Professional Documents

Culture Documents

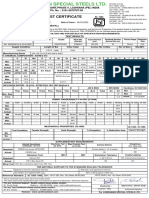

iNVENTA 515UL Material: Properties Values (Metric) Values (English) Test Method

Uploaded by

satheez3251Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

iNVENTA 515UL Material: Properties Values (Metric) Values (English) Test Method

Uploaded by

satheez3251Copyright:

Available Formats

iNVENTA 515UL Material

Properties Values (Metric) Values (English) Test Method

Tensile Strength 62 MPa. 8,500 psi D-638

Tensile Modulus 10,135 MPa. 1.47 X 106 psi D-638

Flex Strength 172 MPa. 24,500 psi D-790

6

Flex Modulus 10,342 MPa. 1.50 X 10 psi D-790

Izod Impact 694 J/m. 13 ft-lbs/in D-256A

Un-notched Izod 1015 J/m. 19 ft-lbs/in D-4812

% Elongation 1.5 1.5 D-638

Shrinkage mils/in -1.4 -1.4 ICOM 210-MIX-003

Specific Gravity 1.73 1.73 D-792

Glass Content % 22 22 D-2584

Flammability: UL Certification MFG Internal Test

94-5V @ 0.050 (2201)

Rockwell Hardness 78 78 D-785

Heat Deflection TemperatureC >300 >300 D-648

Moisture Absorption % 0.13 0.13 D-570

Approvals/Certifications:

• UL 94-5V Approved.

Applications: HVAC components such as condensate pans, HVAC bases and blower

housings. Electrical utility equipment. Automotive structural components. Other applications

where fire retardant characteristics are essential.

MFG offers a number of UL-approved formulations specifically designed for various

applications, and also support customer applications for specific UL approvals. Our

engineering and R&D laboratory is available to assist with evaluation, testing and certification

of material options that will result in the performance target you desire.

The values presented in this data sheet are typical values and are not to be interpreted as product specifications. All

statements, information and data given herein are believed to be accurate and reliable but are presented without guarantee,

express or implied. Data were obtained from laboratory test plaques and do not necessarily represent the values that will be

attained on molded part. Rev. 1 (4/20/2012)

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Property ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalDocument1 pageProperty ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalEktor RamirzNo ratings yet

- Mapex AN0320SN PDFDocument1 pageMapex AN0320SN PDFDiegoTierradentroNo ratings yet

- Rgf33 Natural New - Nominal PropDocument1 pageRgf33 Natural New - Nominal PropRanjan GnanaoliNo ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- Ptfe 25 GF 25 CF PDFDocument1 pagePtfe 25 GF 25 CF PDFseeralan_1986No ratings yet

- Engineering Data: GPO-3 8/11/2011 H900Document2 pagesEngineering Data: GPO-3 8/11/2011 H900Fernando OrtizNo ratings yet

- Mapex An0920sn 1Document1 pageMapex An0920sn 1Muhd IzzurinNo ratings yet

- PP - Braskem - CP 442 XP PDFDocument1 pagePP - Braskem - CP 442 XP PDFAdemilson Alves Dos SantosNo ratings yet

- ALATHON L5005 y CERTENE 122DDocument4 pagesALATHON L5005 y CERTENE 122DJuan Carlos Otero JaramilloNo ratings yet

- Compound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCDocument1 pageCompound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCBrian García AguirreNo ratings yet

- H 301-enUS-ASTMDocument1 pageH 301-enUS-ASTMfernandoincesaNo ratings yet

- Petrothene: High Density Polyethylene Blow Molding Grade Melt Index 0.35 Density 0.953Document1 pagePetrothene: High Density Polyethylene Blow Molding Grade Melt Index 0.35 Density 0.953Junior Lazaro AnticonaNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocument1 pageCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaNo ratings yet

- Product Data Sheet: Gulfsea Gear Oil SeriesDocument2 pagesProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanNo ratings yet

- PVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10Document1 pagePVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10JorgeLuisRiveraNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- DP03HDocument1 pageDP03HDiadam SharmaNo ratings yet

- Meco4000 WebDocument1 pageMeco4000 WebSh.nasirpurNo ratings yet

- High Density Polyethylene HC7260LS-L: DescriptionDocument1 pageHigh Density Polyethylene HC7260LS-L: DescriptionJaime222No ratings yet

- Petrothene: Low Density Polyethylene Film Extrusion GradeDocument1 pagePetrothene: Low Density Polyethylene Film Extrusion GradeGabriela Lopez MunozNo ratings yet

- Pghsim33 01NCDocument2 pagesPghsim33 01NCRanjan GnanaoliNo ratings yet

- SCH 40Document12 pagesSCH 40haithamNo ratings yet

- Sabic Lldpe MG200024: PolymersDocument2 pagesSabic Lldpe MG200024: PolymersYoshie IwaiNo ratings yet

- RTP 2500 FR ADocument2 pagesRTP 2500 FR ASoopNo ratings yet

- Pghsaw33 01BKDocument2 pagesPghsaw33 01BKRanjan GnanaoliNo ratings yet

- PVC Waterstop Technical Data SheetDocument1 pagePVC Waterstop Technical Data SheetPerla HernándezNo ratings yet

- M6007LDocument1 pageM6007LempacNo ratings yet

- Matrix EP and TK TDS 2035Document1 pageMatrix EP and TK TDS 2035Don HowardNo ratings yet

- Product Information: Crystal PolystyreneDocument1 pageProduct Information: Crystal PolystyreneEGNo ratings yet

- Hojas TécnicasDocument2 pagesHojas TécnicasalejandrocharlescollNo ratings yet

- PRB 0131-enUS-ASTMDocument1 pagePRB 0131-enUS-ASTMquanghoang10986No ratings yet

- High Impact Polystyrene: Product InformationDocument1 pageHigh Impact Polystyrene: Product InformationOswald SolorzanoNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- Lotte Titanpro PM903 Product DataDocument1 pageLotte Titanpro PM903 Product DataJoni Sie MssNo ratings yet

- Gearmate 1000 ICT TDS 3041Document1 pageGearmate 1000 ICT TDS 3041Don HowardNo ratings yet

- 3 NEPROPLAST CPVC PipesFlowGuard EmailDocument12 pages3 NEPROPLAST CPVC PipesFlowGuard EmailperezismaelNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- LLBF 122FDocument1 pageLLBF 122FYefrain J. ArzolayNo ratings yet

- Idemitsu Irg3 2t FC S S IdDocument2 pagesIdemitsu Irg3 2t FC S S IdyugihardiatnaNo ratings yet

- Corrapol Clear Corrugated Sheet Ranges Technical GuideDocument8 pagesCorrapol Clear Corrugated Sheet Ranges Technical GuideDavid Galvis VelozaNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- Molykote D 321R - BrochureDocument2 pagesMolykote D 321R - Brochuretaufik perdanaNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Terluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Jose VillarrealNo ratings yet

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuNo ratings yet

- Q8 Formula Special D1 5W-30: DescriptionDocument1 pageQ8 Formula Special D1 5W-30: DescriptionArief SuprayogoNo ratings yet

- Gear Shield NC PDS 4.19.18Document2 pagesGear Shield NC PDS 4.19.18JhinkuNo ratings yet

- CP 191-enUS-ASTMDocument1 pageCP 191-enUS-ASTMAndersonNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- Envirolube XE Extreme TDS 190828 203810Document1 pageEnvirolube XE Extreme TDS 190828 203810Don HowardNo ratings yet

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Galvanic CorrosionDocument5 pagesGalvanic Corrosionsatheez3251No ratings yet

- RBI Customer Service Guidelines Collated 2006-07Document104 pagesRBI Customer Service Guidelines Collated 2006-07satheez3251No ratings yet

- Sannce Home DVR User ManualDocument29 pagesSannce Home DVR User Manualsatheez3251No ratings yet

- Relay Module - PLC-RSC-24DC/21 - 2966171: Key Commercial DataDocument15 pagesRelay Module - PLC-RSC-24DC/21 - 2966171: Key Commercial Datasatheez3251No ratings yet

- Weforma 19 LDS PDFDocument19 pagesWeforma 19 LDS PDFsatheez3251No ratings yet

- Zinc ElectroplatingDocument1 pageZinc Electroplatingsatheez3251No ratings yet

- Interthane 990: Long Term Recoatability With AestheticsDocument2 pagesInterthane 990: Long Term Recoatability With Aestheticssatheez3251No ratings yet

- Mechanical Properties Enhancement of Al-Si (Adc12) Alloy by Heat TreatmentDocument5 pagesMechanical Properties Enhancement of Al-Si (Adc12) Alloy by Heat Treatmentsatheez3251No ratings yet

- Bonderite M-CR 1132: Aero/ Chromate CoatingDocument4 pagesBonderite M-CR 1132: Aero/ Chromate Coatingsatheez3251No ratings yet

- Getting Your Threads RightDocument4 pagesGetting Your Threads Rightsatheez3251No ratings yet

- Valvemag Articles 2003 2010Document8 pagesValvemag Articles 2003 2010satheez3251No ratings yet

- Derivation of Pressure Loss To Leak Rate Formula From The Ideal Gas LawDocument3 pagesDerivation of Pressure Loss To Leak Rate Formula From The Ideal Gas Lawsatheez3251No ratings yet

- Shell Rerinax EP-2 MSDSDocument7 pagesShell Rerinax EP-2 MSDSsatheez3251No ratings yet

- Quick ExhaustDocument2 pagesQuick Exhaustsatheez3251No ratings yet

- High Performance Lubricants Molykote: 55 O-Ring GreaseDocument2 pagesHigh Performance Lubricants Molykote: 55 O-Ring Greasesatheez3251No ratings yet

- Lubrication: Benefit in Using A Lubricant Is Obtained During The Installation of The O-RingDocument2 pagesLubrication: Benefit in Using A Lubricant Is Obtained During The Installation of The O-Ringsatheez3251No ratings yet

- Design - Bolt Design and Avoiding Failure PDFDocument5 pagesDesign - Bolt Design and Avoiding Failure PDFsatheez3251No ratings yet

- Bimetal ThermometerDocument3 pagesBimetal ThermometerfrenieNo ratings yet

- Shrinkage DefectsDocument11 pagesShrinkage DefectsMohsin Abbas100% (1)

- Gas Power Cycles: Diesel CycleDocument38 pagesGas Power Cycles: Diesel Cycleaamersid2882No ratings yet

- Effect of Shot Peening Operation On Gears PDFDocument9 pagesEffect of Shot Peening Operation On Gears PDFasdNo ratings yet

- Homework 4 - Transient Thermal Analysis of A Laptop StandDocument8 pagesHomework 4 - Transient Thermal Analysis of A Laptop Standapi-120516727No ratings yet

- Melting Point and Boiling PointDocument14 pagesMelting Point and Boiling PointMALOU ELEVERANo ratings yet

- CBSE Class12 Phy Part2Document28 pagesCBSE Class12 Phy Part2maniTifertNo ratings yet

- Dye Sensitized Solar CellDocument21 pagesDye Sensitized Solar CellMichel G. RahalNo ratings yet

- Velocity Pressure Method Calculation SheetDocument16 pagesVelocity Pressure Method Calculation SheetMahmud AnshoryNo ratings yet

- Advanced Ceramics - Material Matters v4n2Document28 pagesAdvanced Ceramics - Material Matters v4n2Sigma-Aldrich100% (1)

- Seakeeping LectureDocument30 pagesSeakeeping Lectureknowme73100% (1)

- Test Certificate: Highway Industries Ltd. (Sahnewal)Document1 pageTest Certificate: Highway Industries Ltd. (Sahnewal)Deepak MehtaNo ratings yet

- Tabla IEC 62219Document5 pagesTabla IEC 62219ManuelNo ratings yet

- Ac 800 Series BrochureDocument12 pagesAc 800 Series BrochureAnung PriyantoNo ratings yet

- MiniFlex Quick Reference Guide 2018 09 26 PDFDocument2 pagesMiniFlex Quick Reference Guide 2018 09 26 PDF123hohoa123No ratings yet

- Sifang Csc-211eb V1.06Document346 pagesSifang Csc-211eb V1.06MarkusKunNo ratings yet

- Technical Information: (A) (SF) (ST) (F)Document1 pageTechnical Information: (A) (SF) (ST) (F)johnNo ratings yet

- Ragone - Enunciados Problemas (Cap. 1 A 5)Document14 pagesRagone - Enunciados Problemas (Cap. 1 A 5)LucioNo ratings yet

- Astm D695 23Document7 pagesAstm D695 23Della MonicaNo ratings yet

- Physics ProjectDocument22 pagesPhysics Projectmokey420op100% (1)

- ShaliUrethane WPUDocument3 pagesShaliUrethane WPURana MahatoNo ratings yet

- Cellulose Acetate AdhesionDocument23 pagesCellulose Acetate AdhesionblackbutterflyNo ratings yet

- (2015) Study On Creep Property of Polyurethane CompositesDocument4 pages(2015) Study On Creep Property of Polyurethane CompositesPhamNo ratings yet

- Science Chapter - 10 NumericalDocument3 pagesScience Chapter - 10 NumericalDilip Kumar KumawatNo ratings yet

- Workbook Answers p2 Asal PhysicsDocument4 pagesWorkbook Answers p2 Asal PhysicsSaw Lip Xuan JeffNo ratings yet

- 1 3 Material BehaviorDocument30 pages1 3 Material Behaviorrowaters0% (1)

- Periodic Properties: Chapter HighlightsDocument26 pagesPeriodic Properties: Chapter HighlightsNatish JaglanNo ratings yet

- DPP 2 18TH April 2020Document10 pagesDPP 2 18TH April 2020gauravNo ratings yet

- Application of Composites For Centrifugal PumpsDocument4 pagesApplication of Composites For Centrifugal Pumpsravide76No ratings yet

- N30 Grade Neodymium Magnets DataDocument1 pageN30 Grade Neodymium Magnets DataSteve HsuNo ratings yet