Professional Documents

Culture Documents

Energy Audit in Cement Industry (1500 TPD)

Uploaded by

IJSTECopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Audit in Cement Industry (1500 TPD)

Uploaded by

IJSTECopyright:

Available Formats

IJSTE - International Journal of Science Technology & Engineering | Volume 3 | Issue 10 | April 2017

ISSN (online): 2349-784X

Energy Audit in Cement Industry (1500 tpd)

Anantharaman N

Assistant Professor

Department of Mechanical Engineering

Kings College of Engineering Punalkulam, Thanjavur

Abstract

Cement industry is known to be an energy-intensive, one which consumes considerable amount of energy during the production

process. In the present industrial scenario, importance is given to the energy-intensive sectors, in terms of use of energy and

energy conversion efficiency. The present investigation concentrates on energy conversion and optimization of operational

parameters of a cement industry, with respect to the factors such as increased competition, costs, reduced profit margin, impact

on environment etc. To find a viable alternate to these factors, a study on the electrical and thermal energy analysis was carried

out in a cement plant with a capacity of 1500 tonnes per day. The conservation of energy could be made in three effective ways,

such as effective use of electrical equipment, effective and change in operation of existing operational equipment without

investment, change of existing equipment with the state-of-the-art equipment with investment. Ten years of operational data of

Specific Energy Consumption (SEC) of equipments of the industry is collected and analysed for this study. From the energy

study, the Energy Conservation Opportunities (ECO) amounting to net saving of SEC 14kWh per ton of clinker (11.6%) is

identified. On successful implementation of suggestions that the 9.5 kWh per ton of clinker is realised without major investment

and 4.6 kWh per ton of clinker with investment with a payback period of less than 2 years. The possibility of thermal energy

saving upto 1000 kJ per kg of clinker is also identified by this study.

Keywords: Cement Industry; energy audit; energy audit; SEC; ECO

________________________________________________________________________________________________________

I. INTRODUCTION

Energy is present in nature in various forms. The various forms of energy are used by mankind for different purposes like

lighting, heating, running machinery, transportation and for other such applications. Energy should be efficiently utilized in order

to ensure maximum productive work and more profit from a given amount of energy. It is thus slightly different from the work

saving which may in strict sense, mean avoiding spending or consumption or suppression of demand. The word energy

conservation symbolizes efficient, economical and effective use of energy.

A number of research papers have been published on energy analysis of cement plants, with primary focus on the analysis

using first law of thermodynamics. Tahsin Engin et al. [1] have conducted energy audit study for a dry type rotary kiln system in

a cement plant. They designed a waste heat recovery steam generator to recover the waste heat leaving from the kiln with a

payback calculation. Koroneos et al. [2] contented that the exergy analysis of a cement plant was found to be a method of

minimizing the energy cost and environmental effects. Zafer et al. [3] have analyzed the energy and exergy balance of the raw

mill of a cement plant and observed that there is a potential for enhancing the exergy utilization. Mont Hubbard et al [4] have

studied the oxide concentration in a raw meal (homogeneous mixture of raw material ready for clinker production) used in

cement manufacturing by X- ray analysis. Their research concludes that the estimation has been made accurately at higher flow

rates of the feed material. Joseph O. Odigure [5] has undertaken a study of the factors influencing the grindability of clinkers

during cement milling. It is contented that the formation of micro cracks during clinker production may influence the grindability

of clinker. Further, adding by product waste containing metallic particles led to increase the micro cracks on clinker material in

kiln process. Rasul et al. [6] assessed the thermal performance of a cement plant with a view to enhance the plant productivity.

The suggestions made by them are that the existing industrial diesel oil used for drying the raw material in raw mill operation can

be replaced by the use of exhaust gas leaving from kiln system. Ziya Sogut et al. [7] have studied the operation of kiln system

used in cement manufacturing. They suggested and developed a mathematical model of new heat recovery exchanger for the

plant as a waste heat recovery system in order to make use of the waste heat from the kiln system.

The availability of commercial sources of energy such as oil, coal and gas in our country (India) are rapidly dwindling and the

supply of fuel has to be supplemented by imports. The cost of importing them is very high and steeply increasing which will

drain the foreign exchange reserves of the country. It has been established that the gap between our future demand and supply of

energy is bound to increase in the industrialization of the country. The estimated availability of domestic resources of

commercial energy against present demands will create considerable gap in supply especially for oil and gas unless imports are

resorted to supplement the domestic supply

Thus the known commercial energy resources will:

last for limited time only, at present rates of consumption.

last for short period at the increased anticipated consumption rates which is necessary to sustain present economic growth.

entail huge imports to fill in the supply demand of valuable foreign exchange to the nation.

All rights reserved by www.ijste.org 12

Energy Audit in Cement Industry (1500 tpd)

(IJSTE/ Volume 3 / Issue 10 / 003)

Hence, alternative sources of energy need to be explored. There are only few alternatives left which would find public

acceptance. Alternatives such as creating new thermal power plants, mining of more coal and tapping of more gas reserves will

deplete the present availability faster, apart from their contribution to environmental effects and increased pollution. Production

of more power through hydel station depends on vagaries of rain fall and will also cause detrimental effects to environment such

as denudation of forests, dislocation of wild life, villages etc.

Resorting the increased use of alternatives such as wood, Bio-gas, solar and wind is one options to produce more energy.

The increased uses of wood only cause faster deforestation and consequent environmental degradation. The use of solar and

wind energies are yet to be proved commercially viable alternatives except probably in isolated places or in large

organization where such capital intensive appliances are affordable. Energy from bio-gas offers considerable scope for but in

rural areas cannot be produced in large quantities.

Production of nuclear energy is a subject of strong public dispute and will need public acceptance before setting up of large

nuclear stations.

Conserving the available sources for a longer time has better advantages than going for alternative sources.

The methods of energy conservation prove to be cost effective.

Energy conservation helps for reduction in emission.

Many Western nations drastically reduced their energy consumption per unit of production. Many of them have achieved a

reduction in Specific Energy Consumption (SEC) of 20% to 30% during 1975-95, while ensuring a steady industrial and

economic growth. In India, it has been a different story. During the same period our SEC has increased by 20% to 30% mainly

due to the following:

Lack of awareness for conservation.

Unbridled production increases, with scant regard to proper resource utilization and productivity deals.

Continued use of old and inefficient plants, machinery and process technologies.

Recourse to short-term measures such as having captive generation of power etc.

Lack of motivational aspects, incentives and legislative polices for promoting reduced energy consumption.

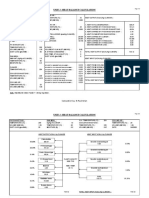

Table 1. shows the energy consumption norms of selected industries as compared to what is normally prevailing abroad, in the

corresponding energy intensive industries. The table shows that our energy consumption is 50% to 100% more than that of other

countries. (Except in the case of fertilizer industry) This shows the vast potential that exists in India for more economic and

efficient use of energy.

II. ENERGY CONSERVING METHODS

Conserving energy is a matter of national importance in which every individual must contribute. Energy conservation can be

practiced by school children, house wives, farmer, factory worker, any adult or child in their respective share of work or leisure

life. One can save 10 to 30% of energy through simple action. Energy conservation can be attempted through the following three

levels of implementation.

Table – 1

Energy consumption norms in selected industries (GJ/ton)

Country Steel Cement Aluminium Pulp & Paper Fertilizer Textiles

India 39.77 8.37 138.16 46.60 47.10 93.78

Italy 19.38 3.73 - - 41.11 -

Japan 17.50 3.73 70.76 - - -

Sweden 21.02 5.86 69.08 31.65 - -

UK 25.41 5.44 88.34 31.90 47.02 -

USA 25.37 3.98 39.77 40.61 47.39 50.66

Germany 21.81 3.43 20.52 - - -

Low Cost Methods:

There are actions which need the least effort and money. Such actions are generally termed as good housekeeping. Actions such

as switching off lights and other appliances when not actually needed use of natural light, good operations / maintenance

practices to prevent losses of heat and energy through leakage etc. will come under this category. These actions would not take

long time to implement but would help conserve energy from 5% to 10% with practically no investment at all.

Medium Cost Methods:

This would normally cover simple modifications to existing equipment such as efficiency improving ballast replacement of

inefficient lighting fixtures with more efficient fixtures, capacitors or other control mechanisms, use of efficient burner, more

effective insulation materials etc. Such actions would contribute a further consumption of 10% to 15% but would involve

nominal expenditure.

All rights reserved by www.ijste.org 13

Energy Audit in Cement Industry (1500 tpd)

(IJSTE/ Volume 3 / Issue 10 / 003)

High Cost Methods:

These methods would involve substantial investment of money in partially or wholly adapting new and efficient accessories to

existing plant and machinery. These methods generally form part of long range planning and would additionally contribute to

another 10% to 15% of energy conservation. In most of the cases, money spent would be recovered in, what is called a payback

period of 2 to 3 years after which all savings would add into direct profits of the organization.

III. ENERGY CONSERVATION IN CEMENT INDUSTRY

A study was conducted on energy conservation Tamilnadu Cements, Tamilnadu, India.

The Energy Conservation by Effective Use of the existing Electrical Equipment’s:

It has been observed in the industry that there are thirty electrical drives running at less than 50% of rated load, and in some

places the electrical motors were underutilized. In order to conserve the energy, the star drive was recommended instead of delta

derive wherever the electrical drives operated at less than 50% of loading.

Electrical Motors:

Electrical motor drives account for about 75% of electricity used in the industry and 90 % of electrical motors used in the

industry are squirrel-cage induction motors, DC motors, slip ring motors, which account for the remaining 10%.

Before 1973, Motor manufacturers have concentrated only on optimizing the use of materials, especially copper and iron.

Improvements of performance parameters like efficiency and power factor were of secondary importance. Many a time

performance was sacrificed to reduce material cost. After 1973 energy crisis, the emphasis is now on improving performance.

Energy saving opportunities can be summarized as follows.

Selection of motors properly matched with load.

Minimizing idle running, maintenance & rewinding.

Efficiency of driven equipment.

High efficiency motors.

For the selection of motor ascertain the total cost and life cycle cost. The running cost of the motor for one year is higher than

the cost of motor. The widely prevalent practice of purchasing motors by comparing the initial cost has little justification now.

Table 2 shows the first cost and life cost of electrical motors.

Table – 2

Comparison of first cost and life cost of electric motors.

MOTOR RATING 7.5 kW 15 kW 37 kW

Efficiency 86 89 91

Input kW 8.72 16.85 40.65

kWh consumption per annum (6000 run hours ) 52325 101123 243956

Running cost/annum @Rs. 6/kWh 313950 606738 1463736

Running cost for 10 years 3139500 6067380 14637360

Initial capital cost 22500 45000 11100

Capital cost at percentage Of running cost 0.72% 0.74% 0.08%

It is possible to select motors with the highest available efficiency. The power factor of motor can be corrected by the external

means but efficiency cannot be corrected by external means. There are wide variations in efficiency for standard motors and it is

worthwhile to collect performance data from different manufacturers and select a motor with good performance. In many cases

motors come as integral part of machinery like machine tools, compressors, and ring frames, paper machines etc. In such cases

motors selection must be discussed with machine manufacturer. If after installation and operation it is found that change in motor

is economical, one should not hesitate to do so.

Motor power factor varies depending upon the load on the motor and is very low at no load and may increase to 0.8 or higher

at full load and no load current may be 30% to 40% of the full load current.

Motor and Load Matching:

Studies by electrical engineers on the measurement of motor loads show that larger sizes are used, where the loads are less than

50% of rated and so on. In most of the cases this is due to large factor of safety or lack of knowledge of actual operation loads.

Oversized motors lead to the following penalties.

Low efficiency and higher power consumption.

Poor power factor higher maximum demand and distribution losses.

Higher first cost for motor and control gear.

Higher installation cost and larger space requirement.

All rights reserved by www.ijste.org 14

Energy Audit in Cement Industry (1500 tpd)

(IJSTE/ Volume 3 / Issue 10 / 003)

Over Sized Motors:

For many industries, it is essential to carry out motor load surveys and prepare a list with proper rating. A general replacement

program can be taken up by inter changing of motors. Similarly when a motor burns out, replacement by properly sized motors

should be considered. This will be a cheaper option. For lightly loaded motors, energy saving starters and star connection offer

other opportunities. Table 3. Show the comparison in load, efficiency, power factor and power supplied to use of different rated

motors for a particular motor load.

Table – 3

Comparison of using oversized motors.

Motor load 3.7 kW 3.7 kW 3.7 kW

Motor rating 3.7 kW 7.5 kW 18.5 kW

% Load 100% 50% 20%

Efficiency 83% 83% 77%

kW input 4.45 4.45 4.8

kWh for 6000 hrs per annum 26746 26746 28832

Power factor 0.8 0.65 0.5

kVA input 5.57 6.85 9.6

Idle running of motors must be avoided. In many industrial plants, it is not practiced. Machine tools are not stopped in recess

or other periods. Conveyor continues to run even without any load. Auxiliaries like exhaust fans, cooling tower fans, pumps

continue to run when many process machines have stopped or running at lower loads. A careful study and training of operators

can lead to significant savings. Safety and quality should not be sacrificed but there is no justification for wasteful running.

Regular maintenance of motors will keep the bearing in good condition and it will keep cooling passages clean, leading to

good air flow and proper heat dissipation. Motors are to be cleaned during every shift in industries. In some factories, they are

not cleaned at all. Poor ventilation can increase the winding temperature and to lead higher copper losses. Overhauling of

machine rolls, ring frames etc., leads to as much as 5 to 10% reduction in energy consumption.

Rewinding of motors normally leads to deterioration in motor efficiency. Heating of stator for winding removal can lead to

increase in iron losses due to damage of stamping insulation. Rewinding with small wire-size will also lead to loss of efficiency.

When slot space is available putting more copper by increasing the wire gauge will improve efficiency. Wherever oversized

motors are used, in case of failure, installation of new motors must be considered rather than rewinding older ones.

High Efficiency Motors:

After 1973 energy crisis, considerable attention has been given on improving motor efficiency. Most manufacturers now offer a

line of high efficiency motor with price premium of 30% to 50%. In India also, these are available. Main features of high

efficiency motors are:

More copper / Aluminium in stator and rotor to reduce core losses.

Improved quality of stampings to reduce iron losses.

Improved design of fans and ventilation circuits.

Improved Electromagnetic design and manufacturing methods to reduce stray losses.

BIS (Bureau of Indian Standards) have brought out IS-12615 of 1990 on energy efficient motors.

High efficiency motors can be considered as replacement for all drives running for 5000 hr. or more in a year. Payback period for

replacement by high efficiency motors would be 2 to 3 years.

Energy Saving by Star Delta Change Over:

For delta connected motors running at light load, connection in the star reduces the motor voltage and saves energy. The scheme

is observed with the help of performance curves of a 3.7 kW 4 pole motor. The principle developed would also be applicable to

motors having any capacity.

Efficiency in star connection is higher than that in delta connection upto 48% of full load. Difference in efficiency is

significant (10% to 20%) upto 30% load.

Current is significantly lower in star connection upto 50% of full load. At no load, current less than 50% of value of delta

connection, Distribution also thus would be less.

Power factor is also significantly higher in star connection compared to delta connections.

speed in star connection is marginally lower than speed in delta connection

This mean that output of equipment like fans and pumps will be lower.

Energy Saving by Micro Processor Controllers:

By reducing terminal voltage at a motor under part load, it is possible to reduce the magnetic core losses and copper winding

losses there by increasing the overall efficiency.

All rights reserved by www.ijste.org 15

Energy Audit in Cement Industry (1500 tpd)

(IJSTE/ Volume 3 / Issue 10 / 003)

The controller is a micro-processor controlled thyristor based system which has Phase-Control to vary the motor terminal

values in responds to changes in loading on the motor. It is also ensures sudden heavy loads transients are handled without

noticeable slowing of motor.

Providing of controller could increase the efficiency of motor operated below the 50% of full load and could save the energy

upto 40%.

Soft starting by progressively ramping up the voltage, a motor may be started smoothly to reduce starting current to a

value typically 2.5 times the direct on line value and to avoid mechanical shock to the drive mechanisms and load The ramp

starting line is adjustable from 1/2 to 60 sec.

Power Factor and Supply Current Improvements: The overall power factors at light loads are much improved without

affecting the full load value. Supply current demand is reduced progressively towards zero load and is typically one third of

the uncontrolled value at very light loads, Full load current is unaffected.

Efficiency of Drive Transmission:

Direct drive is the best option wherever feasible where belt drives are used; modern flat-belt with synthetic material can give

transmissions as high as 97-98%. This is to be compared with 90-92% of conventional V-belts.

Gear Drives:

Efficiency of spur gear and bevel gearing for high speed gearing can be 99% and for slow speed gear about 96% on an average

of 97-98%. Efficiency is normal as shown in table. In helical gear, the friction is much greater due to the considerable transverse

sliding motion.

Efficiency of Various Gear Drives:

Efficiency of integral high power motors are always in the range of 80% and above. Efficiency of driven equipment like pumps

and fans can be appreciably lower. Also pumps are designed to operate maximum efficiency at certain head flow condition.

Operation at other condition will lead to significant drops in efficiency. In view of this, much more care has to be taken in

improving the efficiency of driven equipment. Better design of fans has led to drop power consumption by 30 %. Trimming of

impellers, change in number of stages, lead to significant reduction in power consumption. Similarly proper size of distribution

lines, stoppage of air leakage etc. can lead to significant reduction in power consumption of compressor motors.

IV. ENERGY CONSERVATION OF ARRESTING AIR INFILTRATION IN THE RAW MILL CIRCUIT

Existing System:

At present, hot gases from the preheater exit of both kilns are used to dry the raw meal. From the measurement the volume of

hot gases inside the raw mill is 94682Nm3/h and the volume outflow is 118750 Nm3/h. Thus there is a net air ingress of

24068Nm3/h (25.41%) in the raw mill circuit. The air ingress is mainly in the mill feeding points, leakages in grit separator and

cyclones. This results in wastage of energy in the following area.

Raw mill vent fan consumes more power (402 kW). The specific energy consumption in raw mill vent fan is 4.0379 kWh per

ton of raw meal. i.e. 5.4512 kWh per ton of clinker (ratio of rawmeal to clinker is 1.35) against a norm of 5 kWh per ton of

clinker. This excess power consumption is due to air infiltration. Kiln ESP fans are consumes 220kW each. The specific energy

consumption is 7.04 kWh per ton of clinker against a norm of 3.5 kWh per ton of clinker. This excess power consumption is also

due to air infiltration. Due to dilution of heat energy inside the mill by the false air infiltration in raw mill, the feed material

cannot be dried properly to the required residual moisture. This in turn affects the raw mill capacity and increase the specific

energy consumption.

Suggestions and Modifications:

type Method of manufacturing. Efficiency ƞ %

cast teeth 93

spur gear

cut teeth 96

cast teeth 92

bevel gear

cut teeth 95

for thread angle 30o 85-95

worm gear

for thread angle 15o 75-90

All the ingress points have to be arrested properly. Proper air seal has to be maintained at the mill feeding points (eg. discharge

end and fresh air damper). All measures have to be made to restrict the air ingress in raw mill circuit to a minimum.

All rights reserved by www.ijste.org 16

Energy Audit in Cement Industry (1500 tpd)

(IJSTE/ Volume 3 / Issue 10 / 003)

Investment, Savings and Payback Period:

Investment Negligible

Saving in SEC 0.462kWh/t of clinker RM vent fan.

2.366kWh/t of clinker in ESP fan.

Annual saving in energy 187755 kWh in RM vent fan.

961142 kWh in ESP fan.

11.265 lac rupees in RM vent fan

Saving in energy cost per annum

57.668 lac rupees in ESP fans.

Payback period

Immediate

V. ENERGY CONSERVATION IN SIZING OF RAW MILL TURBO AIR SEPARATOR (TAS) DRIVE

Existing System:

Initially a 250kW capacity motor is used in TAS drive. It has been replaced by a 200kW LT drive motor. The power

consumption of motor is around 110 to 120 kW.

Suggestions and Modifications:

As per the motor characteristic curves, any motor will be running to its maximum efficiency near to its maximum load. Moreover

at lower loads the power factor also reduces. It is observed that if the loading is 55% to 60% and the corresponding power factor

is 0.65. It has been suggested that it is better to replace the existing motor with the lower rated high efficiency motor rating of

120kW.

Investment, Savings and Payback Period:

Investment 3.6 lac rupees

Saving in SEC 0.415 kWh per ton of clinker

168593 kWh

Annual saving in energy

10.116 lac rupees

Saving in energy cost per annum

Nearly 4 months

Payback period

VI. HEAT BALANCE IN KILN PROCESS SYSTEM.

Coal is the main source for supplying heat for the kiln process. The following two figures show the thermal energy supplied to

kiln and leave from the kiln. Figures.1 & 2 show the energy in and out of a kiln system.

The heat loss due to cooler vent and heat loss due radiation (Fig. 2) is around 22% of the total heat supplied to the kiln in

which 8% of the heat can be saved. The heat lost in preheater waste is around 21% in which 18% of the heat is effectively used.

The heat energy consumption in kiln is varying from 4050 to 4788 kJ per kg of clinker. At present the heat consumption is

above the norms of 3780 kJ per kg of clinker. By adopting the effective method of operations 1000 kJ per kg of heat can be

saved in clinker production.

Fig. 1: Various forms of heat energy supplied to kiln.

All rights reserved by www.ijste.org 17

Energy Audit in Cement Industry (1500 tpd)

(IJSTE/ Volume 3 / Issue 10 / 003)

Fig. 2: Various form of heat energy distribution in kiln process.

VII. CONCLUSIONS

From the above energy study carried out in cement industry, we can arrive at the following conclusions.

Motors running below 50% of rated load can be operated in star connection instead of delta connection.

Oversized motors can be replaced by new energy efficient motors.

By controlling the air infiltrate, the size of fans and drives can be reduced, which in turn reduces the power requirement to

operate the fans.

There will be a potential for saving and effective use thermal energy nearly 1000kJ/kg of clinker.

The study thus concentrates on a very important area of energy conservation in one of the large energy intensive industry.

Conducting periodical energy audits in such industries will help for better energy conservation and prove to a cost cutting

measure.

ACKNOWLEDGEMENTS

The authors are also grateful to the authorities of TANCEM, Ariyalur for providing the operational data of the cement plant.

REFERENCES

[1] Tahsin Engin, Vedat Ari, Energy Auditing and Recovery for Dry Type Cement Rotary Systems – A case study, Energy Conversion & Management, 46

(2005), pp:551-562.

[2] C. Koroneos, G. Roumbas and N. Moussiopoulos, Exergy Analysis in Cement Production, Int. J. Exergy, vol.2 No. 1, (2005), pp:55-68.

[3] Zafer utlu, Ziya Sogut, Arif hepbasli, Zuhal Oktay, Energy and Exergy Analyses of A Raw Mill in Cement Production, Applied Thermal Engineering, 26

(2006), pp:2479–2489.

[4] Mont Hubbard and Tom DASilva, Estimation of Feedstream Concentrations in Cement Raw Material Blending, Automatica, (1982), vol. 18, No. 5, pp:

595-606.

[5] Joseph O. Odigure, Grindability of Cement Clinker From Raw Mix Containing Metallic Particles, Cement and Concrete Research 29, (1999), pp:030-307.

[6] M.G. Rasul, W.Widianto, B. Mohanty, Assessment of Thermal Performance and Energy Conservation Opportunities of A Cement Industry in Indonesia,

Applied Thermal Engineering, 25, (2005), pp:2950-2965.

[7] Ziya Sogut, Zuhal Oktay, Hikmet Karakoc, Mathematical Modeling of Heat Recovery from Rotary Kiln, Applied Thermal Engineering, 30, (2010), pp:

817-825.

[8] B.G. Desai, B.S. Vaidhya, D.P. pate, P.Paraman “saving electricity in utility systems of Industrial plants., 1999

[9] Dr. S.K. Awaathi, Dr Ramprasad, “Energy Conservation” AICTE proceedings, 1999

[10] Albert Thumann, William J. Younger, sixth edition. Hand book of energy audits, The Fairmont press, Georgia. 2003.

[11] MaichealF. Hordeski, New technologies for energy efficiency, The Fairmont press, Georgia., 2003

[12] Records available in Tamilnadu cements library Ariyalur.

[13] T. Ashok kumar, “Energy and themal energy report on cement industry” A thesis submitted for master of engineering, Shanmugha College of Engineering

(Affiliated to Bharathidasan University, Tirchy), India, Nov 2000.

All rights reserved by www.ijste.org 18

You might also like

- Reduce Raw Mill Energy Cement IndustryDocument9 pagesReduce Raw Mill Energy Cement Industryhasan_jafri_2No ratings yet

- Cement Energy GuideDocument70 pagesCement Energy GuideAmr A. NaderNo ratings yet

- Energy Balance and Cogeneration For A Cement PlantDocument11 pagesEnergy Balance and Cogeneration For A Cement PlantHeron SoaresNo ratings yet

- UltraTech AFR Presentation PDFDocument11 pagesUltraTech AFR Presentation PDFAnonymous Cxriyx9HIXNo ratings yet

- Cement IndustryDocument27 pagesCement IndustryAhmed Mahmoud100% (1)

- AlternativeFuel - Ashx Foir Cement PlantDocument4 pagesAlternativeFuel - Ashx Foir Cement PlantRavindra BhatnagarNo ratings yet

- Heat and Mass BalanceDocument16 pagesHeat and Mass BalanceAndy TpNo ratings yet

- Calcined Clay - Brazilian ExperienceDocument25 pagesCalcined Clay - Brazilian ExperiencecpessoasalesNo ratings yet

- 15.00 Paolo Bossi, MD, Sinai White CementDocument38 pages15.00 Paolo Bossi, MD, Sinai White CementMohd AliNo ratings yet

- Ball Mill OptimiztionDocument8 pagesBall Mill OptimiztionShakil AhmadNo ratings yet

- Power Cement Report - 055239Document28 pagesPower Cement Report - 055239Khalil AhmedNo ratings yet

- Energy Audit and Conservation Case Cement FactoryDocument43 pagesEnergy Audit and Conservation Case Cement FactoryMuluken TemesgenNo ratings yet

- Cement KilnDocument2 pagesCement Kilnamir100% (2)

- ATC Report on Dynamic Separator Gap IssuesDocument4 pagesATC Report on Dynamic Separator Gap IssuesDilnesa EjiguNo ratings yet

- Sustainable cement production through co-processing of wasteDocument16 pagesSustainable cement production through co-processing of wasteIbnuyusoff77No ratings yet

- Reverse Air Bag House PDFDocument4 pagesReverse Air Bag House PDFRanga VamshiNo ratings yet

- Clinker CoolersDocument17 pagesClinker Coolersemad sabri0% (1)

- ABC Cooler Inlet PDFDocument4 pagesABC Cooler Inlet PDFSushant GuptaNo ratings yet

- Alkali Bypass WHRPP Nov - 11 PDFDocument18 pagesAlkali Bypass WHRPP Nov - 11 PDFNinad Bhave100% (1)

- Kiln Heat Balance 1Document33 pagesKiln Heat Balance 1Vipan Kumar Dogra75% (4)

- Electrical Energy Module Final Draft 20Document161 pagesElectrical Energy Module Final Draft 20Safrin SangiaNo ratings yet

- Mod 6Document49 pagesMod 6mkpq100% (1)

- Cement Grinding OPtimizationDocument13 pagesCement Grinding OPtimizationTgemunuNo ratings yet

- 3500TPD Cement Plant Heat BalanceDocument2 pages3500TPD Cement Plant Heat BalanceIrshad HussainNo ratings yet

- Preheater & Precalciner Performance StudyDocument14 pagesPreheater & Precalciner Performance StudyDilnesa EjiguNo ratings yet

- CPB Brochure Diaphragms en 2Document12 pagesCPB Brochure Diaphragms en 2ebrahimNo ratings yet

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDocument5 pagesUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditNo ratings yet

- 4 Cement TechnologyDocument43 pages4 Cement TechnologySomu AdityaNo ratings yet

- ENERGY STAR Guide For The Cement Industry 28-08-2013 FinalDocument141 pagesENERGY STAR Guide For The Cement Industry 28-08-2013 Finalnsprasad88No ratings yet

- Cement ProcessDocument14 pagesCement ProcessChristian RuedaNo ratings yet

- Cement Industry Environment Report 2003Document24 pagesCement Industry Environment Report 2003tesfayregs gebretsadik100% (2)

- Quality Assessment of Clay For Limestone Calcined Clay Cement ProductionDocument6 pagesQuality Assessment of Clay For Limestone Calcined Clay Cement ProductionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocument2 pagesBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyNo ratings yet

- Design of Large Size Cement PlantsDocument9 pagesDesign of Large Size Cement PlantsSaravanan ParamasivamNo ratings yet

- 05 Measurement Gas FlowDocument68 pages05 Measurement Gas FlowYhaneNo ratings yet

- Process Costing LafargeDocument23 pagesProcess Costing LafargeGbrnr Ia AndrntNo ratings yet

- Cement Process ExpertDocument9 pagesCement Process ExperttadagidsNo ratings yet

- Tromp Curve Example PDFDocument3 pagesTromp Curve Example PDFThaigroup Cement100% (1)

- Cooler-2 DiagramDocument3 pagesCooler-2 DiagramPraveen Singh Chouhan100% (1)

- Energy Saving Cement PlantDocument19 pagesEnergy Saving Cement PlanttankeanleongNo ratings yet

- Energy Audit Helps Cement Plant Improve EfficiencyDocument14 pagesEnergy Audit Helps Cement Plant Improve Efficiencytsrinivasan5083No ratings yet

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 pagesThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNo ratings yet

- White CementDocument31 pagesWhite CementMohamed Osama Ragaa100% (2)

- 1Document5 pages1Dee HsNo ratings yet

- FormulaeDocument163 pagesFormulaeilvspeedNo ratings yet

- Kiln Area Learning ReportDocument24 pagesKiln Area Learning ReportAbasiemekaNo ratings yet

- Fan Performance Measurement and CalculationDocument15 pagesFan Performance Measurement and CalculationSundara SubramaniyanNo ratings yet

- Chemical AnalysisDocument8 pagesChemical Analysisصفاء رجبNo ratings yet

- Energy Consumption Benchmark Guide: Cement Clinker ProductionDocument14 pagesEnergy Consumption Benchmark Guide: Cement Clinker ProductionVisnu SankarNo ratings yet

- CSI Guidelines For Co-Processing Fuels and Raw Materials in Cement Manufacturing - v2 PDFDocument36 pagesCSI Guidelines For Co-Processing Fuels and Raw Materials in Cement Manufacturing - v2 PDFnaldsonNo ratings yet

- CementDocument76 pagesCementAmr Samy100% (3)

- Energy Conservation in IndustriesDocument31 pagesEnergy Conservation in IndustriesAmit AnandNo ratings yet

- Industrial Energy EfficiencyDocument6 pagesIndustrial Energy EfficiencyArvind GuptaNo ratings yet

- Energy Conservation Techniques For Manufacturing IndustriesDocument11 pagesEnergy Conservation Techniques For Manufacturing IndustriesIJRASETPublicationsNo ratings yet

- Energy Use, Energy Savings and Emission Analysis in The Malaysian Rubber Producing IndustriesDocument13 pagesEnergy Use, Energy Savings and Emission Analysis in The Malaysian Rubber Producing IndustriesheljoalNo ratings yet

- Energy Efficiency and ConservationDocument19 pagesEnergy Efficiency and ConservationM Raihan Saputra100% (1)

- Cement Industry To Select Energy Efficiency MeasuresDocument14 pagesCement Industry To Select Energy Efficiency MeasureszeeNo ratings yet

- 13.energy Consumption Assessment in A Cement Production PlantDocument6 pages13.energy Consumption Assessment in A Cement Production PlantzeeNo ratings yet

- FPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignDocument4 pagesFPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignIJSTENo ratings yet

- Enriching Gum Disease Prediction Using Machine LearningDocument6 pagesEnriching Gum Disease Prediction Using Machine LearningIJSTENo ratings yet

- Optimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryDocument8 pagesOptimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryIJSTENo ratings yet

- Design and Analysis of Magneto Repulsive Wind TurbineDocument7 pagesDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENo ratings yet

- Optimum Placement of DG Units Using CPF MethodDocument6 pagesOptimum Placement of DG Units Using CPF MethodIJSTENo ratings yet

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDocument6 pagesDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENo ratings yet

- Multipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationDocument9 pagesMultipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationIJSTENo ratings yet

- Automatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"Document8 pagesAutomatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"IJSTENo ratings yet

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDocument7 pagesPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENo ratings yet

- A Mixture of Experts Model For ExtubationDocument4 pagesA Mixture of Experts Model For ExtubationIJSTENo ratings yet

- Optimization of Treatability by FACCO For Treatment of Chemical Industry EffluentDocument9 pagesOptimization of Treatability by FACCO For Treatment of Chemical Industry EffluentIJSTENo ratings yet

- A Radar Target Generator For Airborne TargetsDocument8 pagesA Radar Target Generator For Airborne TargetsIJSTENo ratings yet

- RFID Based Toll Gate AccessDocument5 pagesRFID Based Toll Gate AccessIJSTENo ratings yet

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDocument9 pagesEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENo ratings yet

- A Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemDocument6 pagesA Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemIJSTENo ratings yet

- A Cloud Based Healthcare Services For Remote PlacesDocument4 pagesA Cloud Based Healthcare Services For Remote PlacesIJSTENo ratings yet

- App-Based Water Tanker Booking, Monitoring & Controlling SystemDocument6 pagesApp-Based Water Tanker Booking, Monitoring & Controlling SystemIJSTENo ratings yet

- The Bicycle As A Mode Choice - A Gendered ApproachDocument4 pagesThe Bicycle As A Mode Choice - A Gendered ApproachIJSTENo ratings yet

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDocument6 pagesWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENo ratings yet

- Comparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridDocument7 pagesComparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridIJSTENo ratings yet

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDocument5 pagesAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENo ratings yet

- Onerider The Bike TaxiDocument3 pagesOnerider The Bike TaxiIJSTENo ratings yet

- Interstage Construction Techniques For Mass Gain: An OverviewDocument5 pagesInterstage Construction Techniques For Mass Gain: An OverviewIJSTENo ratings yet

- Optimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersDocument4 pagesOptimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersIJSTENo ratings yet

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDocument6 pagesUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENo ratings yet

- Technology Advancement For Abled PersonDocument9 pagesTechnology Advancement For Abled PersonIJSTENo ratings yet

- Duplicate Detection Using AlgorithmsDocument3 pagesDuplicate Detection Using AlgorithmsIJSTENo ratings yet

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDocument6 pagesResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENo ratings yet

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDocument5 pagesAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENo ratings yet

- EINC ChecklistDocument3 pagesEINC ChecklistMARK JEFTE BRIONESNo ratings yet

- Trishasti Shalaka Purusa Caritra 4 PDFDocument448 pagesTrishasti Shalaka Purusa Caritra 4 PDFPratik ChhedaNo ratings yet

- Asus X553MA Repair Guide Rev2.0Document7 pagesAsus X553MA Repair Guide Rev2.0UMA AKANDU UCHENo ratings yet

- Figures of Speech ExplainedDocument5 pagesFigures of Speech ExplainedDarenJayBalboa100% (1)

- Neural Network For PLC PDFDocument7 pagesNeural Network For PLC PDFMarcelo Moya CajasNo ratings yet

- Axel LeijonhufvudDocument7 pagesAxel LeijonhufvudDario CoceresNo ratings yet

- Assignment 2Document4 pagesAssignment 2maxamed0% (1)

- Department of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityDocument2 pagesDepartment of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityRica Tano50% (2)

- Technology & Livelihood Education: WEEK 6-7Document28 pagesTechnology & Livelihood Education: WEEK 6-7my musicNo ratings yet

- Direction: Read The Questions Carefully. Write The Letters of The Correct AnswerDocument3 pagesDirection: Read The Questions Carefully. Write The Letters of The Correct AnswerRomyross JavierNo ratings yet

- Mechanical EngineeringDocument14 pagesMechanical EngineeringSamuel WozabNo ratings yet

- Non Deterministic Finite AutomataDocument30 pagesNon Deterministic Finite AutomataAnikNo ratings yet

- 1 - Gear Seminar ManualDocument125 pages1 - Gear Seminar Manualgustool7100% (1)

- The Daily Tar Heel For September 18, 2012Document8 pagesThe Daily Tar Heel For September 18, 2012The Daily Tar HeelNo ratings yet

- The Pathogenic Basis of Malaria: InsightDocument7 pagesThe Pathogenic Basis of Malaria: InsightRaena SepryanaNo ratings yet

- Science SimulationsDocument4 pagesScience Simulationsgk_gbuNo ratings yet

- SPSS-TEST Survey QuestionnaireDocument2 pagesSPSS-TEST Survey QuestionnaireAkshay PatelNo ratings yet

- Writing A Formal Letter To The PresidentDocument1 pageWriting A Formal Letter To The PresidentPiaAnaisNo ratings yet

- Clustering Social Network GraphsDocument12 pagesClustering Social Network GraphsRáhùl SréédhãrNo ratings yet

- Mini Centre CatalogDocument26 pagesMini Centre CatalogJohn EarleyNo ratings yet

- Stmma-Fd: Zhejiang Castchem New Material Co.,Ltd&Castchem (Hangzhou), IncDocument2 pagesStmma-Fd: Zhejiang Castchem New Material Co.,Ltd&Castchem (Hangzhou), IncYash RaoNo ratings yet

- Surface water drainage infiltration testingDocument8 pagesSurface water drainage infiltration testingRay CooperNo ratings yet

- OsmanabadDocument5 pagesOsmanabadKirankumar MutnaliNo ratings yet

- Sample Interview Questions for Motivation, Communication, TeamsDocument6 pagesSample Interview Questions for Motivation, Communication, TeamsSahibzada Muhammad MubeenNo ratings yet

- Matrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEDocument41 pagesMatrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEkhateeb ul islam qadriNo ratings yet

- Primavera Inspire For Sap: Increased Profitability Through Superior TransparencyDocument4 pagesPrimavera Inspire For Sap: Increased Profitability Through Superior TransparencyAnbu ManoNo ratings yet

- Jharkhand Steel Casting CompaniesDocument6 pagesJharkhand Steel Casting CompaniesCatherine Jovita50% (2)

- Strata KT Office OpportunityDocument41 pagesStrata KT Office OpportunitySanskar SurekaNo ratings yet

- Oxy AcetyleneDocument43 pagesOxy Acetyleneregupathi100% (1)

- Unitisation of Legal Methodsalsdkgh GHNJFKL A SDFG LKJH Asdfgf Lkjhasdfg LKKJ Asdfg LKJH A Slkjfs Aaaaaaaaaaaaslkdfj Asldkjf SLDKFJDocument3 pagesUnitisation of Legal Methodsalsdkgh GHNJFKL A SDFG LKJH Asdfgf Lkjhasdfg LKKJ Asdfg LKJH A Slkjfs Aaaaaaaaaaaaslkdfj Asldkjf SLDKFJKailashnath Reddy AjjuguttuNo ratings yet