Professional Documents

Culture Documents

Pillow

Uploaded by

Kristine Marie Yson BocadoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pillow

Uploaded by

Kristine Marie Yson BocadoCopyright:

Available Formats

Rom, Rex E.

CSC-35

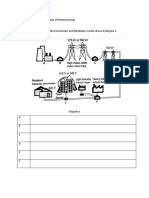

Fiber Optic Lay-Out Design

The operation of an optical fiber is based on the principle of total internal reflection. An optical fiber

consists of two different types highly pure, solid glass, composed to form the core and cladding. A

protective acrylate coating then surrounds the cladding. In most cases, the protective coating is a dual

layer composition.

A protective coating is applied to the glass fiber as the final step in the manufacturing process. This

coating protects the glass from dust to scratches that can affect fiber strength. This protective coating can

be comprised of two layers: a soft inner layer that cushions the fiber and allows the coating to be stripped

from the glass mechanically and harder outer layer that protects the fiber during handling, particularly

cabling, installation, and termination processes.

Tools and Equipments for Fiber Optic networking

FIBER TOOLS Fiber Light Sources

Fiber Scopes

Buffer Tube Access Fiber Talk Sets

Cleavers Optical Loss Test Sets

Fiber Cable Slitters Optical Power Meters

Fiber Crimp Tools OTDR Launch Cables

Fiber Cutters & Scissors OTDRs

Fiber Optic Scribes Test and Inspection Kits

Fiber Optic Strippers Visual Fault Locators

Focus Tool

TOOL AND TEST KITS

TEST EQUIPMENT

Installer Tool Kits

Adapter Caps Splice Kits

Certification Tools Termination Kits

DWDM and CWDM Testers Test and Inspection Kits

Fiber Identifiers TKT UniCam Tool Kits

Rom, Rex E. CSC-35

Operating Parameters for Fiber Optic Transmission

Three key performance parameters for single-mode fibers are:

1. Attenuation

2. Dispersion

3. Mode-Field Diameter

It is important to know that these performance parameters can vary significantly among fibers by different

manufacturers. Before making a decision, please find out the best fiber that will not lead to system

malfunction and offer the best performance for your system's needs.

Attenuation/Transmission Loss

Attenuation is the loss or reduction in signal strength over a certain distance. In the case of optical fiber,

this is measured in decibels per kilometer (dB/km). When first developed, optical fiber handled

attenuation of less than 20 dB per km. Now, typical attenuation is 0.35 dB per km at a wavelength of

1310 nanometers (nm) and even lower at 1550 km (0.25 dB per km).

Several factors lead to increased attenuation, primarily scattering and dispersion. Molecular irregularities

in the glass cause the light to scatter. Further attenuation is caused by light being absorbed by residual

materials, such as metal and water ions. It is recommended to buy a fiber cable that has a low water loss

to try to prevent as much attenuation as possible.

Dispersion

In optics, dispersion is a phenomenon that causes the separation of a wave into spectral components with

different frequencies, due to a dependence of the wave's speed on its frequency. During the process of

digital transmission, dispersion can limit the maximum data rate, maximum distance, or the information-

carrying capacity of the single-mode fiber. With analog transmission, dispersion can create unacceptable

levels of composite second-order distortion (CSO).

Mode-Field Diameter

This describes the size of the light-carrying part of fiber, including the core and a small part of the

cladding glass for single-mode fibers. Mode-field diameter (MFD) is important to note because it is a

performance parameter that can determine the effect of bend-induced loss as well as splice loss. Rather

than being only the core diameter, MFD is a function of wavelength, the aforementioned core diameter,

and the refractive-index

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- KDL 40ex705 BR VerDocument31 pagesKDL 40ex705 BR Vernivaldo de oliveira OliveiraNo ratings yet

- AscTec RESEARCH CatalogueDocument12 pagesAscTec RESEARCH Cataloguevikym14No ratings yet

- RPM Counter Using Micro ControllerDocument16 pagesRPM Counter Using Micro ControllerNitesh Kumar Sen100% (1)

- Digital I/O Modules: 17.5Mm Din-Rail Output Modules FeaturesDocument31 pagesDigital I/O Modules: 17.5Mm Din-Rail Output Modules FeaturesJose Luis PintoNo ratings yet

- 2n3903 2n3904 PDFDocument8 pages2n3903 2n3904 PDFOpik BiasaNo ratings yet

- 3VM11104EE320AA0 Datasheet enDocument5 pages3VM11104EE320AA0 Datasheet enEverton Pereira HilzendegerNo ratings yet

- Parasound Hca3500 OmDocument11 pagesParasound Hca3500 OmBmwmotorsport GabriNo ratings yet

- Asr 9001 DatasheetDocument5 pagesAsr 9001 DatasheetLecc0No ratings yet

- Salwico IC21 WP: Indication Control UnitDocument5 pagesSalwico IC21 WP: Indication Control UnitrolandseNo ratings yet

- Soni CDX-GT300. 2Document8 pagesSoni CDX-GT300. 2Percy BernuyNo ratings yet

- Module 5 - Digital Techniques Electronic Instrument Systems PDFDocument42 pagesModule 5 - Digital Techniques Electronic Instrument Systems PDFanilmathew244No ratings yet

- LM358Document23 pagesLM358Anonymous sIAUueNo ratings yet

- ## Tda93xx PinoutDocument2 pages## Tda93xx Pinoutdreamyson1983No ratings yet

- Installation Instruction of Bluetech: Windows XPDocument4 pagesInstallation Instruction of Bluetech: Windows XPGeorgi CherkezovNo ratings yet

- Universiti Tun Hussein Onn Malaysia Group Assignment Electronic Principles I (Bnr27103) SEMESTER 1, SESSION 2021/2022Document16 pagesUniversiti Tun Hussein Onn Malaysia Group Assignment Electronic Principles I (Bnr27103) SEMESTER 1, SESSION 2021/2022Izzul HakimNo ratings yet

- Worksheet Form 3 6.3Document4 pagesWorksheet Form 3 6.3Acyuta Raj67% (3)

- Fanuc Field Control™ Genius® Bus Interface UnitDocument248 pagesFanuc Field Control™ Genius® Bus Interface UnitsunhuynhNo ratings yet

- Division of Guihulngan City: Detailed Lesson Plan (DLP)Document18 pagesDivision of Guihulngan City: Detailed Lesson Plan (DLP)Giel Ryzen100% (3)

- 1557275886464lh4el Nari Dis Prot 2Document2 pages1557275886464lh4el Nari Dis Prot 2Kelly chatNo ratings yet

- 1 Electronica IndustrialDocument17 pages1 Electronica Industrialjerrygo_03No ratings yet

- Intermatic dt620 Instructions PDFDocument8 pagesIntermatic dt620 Instructions PDFHerling CaceresNo ratings yet

- De0-Nano-Soc User Manual: November 7, 2019Document80 pagesDe0-Nano-Soc User Manual: November 7, 2019LuisNo ratings yet

- Chapter 13 - 2 Energy in Coupled CircuitsDocument17 pagesChapter 13 - 2 Energy in Coupled CircuitsAgung FauziNo ratings yet

- The Compression HandbookDocument48 pagesThe Compression HandbookStephan KhodyrevNo ratings yet

- Class 5 - Node Voltage AnalysisDocument22 pagesClass 5 - Node Voltage AnalysisSwayam Tejas PadhyNo ratings yet

- Semiconductor Basics: N Pérez SM Olaizola 2004Document33 pagesSemiconductor Basics: N Pérez SM Olaizola 2004swad1705No ratings yet

- Portable Lte Base StationDocument5 pagesPortable Lte Base StationGülçin KöseNo ratings yet

- Cas-Gps Light Vehicle System: Type VG For Portable InstallationsDocument3 pagesCas-Gps Light Vehicle System: Type VG For Portable InstallationsAbhinandan PadhaNo ratings yet

- Paper - A Measurement Technique To Identify and Locate Partial Discharge in Transformer With AE and HFCTDocument6 pagesPaper - A Measurement Technique To Identify and Locate Partial Discharge in Transformer With AE and HFCTNguyen Vu Nhat HaNo ratings yet