Professional Documents

Culture Documents

Overhead Tank Report File

Uploaded by

Pranav MahajanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhead Tank Report File

Uploaded by

Pranav MahajanCopyright:

Available Formats

CHAPTER 1

INTRODUCTION

1.1. PROJECT AIM

TO ANALYZE AND DESIGN AN OVERHEAD TANK FOR THE USAGE OF

COLLEGE AND HOSTEL USING STAAD PRO.

1.2. SCOPE

The main scope of this project is to apply class room knowledge in the real world by designing

an overhead tank. These tanks require large and clear areas unobstructed by the columns.

Overhead water tanks are used for domestic water storage and commercial water purposes to

maintain flow of water to the general usage and other water requiring appliances.

1.3 GENERAL

STAAD Pro. V8i is the most popular structural engineering software product for model

generation, analysis and multi-material design. It has an intuitive, user-friendly GUI,

visualization tools, powerful analysis and design facilities and seamless integration to several

other modeling and design software products. The software is fully compatible with all

Windows operating systems but is optimized for Windows 7.

The ultimate power tool for Computerized Structural Engineering For static or dynamic

analysis of bridges, containment structures, embedded structures (tunnels and culverts), pipe

racks, steel, concrete, aluminum or timber buildings, transmission towers, stadiums or any

other simple or complex structure, STAAD Pro has been the choice of design professionals

around the world for their specific analysis needs.

Our project involves analysis and design of overhead tank using a very popular designing

software STAAD Pro (V8i).

GCET JAMMU 1 MINOR PROJECT

We have chosen STAAD Pro because of its following advantages:

easy to use interface,

conformation with the Indian Standard Codes, versatile nature of solving any type of

problem,

accuracy of the solution.

Fig. 1.1 : Staad Pro Outlook

STAAD.Pro consists of the following:

The STAAD.Pro Graphical User Interface: It is used to generate the model, which can then

be analyzed using the STAAD engine. After analysis and design is completed, the GUI can

also be used to view the results graphically.

The STAAD analysis and design engine: It is a general-purpose calculation engine for

structural analysis and integrated Steel, Concrete, Timber and Aluminum design. To start with

we have solved some sample problems using STAAD Pro and checked the accuracy of the

results with manual calculations. The results were to satisfaction and were accurate. In the

GCET JAMMU 2 MINOR PROJECT

initial phase of our project we have done calculations regarding loadings on buildings and also

considered seismic and wind loads.

Structural analysis comprises the set of physical laws and mathematics required to study and

predicts the behavior of structures. Structural analysis can be viewed more abstractly as a

method to drive the engineering design process or prove the soundness of a design without a

dependence on directly testing it.

To perform an accurate analysis a structural engineer must determine such information as

structural loads, geometry, support conditions, and materials properties. The results of such an

analysis typically include support reactions, stresses and displacements. This information is

then compared to criteria that indicate the conditions of failure. Advanced structural analysis

may examine dynamic response, stability and non-linear behavior.

The aim of design is the achievement of an acceptable probability that structures being designed

will perform satisfactorily during their intended life. With an appropriate degree of safety, they

should sustain all the loads and deformations of normal construction and use and have adequate

durability and adequate resistance to the effects of seismic and wind. Structure and structural

elements shall normally be designed by Limit State Method. Account should be taken of

accepted theories, experiment and experience and the need to design for durability.

Design, including design for durability, construction and use in service should be considered

as a whole. The realization of design objectives requires compliance with clearly defined

standards for materials, production, workmanship and also maintenance and use of structure in

service.

The design of the building is dependent upon the minimum requirements as prescribed in the

Indian Standard Codes. The minimum requirements pertaining to the structural safety of

buildings are being covered by way of laying down minimum design loads which have to be

assumed for dead loads, imposed loads, and other external loads, the structure would be

required to bear. Strict conformity to loading standards recommended in this code, it is hoped,

will not only ensure the structural safety of the buildings which are being designed.

GCET JAMMU 3 MINOR PROJECT

CHAPTER 2

ABOUT THE PROJECT

2.1 ABOUT THE PROJECT

This is an estimated project whose design values can be used for the construction of overhead

tank for the college and hostel, GCET Jammu along with other necessary utilities.

This document pertains to the structural designs carried out for a part of above said residential

township project for various structures. The development is in the seismic Zone – IV. The basic

wind speed at location of the development is 100 m/s. SBC of soil according to soil

investigations is 200 KN/m2. The design parameters considered are as per Indian Standard

Code of practice.

Fig. 2.1 : Rendering View of the Overhead Tank

GCET JAMMU 4 MINOR PROJECT

2.2 STATEMENT OF THE PROJECT

The water demand for various purposes to which the project satisfies are as follows:

NO. OF STUDENTS

Intake capacity = 320 * 4 = 1280 students

Hostel Living students = 35% of total students

= 35/100 * 1280

= 448 students (500 students approx.)

No. of staff members + other employees = 500 members

WATER DEMAND FOR VARIOUS USES:

Day scholars water demand = 50 lphd = 50 * 800 = 40000 litres per day

Hostel water demand = 150 lphd = 150 * 500 = 75000 litres per day

Garden watering demand = 100 litres per day

CLEANING WATER DEMAND:

Civil + Mechanical Block = 2 * 50 = 100 litres per day

Computer + Electrical + Electronics Block = 75 litres per day

Common Lecture Hall = 100 litres per day

Workshop = 30 litres per day

Administrative Block = 75 litres per day

Hostel Water Consumption = 5000 litres per day (@10 litres

per head per day)

TOTAL = 5380 (litres per day)

GCET JAMMU 5 MINOR PROJECT

Garden Water Demand = 100 litres per day

Labs (Civil+ Chemistry) Water Demand = 30 litres per day

Fire Demand = 5% of total capacity

Pantry for Hostel = 15 litres per head per day

= 7500 litres per day

Staff members Water Demand = 30 litres per head per day

= (30 * 500) litres per day

= 15000 litres per day

TOTAL CAPACITY = 1,52,010 litres per day

Applying 20% capacity extra for miscellaneous purposes.

DESIGN CAPACITY = 1,80,000 litres

MATERIAL PROPERTIES:

CONCRETE

All components unless specified in design: M30 grade all

STEEL

HYSD reinforcement of grade Fe 500 confirming to IS: 1786 is used throughout.

GCET JAMMU 6 MINOR PROJECT

CHAPTER 3

DESIGN PARAMETERS

3. DESIGN PARAMETERS

The program contains a number of parameters that are needed to perform design as per IS:

13920. It accepts all parameters that are needed to perform design as per IS: 456. Over and

above it has some other parameters that are required only when designed is performed as per

IS: 13920. Default parameter values have been selected such that they are frequently used

numbers for conventional design requirements. These values may be changed to suit the

particular design being performed by this manual contains a complete list of the available

parameters and their default values. It is necessary to declare length and force units as

Millimeter and Newton before performing the concrete design.

3.1. BEAM DESIGN

Beams are designed for flexure, shear and torsion. If required the effect of the axial force may

be taken into consideration. For all these forces, all active beam loadings are prescanned to

identify the critical load cases at different sections of the beams. For design to be performed as

per IS: 13920 the width of the member shall not be less than 200mm.

Also the member shall preferably have a width-to depth ratio of more than 0.3.

Design for Flexure:

Design procedure is same as that for IS: 456. However while designing following criteria are

satisfied as per IS: 13920

1. The minimum grade of concrete shall preferably be M25.

2. Steel reinforcements of grade Fe415 or less only shall be used.

3. The minimum tension steel ratio on any face, at any section, is given by:

ρmin = 0.24 √fck/fy

GCET JAMMU 7 MINOR PROJECT

The maximum steel ratio on any face, at any section, is given by ρmax = 0.025.

4. The positive steel ratio at a joint face must be at least equal to half the negative

steel at that face.

5. The steel provided at each of the top and bottom face, at any section, shall at

least be equal to one-fourth of the maximum negative moment steel provided at

the face of either joint.

Design for Shear:

The Shear force to be resisted by vertical hoops is guided by the IS 13920:1993 revision. Elastic

sagging and hogging moments of resistance of the beam section at ends are considered while

calculating shear force. Plastic sagging and hogging moments of resistance can also be

considered for shear design if PLASTIC parameter is mentioned in the input file. Shear

reinforcement is calculated to resist both shear forces and torsional moments.

3.2 COLUMN DESIGN

Columns are designed for axial forces and biaxial moments per IS 456:2000. Columns are also

designed for shear forces. All major criteria for selecting longitudinal and transverse

reinforcement as stipulated by IS: 456 have been taken care of in the column design of STAAD.

However following clauses have been satisfied to incorporate provisions of IS: 13920

1. The minimum grade of concrete shall preferably be M25.

2. Steel reinforcements of grade Fe415 or less only shall be used.

3. The minimum dimension of column member shall not be less than 200 mm.For

columns having unsupported length exceeding 4m, the shortest dimension of

column shall not be less than 300 mm.

4. The ratio of the shortest cross-sectional dimension to the perpendicular

dimension shall preferably be not less than 0.

5. The spacing of hoops shall not exceed half the least lateral dimension of the

column, except where special confining reinforcement is provided.

GCET JAMMU 8 MINOR PROJECT

6. Special confining reinforcement shall be provided over a length lo from each

joint face, towards mid span, and on either side of any section, where flexural

yielding may occur.

The length lo shall not be less than

a) larger lateral dimension of the member at the section where yielding occurs,

b) 1/6 of clear span of the member, and

c) 450 mm.

7. The spacing of hoops used as special confining reinforcement shall not exceed

of minimum member dimension but need not be less than 75 mm nor > 100 mm.

GCET JAMMU 9 MINOR PROJECT

CHAPTER 4

DESIGN OPERATIONS

4. DESIGN OPERATIONS

STAAD contains a broad set of facilities for designing structural members as individual

components of an analyzed structure. The member design facilities provide the user with the

ability to carry out a number of different design operations.

These facilities may design problem. The operations to perform a design are:

Specify the members and the load cases to be considered in the design.

Specify whether to perform code checking or member selection.

Specify design parameter values, if different from the default values.

Specify whether to perform member selection by optimization.

These operations may be repeated by the user any number of times depending upon the design

requirements. Earthquake motion often induces force large enough to cause inelastic

deformations in the structure. If the structure is brittle, sudden failure could occur. But if the

structure is made to behave ductile, it will be able to sustain the earthquake effects better with

some deflection larger than the yield deflection by absorption of energy. Therefore ductility is

also required as an essential element for safety from sudden collapse during severe shocks.

STAAD has the capabilities of performing concrete design as per IS: 13920. While designing

it satisfies all provisions of IS: 456 - 2000 and IS: 13920 for beams and columns.

4.1 GENERAL COMMENTS

This section presents some general statements regarding the implementation of Indian Standard

code of practice (IS: 800 - 1984) for structural steel design in STAAD. The design philosophy

and procedural logistics for member selection and code checking are based upon the principles

of allowable stress design. Two major failure modes are recognized:

GCET JAMMU 10 MINOR PROJECT

failure by overstressing, and

failure by stability considerations.

The flowing sections describe the salient features of the allowable stresses being calculated and

the stability criteria being used. Members are proportioned to resist the design loads without

exceeding the allowable stresses and the most economic section is selected on the basis of least

weight criteria. The code checking part of the program checks stability and strength

requirements and reports the critical loading condition and the governing code criteria. It is

generally assumed that the user will take care of the detailing requirements like provision of

stiffeners and check the local effects such as flange buckling and web crippling.

Allowable Stresses:

The member design and code checking in STAAD are based upon the allowable stress design

method as per IS: 800 (1984). It is a method for proportioning structural members using design

loads and forces, allowable stresses, and design limitations for the appropriate material under

service conditions. It would not be possible to describe every aspect of IS: 800 in this manual.

This section, however, will discuss the salient features of the allowable stresses specified by

IS: 800 and implemented in STAAD. Appropriate sections of IS: 800 will be referenced during

the discussion of various types of allowable stresses.

Multiple Analyses:

Structural analysis/design may require multiple analyses in the same run. STAAD allows the

user to change input such as member properties, support conditions etc. in an input file to

facilitate multiple analyses in the same run. Results from different analyses may be combined

for design purposes. For structures with bracing, it may be necessary to make certain members

inactive for a particular load case and subsequently activate them for another. STAAD provides

an INACTIVE facility for this type of analysis.

4.2 POST PROCESSING FACILITIES:

All output from the STAAD run may be utilized for further processing by the STAAD.Pro

GUI.

GCET JAMMU 11 MINOR PROJECT

4.3 STABILITY REQUIREMENTS:

Slenderness ratios are calculated for all members and checked against the appropriate

maximum values. IS: 800 summarize the maximum slenderness ratios for different types of

members. In STAAD implementation of IS: 800, appropriate maximum slenderness ratio can

be provided for each member. If no maximum slenderness ratio is provided, compression

members will be checked against a maximum value of 180 and tension members will be

checked against a maximum value of 400.

4.4 DEFLECTION CHECK:

This facility allows the user to consider deflection as criteria in the CODE CHECK and

MEMBER SELECTION processes. The deflection check may be controlled using three

parameters. Deflection is used in addition to other strength and stability related criteria. The

local deflection calculation is based on the latest analysis results.

4.5 EARTHQUAKE COLLAPSE CHECK:

This checks at each column / beam interface, the program checks that the capacity of the

column exceeds the total capacity of all beams that connect to it. The earthquake check only

uses the results from Design Groups that have Design Briefs from the selected Design Code.

4.6 CODE CHECKING:

The purpose of code checking is to verify whether the specified section is capable of satisfying

applicable design code requirements. The code checking is based on the IS: 800 (1984)

requirements. Forces and moments at specified sections of the members are utilized for the

code checking calculations. Sections may be specified using the BEAM parameter or the

SECTION command. If no sections are specified, the code checking is based on forces and

moments at the member ends.

GCET JAMMU 12 MINOR PROJECT

CHAPTER 5

PROJECT ANALYSIS

5. ANALYSIS OF OVERHEAD TANK USING STAAD PRO V8i

Fig. 5.1 : Isometric View of the Designed Overhead Tank

This overhead tank is designed for 1,80,000 litres for the supply of water to college and

hostel students of GCET Jammu having the following specifications:

Take D = Diameter of the water tank

GCET JAMMU 13 MINOR PROJECT

Average Depth = 0.75 D

Volume of the water reservoir = 180000 litres

= 180 m3

𝜋

∗ 𝐷2 * 0.75 D = 180

4

D = 6.74 m

Taking D = 8.00 m

Height of the cylindrical portion of the beam = 0.75 * 6.74

= 5.00 m

Central rise of the top dome = D/6 = 8/6

= 1.5 m (approx.)

Radius of the top dome = (D/22 + r2) / 2r

= (16 + 2.25) / ( 2 * 1.5 )

= 6.0833 m

Diameter of the top dome = 2 * 6.0833 = 12.167 m

Central rise of the top dome = D/6 = 5/6

= 0.83 m (approx.)

Radius of the bottom dome = (D/22 + r2) / 2r

= (5/22 + 0.832) / (2 * 0.83)

= 4.18 m

Diameter of the bottom dome = 2 * 4.18 = 8.36 m

GCET JAMMU 14 MINOR PROJECT

Total height of the overhead tank = 20m

Total height of staging = 12m

Height of circular portion of water reservoir = 5m

Height of trapezoidal portion of water reservoir = 1.5m

Diameter of circular portion of water reservoir = 8m

Diameter of staging tube = 5m

5.1 GENERATION OF THE MEMBER PROPERTY:

Fig. 5.2 : Generation of the Property of the top dome plate

GCET JAMMU 15 MINOR PROJECT

Fig. 5.3 : Generation of the Property of the Ring Beams

Generation of member property can be done in STAAD.Pro by using the window as shown

above. The member section is selected and the dimensions have been specified.

The properties of various elements used are as follows :

1. Top Dome Plate Concrete 150mm thick

2. Circular Region Plate Concrete 250mm thick

GCET JAMMU 16 MINOR PROJECT

3. Trapezoidal Plate Concrete 250mm thick

4. Ring Beams Concrete 500 x 500 mm

5. Staging Tube Concrete 250mm thick

5.2 SUPPORTS:

Fig. 5.4 : Fixed Support at Bottom

The base supports of the structure were assigned as fixed. The supports were generated using

the STAAD.Pro support generator.

5.3 MATERIALS FOR THE STRUCTURE:

The materials for the structure were specified as concrete with their various constants as per

standard IS code of practice.

5.4 LOADING:

The loadings were calculated partially manually and rest was generated using STAAD.Pro load

generator. The loading cases were categorized as:

1. Seismic load

2. Wind load

3. Dead load

4. Live load

5. Load combinations

GCET JAMMU 17 MINOR PROJECT

5.4.1 SEISMIC LOAD:

The seismic load values were calculated as per IS 1893-2002. STAAD.Pro has a seismic load

generator in accordance with the IS code mentioned.

Fig. 5.5 : STAAD utilizes the following procedure to generate the lateral seismic loads

GCET JAMMU 18 MINOR PROJECT

5.4.2 WIND LOAD:

The wind load values were generated by the software itself in accordance with IS 875. Under

the define load command section, in the wind load category, the definition of wind load was

supplied. The wind intensities at various heights were calculated manually and feed to the

software. Based on those values it generates the wind load at different floors. We consider

ASCE-7 for wind loads with basic wind speed of 50 kmph.

Fig. 5.6 : Window showing Wind Force action on Overhead Tank

5.4.3 DEAD LOAD:

5.4.3.1 SELF-WEIGHT:

The self-weight of the structure can be generated by STAAD.Pro itself with the self-weight

command given in the load case column.

GCET JAMMU 19 MINOR PROJECT

5.4.3.2 DEAD LOAD FROM WALLS:

Dead load from walls can also be generated by STAAD.Pro by specifying the wall thickness.

Calculation of the load per metre was done considering the weight of wall.

Weight of the wall = density of the wall x volume of wall per unit run

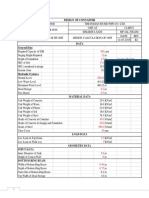

REGION THICKNESS HEIGHT DENSITY LOAD

(m) (m) (kN/m3) (kN/m)

TOP DOME 0.15 0.1 25 0.375

CIRCULAR 0.25 5 25 31.25

TRAPEZOIDAL 0.25 0.2 25 1.25

STAGING TUBE 0.25 12 25 75

TOP RING 0.5 0.5 25 6.25

BOTTOM RING 0.5 0.5 25 6.25

Fig. 5.7 : Window showing the Self-weight of Overhead Tank

GCET JAMMU 20 MINOR PROJECT

5.5 LOAD COMBINATION:

The structure has been analyzed for auto load combination considering all the previous loads

in proper ratio and generates load combination code as per Indian code under load combination

category of general structures.

5.5.1 Combination Rules:

For each Code/Category, each load category can be set with one of three rules:

a) Combine all cases together

b) Separate combination for each case

c) All possible combinations.

It will take a load combination of earthquake load, wind load, self-weight, dead load &live

loads.

Fig. 5.8 : Auto Load Combination Window

GCET JAMMU 21 MINOR PROJECT

Fig. 5.9 : GUI showing the analyzing window

GCET JAMMU 22 MINOR PROJECT

CHAPTER 6

PROJECT DESIGN

6.1 DESIGN OF OVERHEAD TANK USING STAAD PRO:

The structure was designed for concrete in accordance with IS: 456 codes. The parameters such

as Fy, Fck, etc were specified. The window shown below is the input window for the design

purpose. Then it has to be specified which members are to be designed as beams and which

member are to be designed as columns.

6.2 DESIGN PARAMETERS

Fig. 6.1 : Input Windows for Design Purpose

GCET JAMMU 23 MINOR PROJECT

FC: Compressive Strength of concrete

FYMAIN: Yield Strength for main reinforcement steel (For slabs, it the reinforcement used

in both directions)

FYSEC: Yield Strength for main reinforcement steel (Only used in beam design)

6.3 DESIGN COMMANDS:

DESIGN BEAM : Design beams for flexure, shear and torsion

DESIGN COLUMN : Design columns for axial load plus biaxial bending

TAKE OFF : Print the total volume of concrete and weight of steel

Reinforcement for the beams, columns and elements designed.

Fig. 6.2 : Design Specifications in STAAD.Pro

GCET JAMMU 24 MINOR PROJECT

Fig. 6.3 : STAAD Pro Command Input File

GCET JAMMU 25 MINOR PROJECT

CHAPTER 7

ANALYSIS AND DESIGN RESULTS

7. ANALYSIS AND DESIGN RESULTS:

7.1 TOTAL APPLIED LOAD 1 (SEISMIC LOAD)

GCET JAMMU 26 MINOR PROJECT

7.2 TOTAL APPLIED LOAD 2 (WIND LOAD)

GCET JAMMU 27 MINOR PROJECT

7.3 TOTAL APPLIED LOAD 3 (DEAD LOAD)

GCET JAMMU 28 MINOR PROJECT

7.4 CONCRETE DESIGN

GCET JAMMU 29 MINOR PROJECT

Fig. 7.1 : Shear Force Diagram of the Beam 1591

Fig. 7.2 : Bending Moment Diagram of the Beam 1591

GCET JAMMU 30 MINOR PROJECT

Fig. 7.3 : Reinforcement Detailing of the Beam Section 1591

GCET JAMMU 31 MINOR PROJECT

GCET JAMMU 32 MINOR PROJECT

Fig. 7.4 : Shear Force Diagram of the Beam 1623

Fig. 7.5 : Bending Moment Diagram of the Beam 1623

GCET JAMMU 33 MINOR PROJECT

Fig. 7.6 : Reinforcement Detailing of the Beam Section 1623

GCET JAMMU 34 MINOR PROJECT

7.5 REINFORCEMENT OF TOP DOME :

Hence, provide longitudinal reinforcement = 138.00 mm2 / metre and transverse reinforcement

= 138.00 mm2 / metre.

7.6 REINFORCEMENT OF THE OVERHEAD TANK (except top dome) :

Hence, provide longitudinal reinforcement = 258.00 mm2 / metre and transverse reinforcement

= 258.00 mm2 / metre.

GCET JAMMU 35 MINOR PROJECT

CHAPTER 8

POST PROCESSING OF PROJECT

8. POST PROCESSING MODE

Fig. 8.1 : Window showing Post processing mode of design

GCET JAMMU 36 MINOR PROJECT

Fig. 8.2 : Max Absolute Plate Stress Contours showing Structural Diagrams

GCET JAMMU 37 MINOR PROJECT

Fig. 8.3 : Windows showing various graphs

GCET JAMMU 38 MINOR PROJECT

CHAPTER 9

FOUNDATION DESIGN

9. FOUNDATION DESIGN:

Fig. 9.1 : GUI showing the foundation design of designed project

GCET JAMMU 39 MINOR PROJECT

The overhead tank is to be designed for mat foundation having the following properties:

1. Depth of the foundation below GL (Ground Level) = 5.00 m

2. Meshing Type = Triangular

3. Radius of circular footing = 4.00 m

4. Subgrade Modulus = 0.001 kip/in2/in

9.1 ANALYSIS OF THE FOUNDATION

Fig. 9.2 : Max Absolute Stresses on the Foundation

GCET JAMMU 40 MINOR PROJECT

Fig. 9.3 : Window showing Reinforcement Zoning for Longitudinal Bottom

Area of steel Provided = 6000 mm2

Hence, provide 20 mm bars @ 50 mm c-c spacing

9.2 DESIGN OUTPUT :

Top of Mat Longitudinal Direction

Bottom of Mat Longitudinal Direction

Zone:- 1

Governing Moment(MGOV)= -8356.881(kN-m/m)

For FC <4.0

Effective Depth = = 4.936 (m)

Limit Moment of Resistance (Mumax) =

83915.495 (kNm)

=

MGOV<= Mumax hence OK

Steel Required

GCET JAMMU 41 MINOR PROJECT

Calculated Area of Steel = 6000.000 (mm2)

Minimum Area of Steel = 6000.000 (mm2)

Provided Area of Steel = 6000.000 (mm2)

Reinforcement Details

Bar No= 20

Maximum Spacing(Smax)(User Specified) = 500.000(mm)

Minimum Spacing(Smin)(User Specified) = 50.000(mm)

Actual Spacing (S) = 50(mm)

Smin<= S <= Smax

---------------------------------------

Bottom of Mat Transverse Direction

Zone:- 1

Governing Moment(MGOV)= -6508.275(kN-m/m)

For FC <4.0

Effective Depth = = 4.928 (m)

Limit Moment of Resistance (Mumax) =

83643.704 (kNm)

=

MGOV<= Mumax hence OK

Steel Required

Calculated Area of Steel = 6000.000 (mm2)

Minimum Area of Steel = 6000.000 (mm2)

Provided Area of Steel = 6000.000 (mm2)

Reinforcement Details

Bar No= 20

Maximum Spacing(Smax)(User Specified) = 500.000(mm)

Minimum Spacing(Smin)(User Specified) = 50.000(mm)

Actual Spacing (S) = 50(mm)

Smin<= S <= Smax

GCET JAMMU 42 MINOR PROJECT

CHAPTER 10

OVERHEAD COLUMN TYPE TANK

10.1 OVERHEAD COLUMN TYPE TANK

Overhead column type tank are used in today world to increase the safety of the structure

against failing. Current design of circular shaft type staging of elevated water tanks are

extremely vulnerable under earthquake forces. Shaft type staging contains poor ductility of thin

shell section and in addition to that it has lack of load paths and toughness. Hence, the overhead

column type tank is more resistant to earthquake and seismic forces.

Fig. 10.1 : Render View of the Column Fig. 10.2 : Geometric View of the

Type Overhead Tank Column Type Overhead Tank

GCET JAMMU 43 MINOR PROJECT

10.2 GENERATION OF MEMBER PROPERTY

Fig. 10.3 : Plate Thickness of the Circular Tank

10.3 LOADINGS

The loadings of the column type overhead tank is same as described in shaft type overhead

tank.

Fig. 10.4 : Loading Diagram of Column Overhead Tank

GCET JAMMU 44 MINOR PROJECT

10.4 ANALYSIS

Fig. 10.5 : GUI showing the analyzing window

10.5 DESIGN PARAMETERS

All the design parameters of the column type of overhead tank is same as shaft type overhead

tank except the characteristic strength of the cement is M40.

Fig. 10.6 : Window showing the strength of cement

GCET JAMMU 45 MINOR PROJECT

10.6 PLATE STRESS CONTOURS

Fig. 10.7 : Max Absolute Plate Stress Contours of the Column Type Overhead Tank

GCET JAMMU 46 MINOR PROJECT

CHAPTER 11

ANALYSIS RESULTS OF COLUMN OHT

11.1 TOTAL APPLIED LOAD 1 (SEISMIC LOAD)

GCET JAMMU 47 MINOR PROJECT

11.2 TOTAL APPLIED LOAD 3 (DEAD LOAD)

GCET JAMMU 48 MINOR PROJECT

11.3 CONCRETE DESIGN

GCET JAMMU 49 MINOR PROJECT

Fig. 11.1 : Shear Force Diagram of the Column Section 1221

Fig. 11.2 : Bending Moment Diagram of the Column Section 1211

GCET JAMMU 50 MINOR PROJECT

Fig. 11.3 : Reinforcement Detailing of the Column Section 1221

GCET JAMMU 51 MINOR PROJECT

GCET JAMMU 52 MINOR PROJECT

Fig. 11.4 : Shear Force Diagram of the Ring Beam Section 1282

Fig. 11.5 : Bending Moment Diagram of the Ring Beam Section 1282

GCET JAMMU 53 MINOR PROJECT

Fig. 11.6 : Reinforcement Detailing of the Ring Beam Section 1282

GCET JAMMU 54 MINOR PROJECT

11.4 REINFORCEMENT OF THE TOP DOME

Hence, provide longitudinal reinforcement = 138 mm2 / metre and transverse reinforcement =

138 mm2 / metre.

11.5 REINFORCEMENT OF THE WATER TANK (except top dome)

Hence, provide longitudinal reinforcement = 438 mm2 / metre and transverse reinforcement =

438 mm2 / metre.

GCET JAMMU 55 MINOR PROJECT

CHAPTER 12

FOUNDATION DESIGN OF COLUMN OHT

12. FOUNDATION DESIGN

Fig. 12.1 : Window showing the Foundation of Column OHT

GCET JAMMU 56 MINOR PROJECT

The overhead tank is to be designed for ISOLATED FOOTING having the following

properties:

1. Unit Weight of Concrete = 30 N/mm2

2. Yield Strength of Steel = 500 N/mm2

3. Soil Type = Drained Condition

4. Unit Weight of Soil = 22 kN/m3

5. Bearing Capacity of Soil = 100 kN/m2

12.2 DIMENSIONS OF THE ANALYSED FOOTINGS

Hence, provide ISOLATED footings of φ12 mm at a spacing of 60 mm centre to centre.

GCET JAMMU 57 MINOR PROJECT

12.3 DESIGN OUTPUT

FOR ISOLATED FOOTING

Fig. 12.2 : Reinforcement Detailing of Isolated Footing

Footing Size

Initial Length (Lo) = 1.000 m

Initial Width (Wo) = 1.000 m

Uplift force due to buoyancy = 0.000 kN

Effect due to adhesion = 0.000 kN

Area from initial length and width, Ao =Lo X Wo = 1.000 m2

Min. area required from bearing pressure, Amin =P / qmax = 24.458 m2

Note: Amin is an initial estimation.

P = Critical Factored Axial Load(without self weight/buoyancy/soil).

qmax = Respective Factored Bearing Capacity.

GCET JAMMU 58 MINOR PROJECT

Final Footing Size

Length (L2) = 5.400 m Governing Load Case : # 11

Width (W2) = 5.400 m Governing Load Case : # 11

Depth (D2) = 0.508 m Governing Load Case : # 11

Area (A2) = 29.160 m2

------------------------------------------------------

Pressures at Four Corner

Area of

Pressure at Pressure at Pressure at Pressure at

footing in

Load Case corner 1 (q1) corner 2 (q2) corner 3 (q3) corner 4 (q4)

uplift (Au)

(kN/m2) (kN/m2) (kN/m2) (kN/m2)

(m2)

11 86.6277 98.7959 98.7959 86.6276 0.000

11 86.6277 98.7959 98.7959 86.6276 0.000

11 86.6277 98.7959 98.7959 86.6276 0.000

11 86.6277 98.7959 98.7959 86.6276 0.000

If Au is zero, there is no uplift and no pressure adjustment is necessary. Otherwise,

to account for uplift, areas of negative pressure will be set to zero and the pressure

will be redistributed to remaining corners.

GCET JAMMU 59 MINOR PROJECT

Summary of adjusted Pressures at Four Corner

Pressure at Pressure at Pressure at Pressure at

corner 1 (q1) corner 2 (q2) corner 3 (q3) corner 4 (q4)

Load Case

(kN/m2) (kN/m2) (kN/m2) (kN/m2)

11 86.6277 98.7959 98.7959 86.6276

11 86.6277 98.7959 98.7959 86.6276

11 86.6277 98.7959 98.7959 86.6276

11 86.6277 98.7959 98.7959 86.6276

Details of Out-of-Contact Area

(If Any)

Governing load case = N/A

Plan area of footing = 29.160 sq.m

Area not in contact with soil = 0.000 sq.m

% of total area not in contact = 0.000%

------------------------------------------------------

Check For Stability Against Overturning And Sliding

- Factor of safety against sliding Factor of safety against overturning

Load Case Along X-

Along Z-Direction About X-Direction About Z-Direction

No. Direction

1 11.626 2821871.163 12381901.039 20.920

3 674.758 220465831.417 34646616.872 2631.951

4 629.391 231348176.512 32285313.683 2454.993

5 652.075 191748897.142 33460788.309 2543.472

6 652.075 191748897.142 33460788.309 2543.472

7 26.426 6368227.195 17492285.575 46.843

8 9.618 2353147.174 24414479.249 17.558

9 629.391 231348176.512 32285313.683 2454.993

10 629.391 231348176.512 32285313.683 2454.993

11 25.790 6229206.430 17047266.690 45.715

GCET JAMMU 60 MINOR PROJECT

12 9.016 2208176.476 22851340.222 16.458

13 19.527 4725768.905 15278213.863 34.823

14 3.328 813631.898 5488340.189 6.040

Critical Load Case And The Governing Factor Of Safety For Overturning and Sliding X Direction

Critical Load Case for Sliding along X-Direction : 14

Governing Disturbing Force : -54.765 kN

Governing Restoring Force : 182.254 kN

Minimum Sliding Ratio for the Critical Load Case : 3.328

Critical Load Case for Overturning about X-Direction : 0

Governing Overturning Moment : 0.000 kNm

Governing Resisting Moment : 0.000 kNm

Minimum Overturning Ratio for the Critical Load Case 1000000.000

:

Critical Load Case And The Governing Factor Of Safety For Overturning and Sliding Z Direction

Critical Load Case for Sliding along Z-Direction : 14

Governing Disturbing Force : 0.000 kN

Governing Restoring Force : 182.254 kN

Minimum Sliding Ratio for the Critical Load Case : 813631.898

Critical Load Case for Overturning about Z-Direction : 14

Governing Overturning Moment : 162.926 kNm

Governing Resisting Moment : 984.151 kNm

Minimum Overturning Ratio for the Critical Load Case 6.040

:

Moment Calculation

Check Trial Depth against moment (w.r.t. X Axis)

Critical Load Case = #11

GCET JAMMU 61 MINOR PROJECT

Effective Depth = = 0.452 m

Governing moment (Mu) = 1219.578 kNm

As Per IS 456 2000 ANNEX G G-1.1C

= 0.479107

Limiting Factor1 (Kumax) =

Limiting Factor2 (Rumax) =

= 3444.291146 kN/m2

Limit Moment Of Resistance (Mumax) =

= 3799.815884 kNm

Mu <= Mumax hence, safe

Check Trial Depth against moment (w.r.t. Z Axis)

= #11

Critical Load Case

Effective Depth = = 0.452 m

Governing moment (Mu) = 1282.934 kNm

As Per IS 456 2000 ANNEX G G-1.1C

= 0.479107

Limiting Factor1 (Kumax) =

Limiting Factor2 (Rumax) = = 3444.291146 kN/m2

Limit Moment Of Resistance (Mumax) = = 3799.815884 kNm

Mu <= Mumax hence, safe

Shear Calculation

Check Trial Depth for one way shear (Along X Axis)

(Shear Plane Parallel to X Axis)

GCET JAMMU 62 MINOR PROJECT

Critical Load Case = #11

DX = 0.452 m

Shear Force(S) = 845.161 kN

Shear Stress(Tv) = 346.263783 kN/m2

Percentage Of Steel(Pt) = 0.3414

As Per IS 456 2000 Clause 40 Table 19

Shear Strength Of Concrete(Tc) = 417.029 kN/m2

Tv< Tc hence, safe

Check Trial Depth for one way shear (Along Z Axis)

Critical Load Case = #11

GCET JAMMU 63 MINOR PROJECT

DZ = 0.452 m

Shear Force(S) = 885.353 kN

Shear Stress(Tv) = 362.730590 kN/m2

Percentage Of Steel(Pt) = 0.3236

As Per IS 456 2000 Clause 40 Table 19

Shear Strength Of Concrete(Tc) = 407.600 kN/m2

Tv< Tc hence, safe

Check Trial Depth for two way shear

Critical Load Case = #11

Shear Force(S) = 2315.931 kN

Shear Stress(Tv) = 1065.670 kN/m2

As Per IS 456 2000 Clause 31.6.3.1

Ks = = 1.000

Shear Strength(Tc)= = 1250.0000 kN/m2

Ks x Tc = 1250.0000 kN/m2

Tv<= Ks x Tc hence, safe

GCET JAMMU 64 MINOR PROJECT

Reinforcement Calculation

Calculation of Maximum Bar Size

Along X Axis

Bar diameter corresponding to max bar size (db) = 32 mm

As Per IS 456 2000 Clause 26.2.1

Development Length(ld) = = 1.289 m

Allowable Length(ldb) = = 2.275 m

ldb >=ld hence, safe

Along

Z Axis

Bar diameter corresponding to max bar size(db) = 32 mm

As Per IS 456 2000 Clause 26.2.1

Development Length(ld) = = 1.289 m

Allowable Length(ldb) = = 2.275 m

ldb >=ld hence, safe

Bottom Reinforcement Design

Along Z Axis

GCET JAMMU 65 MINOR PROJECT

Selected bar Size (db) = Ø10

Minimum spacing allowed (Smin) = 50.000 mm

Selected spacing (S) = 52.900 mm

Smin <= S <= Smax and selected bar size < selected maximum bar size...

The reinforcement is accepted.

As Per IS 456 2000 Clause 26.5.2.1

Critical Load Case = #11

Minimum Area of Steel (Astmin) = 3285.360 mm2

Calculated Area of Steel (Ast) = 7897.468 mm2

Provided Area of Steel (Ast,Provided) = 7897.468 mm2

Astmin<= Ast,Provided Steel area is accepted

Based on spacing reinforcement increment; provided reinforcement is

Ø10 @ 50.000 mm o.c.

GCET JAMMU 66 MINOR PROJECT

CHAPTER 13

COMPARISON

S.NO. SHAFT TYPE OVERHEAD COLUMN TYPE OVERHEAD

TANK TANK

1. The characteristic strength of the The characteristic strength of the

cement is M30. cement is M40.

2. Plate Thickness of the Circular Tank Plate Thickness of the Circular Tank

is 250 mm. is 400 mm.

3. Max. Absolute Plate Stresses acting is Max. Absolute Plate Stresses acting

1.6 N/mm2. is 2.98 N/mm2.

4. Cross-Section of the Ring Beam Cross-Section of the Ring Beam

Section is (500*500) mm. Section is (750*750) mm.

5. The Foundation used for the design is The Foundation used for the design

Mat Foundation. is Isolated Footing.

6. The Longitudinal Reinforcement of The Longitudinal Reinforcement of

the Plate Section of tank is 258 mm2 the Plate Section of tank is 438 mm2

per metre. per metre.

7. The area of steel in ring beam cross- The area of steel in ring beam cross-

section is 1608.5 mm2. ( 8 no’s 16 φ section is 2305.927 mm2. ( 6 no’s 16

bars) . φ bars + 14 no’s 10 φ bars )

GCET JAMMU 67 MINOR PROJECT

Current designs of circular shaft type staging of elevated tanks are extremely vulnerable under

earthquake forces. In 2001 Bhuj earthquake, another illustration of this vulnerability had been

seen when many water tank with shaft staging suffered damage as distant as 100 km from the

epicenter. Shaft type staging contains poor ductility of thin shell sections and in addition to that

it has lack of redundancy of load paths and toughness.

Lateral strength analysis of number of damaged shaft staging clearly show that all of them are

either met or exceeded the requirements of IS: 1893(1984), however, they were all found to be

deficient when compared with the requirements of IBC in similar seismic exposure conditions.

IS: 1893(1984) design forces are inexcusably low for the systems which do not have enough

ductility or redundancy.

The current design parameters seismic codes for elevated tanks result in extremely vulnerable

shaft type supporting structures as evidenced in the 2001 Bhuj earthquake. Supporting shafts

developed flexural-tension cracks were observed in tanks as far as 100 km away from epicenter

regions despite the fact that most had lateral strength far greater that that specified by

IS:1893(1984).

Multipurpose elevated water storage facility of present invention includes a pillar supporting

the elevated water storage tanks which has the flute portion, by rendering overall facility more

efficiently and aesthetically pleasing. The fluted portion of the tank includes a plurality of the

fluted plates, and is coupled to a pillar by a box girder in preferred personification. Additional

stiffening rings are also included and additional floor can be included above water stored in the

tank.

GCET JAMMU 68 MINOR PROJECT

13.1 DIAGRAMATIC COMPARISON BETWEEN SHAFT AND COLUMN TYPE

OVERHEAD TANK

GCET JAMMU 69 MINOR PROJECT

You might also like

- 350kl Overhead Water Intze Tank DesignDocument30 pages350kl Overhead Water Intze Tank DesignHarish Kumar Mahavar60% (5)

- Causes of Failure of Weirs On Permeable Soils and Their RemediesDocument18 pagesCauses of Failure of Weirs On Permeable Soils and Their RemediesMr. Y. RajeshNo ratings yet

- Design of Over Head Water TankDocument20 pagesDesign of Over Head Water TankRomyMohan100% (1)

- Design of Overhead Circular Water TankDocument30 pagesDesign of Overhead Circular Water Tankvishnumani3011100% (1)

- Project Report On Intz Tank-Kapil Solanki PDFDocument104 pagesProject Report On Intz Tank-Kapil Solanki PDFvikas solankiNo ratings yet

- Design and Analysis of Stadium Using Staad ProDocument18 pagesDesign and Analysis of Stadium Using Staad Probabu14340% (1)

- Water Tank DesignDocument28 pagesWater Tank DesignDurval Párraga100% (3)

- Design of 1.50KL OH Tank 9M Staging PDFDocument21 pagesDesign of 1.50KL OH Tank 9M Staging PDFshivanandarcotNo ratings yet

- 2.areator & Flash MixerDocument16 pages2.areator & Flash MixerG.C.PatilNo ratings yet

- Staad Pro ReportDocument35 pagesStaad Pro ReportPangerwati OzukumNo ratings yet

- A Project Report in Civil Engineering Civil Engineering Iit Kanpur34 PagesDocument33 pagesA Project Report in Civil Engineering Civil Engineering Iit Kanpur34 PagesAbhi SinghNo ratings yet

- Intzetankdesign 170211222454Document43 pagesIntzetankdesign 170211222454Vishwanath KrNo ratings yet

- 150 KLD NirmalpurDocument19 pages150 KLD NirmalpurHirak BhattacharyaNo ratings yet

- Rectangular TankDocument21 pagesRectangular TankNaveen Kumar100% (2)

- Overhead TankDocument55 pagesOverhead TankamanrajNo ratings yet

- Cd-17-Major Project Report PDFDocument88 pagesCd-17-Major Project Report PDFRahul Singh Parihar91% (11)

- A PROJECT ON g+5 BuildingsDocument36 pagesA PROJECT ON g+5 BuildingsVishakha PatelNo ratings yet

- Steel Sketch With ProblemDocument59 pagesSteel Sketch With Problemmaniram7No ratings yet

- Six Month Training Report On Construction of Railway Overbridge PDFDocument49 pagesSix Month Training Report On Construction of Railway Overbridge PDFGurpreet SinghNo ratings yet

- Design of Cantilever Slab As Per Is 456 2000Document2 pagesDesign of Cantilever Slab As Per Is 456 2000airtelNo ratings yet

- Design Report 600 KL 25 MTR Gajabandh & BadkarliDocument70 pagesDesign Report 600 KL 25 MTR Gajabandh & BadkarlishailenderNo ratings yet

- Project 2 ReportDocument26 pagesProject 2 Reportarjun kumarNo ratings yet

- Combined Footing Vtu DocumentDocument22 pagesCombined Footing Vtu DocumentSyed IsmailNo ratings yet

- Project Staad ProDocument35 pagesProject Staad ProDevasya SinghNo ratings yet

- 4th Semester RCC Notes 170745Document32 pages4th Semester RCC Notes 170745Santosh67% (3)

- Analysis & Design of Water Tank Using Staad Pro V8iDocument1 pageAnalysis & Design of Water Tank Using Staad Pro V8iDharma banothuNo ratings yet

- Beam, Column DesignDocument6 pagesBeam, Column DesignDhanush M.R.No ratings yet

- Load Banquet Hall Column 123Document4 pagesLoad Banquet Hall Column 123gchakroNo ratings yet

- A Mini Project ReportDocument37 pagesA Mini Project ReportChintuu Sai100% (2)

- Civil Engg PDFDocument53 pagesCivil Engg PDFSatyadev RanaNo ratings yet

- Staad Viva QuestionDocument4 pagesStaad Viva QuestionMohmmand Aslam-CE88% (8)

- Design and Drawing of Irrigation StructuresDocument6 pagesDesign and Drawing of Irrigation StructuresRam Krishna Arikatla100% (3)

- Analysis and Design of Water TankDocument59 pagesAnalysis and Design of Water Tankmeetshah9267% (3)

- Design of Elevated Service ReservoirDocument88 pagesDesign of Elevated Service ReservoirNitish Ramdawor86% (7)

- Introduction To RCC: Computer Aided Detailing of Structures Laboratory Manual (15Cvl 77)Document58 pagesIntroduction To RCC: Computer Aided Detailing of Structures Laboratory Manual (15Cvl 77)Ullas S Lokesh100% (1)

- Properties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelDocument19 pagesProperties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelRaju Sharma75% (4)

- Is 7784 2 3 1996 PDFDocument13 pagesIs 7784 2 3 1996 PDFmanoj_structureNo ratings yet

- ESRDocument30 pagesESRAjayvidyanand SharmaNo ratings yet

- Hydraulic Design of Check DamDocument2 pagesHydraulic Design of Check DamSooraj Kannan, P.V.No ratings yet

- IAT-III Question Paper With Solution of 18CV72 Design of RCC and Steel Structures Feb-2022-Sreelakshmi GDocument27 pagesIAT-III Question Paper With Solution of 18CV72 Design of RCC and Steel Structures Feb-2022-Sreelakshmi GSrikanth ReddyNo ratings yet

- Staad Pro Project ReportDocument28 pagesStaad Pro Project Reportsunbo57% (7)

- Design&Drng Compiled G.S.sureshDocument82 pagesDesign&Drng Compiled G.S.sureshBilal Ahmed Barbhuiya100% (1)

- Design of Intake WellDocument2 pagesDesign of Intake WellMaria Hazel AbayaNo ratings yet

- Design of Overhead Water Tank 29Document28 pagesDesign of Overhead Water Tank 29rashmi bhailaNo ratings yet

- Beam Design by SP 16Document1 pageBeam Design by SP 16Arnab Deb67% (3)

- Design of Clear Water Reservoir and Pump House of MahishnadiDocument25 pagesDesign of Clear Water Reservoir and Pump House of MahishnadiMukhlish AkhatarNo ratings yet

- Cad DrawingDocument53 pagesCad DrawingAvish Gunnuck100% (3)

- Staad ProDocument48 pagesStaad ProSanjithRNairNo ratings yet

- Design and Analysis of G+6 Storeyed BuildingDocument31 pagesDesign and Analysis of G+6 Storeyed BuildingMadhav MishraNo ratings yet

- Super Passage Trough Design-User ManualDocument13 pagesSuper Passage Trough Design-User Manualpaaji100% (1)

- 3 - Design Calculation 100KL OHT 12 M Height PDFDocument29 pages3 - Design Calculation 100KL OHT 12 M Height PDFEr.Ruchik Soni100% (3)

- Design and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareDocument7 pagesDesign and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareIJRASETPublicationsNo ratings yet

- Design Project Paper Latest 7 10 22Document29 pagesDesign Project Paper Latest 7 10 22francis john gotomangaNo ratings yet

- CP11Document9 pagesCP11Bharat KhandekarNo ratings yet

- Irjet V9i6413Document14 pagesIrjet V9i6413Vinit KondapureNo ratings yet

- Design of 5-Megawatt Small-Hydroelectric Power PlantDocument39 pagesDesign of 5-Megawatt Small-Hydroelectric Power PlantDeteu Cabadonga100% (1)

- IEA Annex-2 STB2 Data Sheet About Innovative Technology 221-1Document2 pagesIEA Annex-2 STB2 Data Sheet About Innovative Technology 221-1Tonny SuakNo ratings yet

- IRJET Energy Analysis of BuildingsDocument5 pagesIRJET Energy Analysis of BuildingsPinninti PavanNo ratings yet

- Analysis and Design of MosqueDocument56 pagesAnalysis and Design of MosqueSabid Kanakkayil86% (7)

- Comparative Analysis of Conventional Formwork and Mivan Formwork Based On Duration and CostDocument5 pagesComparative Analysis of Conventional Formwork and Mivan Formwork Based On Duration and CostJulianne RamonedaNo ratings yet

- Family DetailsDocument1 pageFamily DetailsPranav MahajanNo ratings yet

- Gabion NewDocument81 pagesGabion NewPranav Mahajan50% (2)

- Hon'ble Ch. Lal Singh Ji Minister For Forest Jammu and Kashmir Govt., Civil Sectt. JammuDocument1 pageHon'ble Ch. Lal Singh Ji Minister For Forest Jammu and Kashmir Govt., Civil Sectt. JammuPranav MahajanNo ratings yet

- Sri Ram Sagar Project (SRSP) : A Report OnDocument3 pagesSri Ram Sagar Project (SRSP) : A Report OnPranav MahajanNo ratings yet

- General Abstract of Cost For Augmentation and Extension of Water Supply Scheme, Sunderbani TownDocument3 pagesGeneral Abstract of Cost For Augmentation and Extension of Water Supply Scheme, Sunderbani TownPranav MahajanNo ratings yet

- Plot at SaleDocument2 pagesPlot at SalePranav MahajanNo ratings yet

- R121 E96Document12 pagesR121 E96Giuseppe Gori100% (3)

- Lab InstructionsDocument26 pagesLab InstructionsDileepNo ratings yet

- Laboratory Procedures For Mining Pelletizing Characterization of Iron Ore ConcentrationDocument9 pagesLaboratory Procedures For Mining Pelletizing Characterization of Iron Ore ConcentrationgeodasNo ratings yet

- Anbearthretainingbs 8002 CalcsDocument16 pagesAnbearthretainingbs 8002 Calcsapi-305101869No ratings yet

- Modeling Analysis and Optimization of TADocument11 pagesModeling Analysis and Optimization of TAYãbeçk MâmNo ratings yet

- The Oolitization Rate Determination of Bentonite Moulding MixturesDocument4 pagesThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312No ratings yet

- C62 PDFDocument4 pagesC62 PDFAjay Jain100% (1)

- Viboon Psychrometric DataDocument8 pagesViboon Psychrometric DataTian Fung WangNo ratings yet

- Observer-Based Super Twisting Sliding Mode Control For Fixed Wing Unmanned Aerial VehicleDocument6 pagesObserver-Based Super Twisting Sliding Mode Control For Fixed Wing Unmanned Aerial VehiclemailtosshettyNo ratings yet

- Differentiation of Algebraic Functions and Its Applications: ContentsDocument8 pagesDifferentiation of Algebraic Functions and Its Applications: ContentsAsa KaNo ratings yet

- Printing - Obtaining and Assigning Beam Cross-Section Properties Using HyperBeam - HM-3020Document14 pagesPrinting - Obtaining and Assigning Beam Cross-Section Properties Using HyperBeam - HM-3020api-19817003No ratings yet

- Earth Mat Design 33-11KV SSDocument5 pagesEarth Mat Design 33-11KV SSDipak BandyopadhyayNo ratings yet

- Drag ForceDocument7 pagesDrag ForceehsankotNo ratings yet

- 9709 s10 QP 42Document4 pages9709 s10 QP 42Abrar JahinNo ratings yet

- BoilerIndia2020 Brochure PDFDocument7 pagesBoilerIndia2020 Brochure PDFSri Amudalas Gas Energy SolutionsNo ratings yet

- P Malan AIAA2009 Gamma Re ThetaDocument14 pagesP Malan AIAA2009 Gamma Re ThetaMohammed BarahmehNo ratings yet

- Analysis of Arishta Yoga For Happy Married LifeDocument3 pagesAnalysis of Arishta Yoga For Happy Married LifegeorgeinpuneNo ratings yet

- Fluid StaticDocument24 pagesFluid StaticNurhidayah AzmiNo ratings yet

- Mid Term PresentationDocument16 pagesMid Term PresentationSyed HusamNo ratings yet

- Atomic Force Microscopy AFM Basics and Its ImportaDocument18 pagesAtomic Force Microscopy AFM Basics and Its ImportaEmi ReyesNo ratings yet

- Metric-Based Classifiers: Nuno Vasconcelos (Ken Kreutz-Delgado)Document32 pagesMetric-Based Classifiers: Nuno Vasconcelos (Ken Kreutz-Delgado)Manu VegaNo ratings yet

- Photometric SystemsDocument46 pagesPhotometric SystemsCaioPaesNo ratings yet

- Forward KinematicsDocument4 pagesForward KinematicsZafer Gök100% (1)

- Purity Vs AssayDocument1 pagePurity Vs AssayRagu RajeshNo ratings yet

- Acoustics Wave EquationsDocument27 pagesAcoustics Wave Equationszeeshanahmad111No ratings yet

- Druck - UPS IIDocument2 pagesDruck - UPS IIbugoff700No ratings yet

- Trigonometric Leveling - Heights and Distances Problem (Two Exercises)Document1 pageTrigonometric Leveling - Heights and Distances Problem (Two Exercises)RadhaAnanthalekshmiNo ratings yet

- Exercise # 1.1Document1 pageExercise # 1.1iamniczdejzNo ratings yet

- Calculation of Mole Ratio Jobs MethodDocument7 pagesCalculation of Mole Ratio Jobs MethodAndy KumarNo ratings yet

- First Supplement To USP 40-NF 35 PDFDocument12 pagesFirst Supplement To USP 40-NF 35 PDFDwi Mega PratiwiNo ratings yet