Professional Documents

Culture Documents

Glure Die Cutter

Uploaded by

pigpig1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glure Die Cutter

Uploaded by

pigpig1Copyright:

Available Formats

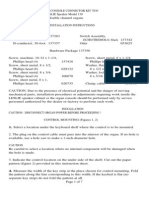

Product Profile

A simple answer to a major production

hurdle !

This Partition Slotter is a solution to the box manufacturers

who have to supply partitions with their product.

This machine gives you 120 partition plates per minute,

duly slotted, as per your requirement. It is a very cost effective

solution to the problems being faced by the corrugated box

Industry in India. The slot depth can be made to your desired The Company offers:

sizes. Two different sets of blade thicknesses are required to

be used for 3ply and 5 ply sheets. • Rotary Dies for corrugated box and E-flute corrugated

cartons.

For more information please contact: • Flat dies for folding cartons and corrugated boxes

info@oneworldinc.in • Stripping Dies-pinless for folding and corrugated cartons

• Counter Dies-pertinex for folding and corrugated cartons.

• Steel counter plates for folding cartons and corrugated

cartons

German technology now in India • Label cutting dies.

Diehard dies Pvt. Ltd. is establishing a full-fledged Die Shop

with advanced German Technology. The Company is equipped The production will start from February 2009.

with high end laser cutting machine and other modern

equipment operating on CAD software. For other details e-mail:

contact@dieharddies.com

The new technology involves innumerable member of

innovative techniques to improve the die quality. The emphasis

is on… How to spot your colour with ease

• Dimensional accuracy The pantone formula guide is the international standard for

• High cutting performance selection and specification of spot Pantone Colours. When a

• Long life of the die for more number of impressions. spot colour is required, the guides, (coated and uncoated)

provide a collection of 1114 solid Pantone colours in a portable

fan deck for easy reference. The choices can be identified by

unique name/number for clarity and precision. And provides

The Corrugator / Oct. - Dec. 2008 87

greater colour area per swatch. The palette includes ink mixing Diagraph has been serving the marking and coding industry

formulations for each colour and icons that indicate if the colour for past 110 years and offers the most comprehensive line of

is achievable in RGB or CMYK. A handy tool for packaging marking. Coding and labeling systems and supplies, including

designers, printers and processors! small character continuous ink jet, large character and high

resolution ink jet, automated label printer/applicators and label

Contact: applicators. It implements radio frequency identification (RFID)

Super Book House, Tel.: 22830446, 22020106 and has own University dedicated solely to RFID training and

application testing for customers.

Industrial Inkjet Direct to Carton For more details e-mail:

admin@muktavan.com

Printing Technology brought to you by

Muktavan Digital Solutions

Muktavan Digital Solutions, a Mumbai-based company, New High Quality Board Material from

known for customer-centric approach and promotion of State Stora Enso

-of-the-art technology, represents Foxjet Trident and Diagraph

divisions of ITW, a fortune 200 manufacturing company, as Stora Enso launches new Aurocard board

its sole distributor and stockists in India. Stora Enso's Aurocard board now features enhanced

brightness, brightness stability and whiteness. In terms of folding

strength, the new Aurocard outperforms all competing folding

boxboard products. The board offers an attractive new material

option for any type of graphical product, such as book covers,

brochures, catalogues and greeting cards.

Aurocard is a well-established brand throughout Europe.

The new board grade is produced at Stora Enso Imatra Mills,

Finland. The central location, high service level and efficient

sheeting machinery ensure prompt and reliable board deliveries

to the customers throughout Europe.

New raw material basis, improved properties

Aurocard's properties have been significantly improved by

changing its raw material basis from groundwood to chemi-

thermomechanical pulp (CTMP). The new Aurocard is

characterized by a bright, white and smooth surface and a

strong multilayer structure. Thanks to its excellent folding

strength, the board works magnificently in folded products,

such as folders, catalogues and covers. The new Aurocard is

available in grammages from 200 to 350 gsm. Stora Enso

Graphical Boards' range also includes Ensocoat and Ensogloss

solid bleached sulphate boards and the CTMP-based Performa

2S and Chromocard boards.

Stora Enso launches new Performa Alto board

FoxJet is a leading manufacturer of industrial inkjet printing Stora Enso has launched its new Performa Alto board for

systems and inkjet inks, which are sold through a network of high-quality folding cartons. The board offers excellent print

quantity distributors in the United States and other places. results and a bright surface, making it ideal for cosmetics and

FoxJet offers a complete line of high resolution case coding luxury packaging. Performa Alto is available in grammages

systems and printing solutions for alpha numeric printing , bar from 200 to 350 gsm.

code printing and logo printing.

Trident having 20+ years experience with industrial inkjet

technology for design and manufacture of inkjet print heads,

formulate and manufacture of inkjet inks, Customised printing

solutions. Trident industrial inkjet printheads are known for

high efficiency, reprintability and original configurations.

The Corrugator / Oct. - Dec. 2008 89

Performa Alto has excellent brightness, brightness stability APEO is an excellent active detergent, unfortunately this

and whiteness. The smoothness of the reverse side also allows powerful activity also strips life giving layers from tiny aquatic

attractive print. Its quality clearly puts it at the top end of CTMP organisms. Moving up through the aquatic life chain, the effect

and folding boxboards in the market. This board is being of APEO is seen wherever waterways carry effluent. Bio

marketed for cosmetics, luxury and other high-end packaging treatment does not significantly breakdown APEO.

applications. Performa Alto will provide an interesting new

material option for our customers. Finally the solution is to stop releasing APEO into the

environment, which means we must stop using APEO based

Stora Enso's Performa CTMP product family now comprises chemicals.

Performa Alto, Performa 2S, Performa White, Performa

Cream and Performa Natura brands. Performa CTMP boards APEO free inks have been available from Pacific Inks for

combine the benefits of folding boxboard with the mechanical many years and the last vestiges of water based products have

properties and chemical purity of solid bleached sulphate board. been stripped of APEO for the EU market, where the release

The odour and taint-neutral boards are also suitable for of APEO is now controlled.

packaging chocolate and pharmaceuticals. CTMP (chemi-

thermomechanical pulp) is used in the middle layer of board to A simple, but very effective solution – box plants simply

achieve superior performance in printing, converting and should stop using APEO based inks and the problem is solved.

demanding end uses.

In the folding boxboards category, Stora Enso has started Paxcific Inks also offers CORROFLEX Ink

the delivery of new, lower grammages of Tambrite in the

market. Tambrite is available in 205-380 gsm and is typically Water-based High Strength Inks for Paper &

used for food, pharmaceuticals and confectionery packaging. Board – for excellent coverage & vivid colours

It can also be used in larger box sizes, thanks to its solid

structure, high bulk and superior stiffness. “Brand owners today General

want to reduce their overall consumption of packaging materials CORROFLEX has been developed specifically to provide

to improve both their profitability and image. Tambrite responds Flexographic printers with an ink that renders vivid colours, is

to market demands for lower-weight packaging,” says the Vice easy to apply, inexpensive, simple to maintain on the machine,

President of Stora Enso. and is environmentally friendly.

For further information visit: Main Application

www.storaenso.com/graphical CORROFLEX INKS are specifically formulated for use with

bleached and natural Kraft liners, Recycled papers, Solid fibre

board, Bleached and unbleached Kraft papers, wet strength

boards and papers, coated papers and Multiwall bags.

Safer Inks from Pacific Inks

As we pour chemicals down the drain, it is easy to forget Characteristics

the consequences for our environment. The corrugated industry CORROFLEX Inks feature, high solids acrylic resin, micro-

uses millions of tonnes of water based inks, cleaners and fine lead free pigment, rapid ink rewetting after press stops

adhesives. All of these vital materials may contain industrial and very stable and rapid drying. CORROFLEX is produced

grade detergent – one particular type is known as APEO fully pigmented, hence it has superior light fastness and density

alkylphenolethoxylate. Even the name sounds nasty. compared with dye based inks.

Resistance Properties

Micro crystalline wax for high rub resistance (wet and dry),

Ammonia resistance, water bleed resistance (when fully dried),

Deep freeze resistance (when fully dried).

Colour Density and Strength

In most cases CORROFLEX colours are opaque. Best colour

density is achieved with clean anilox rollers. Experience

indicates that good density results from a laydown of 7-9bcm.

Colour strength increases as the machine speed increases.

Finish

The finish will vary according to the substrate selected; in

most cases a matt to satin finish is achieved. Viscosity alos

plays an important role in the ink finish. The lower the viscosity

the flatter the finish.

(Contd. on page 95)

The Corrugator / Oct. - Dec. 2008 91

(Contd. from page 91) The Accubatch 2020ME is the latest development in the

Antifoaming Agents range of Pacific Inks Accubatch ink blending systems. This

small footprint, large capacity blender will mix single batches

Antifoam is not required. Excess use causes mottled print

and overprint problems. up to 200 litres that can be poured to suitable sized pails for

transfer to the print machine.

Drying

Maximum resistance of the dried print requires 24 hours to Over 5000 colours are available through the on-board

develop. This may vary according to the pH and porosity of computer controlled formula selector. From a customised menu

the substrate. you can choose the colour you require and blend exactly the

amount you need. The Accubatch 2020ME provides dense

Storage full colour inks, reduces ink costs and down time, saves water,

CORROFLEX inks have at least 12 months storage stability provides easy recycling of left over inks and is easy to install

providing lids are kept on the pails. Any dried material readily and fully serviced by Pacific Inks.

re-desolves. There is no formation of a heavy sediment. This

may only occur when the ink has been heavily diluted. The

addition of a small quantity of Transaid will rapidly reconstitute Coromat 3000 from Cargill

over-thinned ink. If viscosity needs to be raised, add Pacific

Supergel. Due to its water content CORROFLEX needs to be Improving your corrugated

stored in a cool shaded area. Avoid freezing. board production process means

improving cost efficiency and, of

Drying Speed course, profitability.

Drying speed is primarily a function of ink viscosity, the

lower the viscosity the more rapid the penetration. Due to The new Coromat 3000 is

high strength/low viscosity relationship, fast dry at good colour Cargill’s state-of-the-art, compact,

strength can be achieved. fully automated corrugating

adhesive preparation system.

Overprinting

Technologically advanced, flexible

CORROFLEX readily overprints to produce secondary

and adaptable, Coromat 3000

colours.

provides highly efficient viscosity

Wash-up controlled processes which can

Water is the normal wash up liquid. Dried ink can be deliver faster speed, less glue

removed with metholated spirits or Pacific Ink Remover. consumption, waste reduction and wet resistance. What’s more,

the system comes with full after sales support, both on-site

and remotely (via modem). No matter what type of glue

New Accubatch preparation method or starch products you use, Coromat 3000

will help to keep you one step ahead.

As a result of continued

development, Pacific Inks have No-Carrier

recently introduced the Accubatch

Contrary to the Stein Hall system and as its ‘No-Carrier’

2020MA model. This new model

name suggests, this adhesive does not have a fully gelatinized

will allow small to large sized flexo

carrier portion, but all the starch is slightly swollen. This results

or screen printers to mix batches

in lower water retention capacity and can be an advantage for

of ink in 20 litre pails ready for

papers that are difficult to penetrate, since the first water

the print machine. Using Pacific

release, together with the relatively high pH, helps in opening

Inks highly innovative and proven

the paper.

software the 2020MA allows the operator to quickly identify a

PMS colour match and have the resulting formula being

Having a low (or no) quantity of fully gelatinized starch

dispensed within a few minutes. As

granules means that 100% of the starch is active at peak

the first pail is being mixed a second

viscosity, giving a maximum wet-tack.

pail can be receiving computer

controlled ingredients from the

These combined features provide good glue-ability, high-

dispenser head. This means the

bond strength, high machine speeds, shear stability and low

complete ink supply for the job can

waste.

be mixed quickly and easily.

Compared to Stein Hall, No-Carrier adhesives are very

The 2020MA also features

sensitive to swelling, allowing for quick gelatinization when

newly developed dispensing heads

heated. The shorter texture helps keep the corrugator cleaner

to prevent post dispense dripping.

and guarantees optimal glue pick-up by the flute tips, as well

as ensuring low adhesive consumption.

The Corrugator / Oct. - Dec. 2008 95

Using Cargill specialty starches, the solids content of your fluid, no matter what type of

No-Carrier adhesive can be significantly increased, enabling a formula and what type of starch,

major increase in machine speed. from corn to wheat, native or

modified.

Stein Hall

The Stein Hall glue preparation system provides simplicity Very highly concentrated.

at low cost, along with excellent gluing for many different paper The dosage level of Starch

types. Booster is 0.5% on total weight

of the starch in the adhesive

In this adhesive, 10-20% of the total starch content is formula.

gelatinized into a high viscosity paste called primary starch.

The remainder of the starch (80-90%) stays ungelatinized and Depending on the shear forces that are applied to it, the

is called secondary starch. adhesive's viscosity changes accordingly and has the effect that:

• It shows a 'normal' viscosity when the shear force is low (at

Neither the primary nor the secondary starch alone have rest in storage).

satisfactory adhesive property for gluing – taken together, • It shows a very low viscosity when it's shear force is high

however, they form an excellent corrugating adhesive. on the glue-applicator and at 'the contact' with the paper.

Due to the presence of fully gelatinized carrier starch - and • Once in contact with the paper the shear force is completely

the resulting high water retention capacity - Stein Hall glues gone and the viscosity increases instantaneously.

are particularly recommended for use with very absorbent • This is a spectacular saving in adhesive because less adhesive

paper. now leaves the glue roll and therefore less water and starch

has been transferred to the paper flutes enabling a very

Improved performances fast and excellent bond.

Cargill provides a large range of special starches and

additives to improve factors in glue performance, such as wet- Benefits

bond strength and glue penetration. • Improved board quality (better flatness, less wash boarding,

better printability).

Starch Booster overview • Ability to use lower paper weights without decreasing either

Over the last few years the look of the box has become mechanical properties or printing quality of the box.

more and more important and this has lead to higher use of • Higher average line speed on both the corrugator and

white top, coated liners and the production of more (and converting machines.

smaller) micro flute board.

• Reduction in corrugator waste (at least 0.5 percent).

Mainly due to the lower porosity of such papers, a lower • Reduction in starch consumption (up to 30 percent).

water add-on becomes highly important in order to prevent

• Savings in energy (consumption per square meter of board)

blistering in subsequent offset and flexo printing.

due to lower temperatures required.

Moreover, the new generation of wider and faster machines • Single formulas for single facer and double backer are the

require new adhesive recipes, new starch product concepts norm.

and of course, the starch adhesive should deliver the same • Simple all native starch formulas only. Corn, wheat, rice,

performance at both low and high machine speeds. potato, tapioca, no more modified starches or additives

needed.

All this implies an adaptation of a new starch and adhesives

philosophy. • Less adhesive means less water to be evaporated.

• Less adhesive means faster drying. From the dry end to the

Cargill, has realized that not only the type of starch can flexo immediately!

make a difference, but also that the rheological behavior of

• Less adhesive means less water and warp issues minimized

the adhesive is a key issue.

or eliminated.

• Better edge bonding due to better and complete width

Starch Booster 41101 adhesive transfer from the roll to the paper.

• Penetration of the adhesive is enhanced resulting in higher

How does it work?

PIN and ECT and BCT values.

It is a new by Cargill to facilitate production of new glue

added to the primary water, Starch Booster acts like a thickening • Compatible with waterproof resins.

agent that when in contact with caustic soda in any starch • Easy clean up of the starch from equipment and rolls.

formulation, transforms the entire batch into a pseudo plastic

The Corrugator / Oct. - Dec. 2008 97

Industrial Noise Reduction adds on to its manufacturers. INR Ltd. worked closely with the West Coast

management and engineering team to ensure they achieved

satisfied customers list the target set of dealing with the noise, heat and fumes within

the corrugator bay. The heat build up was a particular problem

for West Coast with the then current extract hood and fan

arrangement unable to achieve a useful result. This was

successfully overcome by ensuring that high ventilation rates

were used within the enclosure. Mr. Cliff Graham, West Coast

Managing Director, commented: "We were very impressed by

the improvements in the noise level and ventilation by the

installation of the enclosures. The quality and detail of the design

and installation are excellent. Their installation team worked

closely with our personnel to ensure the least amount of

disruption to our production, understanding our needs to meet

our own targets. We will look forward to working with them

again on future projects".

INR Ltd. have carried on the lasting tradition established

by Noise Reduction Ltd., very well known within the corrugated

industry for producing a lasting quality product. They believe

in working closely with the client to ensure the best results are

Industrial Noise Reduction Ltd. has just successfully achieved. Their strength lies in offering complete package of

completed the installation of two acoustic enclosures on the in-house design and manufacture, to ensure quality, and our

single facer and trim fan for West Coast Corrugated Ltd., one own dedicated installation team provides installation to the

of the North West's leading independent corrugated highest standard.

INSUN – Auto Folder Gluer cum Stitcher + Down Stacker + Counter Ejector + Bundler

This machine is an answer to the bottleneck hitherto being and then straps the bundles. So all that is left for the box

faced by most box manufacturers who have set up high speed manufacturer is to handle the strapped, bundled boxes !

production line. After finding solutions to the issues of quality

board production and suitable printer slotter, the industry was The machine is designed to glue the boards at the speed of

getting stuck at finishing section of the production process. 120 mtrs/mnt or stitch at 80 sheets per minute. Two such

units are functional in India already and the third unit is expected

This is an ideal solution offered by INSUN, South Korea. to be functional by end February. If you want to handle high

volumes at high speeds, this machine is and answer to your

After the board is printed and slotted, this machine then requirements.

does all the processes required; it does folding or gluing as For more information please contact:

desired, then counts the bundle size as required by the customer info@oneworldinc.in

The Corrugator / Oct. - Dec. 2008 99

You might also like

- XR 640 BrochureDocument4 pagesXR 640 BrochureDwayne. JonesNo ratings yet

- Colep_Aerosol_catalogue_v2_2018Document23 pagesColep_Aerosol_catalogue_v2_2018mantenimientoNo ratings yet

- Epson Surecolor SeriesDocument12 pagesEpson Surecolor SeriesdscvsddvfvNo ratings yet

- ProC7100x 12pp Brochure UK v11 MR T 69-84201Document12 pagesProC7100x 12pp Brochure UK v11 MR T 69-84201snakenifNo ratings yet

- Master BatchDocument12 pagesMaster Batchskimmer05100% (1)

- Intec CC-Flatbeds-FB1175-FB775-FB550-EN-web-1Document7 pagesIntec CC-Flatbeds-FB1175-FB775-FB550-EN-web-1Neosys IndonesiaNo ratings yet

- Open Technology Open Mind: You Tell Technology What To Do, Not Vice VersaDocument8 pagesOpen Technology Open Mind: You Tell Technology What To Do, Not Vice VersaChamakhi AmeurNo ratings yet

- Color Inkjet Label Printer: Epson Colorworks C3500Document2 pagesColor Inkjet Label Printer: Epson Colorworks C3500Paulina HenaoNo ratings yet

- RICOH Pro C5300s-C5310s Final Brochure v2 - HR - tcm100-39832Document12 pagesRICOH Pro C5300s-C5310s Final Brochure v2 - HR - tcm100-39832Pascu DanNo ratings yet

- You'Ve Never Experienced Color Quite Like This: Large-Format Inkjet PrinterDocument2 pagesYou'Ve Never Experienced Color Quite Like This: Large-Format Inkjet Printertesfalem kirosNo ratings yet

- Flat Die PET Film: Innovative Extrusion LinesDocument28 pagesFlat Die PET Film: Innovative Extrusion LinesMada PerwiraNo ratings yet

- Pad Printing: High Performance Inks ForDocument7 pagesPad Printing: High Performance Inks Forhesam abbaszadehNo ratings yet

- ADL Particleboard PDFDocument54 pagesADL Particleboard PDFNikhil GuravNo ratings yet

- Label-Printer PRO 1040Document8 pagesLabel-Printer PRO 1040wube hailuNo ratings yet

- RICOH Pro C5300s Series BrochureDocument8 pagesRICOH Pro C5300s Series BrochureArun BennyNo ratings yet

- Ricoh Latex Pro L5130e Pro L5160e: TM TMDocument12 pagesRicoh Latex Pro L5130e Pro L5160e: TM TMbor gabNo ratings yet

- Domino F530i All Sectors BrochureDocument12 pagesDomino F530i All Sectors BrochureTenday Agus Setya WibawaNo ratings yet

- TTR ProspektDocument6 pagesTTR ProspektHussein EidNo ratings yet

- Blown Film Lines BrochureDocument20 pagesBlown Film Lines BrochureOsmar JrNo ratings yet

- Blown Film: Innovative Extrusion LinesDocument20 pagesBlown Film: Innovative Extrusion LinesHiếu Mai ĐứcNo ratings yet

- Professional Color.: Powerful PerformanceDocument6 pagesProfessional Color.: Powerful PerformanceAmr H Fadl HNo ratings yet

- Berry Superfos - IML GuidelineDocument2 pagesBerry Superfos - IML GuidelineHau SinâuđaNo ratings yet

- Xaar 128/80L Xaar 128/40L Xaar 128/80W Xaar 128/40W: Adaptable Printhead With Trouble-Free IntegrationDocument2 pagesXaar 128/80L Xaar 128/40L Xaar 128/80W Xaar 128/40W: Adaptable Printhead With Trouble-Free IntegrationSALISU ABDULWAHEED KOLAWOLENo ratings yet

- Ricoh Pro 8320s/8310s Series: B&W Digital Production PrintersDocument12 pagesRicoh Pro 8320s/8310s Series: B&W Digital Production PrintersspalsvtsNo ratings yet

- RUBNERDocument32 pagesRUBNERarchpavlovicNo ratings yet

- Xaar 1002: A New Standard in Single-Pass Print QualityDocument2 pagesXaar 1002: A New Standard in Single-Pass Print QualityBayu AjiNo ratings yet

- Ricoh Pro 5100s BrochureDocument12 pagesRicoh Pro 5100s BrochurePolygonNo ratings yet

- Xaar 128Document2 pagesXaar 128Proffisional ShopinrioNo ratings yet

- FSC and quality certifications highlight IPL's green credentialsDocument31 pagesFSC and quality certifications highlight IPL's green credentialsNCS FreeNo ratings yet

- Toshiba 6570cDocument6 pagesToshiba 6570cletranquanghaNo ratings yet

- 716Document108 pages716Florin VranceanNo ratings yet

- Placare HPL Prin Lipire Pag 38 PDFDocument108 pagesPlacare HPL Prin Lipire Pag 38 PDFMaria ArionNo ratings yet

- Guide To App Products PDFDocument8 pagesGuide To App Products PDFir_one_danaNo ratings yet

- TASKalfa 2552ci ..Document8 pagesTASKalfa 2552ci ..vikramNo ratings yet

- Inkjet Coding SistemDocument16 pagesInkjet Coding SistemRizal SetiawanNo ratings yet

- Brochure Schuetz Cormaster enDocument12 pagesBrochure Schuetz Cormaster enAnu ChandranNo ratings yet

- Datamax E-4205 Mark IIDocument2 pagesDatamax E-4205 Mark IICesar AugustoNo ratings yet

- c01 r0 22 Product Range UkDocument7 pagesc01 r0 22 Product Range UkJayanti International LtdNo ratings yet

- HammerDocument128 pagesHammerIulian MihaiNo ratings yet

- A12040 Brochure Lores en Int SC T - Series - Range - Brochure - RNZDocument7 pagesA12040 Brochure Lores en Int SC T - Series - Range - Brochure - RNZSudiarto SudiartoNo ratings yet

- Evaluator Guide: Docucolor 242 / 252 / 260Document14 pagesEvaluator Guide: Docucolor 242 / 252 / 260Patricia SolisNo ratings yet

- Flexcel SRM Datasheet USDocument2 pagesFlexcel SRM Datasheet USAdryana StratulatNo ratings yet

- 06 - Markem - Imaje - Full LineDocument2 pages06 - Markem - Imaje - Full LineNemuel CailaoNo ratings yet

- Sayerlack - Movac BROCHUREDocument12 pagesSayerlack - Movac BROCHUREfalcon falconpaintNo ratings yet

- Flexographic (2011) - Low ResDocument44 pagesFlexographic (2011) - Low ResChloe GroemeNo ratings yet

- NH Akustik BrochureDocument24 pagesNH Akustik BrochuremurattekinNo ratings yet

- Compromise Is Not An Option... : Akzonobel Aerospace CoatingsDocument2 pagesCompromise Is Not An Option... : Akzonobel Aerospace CoatingsIzaque GermanoNo ratings yet

- L901 Industrial Color Label Printer: Powerful in Both Roll-to-Roll and Inline ApplicationsDocument2 pagesL901 Industrial Color Label Printer: Powerful in Both Roll-to-Roll and Inline ApplicationsSébastien AmetNo ratings yet

- Get The Best Results: Océ Copypress TechnologyDocument9 pagesGet The Best Results: Océ Copypress TechnologyJPauloNo ratings yet

- Java Print Digital Brochure Reduced File SizeDocument6 pagesJava Print Digital Brochure Reduced File SizeLonely TweentyoneyearoldNo ratings yet

- Nec 4400Document270 pagesNec 4400MapsonNo ratings yet

- Laminate FlooringDocument68 pagesLaminate FlooringGuru Vignesh SelvarajanNo ratings yet

- Partex product catalog guide to marking systems and accessoriesDocument136 pagesPartex product catalog guide to marking systems and accessoriesGrzegorz Greg KrukNo ratings yet

- Canon CLC 1160Document6 pagesCanon CLC 1160mbnamingNo ratings yet

- Ricoh Pro C8200S Product BrochureDocument12 pagesRicoh Pro C8200S Product BrochureclaudeNo ratings yet

- Technical data on Agfa black-and-white RC and baryta papersDocument12 pagesTechnical data on Agfa black-and-white RC and baryta papersgprh999No ratings yet

- OSB SterlingDocument13 pagesOSB SterlingmgalltestNo ratings yet

- Enhanced Reliability and ProductivityDocument12 pagesEnhanced Reliability and ProductivityJohneil Perea AsiNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Crop Production and Management-Solved ExercisesDocument4 pagesCrop Production and Management-Solved ExercisesSbs ReddyNo ratings yet

- Select A Location Under The Keyboard Shelf Where The Control Is To Be MountedDocument7 pagesSelect A Location Under The Keyboard Shelf Where The Control Is To Be MountedRichard UrbanNo ratings yet

- UN 38.3 Lithium-Ion Battery Testing: Vibration and Shock Testing RequirementsDocument27 pagesUN 38.3 Lithium-Ion Battery Testing: Vibration and Shock Testing RequirementsAshok KumarNo ratings yet

- Construction Machines & Equipment GuideDocument48 pagesConstruction Machines & Equipment GuideKlemen KavčičNo ratings yet

- Annular Pressure Packer BypassDocument1 pageAnnular Pressure Packer BypassDenier RubianoNo ratings yet

- Visuals For The Language Classroom PDFDocument126 pagesVisuals For The Language Classroom PDFLupeluny100% (1)

- Colorants Textiles PDFDocument2 pagesColorants Textiles PDFKatNo ratings yet

- API Standard 660 TI PDFDocument7 pagesAPI Standard 660 TI PDFJoko KumboroNo ratings yet

- Install and operate your portable AC safelyDocument8 pagesInstall and operate your portable AC safelyPete PompesNo ratings yet

- 99560engelsk PDFDocument159 pages99560engelsk PDFGerald Ochoa Perez100% (1)

- Current Transformer Technical SpecificationDocument8 pagesCurrent Transformer Technical SpecificationbinodeNo ratings yet

- City of Durban Standard Engineering Specification Part C - Concrete WorkDocument33 pagesCity of Durban Standard Engineering Specification Part C - Concrete WorkLuke Jabulani ReidNo ratings yet

- Assembly and Operation Manual Garden Pellet Heater OrteDocument14 pagesAssembly and Operation Manual Garden Pellet Heater OrteAmândio PintoNo ratings yet

- Intelligent BuildingDocument42 pagesIntelligent BuildingLuis Alonso SA100% (1)

- Appliances Picture Flashcards by Learnwell OyDocument7 pagesAppliances Picture Flashcards by Learnwell OyVeronicaGelfgren100% (3)

- Lesson AGMA Standard - Example 1 & 2Document23 pagesLesson AGMA Standard - Example 1 & 2Sphumelele SibuthaNo ratings yet

- DampavaultDocument8 pagesDampavaultchillerz69No ratings yet

- TSGB 2017 MaritimeDocument35 pagesTSGB 2017 MaritimemarinedgeNo ratings yet

- Marketing VoltasDocument31 pagesMarketing VoltasNiraj Kumar100% (1)

- KOBELCO Arm Shock CountermeasureDocument204 pagesKOBELCO Arm Shock CountermeasurePHÁT NGUYỄN THẾ100% (8)

- (IKCO) Manual de Propietario Ikco CentauroDocument175 pages(IKCO) Manual de Propietario Ikco CentauroTiberio Lugo86% (7)

- Gas Turbines and Turbocompressors For LNG ServiceDocument35 pagesGas Turbines and Turbocompressors For LNG Servicewylie01No ratings yet

- Classic Plan: Artist's EaselDocument5 pagesClassic Plan: Artist's Easelwhorne240% (1)

- Environmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96Document22 pagesEnvironmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96scribdledeeNo ratings yet

- Saso 2221 2004 eDocument18 pagesSaso 2221 2004 eshafeeqm3086No ratings yet

- Instant Dfs System PDFDocument4 pagesInstant Dfs System PDFMithilesh KumarNo ratings yet

- 04 PDFDocument146 pages04 PDFEli RochaNo ratings yet

- Technical Specifications For Ash Handling System 3x135mwDocument16 pagesTechnical Specifications For Ash Handling System 3x135mwananthiNo ratings yet

- Examination of Heat RecoveryDocument70 pagesExamination of Heat RecoveryIdzard MoraisNo ratings yet