Professional Documents

Culture Documents

Certificado Pipeliner 6P+

Uploaded by

Eric RamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificado Pipeliner 6P+

Uploaded by

Eric RamirezCopyright:

Available Formats

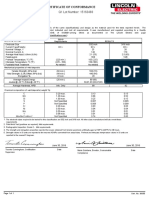

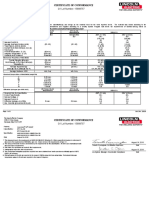

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Avenue

Cleveland, Ohio 44117-1199

Certified Material Test Report

This is to certify that the following material was manufactured under one lot control number per AWS A5.01, Class C3 and tested

per Schedule K. This test report is in accordance with 3.1 per EN 10204.

The product stated here in was manufactured in the U.S.A. and supplied in accordance with the Quality System Program of the

Lincoln Electric Company, Cleveland, Ohio, U.S.A. as outlined in our Quality Assurance Manual which meets the requirements of

ISO 9001, NCA 3800, AWS A5.01, and other specifications, as appropriate. The Quality System Program has been approved by

ASME, ABS, and VdTUV, and is certified to ISO 9001.

The 4.0mm Pipeliner® 6P+ electrode, Q2 Lot® 14602496 was tested according to the requirements of AWS A5.1:2012 and ASME

SFA-5.1 (E6010).

E6010 Actual

Operating Settings

Requirement Lot Results

Electrode Size 4.0mm

Polarity DC+

Plate Thickness, mm (in) 19 (3/4)

Current, A 140

Pass/Layers 18/9

Preheat Temperature, °C (°F) (225 min.) 105 (225)

Interpass Temperature, °C (°F) (225 - 350) 150 (300)

Postweld Heat Treatment As-welded As-welded

Mechanical properties of weld deposits E6010 Actual

Requirement Lot Results

Tensile Strength, MPa (ksi) (60 min.) 530 (77)

Yield Strength, 0.2% Offset, MPa (ksi) (48 min.) 430 (63)

Elongation % 22 min.

E6010

29 Actual

Requirement Lot Results

Average Impact Energy (20 min.) 93 (68)

Joules @ -29 °C (ft-lbs @ -20 °F) 88,92,98 (65,68,72)

Chemical composition of Weld Deposits (weight %) E6010 Actual

Requirement Lot Results

C 0.20 max. 0.15

Mn 1.20 max. 0.63

Si 1.00 max. 0.16

S Not Required 0.011

P Not Required 0.008

Cr 0.20 max. 0.02

Ni 0.30 max. 0.04

Mo 0.30 max. 0.01

V 0.08 max. 0.00

B Not Required 0

We do not use mercury in the design and formulation of our consumable products. In the manufacturing and testing of our

products, our equipment meets mercury exclusion requirements. All material in one container is from one Lot.

1. Test assembly constructed of ASTM A36 steel.

2. Fillet Weld Test (positions as required): Met requirements.

3. Radiographic Inspection: Grade 2 - Met requirements.

4. The strength and elongation properties reported here were obtained from tensile specimens artificially aged at 105°C (220°F) for 48

hours.

5. Results below the detection limits of the instrument or lower than the precision required by the specification are reported as zero.

Strength values in SI units are reported to the nearest 10 MPa converted from actual data. Preheat and interpass temperature

values in SI units are reported to the nearest 5 degrees.

Note: The recording of false, fictitious or fraudulent statements or entries on this document maybe punished as felony under Federal

Statutes including Federal Law, Title 18, Chapter 47.

Certified Material Test Report Q2 ® Lot 14602496, Page 1 of 2

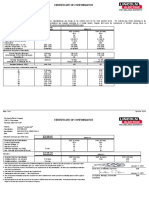

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Avenue

Cleveland, Ohio 44117-1199

Certified Material Test Report

January 28, 2016 January 28, 2016

Ed Bunnell, Quality Assurance Mike Young, Specials Testing Coordinator

Note: The recording of false, fictitious or fraudulent statements or entries on this document maybe punished as felony under Federal

Statutes including Federal Law, Title 18, Chapter 47.

Certified Material Test Report Q2 ® Lot 14602496, Page 2 of 2

You might also like

- 100 IdeasDocument21 pages100 IdeasNo ID100% (1)

- Teacher'S Individual Plan For Professional Development SCHOOL YEAR 2020-2021Document2 pagesTeacher'S Individual Plan For Professional Development SCHOOL YEAR 2020-2021Diether Mercado Padua100% (8)

- Electrical and Electronic Principles: Volume 2From EverandElectrical and Electronic Principles: Volume 2Rating: 4 out of 5 stars4/5 (5)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- Excalibur 11018M MR CertDocument2 pagesExcalibur 11018M MR CertAminNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- L-50 Lincolnweld 980Document1 pageL-50 Lincolnweld 980geloram66No ratings yet

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesNo ratings yet

- Lincolnweld 888 & LA-85Document2 pagesLincolnweld 888 & LA-85Pablo PazNo ratings yet

- Certificate of ConformanceDocument1 pageCertificate of ConformanceedwinNo ratings yet

- Data Sheet For SINAMICS G120 Power Module PM240: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS G120 Power Module PM240: Rated Data General Tech. SpecificationstrynoskNo ratings yet

- Q1 Lot Number: 15888757: Certificate of ConformanceDocument2 pagesQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNo ratings yet

- Certificado Lote Er70s-6Document1 pageCertificado Lote Er70s-6willariasNo ratings yet

- 6SL3210-1PE27-5UL0 Datasheet enDocument2 pages6SL3210-1PE27-5UL0 Datasheet enuniversoemdesencantoNo ratings yet

- 6SE6430 2AD34 5EA0 Datasheet enDocument2 pages6SE6430 2AD34 5EA0 Datasheet envjNo ratings yet

- Data Sheet For SINAMICS Power Module PM240-2: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS Power Module PM240-2: Rated Data General Tech. SpecificationsLuis Pinto RojasNo ratings yet

- Data Sheet For SINAMICS Power Module PM240: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS Power Module PM240: Rated Data General Tech. SpecificationsAsmirZulaZuŁicNo ratings yet

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesNo ratings yet

- 6SL3210 1ke32 4af1Document3 pages6SL3210 1ke32 4af1Rasool SabeghiNo ratings yet

- Data Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsAgus RiyanaNo ratings yet

- 6SL3210 5FE10 4UF0 Datasheet enDocument1 page6SL3210 5FE10 4UF0 Datasheet enpapah pungNo ratings yet

- Data Sheet For SINAMICS G120X: Rated Data General Tech. SpecificationsDocument3 pagesData Sheet For SINAMICS G120X: Rated Data General Tech. SpecificationsRenatoHonorioNo ratings yet

- UnionV90 DatasheetDocument8 pagesUnionV90 DatasheetnattapongthiangdeeNo ratings yet

- Data Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsMARIAMNo ratings yet

- 1 - Primacore LW71 1.2 E208038900Document1 page1 - Primacore LW71 1.2 E208038900Suli HartoNo ratings yet

- 6SL3210 1PE32 5UL0 Datasheet enDocument2 pages6SL3210 1PE32 5UL0 Datasheet enHernando RomeroNo ratings yet

- Data Sheet For SINAMICS Power Module PM250: Article No.: 6SL3225-0BE31-8UA0Document2 pagesData Sheet For SINAMICS Power Module PM250: Article No.: 6SL3225-0BE31-8UA0MARIAMNo ratings yet

- TR13 - REF NCT - Old CT - NCT PH - REF CT - 1 - Copy (3 Files Merged)Document104 pagesTR13 - REF NCT - Old CT - NCT PH - REF CT - 1 - Copy (3 Files Merged)SARAVANAN ANo ratings yet

- 6SL3224 0BE33 7UA0 Datasheet enDocument2 pages6SL3224 0BE33 7UA0 Datasheet enJ Adan Gonzalez LeconaNo ratings yet

- 6SE6420 2UC21 1BA1 Datasheet enDocument2 pages6SE6420 2UC21 1BA1 Datasheet enkatty_89No ratings yet

- Ica540 72hmiDocument1 pageIca540 72hmiMuhammad JanuardiNo ratings yet

- Data Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsFrancisco LobatonNo ratings yet

- 6SL3210 5BB22 2UV0 Datasheet enDocument2 pages6SL3210 5BB22 2UV0 Datasheet enLucas Vinícius CostaNo ratings yet

- Siemens - Sinamics - V20Document2 pagesSiemens - Sinamics - V20Ivan SilvaNo ratings yet

- Data Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS V20: Rated Data General Tech. SpecificationsFrancisco LobatonNo ratings yet

- 6SE6440 2UD24 0BA1 Datasheet enDocument2 pages6SE6440 2UD24 0BA1 Datasheet enpradipNo ratings yet

- 6SL3210-1PE33-7AL0 Datasheet enDocument2 pages6SL3210-1PE33-7AL0 Datasheet enDennisNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- 6SL3220-1YE52-0AF0 Datasheet enDocument3 pages6SL3220-1YE52-0AF0 Datasheet enHend MakhloufNo ratings yet

- 6SL3210-5BE31-8UV0 Datasheet en PDFDocument2 pages6SL3210-5BE31-8UV0 Datasheet en PDFCristina Mejía SolorzanoNo ratings yet

- Q1 Lot Number: 14997588: Certificate of ConformanceDocument3 pagesQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesNo ratings yet

- Data Sheet For MICROMASTER 420: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For MICROMASTER 420: Rated Data General Tech. SpecificationsRudy SotoNo ratings yet

- 6SL3210-5BB17-5UV1 Datasheet enDocument2 pages6SL3210-5BB17-5UV1 Datasheet enCesar NuñezNo ratings yet

- Data Sheet For SINAMICS Power Module PM240: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS Power Module PM240: Rated Data General Tech. SpecificationsEdwaldo de LuciaNo ratings yet

- Certificado de Calidad 6001802 224132 2022 5 19Document1 pageCertificado de Calidad 6001802 224132 2022 5 19David MelendezNo ratings yet

- Datasheet Variador ServoDocument1 pageDatasheet Variador Servoherraezjorge8No ratings yet

- 6SL3210-5BE31-5CV0 Datasheet en PDFDocument2 pages6SL3210-5BE31-5CV0 Datasheet en PDFMohammed AbdelsalamNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- Ficha VDF 37 KW (Disponible)Document3 pagesFicha VDF 37 KW (Disponible)Hugo Patricio Roco CastroNo ratings yet

- 6SL3210-5DE21-8UA0 Datasheet enDocument1 page6SL3210-5DE21-8UA0 Datasheet enherraezjorge8No ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- 6SL3120-1TE24-5AC0 Datasheet enDocument2 pages6SL3120-1TE24-5AC0 Datasheet enBojan BankovicNo ratings yet

- Data Schedule KD3000889Document2 pagesData Schedule KD3000889Jhoaquino HamachiNo ratings yet

- 6SL3210 1KE26 0UF1 Datasheet enDocument3 pages6SL3210 1KE26 0UF1 Datasheet enDanilo MalanchinoNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- Sinamics G120XA - 020128Document3 pagesSinamics G120XA - 020128azizimaul50No ratings yet

- Capital Structure and Leverage: Multiple Choice: ConceptualDocument53 pagesCapital Structure and Leverage: Multiple Choice: ConceptualArya StarkNo ratings yet

- Maintenance Performance ToolboxDocument6 pagesMaintenance Performance ToolboxMagda ScrobotaNo ratings yet

- Asme b16.3 (1998) Malleable Iron Threaded FittingsDocument30 pagesAsme b16.3 (1998) Malleable Iron Threaded FittingsMarcos RosenbergNo ratings yet

- What Is Terrorism NotesDocument3 pagesWhat Is Terrorism NotesSyed Ali HaiderNo ratings yet

- New Compabloc IMCP0002GDocument37 pagesNew Compabloc IMCP0002GAnie Ekpenyong0% (1)

- 5070 s17 QP 22 PDFDocument20 pages5070 s17 QP 22 PDFMustafa WaqarNo ratings yet

- Pell (2017) - Trends in Real-Time Traffic SimulationDocument8 pagesPell (2017) - Trends in Real-Time Traffic SimulationJorge OchoaNo ratings yet

- Basler Electric TCCDocument7 pagesBasler Electric TCCGalih Trisna NugrahaNo ratings yet

- Commercial BanksDocument11 pagesCommercial BanksSeba MohantyNo ratings yet

- 12 Constructor and DistructorDocument15 pages12 Constructor and DistructorJatin BhasinNo ratings yet

- Acc 106 Account ReceivablesDocument40 pagesAcc 106 Account ReceivablesAmirah NordinNo ratings yet

- Knitting in Satellite AntennaDocument4 pagesKnitting in Satellite AntennaBhaswati PandaNo ratings yet

- Template Remarks For IIDocument18 pagesTemplate Remarks For IIjasleeneceNo ratings yet

- Sco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Document4 pagesSco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Udaya PrathimaNo ratings yet

- Wordbank 15 Youtube Writeabout1Document2 pagesWordbank 15 Youtube Writeabout1Olga VaizburgNo ratings yet

- 506 Koch-Glitsch PDFDocument11 pages506 Koch-Glitsch PDFNoman Abu-FarhaNo ratings yet

- Letter Writing: An Informative Powerpoint About LetterDocument11 pagesLetter Writing: An Informative Powerpoint About LetterMalik KamranNo ratings yet

- Wall Panel SystemsDocument57 pagesWall Panel SystemsChrisel DyNo ratings yet

- Haymne Uka@yahoo - Co.ukDocument1 pageHaymne Uka@yahoo - Co.ukhaymne ukaNo ratings yet

- Basic Knowledge About WDM Principle ADocument92 pagesBasic Knowledge About WDM Principle AJosé LópezNo ratings yet

- Sinamics g120 BrochureDocument16 pagesSinamics g120 BrochuremihacraciunNo ratings yet

- Lab Report 2Document5 pagesLab Report 2Md jubayer SiddiqueNo ratings yet

- Zkp8006 Posperu Inc SacDocument2 pagesZkp8006 Posperu Inc SacANDREA BRUNO SOLANONo ratings yet

- Research Paper On Marketing PlanDocument4 pagesResearch Paper On Marketing Planfvhacvjd100% (1)

- I. Objectives:: Semi-Detailed Lesson Plan in Reading and Writing (Grade 11)Document5 pagesI. Objectives:: Semi-Detailed Lesson Plan in Reading and Writing (Grade 11)Shelton Lyndon CemanesNo ratings yet

- Brachiocephalic Artery: AnteriorDocument37 pagesBrachiocephalic Artery: AnteriorFarah FarahNo ratings yet

- Blank FacebookDocument2 pagesBlank Facebookapi-355481535No ratings yet

- Lightolier Lytecaster Downlights Catalog 1984Document68 pagesLightolier Lytecaster Downlights Catalog 1984Alan MastersNo ratings yet