Professional Documents

Culture Documents

Kmac BT 4000

Uploaded by

jrladdu0 ratings0% found this document useful (0 votes)

46 views3 pageskmac drillship

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentkmac drillship

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views3 pagesKmac BT 4000

Uploaded by

jrladdukmac drillship

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

BT-4000 LIGHT WORKOVER UNIT

DESIGNED TO IMPROVE EFFICIENCY DURING WELL INTERVENTION OPERATIONS

The BT-4000 LWO is the new generation DP-3 semi-submer-

sible for efficient light workover/well intervention operations in

water depths up to 2,400 m (7,879 ft) in environment areas

offshore Brazil, in Gulf of Mexico, West of Africa and South East

Asia.

The BT-4000 LWO is designed for efficient and fast change

over between various well intervention operations with maximized

off “critical path” preparation of upcoming operations. The range

of operations the BT-4000 LWO is designed for includes:

• Workover operations, including coiled tubing and wire line/

slick line through an open water intervention riser system

(high pressure riser up to 10,000 psi) with a surface BOP

• Through tubing drilling and completion with coiled tubing or

optional rotary drilling

• Top-hole rotary drilling

• Installation and retrieval of X-mas trees and different subsea

equipment

• Installation and retrieval of electric submersible pumps in

wells and subsea pumping modules

• Well-testing and well-clean-up

• Pumping and circulation of various types of fluids through

the workover/completion riser and into the well, including

the handling of high pressure fluids from a well stimulation

vessel

• Killing of a well

• Installation, handling and operation of a subsea capping

stack

• ROV operations.

To facilitate effective operations, the BT-4000 LWO has

been designed with access to the derrick from three

sides, allowing different operations to be prepared and

carried out independently of each other.

For handling and transport of subsea equipment

the Unit is arranged with a skidding system

accessing the well center from three sides, which

together with the flush drill-floor hatch (moon-pool

door) design improves material handling efficiency

and increases safety. Skidding system is also used

to transport the advanced coiled tubing frame in

and out of the well center, facilitating pre-stabbing

of the coil and testing in advance, further increasing

the operational efficiency.

GENERAL STORAGE CAPACITIES

Class XA1 Column-Stabilized Drilling Unit, Liquids

XAMS, XACCU, XDPS-3, ENVIRO OS,

Mud/brine pits in upper hull 500 m3 3,140 bbls

CRC, UWILD

Mud/brine tanks

Rules and IMO MODU Code, MARPOL, Load Line, 680 m3 4,200 bbls

in pontoons

regulations flag State and Brazilian continental shelf

requirements Total liquid mud/brine 1,140 m3 7,090 bbls

storage

Operational areas Brazil, Gulf of Mexico, West of Africa, SE Asia

Base oil tanks 300 m3 1,800 bbls

POB 130 people in 1+2 bed cabins

Drill water tanks 1,770 m 3

11,100 bbls

Heli deck Sikorski S-92, S-61N, AW-101, CAP 437

Fuel oil tanks 3,000 m 3

18,850 bbls

Fresh water tanks 300 m3 1,800 bbls

DESIGN CRITERIA

Bulk

Water depth 200 to 2,400 m

Bulk cement 214 m3 7,500 cu ft

Drilling depth 8,500 m

Bulk barite/bentonite 214 m 3

7,500 cu ft

Environmental criteria 10-year GOM hurricane,

100-year Brazil storm

MAJOR EQUIPMENT

MAIN DIMENSIONS Installed power 6 x 5,200 kWe 31,200 kWe

Length over all abt. 117.5 m Thrusters 6 x 3,500 kW 21,000 kW

Beam over all abt. 79.7 m Derrick Height 186 ft Static 1,500 kips

Height to box bottom 26.0 m Active/passive crown 1000 kips

mounted compensator

Height to upper deck 34.5 m

False rotary 49 ½”

Pontoons (2)

Drawworks 4,430 hp

Length 100.1 m

Riser tensioners 8 x 160 kips each, 50 ft stroke

Beam 15.6 m

Mud pumps 2 x 1,600 hp

Height 9.1 m

Knuckle-boom cranes 2 x 100 tonnes

Columns (4)

Horizontal section 13.65 x 14.3 m

OPERATIONS

Draughts

Light workover and well intervention operations

Operation 17.5 m

Workover operations Drilling and workover operations

Survival 14.5 m Through tubing drilling and completion

Transit 8.8 m Through tubing live well intervention

Wire lining/slick line Through tubing live well intervention

Displacement

operations

Operation 32,600 tonnes

Rotary drilling of top holes without fluid return to top side

Installation and retrieval of X-mas trees, adaptors and tree caps,

PAYLOAD CAPACITIES lower riser package

Installation and retrieval of electric submersible pumps in wells

Deck payload, operation/survival 3,700 tonnes

and subsea pumping modules

Total payload, operation/survival 8,000 tonnes

Well testing

Total payload, transit 3,100 tonnes

Killing of a well

ROV operations

BT-4000 by

You might also like

- BT 3500Document6 pagesBT 3500RoLuBassoeNo ratings yet

- Dimensions Imperial Metric: Rig SpecificationDocument2 pagesDimensions Imperial Metric: Rig SpecificationCalvin Abelardo GintingNo ratings yet

- SEVAN LOUISIANA OFFSHORE DRILLING RIG SPECSDocument1 pageSEVAN LOUISIANA OFFSHORE DRILLING RIG SPECSfahad mullaNo ratings yet

- Maersk DelivererDocument10 pagesMaersk DelivererMike RossNo ratings yet

- Pacific Bora 2017-08-03 Revision 7Document2 pagesPacific Bora 2017-08-03 Revision 7wangnaNo ratings yet

- Pacific Mistral 2017-08-03 Revision 7Document2 pagesPacific Mistral 2017-08-03 Revision 7wangnaNo ratings yet

- Minerva BlueprintDocument46 pagesMinerva BlueprintRaraInsyiraNo ratings yet

- Pacific Scirocco 2017-08-03 Revision 7Document2 pagesPacific Scirocco 2017-08-03 Revision 7wangnaNo ratings yet

- Maersk InterceptorDocument8 pagesMaersk InterceptorMauricio RicardezNo ratings yet

- Pacific Meltem 2017-08-03 Revision 10Document2 pagesPacific Meltem 2017-08-03 Revision 10wangnaNo ratings yet

- Alp Winger Specifications 2017Document1 pageAlp Winger Specifications 2017thugsdeiNo ratings yet

- Maersk Discoverer PDFDocument12 pagesMaersk Discoverer PDFAarón CespedesNo ratings yet

- Maersk Intrepid PDFDocument8 pagesMaersk Intrepid PDFMauricio RicardezNo ratings yet

- Maersk Intrepid PDFDocument8 pagesMaersk Intrepid PDFMauricio RicardezNo ratings yet

- 06 Al-JassraDocument2 pages06 Al-JassraMuhammad shehryar KhanNo ratings yet

- Island Venture: Offshore Construction / Intervention VesselDocument2 pagesIsland Venture: Offshore Construction / Intervention VesselTra TopoNo ratings yet

- Maersk Developer PDFDocument12 pagesMaersk Developer PDFmuhammad rivaiNo ratings yet

- Pacific-Victory V 6.0-TDWDocument4 pagesPacific-Victory V 6.0-TDWVladi GasperNo ratings yet

- CRONUS-Z Specs 20022020Document2 pagesCRONUS-Z Specs 20022020zba2No ratings yet

- Maersk GallantDocument8 pagesMaersk GallantAarón CespedesNo ratings yet

- Pacific Sharav Udw Drillship: GeneralDocument2 pagesPacific Sharav Udw Drillship: GeneraltxcrudeNo ratings yet

- Pacific Khamsin 2017 08 03 - Revision 10Document2 pagesPacific Khamsin 2017 08 03 - Revision 10wangnaNo ratings yet

- Cos L SeekerDocument2 pagesCos L SeekerNABIL FIKRIENo ratings yet

- 70 Jaya VigilantDocument8 pages70 Jaya VigilantДмитрий ЗинченкоNo ratings yet

- Nusantara: 80m dp2 Subsea Support VesselDocument4 pagesNusantara: 80m dp2 Subsea Support VesselBagus Bagaskara PutraNo ratings yet

- LeTourneau Technologies 116 CDocument3 pagesLeTourneau Technologies 116 CArun Santhakumaran100% (1)

- West VigilantDocument1 pageWest VigilantRyu JrNo ratings yet

- T 43Document1 pageT 43Gustavo RivasNo ratings yet

- Rowan AlaskaDocument2 pagesRowan Alaskaram.nNo ratings yet

- Anchor Handling VesselDocument2 pagesAnchor Handling VesselKenneth TanNo ratings yet

- Pacific-Vixen V 12.0-TDWDocument4 pagesPacific-Vixen V 12.0-TDWjoedouglasrigfloorNo ratings yet

- 939DH Excavator Engine SpecsDocument2 pages939DH Excavator Engine SpecsLakshminarayana BasettiNo ratings yet

- AHTS SpecifDocument4 pagesAHTS SpecifgustavoschardongNo ratings yet

- Akranes Specs 2020Document2 pagesAkranes Specs 2020giovanni julioNo ratings yet

- DAMEN SLa 4510 Landing VesselDocument2 pagesDAMEN SLa 4510 Landing VesselГригорий ШарунNo ratings yet

- Ahts DP2Document6 pagesAhts DP2CESAR VIECNTENo ratings yet

- ALP Striker Specifications - PortraitDocument1 pageALP Striker Specifications - PortraitluciannuNo ratings yet

- Short MODU Specs of Tam Dao 03Document2 pagesShort MODU Specs of Tam Dao 03Them Bui XuanNo ratings yet

- Bro Verlegepflug E RZ 17Document4 pagesBro Verlegepflug E RZ 17mjantuneNo ratings yet

- Construction Equipments: 1. Transit MixerDocument3 pagesConstruction Equipments: 1. Transit MixerRiddhima MukherjeeNo ratings yet

- Vsl4 - Allianz TitaniumDocument2 pagesVsl4 - Allianz TitaniuminterglobalNo ratings yet

- Maersk Convincer PDFDocument8 pagesMaersk Convincer PDFAarón CespedesNo ratings yet

- KWL1600Document8 pagesKWL1600Dam100% (1)

- Technical Specs - MV Belait Barakah - REV 01Document2 pagesTechnical Specs - MV Belait Barakah - REV 01Syed Abdul RahmanNo ratings yet

- Week 5 AssessmentDocument7 pagesWeek 5 AssessmentVenrick CamposNo ratings yet

- Leonardo Da Vinci Datasheet V3defDocument3 pagesLeonardo Da Vinci Datasheet V3defSarvesh SangleNo ratings yet

- Excavator: Engine Gross PowerDocument2 pagesExcavator: Engine Gross PowerJeffsonFigueiredo100% (1)

- 77XR Blasthole Drill Specification SheetDocument3 pages77XR Blasthole Drill Specification Sheetmawei100% (1)

- Seacor TarahumaraDocument3 pagesSeacor TarahumaraTrinidad GraneNo ratings yet

- Msheireb General Rig InfoDocument2 pagesMsheireb General Rig InfoAftandil QarmonNo ratings yet

- General Description: CoslpowerDocument2 pagesGeneral Description: CoslpowerNABIL FIKRIENo ratings yet

- West VencedorDocument1 pageWest Vencedormin thantNo ratings yet

- Bolette Dolphin 17Document4 pagesBolette Dolphin 17Unokhogie EmmanuelNo ratings yet

- JASPER EXPLORER DRILLSHIP SPECSDocument6 pagesJASPER EXPLORER DRILLSHIP SPECSVishaal Raj SoniNo ratings yet

- T 19Document1 pageT 19Richard EVNo ratings yet

- 06.CLV-TSV EN - V2018-6 - Isaac Newton - DP2 2Document2 pages06.CLV-TSV EN - V2018-6 - Isaac Newton - DP2 2iyan supriadiNo ratings yet

- BBC Vessel Description 17 10 2021 WEBDocument88 pagesBBC Vessel Description 17 10 2021 WEBSergey ShevchenkoNo ratings yet

- MV Pioneer (2021)Document2 pagesMV Pioneer (2021)Miguel Angel FriasNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Appendix III 2B Assam Cat 2Document1 pageAppendix III 2B Assam Cat 2jrladduNo ratings yet

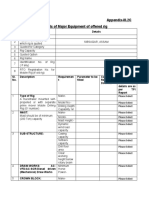

- 10.0 Appendix As Per Annexure IDocument25 pages10.0 Appendix As Per Annexure IjrladduNo ratings yet

- Appendix III 2C Assam Cat 2Document3 pagesAppendix III 2C Assam Cat 2jrladduNo ratings yet

- Appendix III 2B Tripura Cat 1Document1 pageAppendix III 2B Tripura Cat 1jrladduNo ratings yet

- Appendix III 2B Tripura Cat 1Document1 pageAppendix III 2B Tripura Cat 1jrladduNo ratings yet

- 7.0 Annexure VIII Bid MatrixDocument10 pages7.0 Annexure VIII Bid MatrixjrladduNo ratings yet

- DSJ400 Outlined SpecificationDocument2 pagesDSJ400 Outlined SpecificationjrladduNo ratings yet

- 9.0 Annexure X Undertaking Declarition and Annexure IX Power of AttorneyDocument10 pages9.0 Annexure X Undertaking Declarition and Annexure IX Power of AttorneyjrladduNo ratings yet

- Appendix III 2C Assam Cat 2Document3 pagesAppendix III 2C Assam Cat 2jrladduNo ratings yet

- 1.0 Invitation To BidDocument7 pages1.0 Invitation To BidjrladduNo ratings yet

- Appendix III 2B Assam Cat 2Document1 pageAppendix III 2B Assam Cat 2jrladduNo ratings yet

- 8.0 Annexure Ix Format For Power of AttorneyDocument1 page8.0 Annexure Ix Format For Power of AttorneyjrladduNo ratings yet

- 8.0 Annexure Ix Format For Power of AttorneyDocument1 page8.0 Annexure Ix Format For Power of AttorneyjrladduNo ratings yet

- 7.0 Annexure VIII Bid MatrixDocument10 pages7.0 Annexure VIII Bid MatrixjrladduNo ratings yet

- 1.1 Annexure I and II of P4CCC19034Document89 pages1.1 Annexure I and II of P4CCC19034jrladduNo ratings yet

- 3.0 Annexure IV Bid Evaluation CriteriaDocument7 pages3.0 Annexure IV Bid Evaluation CriteriajrladduNo ratings yet

- 10.0 Appendix As Per Annexure IDocument25 pages10.0 Appendix As Per Annexure IjrladduNo ratings yet

- 6.1 Annexure VII A Bidders Response Sheet Indian BidderDocument1 page6.1 Annexure VII A Bidders Response Sheet Indian BidderjrladduNo ratings yet

- 6.2 Annexure VII B Bidders Response Sheet Foreign BidderDocument1 page6.2 Annexure VII B Bidders Response Sheet Foreign BidderjrladduNo ratings yet

- Supply & Install RO Water MakerDocument10 pagesSupply & Install RO Water MakerjrladduNo ratings yet

- 4.0 Annexure V Special Terms and ConditionsDocument4 pages4.0 Annexure V Special Terms and ConditionsjrladduNo ratings yet

- Markwet AnalysisDocument2 pagesMarkwet AnalysisjrladduNo ratings yet

- Farm Layout ModifiedDocument1 pageFarm Layout ModifiedjrladduNo ratings yet

- GrammarDocument1 pageGrammarjrladduNo ratings yet

- Shukrashis: Name: Date of Birth: Time of Birth: Place of BirthDocument1 pageShukrashis: Name: Date of Birth: Time of Birth: Place of BirthjrladduNo ratings yet

- Elliott WaveDocument24 pagesElliott WavejrladduNo ratings yet

- Authorized Real-Time Data Vendors ListDocument1 pageAuthorized Real-Time Data Vendors ListjrladduNo ratings yet

- NSE Maruti Suzuki Ind 1M: O H L CDocument1 pageNSE Maruti Suzuki Ind 1M: O H L CjrladduNo ratings yet

- Press Release Q4FY19 Crores FinalDocument7 pagesPress Release Q4FY19 Crores FinaljrladduNo ratings yet

- Inquiry For NR13 Qualified Engineering: OthersDocument4 pagesInquiry For NR13 Qualified Engineering: OthersjrladduNo ratings yet

- Well Intervention - WikipediaDocument3 pagesWell Intervention - WikipediaHarsh ShahNo ratings yet

- Advanced Applications of Wireline Cased-Hole Formation Testers for Zonal Isolation Studies and Annulus Pressure InvestigationsDocument23 pagesAdvanced Applications of Wireline Cased-Hole Formation Testers for Zonal Isolation Studies and Annulus Pressure InvestigationsDhiaa LaMiNo ratings yet

- Drilling ConceptsDocument9 pagesDrilling ConceptsSamuel VelozNo ratings yet

- Well Data Summary ProgramDocument13 pagesWell Data Summary ProgramTemitope BelloNo ratings yet

- Rig Comparison: Drilling Rig Selection GuideDocument1 pageRig Comparison: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- PLDT Surigao City to Claver FOC Link Project SurveyDocument34 pagesPLDT Surigao City to Claver FOC Link Project SurveyRodelio Aboda Jr.No ratings yet

- Weatherford School: Alexandria University Student Chapter of The AapgDocument15 pagesWeatherford School: Alexandria University Student Chapter of The Aapgmoussa mrzgNo ratings yet

- Guidelines For Volumetric Stripping Rev.1 Feb.2004Document27 pagesGuidelines For Volumetric Stripping Rev.1 Feb.2004Yuri KostNo ratings yet

- Lecture 10 - DrillingWellDocument38 pagesLecture 10 - DrillingWellJuwisa Diky PNo ratings yet

- 2well Control - ExerciseDocument153 pages2well Control - ExerciseMostafa ElghifaryNo ratings yet

- TrabDevico DCD WebDocument10 pagesTrabDevico DCD WebjardelbrunoNo ratings yet

- Well ControlDocument43 pagesWell ControlIsmail Mohammed100% (1)

- HES Casing Accessories CatDocument23 pagesHES Casing Accessories CatJoan Corso100% (1)

- Chapter 1 - Introduction To Drilling Engineering2 PDFDocument110 pagesChapter 1 - Introduction To Drilling Engineering2 PDFFiena AzmiNo ratings yet

- ST 220 Panel Report9 8 2015 PDFDocument87 pagesST 220 Panel Report9 8 2015 PDFRajNo ratings yet

- H09095 - SuperFill Surge Reduction EquipDocument4 pagesH09095 - SuperFill Surge Reduction EquipAQUILES CARRERANo ratings yet

- SPE 170980 - Subsea Well Intervention - Recent Developments and Recommendations To Increase Overall Project ReturnsDocument12 pagesSPE 170980 - Subsea Well Intervention - Recent Developments and Recommendations To Increase Overall Project ReturnsAdri Coca SuaznabarNo ratings yet

- HYDRO-GUARD® Water-Based Drilling Fluid Delivering Stable Wellbore ThroughDocument1 pageHYDRO-GUARD® Water-Based Drilling Fluid Delivering Stable Wellbore ThroughFauzan Rahman HaqNo ratings yet

- Quantitative Risk Analysis of Offshore Drilling OperationsDocument10 pagesQuantitative Risk Analysis of Offshore Drilling OperationsdonprofaghatiseNo ratings yet

- Kill Sheet UcupDocument3 pagesKill Sheet UcupYusuf ArifinNo ratings yet

- CSG Type & DesignDocument45 pagesCSG Type & Designcrown212100% (2)

- 7 Days Look Ahead KKV-1 - 18AUG23Document1 page7 Days Look Ahead KKV-1 - 18AUG23Henokh ImanuelNo ratings yet

- Deepwater Horizon Trial Transcript Excerpts Discuss 2010 Oil Rig DisasterDocument213 pagesDeepwater Horizon Trial Transcript Excerpts Discuss 2010 Oil Rig DisasterOSDocs2012No ratings yet

- API 6a - 16a Drift Dia For Individual Valves - Christmas Trees and Drill-Through EquipmentDocument1 pageAPI 6a - 16a Drift Dia For Individual Valves - Christmas Trees and Drill-Through Equipmentw2jstpm9swNo ratings yet

- Helix Well Ops 15k Irs 7 LTR 06-17-2020 FinalDocument4 pagesHelix Well Ops 15k Irs 7 LTR 06-17-2020 FinalWilliam EvansNo ratings yet

- Test P&PDocument13 pagesTest P&PMuhammad Ali0% (1)

- Mds Odtawc Slidebook - 2015Document460 pagesMds Odtawc Slidebook - 2015Pâmela FontesNo ratings yet

- Wire line operations and tool strings for 5.5Document9 pagesWire line operations and tool strings for 5.5kamgaNo ratings yet

- Maximum Allowable Mud Weight Before Kick: Well Data 4Document5 pagesMaximum Allowable Mud Weight Before Kick: Well Data 4Sachin SahooNo ratings yet

- Company Profile PT Adromeda Rekayasa Fluida - Final-1Document37 pagesCompany Profile PT Adromeda Rekayasa Fluida - Final-1jamsir sabaraNo ratings yet