Professional Documents

Culture Documents

Time and Cost Comparision of PSC and RCC

Uploaded by

mahakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Time and Cost Comparision of PSC and RCC

Uploaded by

mahakCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

Time and Cost Comparison of PSC Superstructure

with RCC for River Bridge

Rajesh B. Jadhav1, Ashok B. More2

1

PG Scholar, Department of Civil Engineering, TSSM’s P.V.P. Institute of Technology, Pune, India

2

Head of Department, Department of Civil Engineering., TSSM’s P.V.P. Institute of Technology, Pune, India

Abstract: Bridges are the key component of the highway infrastructure supporting transport system of India. The design of river

bridges are mainly depend on the navigational flow, available waterway, velocity of water current etc. Executions of such bridges is

always a challenging job. Though the engineers feel the foundation of River Bridge is critical, the construction of superstructure is also

not easy. It depends on various site constraints like land available for construction, resources available, water intensity etc.. The

superstructure type shall be selected considering the river flow and suitability of execution as well as durability of the structure. The use

of advance construction methods will help for faster completion of the projects reducing overall cost and time of project. The proper

selection of superstructure will help to complete the bridge as per schedule which finally saves cost of the project. In the present study,

two superstructure types (RCC/PSC) are studied to review its suitability for bridge having span length of 21.50m. The cost and time

component for both types are evaluated to work out the economical option for superstructure. It is observed that the RCC T Beam is the

economical superstructure type in construction point of view but it is having some limitations for durability of structure.

Keywords: bridge, river, design, method, execution, durability, cost, time

1. Introduction Few of them are narrated here, Natraj Singh, N.P. Devgan

and A. M. Kalra (2015) presented the study which will

Bridges are basic and important components in the highway facilitate as a hand on tool for selection of economical

networks. But in spite of this known importance, bridges superstructure type for 20m span bridges. Keeping in view

continue to receive lesser attention during construction as the fund constraints faced by infrastructure organizations, the

well as maintenance. Many of the bridges serve for many present study aims to develop an economic solution for

years even after their design life overs only if they are construction of superstructure for 20m span bridge under

constructed properly. The routine maintenance of Bridges is Indian Road Congress (IRC) loading. The effects of

also essential activity for a Highway Engineer. The timely placement of span in normal conditions and launching above

and keen supervision during construction along with good the railway line have different cost implications because cost

maintenance monitoring system post construction always associated with the Traffic block has a substantial cost share

gives best results. This will lead to save cost of the project in launching process. An attempt is made to quantify the cost

and this will support economical growth of India. associated with the traffic block and the speed restriction.

Another important aspect is the use of sacrificial shuttering in

The bridges mainly consist three parts: foundation, combination with conventional shuttering and its effects are

substructure and superstructure. The foundation and explored from the economy point of view. The study selected

substructure are being cast in situ as well superstructure can most economical section for four types of super structures.

be in situ or precast. Superstructure is everything from The effects of the placement of span are also studied for

bearing up to finished deck and is the most visible part of the different site conditions.

bridge. Its basic design, in the most simplified form, can be

compared to a log ranging from one side to the other across a Anuja Rajguru and Parag Mahatme (2016) presented that in

river or creek. the construction project, time and cost are the most important

factors to be considered in the planning of every project. It is

The present study suggests the selection of superstructure a difficult task undertaken by project managers in practice,

suitable for bridge based on cost comparison. Here the which include evaluation of plans, corrective actions and

feasibility of PSC I girder superstructure in lieu of RCC T constantly measuring progress should be taken whenever

Beam type is reviewed. The cost will be compared for same required. Cost optimization is an important issue in

span for RCC T Beam type superstructure with PSC I Girder construction project management. It is mostly used by

type. The superstructure work is proposed for a river bridge contractors and needs to carry out throughout the life of a

for a specific span length of 21.50m to observe its impact. construction project. The cost optimization method in a

The basic factors affecting selection of superstructure are construction project is used to identify the problem faced by

generally site conditions, geometrical features, availability of the contractor in optimizing the costs on site. The availability

resources like man, material, machinery etc. of qualified expertise is the main problem faced by contractor

in optimizing the costs on site. The duration of the project

2. Literature Review and ever changing environment are the least problem faced

by contractor in optimizing the costs on site. The study is

The various research appears were studied to know the able to state that, “The problem of cost optimization is

various factors affecting the selection of superstructure type. actually the lack of knowledge and inadequate planning for

Volume 6 Issue 6, June 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20174695 1762

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

the implementation coupled with the poor management of the viability of PSC I Girder will be checked by designing it

construction resources for same span length, ie. 21.50m and its costing will be

reviewed. The feasibility of PSC I Girder will be checked for

3. Objective in situ as well as for precast girder as only erection

methodology will vary here and material cost will remain

1) To analyze RCC and PSC Type bridge superstructure for same in both cases, i.e. in-situ and precast type. For PSC I

span length of 21.50m. Girder bridge, the cost for In-situ erection method and for

2) To compare the cost and time incurred for execution of precast method of erection for superstructure are worked

both types of superstructure because here only cost of launching / staging will differ and

3) To check the economic feasibility of best sup[restructure material cost will remain same in both case.

among both.

The cost analysis covers following components,

4. Cost Comparison i. Basic cost of material incurred for construction of the

structure including all labour cost

In the present study, the actual cost of RCC T Beam ii. Erection/ Placement/ launching of structure element at

superstructure from the ongoing project of construction of designated location including all lead lift, labour, all types

2L/4L major bridges on Mumbai-Goa highway (NH-66) is of equipment hire charges, overheads etc.

worked. The data of RCC T Beam superstructure is collected

from approved drawings. The quantum of PSC I girder is The cost of finishing is not considered for analysis as the

analyzed in line with the quantum of RCC T Beam. The effect of finishing cost has no impact for cost comparison of

sectional properties of PSC I Girder superstructure for span superstructure type.

of 21.50m have been studied from the design drawings. The

design and drawings for PSC I Girder for 21.50m is specially a) Material Cost

worked out for comparison only. In the proposed project of The sectional properties of superstructure in both types are

construction of Janavali Bridge, on LHS, the RCC T Beam studied. The sectional properties of superstructure elements

superstructure type is being executed; RCC T Beam and deck are brought out, summarized and are represented in Table I.

slab both are cast in-situ only. For proposed bridge on RHS,

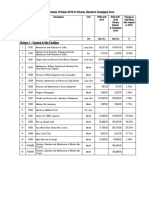

Table 1: Sectional Properties of RCC/PSC Superstructure

Sr. No. Description Unit RCC T Beam PSC I Girder

1 2 3 4 5

1 Name of Bridge M Janavali Janavali

2 Span Length M 21.50 21.50

3 Depth of deck slab M 0.20 0.25

4 Web depth (excluding deck slab) M 1.55 1.30

5 Top width (at Support) M 0.35 1.10

6 Bottom width (at Support) M 0.35 0.70

7 Web width (at Support) M 0.35 0.70

8 Top width (at mid span) M 0.35 1.10

9 Bottom width (at mid span) M 0.35 0.70

10 Web width (at mid span) M 0.35 0.30

Based on sectional properties and detail drawings, the does not require any launching / placement. Hence for RCC

quantity of materials like Concrete, Reinforcement Steel, and T Beam case the cost of erection of temporary structure for

Prestressing Steel is calculated. Also the quantum of staging work is considered for analysis. The work

shuttering (Formwork) required to execute the said methodology for erection of both types of structures needs to

superstructures are figured out. The shuttering charges are be freezed before start of the work. The approval of the

including of labour charges and material hire charges. The methodology is also required to be taken from concerned

quantities of materials for both types of superstructure are authority before actual work starts. The launching cost

tabulated in table (Table II). includes the operating cost of casting and stacking yard, hire

charges for crane and trailer, labour, safety arrangement

b) Placement / Launching / Erection Cost expenses, etc.

The placement / launching of the girder is the process of final

placement of the girders on the piers at required position. The c) Finishing Cost

cost associated with the placement / launching is greatly In case of reinforced or prestressed concrete bridges work

affected by the surrounding site conditions. The free generally does not require any finishing. The surfaces of cast

movement of cranes is being restricted many times due to structures are smooth due to quality concrete work and an

less land width available for crane erection. Greater the only need in case of any honeycombing is observed post

restriction greater the cost involved for placement of the concreting. Hence the cost will not have any major impact on

girder. The cost of launching / placement depends on the total cost. Due to this, the impact of finishing cost is not

weight of the superstructure member being launched. In our considered.

case only PSC I Girder girders will be launched. It is

important to mention that RCC T-beam is cast-in-situ and

Volume 6 Issue 6, June 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20174695 1763

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

d) Maintenance Cost 5. Time Duration and Manpower

The maintenance cost is not considered here for comparison

of PSC I Girder with RCC T Beam superstructure type and Along with the cost comparison analysis, the manpower

same will be reviewed separately at later stage. consumed and the time required to execute the superstructure

work at said bridge are analyzed. The data collected suggests

e) Total Cost that the manpower required for execution of RCC T Beam is

The final cost of the finished structure including cost of about 23% less as compared with the PSC I Girder (In-situ)

material along with cost of launching will be as shown in type of superstructure and is less than 40% when it compared

Table III. with PSC I Girder (Precast) type.

Table 2: Quantities of Materials of RCC/PSC Superstructure Table 4: Time Duration and Manpower of RCC/PSC

Type of Superstructure Superstructure

Sr.

Description Unit PSC I Girder Type of Superstructure

No. RCC T Beam

(In – situ) Sr. PSC I PSC I

Description RCC T

1 2 3 4 5 No. Girder Girder

Beam

1 Span length M 21.50 21.50 (In-situ) (Precast)

2 Concrete Cum 120.00 142.00 1 2 3 4 5

3 Reinforcement MT 18.00 12.80 1 Workers (Nos) 30 32 40

4 Shuttering Sqm 548.00 520.00 2 Supervisory Staff (Nos) 6 8 8

5 Pre-Stressing Steel MT - 2.90 3 Time required for Execution (Days)

a Staging 10 10

36

Table 3: Cost of Superstructure of RCC/PSC Superstructure b Girder Casting 10 16

Type of Superstructure c Deck Slab Casting 6 15 21

Sr. d De-Staging 22 18 10

Description RCC T PSC I Girder PSC I Girder

No. Total 48 59 67

Beam (In-situ) (Precast)

1 2 3 4 5 4 Total Man days (Workers) 1440 1888 2680

1 Material 20,11,640.00 23,15,200.00 23,15,200.00 5 Total Man days (Supervisor) 288 472 536

Transportation,

2 Placement / 1,38,000.00 1,80,000.00 4,70,000.00 6. Results and Discussion

Launching cost

Total Cost (in

3 21,49,640.00 24,95,200.00 27,85,200.00 The cost is worked out for bridge superstructure for two

Rs)

Deck area Sqm

types having same span arrangement. The costs are measured

4 (For width 258.00 258.00 258.00 for basic material cost, shifting and launching cost, staging

12m) cost and all other indirect costs incurred for actual

Cost per Sqm construction and for planned work based on the budget rates.

5 8,332.00 9,671.00 10,795.00

(Rs.) To evaluate correctly, the superstructure costs are converted

in to deck area to form a standard basis for comparison.

The design grade of concrete for PSC I Girder superstructure 1) Based on the cost comparison, it is observed that the

and Deck Slab is M45 while for RCC T Beam type, the RCC T beam type superstructure is economical among

concrete grade is M30. Reinforcement Steel of Grade Fe500 two. But the superstructure type, PSC I Girder (In –situ)

is proposed in both types. High Tensile Steel of 12.7mm can be considered based on important aspects like

diameter will be used as per design drawing for PSC I durability, aesthetic point, etc.

Girders. The bridge superstructure is analysed and compared 2) The rate of deck area for RCC T Beam superstructure

for RCC T Beam and PSC I Girder (In situ/Precast). The cost type is worked out as Rs. 8332/- per sqm while the rate

is compared based on the deck area covered. The cost per per sqm of PSC I Girder is Rs. 9671/- for In-situ type

sqm worked out in Table III is represented through chart (Fig and Rs. 10795/- for precast type PSC I Girder

1). superstructure. Hence the RCC T Beam superstructure is

found economical among all above. The decision

regarding consideration of PSC I Girder type (Precast/In

Situ) needs more research to check its cost effective

benefits.

3) There is saving in time duration of 11 days when RCC T

Beam superstructure is proposed instead of PSC I Girder

for 21.50m span bridge.

The RCC T Beam type superstructure basically saves

construction cost only. But if we consider the working life of

both type of superstructure (PSC/RCC), the PSC I Girder

type superstructure is having more life than RCC T Beam.

The PSC structure is also stronger than RCC structure. The

Figure 1: Cost per Sqm of Deck Area of Superstructure RCC type superstructure is susceptible for corrosion, tensile

cracks, etc. Due to heavy reinforcement steel at tensile zone

there are chances of honeycombing during concrete. Placing

of concrete gets more difficult in RCC T beam type while in

Volume 6 Issue 6, June 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20174695 1764

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

PSC I Girder type, concrete placing is more easier as management in construction, vol. no. 2(2), 2010,Page

congestion of reinforcement steel is avoided. The segregation no. 182-190.

of aggregates does not occur and chances of honeycombing [11] S.K.Dharmadhikari(2012), “Construction of Mega

are less in PSC I Girder type. Bridges using Precast Segmental Methodology,”

Presentation on Precast Segmental Construction in

We may conclude that the cost analysis will help to finalize Mega Bridges, December 14, 2012.

superstructure type well in advance for a specific bridge [12] Rajesh F. Kale, N.G.Gore and P.J.Salunke (2014)

work and it will help to reduce the construction cost and “Applications of MATLAB in optimization of Bridge

required time duration. The availability of resources will Superstructures,” International Journal of Research in

definitely guide to finalize the type of superstructure. It is Engineering and Technology, eISSN: 2319-1163 |

important to state that ii is very difficult to provide the pISSN: 2321-7308, Volume: 03 Issue: 05, May-2014

perfect policy measures to suggest the superstructure type for [13] Seyed Ali MousaviDehmourdi (2014) "Optimization Of

a bridge based on above study as every bridge construction Construction Cost Applying Advanced Techniques"

locations are differs in end users aspects and other important International Journal Of Structural & Civil Engineering

features. Research, Vol.03, P 48-54.

[14] Natraj Singh, N.P. Devgan, A. M. Kalra, Surinder Pal

References (2016) “ Effect on Economy on Successive Increase in

the span of Bridges,” Proceedings of 2ndInternational

[1] Natraj Singh, N.P. Devgan and A. M. Kalra (2015) Conference on Civil, Structural and Transportation

“Economic Solution of Super Structure for Bridge of Engineering (ICCSTE’16),Otawa, Canada,Paper

20m Span,” International Journal of Emerging No.114.

Technology and Advanced Engineering, Volume: 05 [15] N. Dineshkumar, P. Kathirvel (April-

Issue: 07, July-2015. 2015),“Comparative Study on Prefabrication

[2] Vivek G. Abhyankar(Oct-2011), “Bridge Erection Construction with Cast In-situ Construction of

Methods and their influence on Permanent Designs,” Residential Buildings,” International Journal of

National Workshop at COEP Pune on Innovation in Innovative Science, Engineering& Technology, ISSN

Bridge Engineering. 2348-7968, Volume: 02 Issue: 04.

[3] Uros Klansek, Mirko Psunder (2010)“Cost Optimization [16] Seyed Ali MousaviDehmourdi (2014) "Optimization Of

of Time Schedules forProjectManagement”,ISSN:1331- Construction Cost Applying Advanced Techniques"

677X(Print), 1848-9664(Online) Journel, Vol. 23 No. 4 International Journal Of Structural & Civil Engineering

(P 22-36). Research, Vol.03, P 48-54.

[4] Anuj Rajguru, Parag Mahatme (2016), “Effective

Methods in Cost Optimization of Construction Project,” Author Profile

International Journal of Informative & Futuristic

Research, IJIFR/V3/E5/03, Volume: 03 Issue: 05. Rajesh B. Jadhav received the B.E. degree in Civil

[5] Urmila A Mahadik (2015),“Cost Reduction in Engineering from Shivaji University Kolhapur,

Construction Projects,”International Journal of Maharashtra (India) in 1993. Since 1998 onwards, he is

Engineering Technology, Management and Applied working in the infrastructure projects like bridges,

Sciences, ISSN 2349-4476, Volume: 03,Special Issue. flyovers etc. presently pursuing his masters from

[6] T.Subramani , P S Sruthi, M.Kavitha, (2014) “Causes Of S.P.Pune University, Maharshtra.

Cost Overrun In Construction” IOSR Journal of

Engineering, Vol. 04, Issue 6.

[7] Salunkhe. A, Patil R (2014) “Effect of Construction

Delays on Project Time Overrun: Indian

Scenario”IJRET: International Journal of Research in

Engineering and Technology, Volume:03.

[8] Ghatage R B, Pathak R C, (2016) “Appreciation of cost

Control and Optimization in Construction Projects: An

Review”57th International Conference on Recent

Innovation in Science, Engineering and Management, P

248-257.

[9] Monthly Progress Report (Oct-2016) of the Project of

“Construction of 4 lane / 2 lane Major / Minor bridges

and 2 lane ROB'S in the stretch from Km. 161/600

(Kashedi) to 450/000 (Zarap) section of NH-66

(Erstwhile NH-17) in the state of Maharashtra under

NHDP-IV on EPC mode”,Authority Engineer M/S. M/s.

III Engineers JV Shrikhande Consultants Pvt

Ltd.Mumbai.

[10] Nikolaos Fragkakis, Sergios Lambropoulous and John-

Paris Pantouvakis “A cost estimate method for bridge

superstructures using regression analysis and bootstrap,”

International Journal of organization, technology and

Volume 6 Issue 6, June 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20174695 1765

You might also like

- Cost Comparison of Superstructure For Bridges: A ReviewDocument4 pagesCost Comparison of Superstructure For Bridges: A ReviewEditor IJRITCCNo ratings yet

- RA-1 (Abs-1) - AirportDocument27 pagesRA-1 (Abs-1) - AirportSIVA RAMA KRISHNAN chelladuraiNo ratings yet

- Progress Up To 231117Document103 pagesProgress Up To 231117Anonymous UUw70xirblNo ratings yet

- Construction Work DMRCDocument33 pagesConstruction Work DMRCRubeel NaqviNo ratings yet

- Standard Drawing CompleteDocument60 pagesStandard Drawing CompleteRakesh Sharma100% (1)

- Final Presentation AeDocument21 pagesFinal Presentation AeLakhan BeniwalNo ratings yet

- Stagging CalculationDocument6 pagesStagging CalculationParvez KhanNo ratings yet

- Estimate and CostingDocument76 pagesEstimate and Costingupavp cd14No ratings yet

- Flexible Pavement Versus Rigid PavementDocument17 pagesFlexible Pavement Versus Rigid PavementAnirudh GuptaNo ratings yet

- 640 File228729760 PDFDocument278 pages640 File228729760 PDFAbhishek MathurNo ratings yet

- A Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofDocument65 pagesA Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofMadhavpokale100% (1)

- Tech Specifications (HEADS Pro) (Road Design) (Mail)Document32 pagesTech Specifications (HEADS Pro) (Road Design) (Mail)SANDIPNo ratings yet

- Project Closure ProcedureDocument18 pagesProject Closure Procedureapi-26492384No ratings yet

- Launching of Pre Stressed Girder by James R LibbyDocument19 pagesLaunching of Pre Stressed Girder by James R LibbyhammadhouseNo ratings yet

- Cross-Sectional ElementsDocument35 pagesCross-Sectional ElementsRespicus RJNo ratings yet

- NICMAR Distance Education Programs Advance Your CareerDocument22 pagesNICMAR Distance Education Programs Advance Your CareerChhavi SadanNo ratings yet

- Government of Odisha Rural Development Department Odisha, BhubaneswarDocument179 pagesGovernment of Odisha Rural Development Department Odisha, BhubaneswarPradeepta PatraNo ratings yet

- Rate Analysis - Khulna - Barisal - GopalganjDocument280 pagesRate Analysis - Khulna - Barisal - Gopalganjmd mohiuddinNo ratings yet

- Highway Testing Manual by Khanna and JustoDocument4 pagesHighway Testing Manual by Khanna and JustoSajjad Khan0% (3)

- Overcoming Post COVID19 Challenges Through Design AlternativesDocument16 pagesOvercoming Post COVID19 Challenges Through Design AlternativesaarivalaganNo ratings yet

- Project Planning & MonitoringDocument19 pagesProject Planning & MonitoringMahesh KurkundaNo ratings yet

- IPC-50 Month of Oct-2011 - SubmissionDocument149 pagesIPC-50 Month of Oct-2011 - SubmissionnandiniNo ratings yet

- Thumb RuleDocument13 pagesThumb RuleAtiqur RahmanNo ratings yet

- Visvesvaraya Technological University BELAGAVI-590018: Seminar Report On White Topping On Bituminous RoadDocument43 pagesVisvesvaraya Technological University BELAGAVI-590018: Seminar Report On White Topping On Bituminous RoadRutu YalasangiNo ratings yet

- As Inspected by Mr. N.Dhamarajan Senior Pavement SpecialistDocument14 pagesAs Inspected by Mr. N.Dhamarajan Senior Pavement SpecialistBIJAY KRISHNA DASNo ratings yet

- Bridge SOR 20-21Document26 pagesBridge SOR 20-21Venkat PaladuguNo ratings yet

- Dinesh ParmarDocument9 pagesDinesh ParmarjalkunjNo ratings yet

- Presentation On Reinforcing Detailing of R.CDocument16 pagesPresentation On Reinforcing Detailing of R.CbertazcorpNo ratings yet

- Laying of CC Road From Srinivas Naik (H) To Malyanaik (H) of Utakunta Thanda (V) of Narayanpet (M)Document3 pagesLaying of CC Road From Srinivas Naik (H) To Malyanaik (H) of Utakunta Thanda (V) of Narayanpet (M)K KARTHIKNo ratings yet

- Design of Thin White Topping Pavement PDFDocument20 pagesDesign of Thin White Topping Pavement PDFChetan RaulkarNo ratings yet

- SMG-SI-10-DG-002-A3 - SHT 81-100 - Rev.1Document27 pagesSMG-SI-10-DG-002-A3 - SHT 81-100 - Rev.1aan zulwiNo ratings yet

- Typical Road Structure Cross SectionDocument5 pagesTypical Road Structure Cross SectionAKMALNo ratings yet

- Ashok Kumar Bridge EngineerDocument12 pagesAshok Kumar Bridge EngineerabhilashNo ratings yet

- NDT Test Report PDFDocument5 pagesNDT Test Report PDFTGSPL -PART CNo ratings yet

- Ballast Formation and DrainageDocument71 pagesBallast Formation and DrainageVijay Kumar ChoudharyNo ratings yet

- National Highways Authority of IndiaDocument7 pagesNational Highways Authority of IndiaskumarsrNo ratings yet

- Irc 028-1967Document16 pagesIrc 028-1967kruttika_apNo ratings yet

- Mohammad Taha CVDocument1 pageMohammad Taha CVmd taha100% (1)

- Non Destructive Testing MR NR PatilDocument8 pagesNon Destructive Testing MR NR PatilMaxwell RejilNo ratings yet

- PILE LOAD TEST REPORT BR 22 InitialDocument33 pagesPILE LOAD TEST REPORT BR 22 InitialMohabbatNo ratings yet

- Plan and profile drawings from 0+000 to 09+600 kmDocument27 pagesPlan and profile drawings from 0+000 to 09+600 kmNilay GandhiNo ratings yet

- Bbs For BeamDocument14 pagesBbs For BeamprathikNo ratings yet

- WMM Mix DesignDocument23 pagesWMM Mix DesignjanardangaurNo ratings yet

- CI-PN-006 Construction Organ Plan - 0Document6 pagesCI-PN-006 Construction Organ Plan - 0ebsmsartNo ratings yet

- Concrete Mix Design M 35Document9 pagesConcrete Mix Design M 35Gurvinder Singh ChangNo ratings yet

- Specification, Analysis and Estimate On Road Works in OdishaDocument71 pagesSpecification, Analysis and Estimate On Road Works in OdishaTarandeep KaurNo ratings yet

- Road Various Detail RevDocument83 pagesRoad Various Detail RevCIVIL ENGINEERINGNo ratings yet

- 100 TOP Construction Planning and Management Interview Questions - Civil Engineering Objective Type Questions and AnswersDocument19 pages100 TOP Construction Planning and Management Interview Questions - Civil Engineering Objective Type Questions and AnswersImmuNo ratings yet

- Bridges & Structures PDFDocument6 pagesBridges & Structures PDFDeeptiranjan NagNo ratings yet

- S.No Item Description Bar Description Bar Dia in MM Cut Length (M) Total Length (M) WT/M (KG) Total WT (KG) Shape No. of BarsDocument6 pagesS.No Item Description Bar Description Bar Dia in MM Cut Length (M) Total Length (M) WT/M (KG) Total WT (KG) Shape No. of BarsshailendraNo ratings yet

- Methodology ConstructionDocument35 pagesMethodology ConstructionAnurag KumarNo ratings yet

- Price Escalation NewDocument26 pagesPrice Escalation Newgaurav jainNo ratings yet

- Ammendments IRC22 Aug2017Document68 pagesAmmendments IRC22 Aug2017sanjay rockzNo ratings yet

- 13+ Years Construction Project Engineer ResumeDocument5 pages13+ Years Construction Project Engineer Resumeanil mNo ratings yet

- Use of Fly Ash in Road Flyover Embankment Construction On NH Works Reg DT On 23rd October 2020 (1) - Compressed - Compressed PDFDocument27 pagesUse of Fly Ash in Road Flyover Embankment Construction On NH Works Reg DT On 23rd October 2020 (1) - Compressed - Compressed PDFLASA VADODARANo ratings yet

- RFI (TK01 Ringwall Rebar Form)Document16 pagesRFI (TK01 Ringwall Rebar Form)kimyeojunNo ratings yet

- 4-Laning of Old NH-6 from Km.296 to Km.304 in MaharashtraDocument75 pages4-Laning of Old NH-6 from Km.296 to Km.304 in Maharashtram_vamshikrishna22No ratings yet

- Value Engineering On Martadinata PamulanDocument7 pagesValue Engineering On Martadinata PamulanISHAQNo ratings yet

- Irjet V4i5540 PDFDocument5 pagesIrjet V4i5540 PDFMounika ReddyNo ratings yet

- A Study of Cost Comparison of Precast Concrete Vs Cast-In-Place ConcreteDocument11 pagesA Study of Cost Comparison of Precast Concrete Vs Cast-In-Place Concretepicses67890No ratings yet

- 8Document15 pages8api-3696315No ratings yet

- Irc 6-2016Document107 pagesIrc 6-2016Manvendra Nigam100% (26)

- Corbel DesignDocument107 pagesCorbel DesignMrJanji JohnyNo ratings yet

- Interpreter of MaladiesDocument50 pagesInterpreter of MaladiesmahakNo ratings yet

- 161620157356791Document5 pages161620157356791mahakNo ratings yet

- Design of Shallow FootingDocument28 pagesDesign of Shallow FootingDeepak Singh93% (14)

- Nirma Bus RoutesDocument2 pagesNirma Bus RoutesmahakNo ratings yet

- Elastic Analysis of Tall Reinforced Concrete Frames On Elastic Sub-Base"Document8 pagesElastic Analysis of Tall Reinforced Concrete Frames On Elastic Sub-Base"mahakNo ratings yet

- Beam Design: Beam Data Final ResultDocument2 pagesBeam Design: Beam Data Final ResultmahakNo ratings yet

- Bridge RuleDocument105 pagesBridge Ruleamawauce78% (9)

- CRAck WidthDocument4 pagesCRAck WidthmahakNo ratings yet

- fcu fy wc Ec column properties material section loading crackDocument2 pagesfcu fy wc Ec column properties material section loading crackprabhuNo ratings yet

- Design of Shallow FootingDocument28 pagesDesign of Shallow FootingDeepak Singh93% (14)

- 13Document18 pages13api-3696315No ratings yet

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- RCC Design 3/7Document18 pagesRCC Design 3/7Nandan Anil GaikwadNo ratings yet

- Wire Drawn Special Rod Wire Testing LaboratoryDocument2 pagesWire Drawn Special Rod Wire Testing Laboratoryarunt_19No ratings yet

- Determination of Netural Axis and Computing Moment of ResistanceDocument14 pagesDetermination of Netural Axis and Computing Moment of Resistanceshujah1106853No ratings yet

- Ahmedabad Station DBR 24.06.2018 R0 - DBR Comments Via Letter 220724-BLR-MEGA - 017Document40 pagesAhmedabad Station DBR 24.06.2018 R0 - DBR Comments Via Letter 220724-BLR-MEGA - 017mahakNo ratings yet

- Tran To Pdgec 01 09 2017Document3 pagesTran To Pdgec 01 09 2017mahakNo ratings yet

- Nirma Bus RoutesDocument2 pagesNirma Bus RoutesmahakNo ratings yet

- Bangalore Metro DBRDocument30 pagesBangalore Metro DBRmahakNo ratings yet

- Is 6006 1983Document22 pagesIs 6006 1983kannankrivNo ratings yet

- A-IX IRL Comments On Model DBRDocument4 pagesA-IX IRL Comments On Model DBRmahakNo ratings yet

- SP16-Design Aid For RC To IS456-1978Document252 pagesSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- Comparative Study For Shear Design Using IRC 112 2011 IRC 21 2000 PDFDocument4 pagesComparative Study For Shear Design Using IRC 112 2011 IRC 21 2000 PDFrammirisNo ratings yet

- AFC 528 Revised Design ManualCut & Cover StruDocument51 pagesAFC 528 Revised Design ManualCut & Cover Strumahak100% (1)

- 03-Heat Release in CombustionDocument44 pages03-Heat Release in CombustionEvi SiswantoNo ratings yet

- A-IX IRL Comments On Model DBRDocument4 pagesA-IX IRL Comments On Model DBRmahakNo ratings yet

- Solvex BrochureDocument1 pageSolvex BrochureBobby KambodiansyahNo ratings yet

- Jibon Kumar GhoshDocument2 pagesJibon Kumar GhoshArshad SadatNo ratings yet

- Idm 2018Document433 pagesIdm 2018veevthummuri100% (1)

- 1601352-BFP-046 - Recommended Operational Spare Parts For BFP - Rev.CDocument2 pages1601352-BFP-046 - Recommended Operational Spare Parts For BFP - Rev.CMena KamelNo ratings yet

- ChE 101 - Fundamentals of Chemical Engineering: Drying ProblemDocument3 pagesChE 101 - Fundamentals of Chemical Engineering: Drying Problemggwp21No ratings yet

- CCV Databook (15.04.2011)Document50 pagesCCV Databook (15.04.2011)Hasan WanandiNo ratings yet

- Designing CO2 Evaporators for Refrigeration SystemsDocument29 pagesDesigning CO2 Evaporators for Refrigeration SystemsgamunozdNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- Case Study of Urea Reactor Explosion in Lake Charles USADocument50 pagesCase Study of Urea Reactor Explosion in Lake Charles USAGhulam AhmadNo ratings yet

- Dy6003 Hs 094 1g Pu Rubber s1 SRC SizeDocument1 pageDy6003 Hs 094 1g Pu Rubber s1 SRC SizemayNo ratings yet

- Corbel designDocument4 pagesCorbel designnonameNo ratings yet

- Bus Station Design ElementsDocument31 pagesBus Station Design ElementsRapha RachoNo ratings yet

- Aalco Aluminium PDFDocument33 pagesAalco Aluminium PDFMihai NedeaNo ratings yet

- Table of Contents for Elevator Design and Installation StandardsDocument60 pagesTable of Contents for Elevator Design and Installation Standardspastorgee50% (2)

- Registry of Accredited Competency Assessment Centers 082013Document117 pagesRegistry of Accredited Competency Assessment Centers 082013Erickson CastilloNo ratings yet

- ASTM D95 Water ContentDocument6 pagesASTM D95 Water ContentMuhammad Syarif Hidayatullah100% (1)

- Tamilnadu Engineering Admissions 2011 - Information About The CollegesDocument288 pagesTamilnadu Engineering Admissions 2011 - Information About The CollegeskayalonthewebNo ratings yet

- Electrical Engineer Job Jebel AliDocument1 pageElectrical Engineer Job Jebel AliPrakash SelvarajNo ratings yet

- ME1Document41 pagesME1Hardik JogranaNo ratings yet

- Gas Turbine ManualDocument32 pagesGas Turbine ManualmilecsaNo ratings yet

- Sounding Boat EnggDocument2 pagesSounding Boat EnggRaja VelNo ratings yet

- Sample Project Completion ReportDocument1 pageSample Project Completion ReportAndroNo ratings yet

- Guidelines For Health Check Report: 1. Cover PageDocument6 pagesGuidelines For Health Check Report: 1. Cover Pageanon_516655412No ratings yet

- Orona and Lasma Reatment: N VerviewDocument25 pagesOrona and Lasma Reatment: N VerviewRaja Pathamuthu.G0% (1)

- 1135 PDF TocDocument4 pages1135 PDF TocAlex DicuNo ratings yet

- Lecture 9 - Construction Cost EstimatesDocument32 pagesLecture 9 - Construction Cost Estimatesjbjuanzon100% (1)

- 330-333 Elx PDFDocument178 pages330-333 Elx PDFNagendra Kumar PatelNo ratings yet

- Catalogobel ArtDocument68 pagesCatalogobel ArtluevanoNo ratings yet

- Program Imc Nov 2017 v2Document11 pagesProgram Imc Nov 2017 v2Alvaro Balvin VelasquezNo ratings yet

- VIDA Phase 2 Brochure For WebDocument15 pagesVIDA Phase 2 Brochure For WebJaved Abdul JaleelNo ratings yet