Professional Documents

Culture Documents

Enfriador de Placas - Gea Ecoflex Mod. Nt50t 36 Placas - Hoja 2

Uploaded by

roqueCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enfriador de Placas - Gea Ecoflex Mod. Nt50t 36 Placas - Hoja 2

Uploaded by

roqueCopyright:

Available Formats

NT Plate Heat Exchangers

Application:

Within the EcoFlex® product group, the NT Series is a gasketed plate heat

exchanger for multiple applications. Variety of materials that work across

a broad range of liquids, temperatures and pressures. Well-suited for these

liquid-to-liquid applications:

HVAC chemical sugar marine

food renewable energy power

Benefits:

Versatility—

■ The right design, not a “good enough” design. A wide variety of

materials, sizes, and plate configurations combine with sophisticated

selection software to ensure a perfect selection, whatever your needs.

■ The compact footprint allows you to use it in locations that you

wouldn’t dream of with a shell-and-tube heat exchanger.

Higher Performance at a Lower Cost—

■ Optiwave™ plate corrugations distribute the liquid evenly across the

entire plate width, maximizing heat transfer and minimizing the

number of plates (and cost) required.

Peace of Mind—

■ Over 75 years of experience in crafting high performance plate heat

exchangers.

■ Independent performance certification to ASME and other standards.

Convenient Maintenance—

■ PosLoc™ plate lead-ins cause the plate pack to self-align when

re-installing.

■ EcoLoc™ tools-free gaskets make gasket replacement a snap.

■ Individual plates mean no heavy lifting tools are needed. Faster

more efficient maintenance, with shorter down times.

Long Service Life—

■ Careful corrugation design provides the ideal balance of high

turbulence and proper fluid distribution, reducing fouling from

less-than-perfect media.

Process Equipment Division

GEA PHE Systems

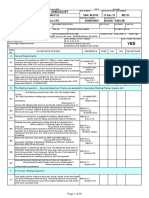

Technical Details:

Heat Transfer Plate: 316 Stainless, 304 Stainless, Titanium,

Hastelloy, 904L, SMO 254, and others on request.

B

Gasket: NBR, NBR High Temperature, EPDM, Viton, and others

on request.

Pressure Plate: Carbon Steel, Stainless Steel, and others on

request.

Port Connection: Unlined, Rubber Lined, Metal Lined

(Stainless, Titanium and others on request), Welded Neck Flange, A C

threaded nipple, and others on request.

Connection

Model Size Dim. A Dim. B Dim. C

Maximum Pressure: Maximum standard pressure is 300 psig

26.6” 16.2-39.2”

(21 bar). Depending on application. NT 50 T (675mm) (411-995mm)

2” nominal 12.7” 40.4” 16.2-39.2”

Maximum Temperature: Maximum standard design NT 50 M (DN 100) (323mm) (1025mm) (411-995mm)

54.9” 16.2-39.2”

temperature is 330°F (170°C). Higher temperatures are

NT 50 X (1395mm) (411-995mm)

available on request. 44.9” 35.9-107.9”

NT 100 T (1140mm) (912-2740mm)

4” nominal 21.3” 60.9” 36.3-84.3”

Maximum Liquid Flow Rate: NT 100 M (DN 100) (540mm) (1546mm) (922-2141mm)

NT50: 175 gpm (40m3/hour) 76.9” 36.3-84.3”

NT 100 X (1952mm) (922-2141mm)

Technical modification reserved. NT-USE 08/06 · 06/08

NT100: 830 gpm (190m3/hour)

67.6” 36.3-108.3”

NT150: 1540 gpm (350m3/hour) NT 150 S 6” nominal 25.1” (1716mm) (922-2750mm)

NT250: 3960 gpm (900m3/hour) (DN 150) (638mm) 86.5” 36.3-108.3”

NT 150 L (2196mm) (922-2750mm)

NT350: 8380 gpm (1900m3/hour)

87.5” 47.8-107.8”

The specifications contained in this printing are intended only to serve the nonbinding NT 250 S (2222mm) (1213-2737mm)

description of our products and services are not subject to guarantee. Binding 10” nominal 35.2” 99.6” 47.6-107.6”

specifications, especially pertaining to performance data and suitability for specific NT 250 M (DN 250) (895mm) (2529mm) (1210-2734mm)

operating purposes, are dependent upon the individual circumstances at the operation

location and can, therefore, only be made in terms of precise requests. Ecoflex is a registered

110.8” 48-108”

trademark of GEA Group. NT 250 L (2815mm) (1220-2744mm)

109.3” 54.8-234.8”

NT 350 S (2776mm) (1391-5963mm)

14” nominal 44.7” 122.5” 54.8-234.8”

NT 350 M (DN 350) (1134mm) (3113mm) (1391-5963mm)

135.8” 54.8-234.8”

NT 350 L (3450mm) (1391-5963mm)

GEA PHE Systems - Competence in Heat Transfer

With emphasis on the highest quality standards and constant innovations, GEA PHE Systems continues to expand its market position:

Within the GEA Process Equipment Division, GEA Ecoflex together with GEA ViEX, GEA WTT, GEA Ecobraze, GEA PHE Systems NA, and

GEA EcoServe forms GEA PHE Systems, the Center of Competence and Service Center for gasketed, fully welded, and brazed plate heat

exchangers of GEA Group:

• HVAC • sugar • paper • life science • power

• refrigeration • chemical • food • marine • renewable energy

For USA: For Canada:

GEA PHE Systems NA, Inc. GEA ViEX Inc.

100 GEA Drive, York, PA 17406 ·USA 1201 Nicholson Road, Newmarket, Ontario · L3Y 9C3 · Canada

Phone: 1-717-268-6200 · Fax: 1-717-268-6119 Phone 1-905-954-1325 · Fax 1-905-954-1391

www.geaphena.com · info@geaphena.com www.gea-viex.com · info@gea-viex.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Arcelormittal A514 and T-1Document6 pagesArcelormittal A514 and T-1Hugo RodriguezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MTC's ARAMCODocument17 pagesMTC's ARAMCOMotahar NajiNo ratings yet

- Astm f436mDocument5 pagesAstm f436mManuel S FarfanNo ratings yet

- Metal Casting ProcessesDocument113 pagesMetal Casting ProcessesSarath ChandraNo ratings yet

- Cored Wires for Iron Foundry TreatmentDocument6 pagesCored Wires for Iron Foundry TreatmentamitkkambleNo ratings yet

- Grounding & Earthing PDFDocument108 pagesGrounding & Earthing PDFRajeevAgrawal100% (1)

- VanadiumDocument12 pagesVanadiumEkha Kirei100% (1)

- 437 Control Valves For General ApplicationsDocument16 pages437 Control Valves For General Applicationsbahador57No ratings yet

- Storage Tank Design: Email:moemen - Hussein@alexu - Edu.egDocument58 pagesStorage Tank Design: Email:moemen - Hussein@alexu - Edu.egahmadhatakeNo ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- Compresor LT - INSTRUCTIONSDocument28 pagesCompresor LT - INSTRUCTIONSroqueNo ratings yet

- Valvula Solenoide SV13-20Document2 pagesValvula Solenoide SV13-20roqueNo ratings yet

- Válvula Solenoide S7ADocument4 pagesVálvula Solenoide S7Aroque100% (1)

- D7100 en PDFDocument19 pagesD7100 en PDFSasko DimitrovNo ratings yet

- Valvula Reguladora - FC51 BrandDocument6 pagesValvula Reguladora - FC51 BrandroqueNo ratings yet

- Motores Hidráulicos Marca HAMWORTHYDocument92 pagesMotores Hidráulicos Marca HAMWORTHYroqueNo ratings yet

- Receta IPA - FrutadaDocument2 pagesReceta IPA - FrutadaroqueNo ratings yet

- Bridge Types - Historical Overviews - 2006 Pre1930metal PDFDocument18 pagesBridge Types - Historical Overviews - 2006 Pre1930metal PDFrobpallotNo ratings yet

- Industrial Training (BHUSHAN STEEL)Document16 pagesIndustrial Training (BHUSHAN STEEL)Ankit Singh MalikNo ratings yet

- Grease 2Document4 pagesGrease 2arunNo ratings yet

- 07092014130558IMYB-2012-Iron & Steel and ScrapDocument27 pages07092014130558IMYB-2012-Iron & Steel and ScrapPriyamNo ratings yet

- Welbond Model 5600: Yarway High Pressure Globe ValveDocument12 pagesWelbond Model 5600: Yarway High Pressure Globe Valveel_apache10No ratings yet

- Csir Net Question PaperDocument41 pagesCsir Net Question PaperAanchal PathakNo ratings yet

- Astm f436 Type 1Document1 pageAstm f436 Type 1seenudesignNo ratings yet

- 0801 1 MineralsDocument48 pages0801 1 MineralsAlexNo ratings yet

- Phase Diagrams 3Document5 pagesPhase Diagrams 3SukhamMichaelNo ratings yet

- Stock AnalysisDocument286 pagesStock AnalysisMBNo ratings yet

- Mechanical Properties and Seawater Behavior of Nitronic 50Document38 pagesMechanical Properties and Seawater Behavior of Nitronic 50wrowletNo ratings yet

- Solenoid Valves 3/2 551 553Document12 pagesSolenoid Valves 3/2 551 553frghertyertyergfhdftyertyNo ratings yet

- Common Casting Defects - Sand Mold, Metal CastingDocument10 pagesCommon Casting Defects - Sand Mold, Metal CastingAbhinav Pratap MauryaNo ratings yet

- CE6302-Mechanics of SolidsDocument20 pagesCE6302-Mechanics of SolidsMaharaja PlacementNo ratings yet

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDocument3 pagesDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadNo ratings yet

- Qcs 2010 Section 16 Part 10 Protective TreatmentDocument5 pagesQcs 2010 Section 16 Part 10 Protective Treatmentbryanpastor106No ratings yet

- Thermophysical PropertiesDocument14 pagesThermophysical PropertiesKalinga BalNo ratings yet

- Color Chart 236 Colors: Tabla de Colores 236 ColoresDocument6 pagesColor Chart 236 Colors: Tabla de Colores 236 ColoresMadar FerencNo ratings yet

- CSBB Fabrication & Installation of PipingDocument26 pagesCSBB Fabrication & Installation of PipingLương TrườngNo ratings yet

- As 7703 Iso Fe Serie enDocument8 pagesAs 7703 Iso Fe Serie enprihartono_diasNo ratings yet