 1 990 mm

E

Voltage ................................................. 24 V Volume, each ............................................................. 1,0 l C

M 8 210 mm L

Batteries .............................................. 2x12 V Excluding Counterweight 2 G

Battery capacity ................................. 2x105 Ah counterweight 1 M

Alternator rating ................................. 1 680 W / 60 A

Starter-motor output ......................... 5,4 kW (7,3 hp) Operating weight kg –300 +500

Tipping Load, full turn kg –500

Counterweight 1 may be used in rehandling and material handling.

+800

Counterweight 2, and combinations of counterweight 1 and 2, may be used within

pallet and material arms handling for stabilizing purposes on firm and level ground.

Counterweight 2 replaces hydroinflation of rear tires and must never be combined

with tire chains.

STEERING SYSTEM HYDRAULIC SYSTEM STANDARD EQUIPMENT

Low-effort steering gives short work cycle times. Power- Open centre hydraulics with highly efficient vane pumps Engine Warning & monitoring lights: Brake System Hydraulic System

VOLVO WHEEL LOADER

L90C

Air cleaner, dry type, dual element, • engine oil pressure Wet, internal oil circulation cooled, Main valve, 3-Spool, pilot operated

efficient system provides good fuel economy, good directional allows precision control even at low rpm´s together with quick • engine coolant temperature

exhaust aspirated pre-cleaner disc brakes, 4-wheel, dual circuit Pilot valve, 3-spool

stability and smooth ride. movements thanks to the high capacity pumps. Coolant level, sight gauge • air cleaner restriction Brake system, secondary Vane pump

Engine intake manifold preheater • alternator malfunction Parking brake alarm Bucket lever detent

Steering system: Load-sensing hydrostatic articulated Pump: Vane pump fitted to a power take-off on the transmis- Muffler, spark arresting • working lights Bucket leveler, automatic with posi-

steering. sion. The pilot system is supplied from a combined pilot/brake • high beam driving lights tion indicator, adjustable

• direction indicator, hazard Cab boom lever detents

pump. Electrical System Warning flasher: ROPS (SAE J10400C) (ISO 3471), Boom kickout, automatic, adjustable

System supply: The steering system is supplied from a

24V – prewired for optional • transmission oil pressure FOPS (SAE J 231) (ISO 3449). Hydraulic control lever safety latch

separate steering pump. Valve: Double-acting 3-spool valve. The control valve is accessories • transmission oil temperature Acoustical lining Boom lowering system

actuated by a 3-spool pilot valve. Alternator, 24V, 60 A • brake system pressure Ashtray Hydraulic pressure test ports, Quick

Pump: Variable-flow axial piston pump. Battery disconnect switch • parking brake applied Cigarette lighter connect

Lift function: The valve has four functions: raise, hold, lower Fuel gauge Central warning (with buzzer): Door lockable (left side access) Hydraulic fluid level, sight gauge

Cylinders: Two double-acting cylinders. Hourmeter • engine oil pressure Heater/defroster/pressurizer

and float. Inductive/magnetic automatic boom kickout can be Hydraulic oil cooler

Horn, electric • engine coolant temperature 11 kW, 37 500 Btu/h with four

Steering cylinders ................................ 2 switched on and off and is adjustable to any position between Instrument panel with symbols (buzzer) speed blower fan

Bore .................................................... 70 mm maximum reach and full lift height. Lights: • transmission oil pressure Filtered air External Equipment

• driving (2 front), halogen • transmission oil temperature Floor mat Isolation mounts: cab, engine,

Piston rod diameter ......................... 40 mm Tilt function: The valve has three functions: rollback, hold and with high/low beam • brake system pressure Interior light gearbox

Stroke ................................................. 419 mm dump. Inductive/magnetic automatic bucket positioner that • parking lights Interior rearview mirror Lifting lugs

Relief pressure ..................................... 21 MPa • stop/tail combination Mirrors rearview (2), exterior Side panels, engine hood

can be switched on and off. (2 rear) Drivetrain Openable window, right-hand side Steering frame lock

Max. flow ................................................ 91 l / min Transmission: modulated with single

• turn signals with hazard Safety glass, tinted Vandalism lock, provison for:

Articulation ............................................ ± 40° Cylinders: Double-acting warning switch lever control, Automatic Power Seat belt (SAE J386) batteries, engine oil

• working lights, halogen Shift, and operator controlled Seat, heated, ergonomically desig-

Filter: Full-flow filtration through 20 µm (absolute) filter (2 front, 2 rear) declutch ned, suspension adjustable

cartridge. • instrument lighting Differentials: Storage compartment

Contronic Monitoring System, ECU • front 100 % hydraulic Sun visor

Neutral start feature differential lock Windshield wiper, front & rear

Vane pump Test function for warning & • rear, conventional Intermittent wiper, front

Relief pressure ..................................... 22,5 MPa monitoring lights Tires 20.5 R25* L2 Goodyear Cab access steps and handrails

Flow ..................................................... 202 l/min Fenders, front & rear with anti-skid-

at .......................................................... 10 MPa tape

and engine speed ............................ 35 r/s (2 100 r/min)

CAB Pilot system

Relief pressure .................................. 3,0 MPa

Care Cab with easy entry and wide door opening. Lined with Cycle times

sound-absorbent material. Sound- and vibration-suppressing Raise* .................................................. 5,5 s

suspension. Good all round visibility, large glass areas. Dump* ................................................. 1,9 s OPTIONAL EQUIPMENT (Standard in certain markets)

Curved windshield of laminated, green-tinted glass. Lower, empty ..................................... 2,3 s

Total cycle time ................................. 9,7 s Service and maintenance Shut down to idle at Hydraulic System Tires

Ergonomically located controls and instruments permit a

• high engine coolant temp Hydraulic control, 3rd function 20.5–25

comfortable operating position. * with load as per ISO 5998 and SAE J818

equipment • low engine oil pressure

Tool box Hydraulic control, 4th function 20.5 R25*

• high transm. oil temp Hydraulic single acting lifting

Instrumentation: All information important to the operator is Tool kit Parking brake applied and

Air pressure equipment function

readily visible in front of him. Cab display for Contronic transmission in forward or Boom Suspension System Protective Equipment

Anti-freeze container reverse (buzzer) Protective grids for front running

monitoring system. Wheel nut wrench kit Biodegradable hydraulic fluid

Hydraulic function 3rd, hydraulic light

hoses Protection guard radiator grille

Heater and defroster: Heating element with filtered fresh air Drivetrain Protective grids for rear working

Engine Forward and reverse switch Servo hoses for separate

and four-speed fan. Defroster outlets for all windows. Coolant filter attachment locking lights

Speed limiter, 3-speed version Window guards for side and rear

Extra fuel filter Limited-slip differentials, front/rear Attachment bracket with separate

Operator’s seat: Spring suspended, adjustable operator’s Cold starting aid, engine locking system window

seat with belt. The seat is mounted on a bracket on the rear coolant preheater (220V/1500 W) Windshield guard

Pre-cleaner, oil bath type Cab Fan protection

wall. The force from the belt is absorbed by the seat rails. External Equipment Protective grids for rear lights

Pre-cleaner, turbo type Installation kit for radio

Fenders, extended Bellyguard rear • Engine output SAE J1349: • Volvo transmission with • Care Cab – pressurized cab

Standards: Tested and approved according to the following LIFTARM SYSTEM Radiator, corrosion protected Hand throttle

Counterweight 1 APS II

standards: ROPS (ISO/CD 3471, SAE J1040), FOPS (ISO

Sliding ventilation window gross 118 kW (160 hp) with high comfort and safety

Counterweight 2

Electrical System Speedometer Attachments net 113 kW (153 hp) – 2nd generation Automatic

3449, SAE J231). Complies with ”Overhead guards for rider TP Linkage combines high breakout torque throughout the Air suspended operator's seat Fenders, axle mounted

• Contronic monitoring system

Reverse alarm (SAE J994) Drawbar with pin Buckets Power Shift with mode

lift trucks” (ISO 6055) and ”Operator Restraint System” (SAE working range with nearly exact parallel lift-arm action. These Retractable seat belt Fork equipment • Operating weight: 14,4–16,1 t

Attachment lights Air conditioner 8 kW, selector

J386). features together with high lift height and long reach make Working lights front, extra Material handling arm • Load-sensing steering system

Working lights rear, extra

Dual service brake pedals Other Equipment Timber grapples • Buckets: 2,2–7,0 m3 – optimises performance

the lift-arm system equally as good in bucket loading as in Armrest (left) Comfort Drive Control (CDC) Diagonal snow blade

Rotating beacon, amber with • Wet disc brakes • Pilot-operated working hydraulics

Emergency exits ................................... 2 work with fork attachments and material handling arms. Contronic display Slow moving vehicle emblem Broom

collapsible mount Cab filter for asbetos contaminated • Volvo high performance- – fully sealed oil-circulation

Sound level in cab Alternator, brushless Secondary steering Cutting edge, 3 pc reversible, bolt-on Optional Equipment

as per ISO 6396, Head lights assym. left

environment 50 km/h sign Bucket teeth, bolt-on low emission engine cooled

Lift cylinder ............................................ 2 Instructor seat

Jump-start connector (Nato) Fuel fill strainer Bucket spillguard – with excellent low rpm – outboard mounted • Hydraulic attachment bracket

max fan position ................................ 72 dBA Bore .................................................... 130 mm Noise reduction kit, cab Electro-hydraulic operated park Bale clamp

Light, registration plate Steering wheel, adjustable tilt, lugging performance

fan position 2 .................................... 69 dBA Piston rod diameter ......................... 70 mm brake Drum rotator • Torque Parallel Linkage

Side marker lights telescopic • Boom Suspension System

Ventilation .............................................. 10 m3/min Stroke ................................................. 710 mm Contronic display – meets all known exhaust – high breakout torque through

Windshield washer, front & rear

Heating capacity .................................. 11 kW (37 500 Btu/h) Tilt cylinder ............................................ 1 emission regulations for off- out the working range • Comfort Drive Control

Air conditioning (optional) ................. 8 kW (27 300 Btu/h) Bore .................................................... 190 mm road vehicles until 2002 – excellent parallel lift-arm

Under our policy of continuous product improvement, we reserve the right to change specifications and design

Piston rod diameter ......................... 90 mm without prior notice. The illustrations do not necessarily show the standard version of the machine. action

Stroke ................................................. 430 mm

Volvo Construction Equipment Group

Ref. No. 212 669 2262 English

Printed in Sweden 98.03 – 6,0 WLO

STEERING SYSTEM HYDRAULIC SYSTEM STANDARD EQUIPMENT

Low-effort steering gives short work cycle times. Power- Open centre hydraulics with highly efficient vane pumps Engine Warning & monitoring lights: Brake System Hydraulic System

VOLVO WHEEL LOADER

L90C

Air cleaner, dry type, dual element, • engine oil pressure Wet, internal oil circulation cooled, Main valve, 3-Spool, pilot operated

efficient system provides good fuel economy, good directional allows precision control even at low rpm´s together with quick • engine coolant temperature

exhaust aspirated pre-cleaner disc brakes, 4-wheel, dual circuit Pilot valve, 3-spool

stability and smooth ride. movements thanks to the high capacity pumps. Coolant level, sight gauge • air cleaner restriction Brake system, secondary Vane pump

Engine intake manifold preheater • alternator malfunction Parking brake alarm Bucket lever detent

Steering system: Load-sensing hydrostatic articulated Pump: Vane pump fitted to a power take-off on the transmis- Muffler, spark arresting • working lights Bucket leveler, automatic with posi-

steering. sion. The pilot system is supplied from a combined pilot/brake • high beam driving lights tion indicator, adjustable

• direction indicator, hazard Cab boom lever detents

pump. Electrical System Warning flasher: ROPS (SAE J10400C) (ISO 3471), Boom kickout, automatic, adjustable

System supply: The steering system is supplied from a

24V – prewired for optional • transmission oil pressure FOPS (SAE J 231) (ISO 3449). Hydraulic control lever safety latch

separate steering pump. Valve: Double-acting 3-spool valve. The control valve is accessories • transmission oil temperature Acoustical lining Boom lowering system

actuated by a 3-spool pilot valve. Alternator, 24V, 60 A • brake system pressure Ashtray Hydraulic pressure test ports, Quick

Pump: Variable-flow axial piston pump. Battery disconnect switch • parking brake applied Cigarette lighter connect

Lift function: The valve has four functions: raise, hold, lower Fuel gauge Central warning (with buzzer): Door lockable (left side access) Hydraulic fluid level, sight gauge

Cylinders: Two double-acting cylinders. Hourmeter • engine oil pressure Heater/defroster/pressurizer

and float. Inductive/magnetic automatic boom kickout can be Hydraulic oil cooler

Horn, electric • engine coolant temperature 11 kW, 37 500 Btu/h with four

Steering cylinders ................................ 2 switched on and off and is adjustable to any position between Instrument panel with symbols (buzzer) speed blower fan

Bore .................................................... 70 mm maximum reach and full lift height. Lights: • transmission oil pressure Filtered air External Equipment

• driving (2 front), halogen • transmission oil temperature Floor mat Isolation mounts: cab, engine,

Piston rod diameter ......................... 40 mm Tilt function: The valve has three functions: rollback, hold and with high/low beam • brake system pressure Interior light gearbox

Stroke ................................................. 419 mm dump. Inductive/magnetic automatic bucket positioner that • parking lights Interior rearview mirror Lifting lugs

Relief pressure ..................................... 21 MPa • stop/tail combination Mirrors rearview (2), exterior Side panels, engine hood

can be switched on and off. (2 rear) Drivetrain Openable window, right-hand side Steering frame lock

Max. flow ................................................ 91 l / min Transmission: modulated with single

• turn signals with hazard Safety glass, tinted Vandalism lock, provison for:

Articulation ............................................ ± 40° Cylinders: Double-acting warning switch lever control, Automatic Power Seat belt (SAE J386) batteries, engine oil

• working lights, halogen Shift, and operator controlled Seat, heated, ergonomically desig-

Filter: Full-flow filtration through 20 µm (absolute) filter (2 front, 2 rear) declutch ned, suspension adjustable

cartridge. • instrument lighting Differentials: Storage compartment

Contronic Monitoring System, ECU • front 100 % hydraulic Sun visor

Neutral start feature differential lock Windshield wiper, front & rear

Vane pump Test function for warning & • rear, conventional Intermittent wiper, front

Relief pressure ..................................... 22,5 MPa monitoring lights Tires 20.5 R25* L2 Goodyear Cab access steps and handrails

Flow ..................................................... 202 l/min Fenders, front & rear with anti-skid-

at .......................................................... 10 MPa tape

and engine speed ............................ 35 r/s (2 100 r/min)

CAB Pilot system

Relief pressure .................................. 3,0 MPa

Care Cab with easy entry and wide door opening. Lined with Cycle times

sound-absorbent material. Sound- and vibration-suppressing Raise* .................................................. 5,5 s

suspension. Good all round visibility, large glass areas. Dump* ................................................. 1,9 s OPTIONAL EQUIPMENT (Standard in certain markets)

Curved windshield of laminated, green-tinted glass. Lower, empty ..................................... 2,3 s

Total cycle time ................................. 9,7 s Service and maintenance Shut down to idle at Hydraulic System Tires

Ergonomically located controls and instruments permit a

• high engine coolant temp Hydraulic control, 3rd function 20.5–25

comfortable operating position. * with load as per ISO 5998 and SAE J818

equipment • low engine oil pressure

Tool box Hydraulic control, 4th function 20.5 R25*

• high transm. oil temp Hydraulic single acting lifting

Instrumentation: All information important to the operator is Tool kit Parking brake applied and

Air pressure equipment function

readily visible in front of him. Cab display for Contronic transmission in forward or Boom Suspension System Protective Equipment

Anti-freeze container reverse (buzzer) Protective grids for front running

monitoring system. Wheel nut wrench kit Biodegradable hydraulic fluid

Hydraulic function 3rd, hydraulic light

hoses Protection guard radiator grille

Heater and defroster: Heating element with filtered fresh air Drivetrain Protective grids for rear working

Engine Forward and reverse switch Servo hoses for separate

and four-speed fan. Defroster outlets for all windows. Coolant filter attachment locking lights

Speed limiter, 3-speed version Window guards for side and rear

Extra fuel filter Limited-slip differentials, front/rear Attachment bracket with separate

Operator’s seat: Spring suspended, adjustable operator’s Cold starting aid, engine locking system window

seat with belt. The seat is mounted on a bracket on the rear coolant preheater (220V/1500 W) Windshield guard

Pre-cleaner, oil bath type Cab Fan protection

wall. The force from the belt is absorbed by the seat rails. External Equipment Protective grids for rear lights

Pre-cleaner, turbo type Installation kit for radio

Fenders, extended Bellyguard rear • Engine output SAE J1349: • Volvo transmission with • Care Cab – pressurized cab

Standards: Tested and approved according to the following LIFTARM SYSTEM Radiator, corrosion protected Hand throttle

Counterweight 1 APS II

standards: ROPS (ISO/CD 3471, SAE J1040), FOPS (ISO

Sliding ventilation window gross 118 kW (160 hp) with high comfort and safety

Counterweight 2

Electrical System Speedometer Attachments net 113 kW (153 hp) – 2nd generation Automatic

3449, SAE J231). Complies with ”Overhead guards for rider TP Linkage combines high breakout torque throughout the Air suspended operator's seat Fenders, axle mounted

• Contronic monitoring system

Reverse alarm (SAE J994) Drawbar with pin Buckets Power Shift with mode

lift trucks” (ISO 6055) and ”Operator Restraint System” (SAE working range with nearly exact parallel lift-arm action. These Retractable seat belt Fork equipment • Operating weight: 14,4–16,1 t

Attachment lights Air conditioner 8 kW, selector

J386). features together with high lift height and long reach make Working lights front, extra Material handling arm • Load-sensing steering system

Working lights rear, extra

Dual service brake pedals Other Equipment Timber grapples • Buckets: 2,2–7,0 m3 – optimises performance

the lift-arm system equally as good in bucket loading as in Armrest (left) Comfort Drive Control (CDC) Diagonal snow blade

Rotating beacon, amber with • Wet disc brakes • Pilot-operated working hydraulics

Emergency exits ................................... 2 work with fork attachments and material handling arms. Contronic display Slow moving vehicle emblem Broom

collapsible mount Cab filter for asbetos contaminated • Volvo high performance- – fully sealed oil-circulation

Sound level in cab Alternator, brushless Secondary steering Cutting edge, 3 pc reversible, bolt-on Optional Equipment

as per ISO 6396, Head lights assym. left

environment 50 km/h sign Bucket teeth, bolt-on low emission engine cooled

Lift cylinder ............................................ 2 Instructor seat

Jump-start connector (Nato) Fuel fill strainer Bucket spillguard – with excellent low rpm – outboard mounted • Hydraulic attachment bracket

max fan position ................................ 72 dBA Bore .................................................... 130 mm Noise reduction kit, cab Electro-hydraulic operated park Bale clamp

Light, registration plate Steering wheel, adjustable tilt, lugging performance

fan position 2 .................................... 69 dBA Piston rod diameter ......................... 70 mm brake Drum rotator • Torque Parallel Linkage

Side marker lights telescopic • Boom Suspension System

Ventilation .............................................. 10 m3/min Stroke ................................................. 710 mm Contronic display – meets all known exhaust – high breakout torque through

Windshield washer, front & rear

Heating capacity .................................. 11 kW (37 500 Btu/h) Tilt cylinder ............................................ 1 emission regulations for off- out the working range • Comfort Drive Control

Air conditioning (optional) ................. 8 kW (27 300 Btu/h) Bore .................................................... 190 mm road vehicles until 2002 – excellent parallel lift-arm

Under our policy of continuous product improvement, we reserve the right to change specifications and design

Piston rod diameter ......................... 90 mm without prior notice. The illustrations do not necessarily show the standard version of the machine. action

Stroke ................................................. 430 mm

Volvo Construction Equipment Group

Ref. No. 212 669 2262 English

Printed in Sweden 98.03 – 6,0 WLO

You might also like

- Hitachi LX290E: Engine Rated PowerDocument8 pagesHitachi LX290E: Engine Rated PowerAbo Achraf Laalawi67% (3)

- SL4640E SL5240E Skid Loader Parts Manual 917291D PDFDocument266 pagesSL4640E SL5240E Skid Loader Parts Manual 917291D PDFArturs LiepinsNo ratings yet

- SM Volvo Ew180c Wheeled ExcavatorDocument22 pagesSM Volvo Ew180c Wheeled ExcavatorAl AminNo ratings yet

- Operators ManualDocument71 pagesOperators ManualmiguelNo ratings yet

- GRW 280-16 / GRW 280-20: - Rubber-Wheeled Roller - Rubber-Wheeled RollerDocument2 pagesGRW 280-16 / GRW 280-20: - Rubber-Wheeled Roller - Rubber-Wheeled RollerJorge Rafael Ayala100% (2)

- Volvo EC210B Maintenance ManualDocument244 pagesVolvo EC210B Maintenance ManualOTM ServiceNo ratings yet

- A35DContainerHauler EnglishDocument6 pagesA35DContainerHauler Englishandreika1970No ratings yet

- Kenwood Ks 201htDocument4 pagesKenwood Ks 201htOctavio CuevasNo ratings yet

- WA80 WA100M 7 Operation ManualDocument304 pagesWA80 WA100M 7 Operation Manualandres sanchez100% (1)

- 202 Mecalac 12 MXT Wheeled Excavator CatalogueDocument3 pages202 Mecalac 12 MXT Wheeled Excavator CatalogueСергій XрестикNo ratings yet

- MHL360 Technical DataDocument10 pagesMHL360 Technical DataRonaldo FernandesNo ratings yet

- d20x22 Series II Operator'sDocument260 pagesd20x22 Series II Operator'sАнвар РахматуллинNo ratings yet

- Cebm014201 PDFDocument364 pagesCebm014201 PDFJoshua Sv100% (1)

- Zaxis 280-5Document13 pagesZaxis 280-5Tri Ono100% (1)

- SM - E175B Calhoun - EN PDFDocument808 pagesSM - E175B Calhoun - EN PDFskywokerNo ratings yet

- CX130BDocument1,536 pagesCX130BKleiton BizutiNo ratings yet

- Loader Maintenance ManualDocument226 pagesLoader Maintenance Manualjoanvasquez61No ratings yet

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoNo ratings yet

- 84576Document146 pages84576Leobardo Genaro Roque NájeraNo ratings yet

- SD100D, SD100F: Volvo SINGLE Drum CompactorsDocument4 pagesSD100D, SD100F: Volvo SINGLE Drum CompactorsAgung ArdhanaNo ratings yet

- DA - 01 - Foreword - EnglishDocument14 pagesDA - 01 - Foreword - EnglishAugusto OliveiraNo ratings yet

- BW 219 DH 5Document2 pagesBW 219 DH 5Hữu Dũng Nguyễn0% (1)

- Operating Manual: Book ID: 4-P06406CU - ENDocument162 pagesOperating Manual: Book ID: 4-P06406CU - ENАнатолий Смирнов100% (1)

- Roadtec Cold Planers BrochureDocument24 pagesRoadtec Cold Planers BrochureKuntawee100% (1)

- Cukurova - Backhoe Loader 880 (NEW)Document2 pagesCukurova - Backhoe Loader 880 (NEW)Felipe Douglas da Silva100% (1)

- Brochure XGMA PDFDocument8 pagesBrochure XGMA PDFJohn JohnNo ratings yet

- V Ec460 212 1621 0009Document10 pagesV Ec460 212 1621 0009Maria Da Graça RomãoNo ratings yet

- HTTP WWW - Motoren.ath - CX Download - PHP Filename Mitsubishi mitsubishi-SL-series-ServiceManualDocument195 pagesHTTP WWW - Motoren.ath - CX Download - PHP Filename Mitsubishi mitsubishi-SL-series-ServiceManualPhilip RappéNo ratings yet

- Volvo L150 F, L180 F, L220 F BrochureDocument36 pagesVolvo L150 F, L180 F, L220 F Brochuresixin93551No ratings yet

- Hitachi-ZX210LC-5-Spec EN WebDocument11 pagesHitachi-ZX210LC-5-Spec EN WebHery Sanukri MunteNo ratings yet

- D51ex D51PX-22 Cebm019109-39-44Document6 pagesD51ex D51PX-22 Cebm019109-39-44Suharto ZuhriNo ratings yet

- Pub20021274 B Eng L20F L25FDocument169 pagesPub20021274 B Eng L20F L25FJulio FernandoNo ratings yet

- Tamping Rammer Model MT65-H: Parts and Operation ManualDocument64 pagesTamping Rammer Model MT65-H: Parts and Operation ManualaleksandrNo ratings yet

- TMC Program Updates: Dtac Solution Number: 76938 SituationDocument13 pagesTMC Program Updates: Dtac Solution Number: 76938 SituationИлиянВасилев100% (1)

- VOLVO EC160e Product BrochureDocument28 pagesVOLVO EC160e Product BrochurePHÁT NGUYỄN THẾ100% (1)

- TA35 Tier IIDocument446 pagesTA35 Tier IIYeison RamirezNo ratings yet

- 314Document65 pages314dim4erema100% (2)

- Navigator d60x90Document268 pagesNavigator d60x90Abraham Johnson50% (2)

- JCB Vibromax - Compaction Equipment Self-Propelled Vibratory Roller Vm115D/Vm115Pd Tier 3Document2 pagesJCB Vibromax - Compaction Equipment Self-Propelled Vibratory Roller Vm115D/Vm115Pd Tier 3greicel marianjas sihombingNo ratings yet

- Daewoo Solar 210W-VDocument16 pagesDaewoo Solar 210W-VAndrea797No ratings yet

- As Long As The EIC Alarm Is Still Active, You Can Get More DetailedDocument3 pagesAs Long As The EIC Alarm Is Still Active, You Can Get More Detailedgerman gualavisiNo ratings yet

- CA610Document106 pagesCA610Jesus DautantNo ratings yet

- LeeBoy - 8816B - Paver Manual - Pavimentadora - ManualDocument282 pagesLeeBoy - 8816B - Paver Manual - Pavimentadora - ManualIGNACIONo ratings yet

- CX210 BHyd-87598354 ADocument1 pageCX210 BHyd-87598354 AAlfredo GuzmánNo ratings yet

- 9822 0975 28 - CIRCUIT DIAGRAM - Size 2 MB LP: V+ 24VDC V+ 5VdcDocument1 page9822 0975 28 - CIRCUIT DIAGRAM - Size 2 MB LP: V+ 24VDC V+ 5Vdccarlos andres salazar sanchezNo ratings yet

- Topcon System 5 2D Machine Control User ManualDocument172 pagesTopcon System 5 2D Machine Control User ManualSofía FainaNo ratings yet

- New Holland T4030F, T4040F, T4050F, T4060F (Preview)Document6 pagesNew Holland T4030F, T4040F, T4050F, T4060F (Preview)Amip Folk50% (2)

- Disassemble Parking Brake Valve 988bDocument5 pagesDisassemble Parking Brake Valve 988bAristi Omar Fandiño GomezNo ratings yet

- Doosan Esquema EletricoDocument129 pagesDoosan Esquema EletricohelioNo ratings yet

- ETNYRE M-101-06rDocument114 pagesETNYRE M-101-06rSamuel BatistaNo ratings yet

- EC210B Forestry Spec SheetDocument2 pagesEC210B Forestry Spec Sheetdalibor_bogdanNo ratings yet

- TRANSMISSION CONTROL VALVE (2 - 2) - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsDocument2 pagesTRANSMISSION CONTROL VALVE (2 - 2) - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsashraf elsayedNo ratings yet

- Triad Diagnostic Solutions Commercial Vehicle Training GuideDocument138 pagesTriad Diagnostic Solutions Commercial Vehicle Training GuideCarlos AlcantaraNo ratings yet

- V Ec360 212 1620 0009 PDFDocument12 pagesV Ec360 212 1620 0009 PDFJessica NoriegaNo ratings yet

- Konika 7045 Service Manual PDFDocument313 pagesKonika 7045 Service Manual PDFleo visaNo ratings yet

- Manual de Operacion - InglesDocument194 pagesManual de Operacion - InglesGustavo Alonso Cappa Salas100% (1)

- Ausa Backhoe Loader Rc3: Spare Parts ManualDocument357 pagesAusa Backhoe Loader Rc3: Spare Parts ManualMeleștean Mihai100% (2)

- EW180C Main Valve Assembly, Assembly Block None 3-3 NoneNone None Autodata Volvo OnlineDocument2 pagesEW180C Main Valve Assembly, Assembly Block None 3-3 NoneNone None Autodata Volvo OnlineSyed Azhar HussainNo ratings yet

- Volvo Wheel Loader: Steering System Hydraulic System Standard EquipmentDocument6 pagesVolvo Wheel Loader: Steering System Hydraulic System Standard Equipmentfilip.chmielewski2121No ratings yet

- Component List, Switches: Service InformationDocument4 pagesComponent List, Switches: Service InformationJozefNo ratings yet

- Flow PDFDocument1 pageFlow PDFJozefNo ratings yet

- Flow PDFDocument3 pagesFlow PDFJozefNo ratings yet

- Arm Regenerating Valve, Description: Service InformationDocument2 pagesArm Regenerating Valve, Description: Service InformationJozefNo ratings yet

- Arm Regenerating Valve, Description: Service InformationDocument2 pagesArm Regenerating Valve, Description: Service InformationJozefNo ratings yet

- FlowDocument1 pageFlowJozef100% (1)

- SI SX MB Actros PowerShift 1-3 enDocument4 pagesSI SX MB Actros PowerShift 1-3 enJozef100% (1)

- ECR88 Aircon (8289618) Installation Instruction - 1Document10 pagesECR88 Aircon (8289618) Installation Instruction - 1Jozef100% (1)

- Jozef Bardhi Jaltest OHW KitDocument1 pageJozef Bardhi Jaltest OHW KitJozefNo ratings yet

- SI SX MB Actros PowerShift 1-3 enDocument4 pagesSI SX MB Actros PowerShift 1-3 enJozef100% (1)

- User's Manual: Series 988Document163 pagesUser's Manual: Series 988JozefNo ratings yet

- Re 91401Document20 pagesRe 91401JozefNo ratings yet

- Flow Doc.1 PDFDocument12 pagesFlow Doc.1 PDFJozefNo ratings yet

- Flow Doc 2 PDFDocument18 pagesFlow Doc 2 PDFJozefNo ratings yet

- Jozef Bardhi Jaltest OHW KitDocument1 pageJozef Bardhi Jaltest OHW KitJozefNo ratings yet

- Yanmar CANplus 600 Operation and Troubleshooting PDFDocument40 pagesYanmar CANplus 600 Operation and Troubleshooting PDFJozefNo ratings yet

- SI SX MB Actros PowerShift 1-3 enDocument4 pagesSI SX MB Actros PowerShift 1-3 enJozef100% (1)

- CAT 10wDocument1 pageCAT 10wJozefNo ratings yet

- Rexroth 92500Document48 pagesRexroth 92500EVCY100% (1)

- Flow Doc 3 PDFDocument2 pagesFlow Doc 3 PDFJozefNo ratings yet

- Yanmar Excavator Vio75 Service Manual + Electrical Wiring Diagrams + Parts CatalogDocument173 pagesYanmar Excavator Vio75 Service Manual + Electrical Wiring Diagrams + Parts CatalogJozef86% (7)

- Re 91401Document20 pagesRe 91401JozefNo ratings yet

- Flow PDFDocument3 pagesFlow PDFJozefNo ratings yet

- Re 92500Document4 pagesRe 92500Jozef100% (1)

- Yanmar CANplus 600 Operation and Troubleshooting PDFDocument40 pagesYanmar CANplus 600 Operation and Troubleshooting PDFJozefNo ratings yet

- Flow Doc.1 PDFDocument12 pagesFlow Doc.1 PDFJozefNo ratings yet

- Diesel Particulate Filter Handling Manual - Sept - 2013 - 9Y111-07332 PDFDocument55 pagesDiesel Particulate Filter Handling Manual - Sept - 2013 - 9Y111-07332 PDFJozefNo ratings yet

- Flow PDFDocument3 pagesFlow PDFJozefNo ratings yet

- Flow Doc.1 PDFDocument12 pagesFlow Doc.1 PDFJozefNo ratings yet

- Flow Doc 2 PDFDocument18 pagesFlow Doc 2 PDFJozefNo ratings yet

- DB Schedule PDFDocument9 pagesDB Schedule PDFMohamed FaragNo ratings yet

- Assessment of Fogging Resistance of AntiDocument6 pagesAssessment of Fogging Resistance of AntiMehrshad GhasemabadiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMa.socorro SaballaNo ratings yet

- Operation Maintenance Manual - Roller ShuttersDocument28 pagesOperation Maintenance Manual - Roller Shuttersluis Albert RMNo ratings yet

- Scotch Marine Boiler Design: Wetback Vs DrybackDocument24 pagesScotch Marine Boiler Design: Wetback Vs DrybackGopal RamalingamNo ratings yet

- 06 Hideki Goto - Toyota JasPar IndustryDocument18 pages06 Hideki Goto - Toyota JasPar IndustrySomeshwar DanappaNo ratings yet

- Training Calendar (2017) : School of Quality: Iso 9001:2015 - Quality Management SystemDocument1 pageTraining Calendar (2017) : School of Quality: Iso 9001:2015 - Quality Management SystemHasbullah MohdNo ratings yet

- Alternador Honda LineasDocument2 pagesAlternador Honda LineasJames JonesNo ratings yet

- 4600 Series Operator S ManualDocument82 pages4600 Series Operator S ManualtangocharliepdxNo ratings yet

- Dry Van ManualDocument234 pagesDry Van ManualMichael Yoanito Oliviano100% (1)

- Instruction Book PA625 (Hfo-Mdo)Document192 pagesInstruction Book PA625 (Hfo-Mdo)ÖzgürMetin100% (1)

- 3 Pin Plug Presentation FinalDocument22 pages3 Pin Plug Presentation Finaljaygamer100% (2)

- AS9102 FormsDocument4 pagesAS9102 Formstongai100% (1)

- Air BagDocument17 pagesAir BagPrabir Kumar PatiNo ratings yet

- Essay Regarding Safe Use of RadiationDocument6 pagesEssay Regarding Safe Use of RadiationmaaseialNo ratings yet

- Amfori BSCI System Manual GuidesDocument78 pagesAmfori BSCI System Manual GuidesTuan VietNo ratings yet

- Akshaya Patra (Final Report)Document31 pagesAkshaya Patra (Final Report)sneharaj86100% (2)

- ZC201UPDocument11 pagesZC201UPChengalrayulu Mudiraj100% (1)

- Economical Structural Steel WorkDocument83 pagesEconomical Structural Steel Workc_arkell100% (20)

- The 70 20 10 Methodology - Jos AretsDocument19 pagesThe 70 20 10 Methodology - Jos AretsCorporate L&DNo ratings yet

- Branz Advisory Trower PartitionsDocument6 pagesBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- 150 52-NM1Document168 pages150 52-NM1Praveesh ThomasNo ratings yet

- CSS Catalogue PDFDocument8 pagesCSS Catalogue PDFahmadgce04100% (1)

- Circuito Integrado TL072 CNDocument16 pagesCircuito Integrado TL072 CNSalvador Francisco Tello OrtízNo ratings yet

- Six Sigma Green Belt ExaminationDocument6 pagesSix Sigma Green Belt ExaminationJagmohan BishtNo ratings yet

- Course Objective - Rhce On Rhel5: Redhat Certified EngineerDocument4 pagesCourse Objective - Rhce On Rhel5: Redhat Certified Engineerarsalanhanif80No ratings yet

- 12 Cnm111 Unidad Vi (Trafic) p1Document42 pages12 Cnm111 Unidad Vi (Trafic) p1rncc2011No ratings yet

- A380 CmsDocument23 pagesA380 CmseuniceanNo ratings yet

- Specification DiverterDocument9 pagesSpecification Diverterhappale2002No ratings yet