Professional Documents

Culture Documents

Head Box

Uploaded by

tsvmpm1765Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Head Box

Uploaded by

tsvmpm1765Copyright:

Available Formats

MENU

1. HEADBOX

1.1 Establishing through detailed analysis of any specific headbox design, the optimum and correct headbox process settings for any machine operator

follow.

We call them "PAPYRUS RELAXATION TABLES" Since the busy operator will be more relaxed in setting the headbox variables and liberated from th

agony of the hit and miss approach. Hence he can devote his time more effectively to other areas of the machinery.

1.2 Calculating in a comprehensive matrix format the safe distance for jet mixing behind rectifier rolls and perforated plates as a function of flow rate, s

temperature and other specific design criteria.

1.3 Calculating in an elaborate format the jet characteristics as a function of different slice geometries for different jet speeds and other settings and ill

the results pictorially in order to compare the actual operating conditions versus the ideal.

1.4 Establishing through detailed analysis of any specific headbox/ approach piping systems the sources of streak development if they are existing and

remedies.

1.5 Calculating the change in the slice bottom lip extension as a function of incremental vertical slice opening movement and incorporate the relationsh

the headbox process settings.

1.6 Determining the limitation and the potential capacity of anyheadbox/approach piping systems.

1.7 Determining if modification of the existing headbox/approach piping system is required, based on NO OR MINIMUM CAPITAL INVESTMENT.

1.8 Comparing the manufacturer's original design criteria with the true requirements.

1.9 Supporting papermill management in a rebuild decision by selecting the right headbox parameters for their specific needs.

1.10 Calculating in a matrix format the required local slice profile bar travel for a specific machine and product basis weights and compare the results wi

intended design criteria.

1.11 Calculating in a matrix format the weight of each ply for multiply sheet machines.

1.12 Calculating in a matrix format the production rate as a function of specific machine speed and basis weight ranges.

1.13 Calculating in a matrix format the relationship between production rate, headbox consistency, and flow rate at six levels of first pass retention.

1.14 Calculating in a simplified matrix format the overall material balance for fibers alone, fillers alone or combined total solids without the agony of mea

white water consistency and conducting the related cumbersome calculations.

1.15 Calculating the critical headbox consistency based on the furnish constituents and compare the results with the operating conditions.

1.16 Calculating the ideal trailing sheet weights in Converflo type headboxes and compare the results with the existing condition for eliminating pulsation

problems.

Client Testimonials "Significant gains in the quality of our products were made during and since your visit."

PAPYRUS Inc. All Rights Reserved.

To

Hire Us!

You might also like

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsFrom EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsRating: 5 out of 5 stars5/5 (3)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Literature Review Centrifugal PumpDocument5 pagesLiterature Review Centrifugal Pumpea44a6t7100% (1)

- SAG Mill ComponentsDocument7 pagesSAG Mill ComponentsRodrigo GarcíaNo ratings yet

- ηrrDocument8 pagesηrribnuNo ratings yet

- Centrifugal Pump Literature ReviewDocument6 pagesCentrifugal Pump Literature Reviewea7gjrm5100% (1)

- Maska TechnicalDocument62 pagesMaska TechnicalAnonymous uXdS9Y7No ratings yet

- Lap Sim EngineDocument5 pagesLap Sim Engineblack_oneNo ratings yet

- Alignment With Target Values Reduces Vibrations PDFDocument4 pagesAlignment With Target Values Reduces Vibrations PDFSantyagoNo ratings yet

- Balancing Pump Efficiency With NPSHDocument2 pagesBalancing Pump Efficiency With NPSHsameeraNo ratings yet

- Interaction of Turbomachinery ComponentsDocument7 pagesInteraction of Turbomachinery ComponentsPedro LeyvaNo ratings yet

- Anti Friction Bearings For PumpsDocument165 pagesAnti Friction Bearings For PumpsJaime BerryNo ratings yet

- Eta SeriesDocument16 pagesEta SeriesjoejumbooNo ratings yet

- How Long Will A Bearing Last? Standardized Life Equations Help To AnswerDocument3 pagesHow Long Will A Bearing Last? Standardized Life Equations Help To AnswervijaykhandgeNo ratings yet

- Balancing of Rigid & Flexible Rotors PDFDocument6 pagesBalancing of Rigid & Flexible Rotors PDFJHON ANGEL VARGAS HUAHUASONCCO100% (1)

- Measurements and Computations For Blade Spindle Torque of Controllable Pitch Propellers in Open WaterDocument8 pagesMeasurements and Computations For Blade Spindle Torque of Controllable Pitch Propellers in Open WaterLelosPinelos123No ratings yet

- Pump AlignmentDocument69 pagesPump AlignmentJ.SIVIRA100% (1)

- EDR Plate Exchanger PDFDocument8 pagesEDR Plate Exchanger PDFMarta VidiellaNo ratings yet

- 11-3532-Rigorous Sizing Shell and Tube - Aspen HYSYSDocument12 pages11-3532-Rigorous Sizing Shell and Tube - Aspen HYSYSRashesh ShahNo ratings yet

- 10 Steps To Pump ReliabilityDocument15 pages10 Steps To Pump ReliabilityaqhammamNo ratings yet

- 8 PDFDocument8 pages8 PDFNicandroGonzalesNo ratings yet

- Design of An Experimental System For Wear Assessment of Slurry PumpsDocument7 pagesDesign of An Experimental System For Wear Assessment of Slurry Pumps최승원No ratings yet

- Mechanical Considerations in Pump DesignDocument5 pagesMechanical Considerations in Pump Designmartin.rubenNo ratings yet

- Potentials of A Numerical Tool For The Simulation of Flow in External Gear MachinesDocument17 pagesPotentials of A Numerical Tool For The Simulation of Flow in External Gear Machines김동하No ratings yet

- B.1.1 Spur Gears With Gearwheels-10Document34 pagesB.1.1 Spur Gears With Gearwheels-10Ganapathy Subramaniam100% (1)

- Optimizing A Hydrofoil For Industrial UseDocument10 pagesOptimizing A Hydrofoil For Industrial UsepavijayaNo ratings yet

- Coupling Design and SelectionDocument11 pagesCoupling Design and SelectionVivek RathodNo ratings yet

- Research Paper On Centrifugal Pump PDFDocument5 pagesResearch Paper On Centrifugal Pump PDFhxmchprhf100% (1)

- Pump System CurveDocument6 pagesPump System CurveMohan MalavNo ratings yet

- Jurnal Internasional Mekanika Fluida Renold Yanspri Pratama - 21410013Document8 pagesJurnal Internasional Mekanika Fluida Renold Yanspri Pratama - 21410013Renold Yanspri PratamaNo ratings yet

- Numerical Simulation of Six Jet Pelton Turbine Model GRUPO 2Document9 pagesNumerical Simulation of Six Jet Pelton Turbine Model GRUPO 2Cristian Polo VallejosNo ratings yet

- Chapter 4 Bearings PDFDocument50 pagesChapter 4 Bearings PDFAnonymous 7aN0oYUm7vNo ratings yet

- 10 Steps To Pump ReliabilityDocument5 pages10 Steps To Pump ReliabilityallmcbeallNo ratings yet

- Hydrofoil P72039Document20 pagesHydrofoil P72039Pukhraj DagaNo ratings yet

- Propeller Design PDFDocument8 pagesPropeller Design PDFwasita wadari100% (1)

- Design and Manufacturing of Hydro Pulper - 1604658130Document7 pagesDesign and Manufacturing of Hydro Pulper - 1604658130vanhuuduc102031No ratings yet

- 10 Steps To Pump ReliabilityDocument13 pages10 Steps To Pump ReliabilityfalconesasNo ratings yet

- Nozzle ProDocument3 pagesNozzle Projojo_323No ratings yet

- FSI PaperDocument10 pagesFSI PaperHasan AdelNo ratings yet

- 12.fluid Couplings in Higher Power Belt Conveyor DriveheadsDocument22 pages12.fluid Couplings in Higher Power Belt Conveyor DriveheadsmahaveenNo ratings yet

- Prop King RecentDocument49 pagesProp King Recentmaaathan100% (1)

- J. M. EngineersDocument10 pagesJ. M. EngineersJainam ShahNo ratings yet

- Integration of The Rudder PropellerDocument41 pagesIntegration of The Rudder PropellerVIVEK NAIRNo ratings yet

- Chapter 04Document20 pagesChapter 04Ubeimar Rivera OspinaNo ratings yet

- Nozzle Load and PipingDocument5 pagesNozzle Load and PipingJose PradoNo ratings yet

- SKF precision bearings: www.bergab.ru Берг АБ bergab@ya.ru Тел. (495) -228-06-21, факс (495) 223-3071Document76 pagesSKF precision bearings: www.bergab.ru Берг АБ bergab@ya.ru Тел. (495) -228-06-21, факс (495) 223-3071msaqibraza93No ratings yet

- FPMC2014-7856: Efficiency Testing of An Adjustable Linkage Triplex PumpDocument7 pagesFPMC2014-7856: Efficiency Testing of An Adjustable Linkage Triplex PumpFa TiNo ratings yet

- Flow Simulation and Efficiency Hill Chart Prediction For A Propeller TurbineDocument11 pagesFlow Simulation and Efficiency Hill Chart Prediction For A Propeller TurbinehoracioNo ratings yet

- 76 79Document4 pages76 79kirivNo ratings yet

- NIKKISO Speed ControlDocument14 pagesNIKKISO Speed ControlsajidkaleemNo ratings yet

- Points To ConsiderDocument9 pagesPoints To Considershy_boyNo ratings yet

- Pump DatasheetDocument15 pagesPump DatasheetHedi Ben MohamedNo ratings yet

- Research Paper On PumpsDocument4 pagesResearch Paper On Pumpsnikuvivakuv3100% (1)

- Gearmotor Sizing Guide PDFDocument5 pagesGearmotor Sizing Guide PDFAnonymous Hy5Ir9QXNo ratings yet

- Submersible Pump Research PaperDocument8 pagesSubmersible Pump Research Paperjcrfwerif100% (1)

- P.E.S College of Engineering, Mandya: Report On Recent Technologies in Workholding Device"Document17 pagesP.E.S College of Engineering, Mandya: Report On Recent Technologies in Workholding Device"kiran kumarNo ratings yet

- Economic Comparisons of Multilateral and Horizontal Wells in Water-Drive Reservoirs-Rivera2003-SPE80927Document7 pagesEconomic Comparisons of Multilateral and Horizontal Wells in Water-Drive Reservoirs-Rivera2003-SPE80927Miguel Angel Vidal ArangoNo ratings yet

- Split Coupled Vertical In-Line Pumps: File No.: Date: Supersedes: 43.10in DateDocument6 pagesSplit Coupled Vertical In-Line Pumps: File No.: Date: Supersedes: 43.10in DateSatawat phothinNo ratings yet

- Propeller Cap TurbineDocument4 pagesPropeller Cap TurbineKapil VermaNo ratings yet

- Rational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialFrom EverandRational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialNo ratings yet

- Arusha Region - WikipediaDocument10 pagesArusha Region - Wikipediatsvmpm1765No ratings yet

- Parliament of South Africa - WikipediaDocument9 pagesParliament of South Africa - Wikipediatsvmpm1765No ratings yet

- Arusha National Park - WikipediaDocument3 pagesArusha National Park - Wikipediatsvmpm1765No ratings yet

- African Great Lakes - WikipediaDocument5 pagesAfrican Great Lakes - Wikipediatsvmpm1765No ratings yet

- Kilimanjaro National Park - WikipediaDocument4 pagesKilimanjaro National Park - Wikipediatsvmpm1765No ratings yet

- Axis Powers - WikipediaDocument49 pagesAxis Powers - Wikipediatsvmpm1765No ratings yet

- Nelson Mandela - WikipediaDocument53 pagesNelson Mandela - Wikipediatsvmpm1765No ratings yet

- White South Africans - WikipediaDocument28 pagesWhite South Africans - Wikipediatsvmpm1765No ratings yet

- Politics of South Africa - WikipediaDocument8 pagesPolitics of South Africa - Wikipediatsvmpm1765No ratings yet

- Kingdom of Hungary - WikipediaDocument19 pagesKingdom of Hungary - Wikipediatsvmpm1765No ratings yet

- Digital Audio - WikipediaDocument7 pagesDigital Audio - Wikipediatsvmpm1765No ratings yet

- Linear Algebra - WikipediaDocument15 pagesLinear Algebra - Wikipediatsvmpm1765No ratings yet

- Cisleithania - WikipediaDocument6 pagesCisleithania - Wikipediatsvmpm1765No ratings yet

- Pesterzsébet - WikipediaDocument4 pagesPesterzsébet - Wikipediatsvmpm1765No ratings yet

- Frigyes Riesz - WikipediaDocument3 pagesFrigyes Riesz - Wikipediatsvmpm1765No ratings yet

- Slovak Soviet Republic - WikipediaDocument2 pagesSlovak Soviet Republic - Wikipediatsvmpm1765No ratings yet

- Pulse-Code Modulation - WikipediaDocument10 pagesPulse-Code Modulation - Wikipediatsvmpm1765No ratings yet

- 3-3 Evaporator FoulingDocument9 pages3-3 Evaporator Foulingtsvmpm1765No ratings yet

- Tratat de Istorie A ReligiilorDocument25 pagesTratat de Istorie A ReligiiloredymicNo ratings yet

- Design and Analysis Multi Purpose Vehicle (MPV) ChassisDocument15 pagesDesign and Analysis Multi Purpose Vehicle (MPV) ChassisusoppukunNo ratings yet

- Installation Guide 12kWGEN+6kWSUN (Edition EN)Document12 pagesInstallation Guide 12kWGEN+6kWSUN (Edition EN)beqsNo ratings yet

- Evasion Tokens (1751-1797) - p1Document7 pagesEvasion Tokens (1751-1797) - p1Nickol HardwayNo ratings yet

- TFH220AEn112 PDFDocument4 pagesTFH220AEn112 PDFJoseph BoshehNo ratings yet

- Replacing SGDH in Field W MP940Document3 pagesReplacing SGDH in Field W MP940jroyal692974No ratings yet

- G35Document16 pagesG35hn7410No ratings yet

- Operation and Maintenance ManualDocument16 pagesOperation and Maintenance ManualJMNo ratings yet

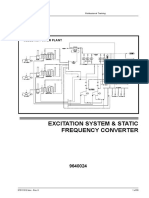

- Excitation Sys & SFCDocument55 pagesExcitation Sys & SFCABVSAI100% (1)

- Indigenisation Ranjit Ghosh StarredDocument190 pagesIndigenisation Ranjit Ghosh StarredSanjay MehrishiNo ratings yet

- Lea 4x Data Sheet (Gps.g4 Ms4 06143)Document18 pagesLea 4x Data Sheet (Gps.g4 Ms4 06143)aj4fall086050No ratings yet

- Vertical Bracing With End Plate ConnectionDocument85 pagesVertical Bracing With End Plate ConnectionFajar Alam HudiNo ratings yet

- NEMA Full Voltage Starters: Fast Shipment Program Cat. Nos. Are Printed inDocument4 pagesNEMA Full Voltage Starters: Fast Shipment Program Cat. Nos. Are Printed insoayNo ratings yet

- Vibration Charts - and Example CalculationsDocument9 pagesVibration Charts - and Example Calculationscarlos alvaradoNo ratings yet

- 2SK 2371 - 2372 - NecDocument8 pages2SK 2371 - 2372 - NecStevenNo ratings yet

- 176 PDFDocument224 pages176 PDFnouvemadNo ratings yet

- AmeronDocument355 pagesAmeronJonas TedescoNo ratings yet

- Inco TermsDocument5 pagesInco TermsPankaj DograNo ratings yet

- Skilsaw 5400Document36 pagesSkilsaw 5400Jacinto Ramirez LopezNo ratings yet

- Astm F 1602 - 95 R01Document7 pagesAstm F 1602 - 95 R01Francisco Guerra100% (1)

- PDFDocument103 pagesPDFEduRoiNo ratings yet

- D 010 Well Integrity in Drilling and Well Operations PDFDocument162 pagesD 010 Well Integrity in Drilling and Well Operations PDFdrascoviNo ratings yet

- SR100 PDFDocument6 pagesSR100 PDFSandeep Kumar Dangda100% (1)

- Catridges ValvesDocument316 pagesCatridges ValvesSamad A Bakar100% (1)

- SikaFix®-121 Ground BondDocument2 pagesSikaFix®-121 Ground BondSisuangly SimamoraNo ratings yet

- Aircraft Instrument MaintenanceDocument22 pagesAircraft Instrument MaintenanceBharath Kumar Goud83% (6)

- KGEL Tente Catalogue Aug 2022Document67 pagesKGEL Tente Catalogue Aug 2022Anton WilliamsNo ratings yet

- XAS 756Cd PDFDocument98 pagesXAS 756Cd PDFNicolásOCNo ratings yet

- Well Completion Types and ApplicationsDocument22 pagesWell Completion Types and ApplicationsJosue Fish100% (2)

- Genaral Bridge Q & ADocument5 pagesGenaral Bridge Q & AKarthikeyan100% (3)