Professional Documents

Culture Documents

Vents

Uploaded by

Sk Abdul RavoofCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vents

Uploaded by

Sk Abdul RavoofCopyright:

Available Formats

CHAPTER 9

VENTS

SECTION 901 open air.

GENERAL 903.1.1 Connection to drainage system. A main vent that is

a vent stack shall connect to the building drain or to the base

901.1 Scope. The provisions of this chapter shall govern the of a drainage stack in accordance with Section 903.4. A main

materials, design, construction and installation of vent systems. vent that is a stack vent shall be an extension of the drainage

stack.

901.2 Trap seal protection. The plumbing system shall be pro-

vided with a system of vent piping that will permit the admis- 903.2 Vent stack required. A vent stack shall be required for

sion or emission of air so that the seal of any fixture trap shall every drainage stack that is five branch intervals or more.

not be subjected to a pneumatic pressure differential of more

than 1 inch of water (249 Pa). 903.3 Vent termination. Every vent stack or stack vent shall

extend outdoors and terminate to the open air.

901.2.1 Venting required. Every trap and trapped fixture

shall be vented in accordance with one of the venting meth- 903.4 Vent connection at base. Every vent stack shall connect

ods specified in this chapter. to the base of the drainage stack. The vent stack shall connect at

or below the lowest horizontal branch. Where the vent stack

901.3 Chemical waste vent system. The vent system for a connects to the building drain, the connection shall be located

chemical waste system shall be independent of the sanitary downstream of the drainage stack and within a distance of ten

vent system and shall terminate separately through the roof to times the diameter of the drainage stack.

the open air.

903.5 Vent headers. Stack vents and vent stacks connected

901.4 Use limitations. The plumbing vent system shall not be into a common vent header at the top of the stacks and extend-

utilized for purposes other than the venting of the plumbing ing to the open air at one point shall be sized in accordance with

system. the requirements of Section 916.1. The number of fixture units

shall be the sum of all fixture units on all stacks connected

901.5 Tests. The vent system shall be tested in accordance with thereto, and the developed length shall be the longest vent

Section 312. length from the intersection at the base of the most distant stack

to the vent terminal in the open air, as a direct extension of one

901.6 Engineered systems. Engineered venting systems shall stack.

conform to the provisions of Section 918.

SECTION 902 SECTION 904

MATERIALS VENT TERMINALS

902.1 Vents. The materials and methods utilized for the 904.1 Roof extension. All open vent pipes that extend through

construction and installation of venting systems shall comply a roof shall be terminated at least 6 inches (mm) above the roof,

with the applicable provisions of Section 702. except where the roof space is accessible by the public or the

building tenants, the vent extensions shall be run at least 7 feet

902.2 Sheet copper. Sheet copper for vent pipe flashings shall (2134 mm) above the roof.

conform to ASTM B 152 and shall weigh not less than 8 ounces

per square foot (2.5 kg/m2). 904.2 Frost closure. Where the 97.5-percent value for outside

design temperature is less than 0°F (-18°C), every vent exten-

902.3 Sheet lead. Sheet lead for vent pipe flashings shall weigh sion through a roof or wall shall be a minimum of 3 inches

not less than 3 pounds per square foot (15 kg/m 2) for field- (76 mm) in diameter. Any increase in the size of the vent shall

constructed flashings and not less than 2.5 pounds per square be made inside the structure a minimum of 1 foot (304.8 mm)

foot (12 kg/m2) for prefabricated flashings. below the roof or inside the wall.

SECTION 903 904.3 Flashings. The juncture of each vent pipe with the roof

VENT STACKS AND STACK VENTS line shall be made water tight by an approved flashing.

903.1 Stack required. Every building in which plumbing is 904.4 Prohibited use. Vent terminals shall not be used as a flag

installed shall have at least one stack the size of which is not less pole or to support flag poles, television aerials or similar items,

than one-half of the required size of the building drain, and not except when the piping has been anchored in an approved

less than 2 inches in diameter. Such stack shall run undimin- manner.

ished in size and as directly as possible from the building drain

through to the open air or to vent header that extends to the 904.5 Location of vent terminal. An open vent terminal from

2000 INTERNATIONAL PLUMBING CODE ®/NC 2002 65

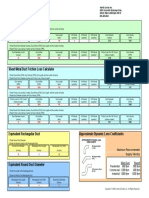

904.6 - TABLE 908.3 VENTS

a drainage system shall not be located directly beneath any are within the requirements set forth in Table 906.1.

door, openable window, or other air intake opening of the TABLE 906.1

building or of an adjacent building, and any such vent terminal MAXIMUM DISTANCE OF FIXTURE TRAP FROM VENT

SIZE OF

shall not be within 10 feet (3048 mm) horizontally of such an FIXTURE DISTANCE

opening unless it is at least 2 feet (610 mm) above the top of SIZE OF TRAP DRAIN SLOPE FROM TRAP

such opening. (inches) (inches) (inch per foot) (feet)

11/4 11/ 4 1/4 31/2

904.6 Extension through the wall. Vent terminals extending 11/4 11/ 2 1/4 5

through the wall shall terminate a minimum of 10 feet (3048 11/2 11/ 2 1/4 5

mm) from the lot line and 10 feet (3048 mm) above average 11/2 2 1/4 6

ground level. Vent terminals shall not terminate under the over- 2 2 1/4 8

hang of a structure with soffit vents. Side wall vent terminals 3 3 1/8 10

shall be protected to prevent birds or rodents from entering or 4 4 1/8 12

blocking the vent opening. For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 inch per foot = 0.0833 mm/m.

904.7 Extension outside a structure. In climates where the

906.2 Venting of fixture drains. The vent for a fixture drain,

97.5-percent value for outside design temperature is less than

except where serving a fixture with integral traps, such as water

0°F (-18°C), vent pipes installed on the exterior of the structure closets, shall connect above the weir of the fixture trap being

shall be protected against freezing by insulation, heat or both. vented.

906.3 Crown vent. A vent shall not be installed within two pipe

diameters of the trap weir.

SECTION 905

VENT CONNECTIONS AND GRADES

SECTION 907

905.1 Connection. All individual, branch and circuit vents INDIVIDUAL VENT

shall connect to a vent stack, stack vent, air admittance valve or

extend to the open air. 907.1 Individual vent permitted. Each trap and trapped fix-

ture is permitted to be provided with an individual vent. The

905.2 Grade. All vent and branch vent pipes shall be so graded individual vent shall connect to the fixture drain of the trap or

and connected as to drain back to the drainage pipe by gravity. trapped fixture being vented.

905.3 Vent connection to drainage system. Every dry vent

connecting to a horizontal drain shall connect above the center- SECTION 908

line of the horizontal drain pipe. COMMON VENT

905.4 Vertical rise of vent. Every dry vent shall rise vertically 908.1 Individual vent as common vent. An individual vent is

to a minimum of 6 inches (152 mm) above the flood level rim of permitted to vent two traps or trapped fixtures as a common

the highest trap or trapped fixture being vented. vent. The traps or trapped fixtures being common vented shall

be located on the same floor level.

905.5 Height above fixtures. A connection between a vent

pipe and a vent stack or stack vent shall be made at least 6 inches 908.2 Connection at the same level. Where the fixture drains

(152 mm) above the flood level rim of the highest fixture served being common vented connect at the same level, the vent con-

by the vent. Horizontal vent pipes forming branch vents, relief nection shall be at the interconnection of the fixture drains or

vents or loop vents shall be at least 6 inches (152 mm) above the downstream of the interconnection.

flood level rim of the highest fixture served.

905.6 Vent for future fixtures. Where the drainage piping has 908.3 Connection at different levels. Where the fixture drains

connect at different levels, the vent shall connect as a vertical

been roughed-in for future fixtures, a rough-in connection for a

extension of the vertical drain. The vertical drain pipe connect-

vent shall be installed. The vent size shall be not less than one-

ing the two fixture drains shall be considered the vent for the

half the diameter of the rough-in drain to be served. The vent

lower fixture drain, and shall be sized in accordance with Table

rough-in shall connect to the vent system, or shall be vented by

908.3. The upper fixture shall not be a water closet.

other means as provided for in this chapter. The connection TABLE 908.3

shall be identified to indicate that the connection is a vent. COMMON VENT SIZES

PIPE SIZE (inches) MAXIMUM DISCHARGE FROM

SECTION 906 UPPER FIXTURE DRAIN (dfu)

FIXTURE VENTS 11/2 1

2 4

906.1 Distance of trap from vent. Each fixture trap shall have 21/2 to 3 6

a protecting vent located so that the slope and the developed For SI: 1 inch = 25.4 mm.

length in the fixture drain from the trap weir to the vent fitting

66 2000 INTERNATIONAL PLUMBING CODE®/NC 2002

VENTS 917.4 - 919.2

sized in accordance with Section 916.2 and installed in

accordance with Section 905. The relief vent shall be per-

mitted to serve as the vent for other fixtures.

917.4 Location. The air admittance valve shall be located a

minimum of 4 inches (102 mm) above the horizontal branch

drain or fixture drain being vented. The air admittance valve

shall be located within the maximum developed length per-

mitted for the vent. The air admittance valve shall be installed a

minimum of 6 inches (152 mm) above insulation materials.

917.5 Access and ventilation. Access shall be provided to all

air admittance valves. The valve shall be located within a venti-

lated space that allows air to enter the valve.

917.6 Size. The air admittance valve shall be rated in accor-

dance with the standard for the size of the vent to which the

valve is connected.

917.7 Vent required. Within each plumbing system, a mini-

mum of one stack vent or vent stack shall extend outdoors to the

open air.

917.8 Prohibited installations. Air admittance valves shall

not be installed in nonneutralized special waste systems as

described in Chapter 8. Valves shall not be located in spaces

utilized as supply or return air plenums.

SECTION 918

SINGLE STACK PLUMBING SYSTEM

918.1 Approval. The plumbing official shall require that nec-

essary plans submitted under this section are signed by a reg-

istered professional engineer

TABLE 918.2

MINIMUM DIAMETER AND MAXIMUM LENGTH OF INDIVIDUAL BRANCH FIXTURE VENTS AND

INDIVIDUAL FIXTURE HEADER VENTS FOR SMOOTH PIPES

Deleted.

Deleted.

2000 INTERNATIONAL PLUMBING CODE ®/NC 2002 71

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Financial Engineering Principles - Perry BeaumontDocument0 pagesFinancial Engineering Principles - Perry BeaumontShankey Gupta100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Glossary of Valve Terms CameronDocument120 pagesGlossary of Valve Terms CameronHernán H.100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Rich's MEEB Quiz NotesDocument16 pagesRich's MEEB Quiz NotesSk Abdul RavoofNo ratings yet

- Electrical WorkDocument16 pagesElectrical WorkGalip KuyukNo ratings yet

- Motor Regreasing PGMDocument8 pagesMotor Regreasing PGMmuhamad.badar9285No ratings yet

- Project fixture inventory and drainage designDocument8 pagesProject fixture inventory and drainage designArch Ronel Magistrado DescargaNo ratings yet

- Pipe Hydraulics and Sizing GuideDocument23 pagesPipe Hydraulics and Sizing GuidemshNo ratings yet

- IIT-JEE Physics Guidebook on Elasticity and Thermal ExpansionDocument20 pagesIIT-JEE Physics Guidebook on Elasticity and Thermal Expansionabc9999999999No ratings yet

- Daylighting Guide For Buildings PDFDocument23 pagesDaylighting Guide For Buildings PDFShaaya ShanmugaNo ratings yet

- Aluminium Extrusion Process PlanningDocument10 pagesAluminium Extrusion Process PlanningHarshith Rao VadnalaNo ratings yet

- Passed Report - Glass - 17.5mmDocument29 pagesPassed Report - Glass - 17.5mmsaravqwerty100% (1)

- VSL - Multistrand Post TensioningDocument15 pagesVSL - Multistrand Post TensioningkmabdNo ratings yet

- HVAC Rule of Thumb Electrical LoadDocument1 pageHVAC Rule of Thumb Electrical LoadSk Abdul RavoofNo ratings yet

- Design Variables That Affect Building ConstructionDocument5 pagesDesign Variables That Affect Building ConstructionK_O_Ennin100% (6)

- Tunnel KilnDocument4 pagesTunnel KilnSatria PurwantoNo ratings yet

- Flexible Duct Friction Loss CalculatorDocument1 pageFlexible Duct Friction Loss CalculatorThinh TranNo ratings yet

- Design load and shear calculations for reinforced concrete beamDocument4 pagesDesign load and shear calculations for reinforced concrete beamaremyulNo ratings yet

- Static Calculation ExampleDocument3 pagesStatic Calculation ExampleSk Abdul RavoofNo ratings yet

- Motor MEPS GuideDocument19 pagesMotor MEPS Guide23OtterNo ratings yet

- Tutorial For Modeling Victaulic Coupling in CAEPIPE: GeneralDocument6 pagesTutorial For Modeling Victaulic Coupling in CAEPIPE: GeneralSk Abdul RavoofNo ratings yet

- Irrigation Engineering FormulaeDocument32 pagesIrrigation Engineering Formulaemirab89100% (1)

- Esp Calculation Data Sheet FinalDocument14 pagesEsp Calculation Data Sheet FinalTanveerNo ratings yet

- HVAC Rule of Thumb Electrical LoadDocument1 pageHVAC Rule of Thumb Electrical LoadSk Abdul RavoofNo ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Static Calculation ExampleDocument3 pagesStatic Calculation ExampleSk Abdul RavoofNo ratings yet

- SPF Estimating GuideDocument64 pagesSPF Estimating GuideSk Abdul RavoofNo ratings yet

- 18 Plot Plan FundamentalsDocument12 pages18 Plot Plan FundamentalsSk Abdul RavoofNo ratings yet

- CH 21Document81 pagesCH 21Sk Abdul RavoofNo ratings yet

- Sustainable Building A Materials PerspectiveDocument21 pagesSustainable Building A Materials PerspectiveSk Abdul RavoofNo ratings yet

- Costing GreenDocument27 pagesCosting GreenSk Abdul RavoofNo ratings yet

- Professional Accreditation Exam: Study GuideDocument4 pagesProfessional Accreditation Exam: Study GuideSk Abdul RavoofNo ratings yet

- Use a Simplified Psychrometric Chart to Understand Air PropertiesDocument7 pagesUse a Simplified Psychrometric Chart to Understand Air PropertiesSyarifah Humaira Al'mudhirNo ratings yet

- 09 Piping Network DesignDocument7 pages09 Piping Network DesignSk Abdul RavoofNo ratings yet

- Learning To LEED: Day 2 Indoor Environmental Quality QuizDocument6 pagesLearning To LEED: Day 2 Indoor Environmental Quality QuizSk Abdul RavoofNo ratings yet

- ARE-Ch29 Building CodesDocument12 pagesARE-Ch29 Building CodesRithwik T. HariNo ratings yet

- Chapter 5: Human Comfor & Mechanical Systems Fundamentals: DefinitionsDocument7 pagesChapter 5: Human Comfor & Mechanical Systems Fundamentals: DefinitionsSk Abdul RavoofNo ratings yet

- LCCDocument3 pagesLCCSk Abdul RavoofNo ratings yet

- Terminology and MetricsDocument51 pagesTerminology and MetricsRonald KahoraNo ratings yet

- Basic Principles of ElectricityDocument3 pagesBasic Principles of ElectricitySk Abdul RavoofNo ratings yet

- 3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsDocument32 pages3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsBoy AlfredoNo ratings yet

- Castrol BulletinDocument1 pageCastrol BulletinHarrier ESNo ratings yet

- Air Fiter - Regulator SB10Document3 pagesAir Fiter - Regulator SB10Abhishek SinghNo ratings yet

- Technical Report Documentation PageDocument149 pagesTechnical Report Documentation PageANo ratings yet

- Pressure Relief Device Testing and Capacity FactorsDocument2 pagesPressure Relief Device Testing and Capacity Factorsgabao123No ratings yet

- Ventilation CowlsDocument12 pagesVentilation CowlsShahadatuliskandar RosliNo ratings yet

- ProgressivTube Installation Operations Manual 03 02 09 PDFDocument58 pagesProgressivTube Installation Operations Manual 03 02 09 PDFMohamd LabeabNo ratings yet

- MOR and Modes of Failure of BeamsDocument9 pagesMOR and Modes of Failure of Beamsward dhapakhelNo ratings yet

- HW1Document1 pageHW1Mohammed Essam ShatnawiNo ratings yet

- Lecture 34Document11 pagesLecture 34فردوس سليمانNo ratings yet

- Laser Surface Preparation For Adhesive Bonding of Aerospace Structural CompositesDocument8 pagesLaser Surface Preparation For Adhesive Bonding of Aerospace Structural CompositesManojmsvssc KaravoorNo ratings yet

- Software Verification: ACI 318-14 Example 002Document4 pagesSoftware Verification: ACI 318-14 Example 002yudhi putraNo ratings yet

- PP 1-SERIES METHACRYLATE ADHESIVE TECH DATADocument3 pagesPP 1-SERIES METHACRYLATE ADHESIVE TECH DATAJoanna SąsaraNo ratings yet

- OECSwceDocument12 pagesOECSwceChristopher WeeksNo ratings yet

- Solutions For Agricultural FilmsDocument12 pagesSolutions For Agricultural FilmsAlfredo Ch. LinoNo ratings yet

- 16 Duct Suspension AdsDocument46 pages16 Duct Suspension AdsdheerajdorlikarNo ratings yet

- Инструкция Сервисная Daikin VRV Service Diagnosis Si30-701ADocument385 pagesИнструкция Сервисная Daikin VRV Service Diagnosis Si30-701ANani FerrerNo ratings yet

- Reul Randolph Geotechnique2003Document15 pagesReul Randolph Geotechnique2003YuryPasichnyNo ratings yet

- SUPERCITO MMA Electrodes for Structural and Heavy WorkDocument1 pageSUPERCITO MMA Electrodes for Structural and Heavy Workantonio111aNo ratings yet

- BoQ-Beam Retrofitting Works LandTDocument2 pagesBoQ-Beam Retrofitting Works LandTAbhijit KarpeNo ratings yet