Professional Documents

Culture Documents

WEG Guia de Instalacao pws5610 Quick Guide English PDF

Uploaded by

Ágó AttilaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WEG Guia de Instalacao pws5610 Quick Guide English PDF

Uploaded by

Ágó AttilaCopyright:

Available Formats

Installation Guide

1 Safety Precautions Dismantling and Scrapping 4 Grounding 6 Battery Replacement

– The PWS or parts thereof shall be recycled according to local regulations.

Both the installer, the owner, and the operator of this PWS must read and understand this installation manual.

– The following components contain substances that might be hazardous to health and the environment:

Make sure that the PWS works properly. To prevent it from radiating radio frequency noise, the PWS must be Steps to replace the battery:

connected to earth ground.

General lithium battery, electrolytic capacitor and display. 1. Use a screwdriver to loose the two screws and remove the back cover.

– Only qualified personnel may install or operate the PWS. – Without grounding, the PWS may be severely affected by excess noise. Make sure that the grounding is

Note: done properly from the power connector at the rear side of the PWS. When power is connected, make sure 2. Remove the battery and replace a new one (PN:CR-2032).

– The PWS must be installed according to the installation instructions. Indicated loss of life, severe personal injury, or substantial property damage that the wire is grounded.

– The PWS is designed for stationary installation on a plane surface, where the following conditions are ful- ! will result if proper precautions are not taken.

– Use a cable of at least 2 mm2 (AWG 14) to ground the PWS. Ground resistance must be less than 100

3. Re-assemble the back cover and tighten the two screws properly.

filled:

Ohms (class3). Note that the ground cable must not be connected to the same ground point as the power

• no high explosive risks

• no strong magnetic fields 2 Package Contents circuit.

• no direct sunlight

• no large, sudden temperature changes

5 Power Supply and Wiring

• for use in Pollution Degree 2 Environment 4 x Installation Fasteners

The PWS must use a power supply with 24 V DC and the power consumption is 8W.

• for use on the flat surface of a Type 1 enclosure

Warning:

– Never allow fluids, metal filings or wiring debris to enter any openings in the PWS. This may cause fire or To avoid an electric shock, be sure to switch off the power before connecting the communica-

electrical shock. tion/download cable to the PWS.

– The PWS fulfills the requirements of EMC directive 2004/108/EC. Warning:

– Storing the PWS where the temperature is lower/higher than recommended in this manual can cause the 1 x PWS5610

Steps to wire To avoid the loss of the data, be sure to check the power supply before replacing the battery!

LCD display liquid to congeal/become isotopic. 1. Unplug the power connector and unscrew the screws.

– The LCD display liquid contains a powerful irritant. In case of skin contact, wash immediately with plenty 2. Strip about 7-8mm of insulation. Insert the wire all the way into the power connector and then turn the

of water. In case of eye contact, hold the eye open, flush with plenty of water and get medical attention. screws tight. 7 External and Cut-out Dimensions

– The supplier is not responsible for modified, altered or reconstructed equipment.

1 x Power Connector 3. Plug in the connector to the power input of the PWS.

– Use only parts and accessories manufactured according to specifications of the supplier.

– Peripheral equipment must be appropriate for the application and location.

(wired to the power supply )

185,8+-0.5

Note:

– The figures in this manual serves an illustrative purpose. Because of the many variables associated with any Power connector is already plugged in the power input of the PWS when the package is first

particular installation, the supplier cannot assume responsibility for actual use based on the figures. 3 Mounting Procedure opened. 185

135,8+- 0.5

– The supplier neither guarantees that the PWS is suitable for your particular application, nor assumes re-

sponsibility for your product design, installation or operation. 1. Cut out the control front panel to match the dimensions (mm) specified under the External and Cut-out

dimensions chapter.

Power Source 2. Mount the PWS into the cut-out. Insert the fixtures to the holes on the unit and fasten the screws into

– The PWS is equipped with a 24 V DC input. Supply power other than 24 V DC ± 15% will severely dam- the front panel. Do not tighten the screws with too much or uneven force, or it may cause deformation

age the PWS. Thus, check the power supply supporting the DC power regularly. of the PWS. 40,2

– To avoid electric shock, be sure the power cable is unplugged from the power input when connecting the

CUTOUT DIMENSION

cable to the PWS.

STEP 1 STEP 2 STEP 3

195 (4)

Installation

– Communication cables must be separated from the power cables for operational circuits. Use shielded ca-

bles or it may cause unpredictable problems.

-

+

FG

145

135

During Use

90º

– Emergency stop and other safety functions may not be controlled from the PWS. DC 24V

– Do not use force or sharp objects when touching the keys, display etc. 135º

135º

Use Copper Conductors Only

y

Service and Maintenance

la

sp

Di

– Only qualified personnel should carry out repairs. (UNIT:mm)

– Before carrying out any cleaning or maintenance operations, disconnect the equipment from the electrical Wire Gauge

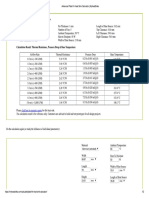

supply. Type Stripped Length Torque

Max torque: 0.3 Nm (2.65 lb-in) (AWG)

– Clean the display and surrounding front cover with a soft cloth and mild detergent. 0º Solid 28-12 7-8 mm 4.5 lb-in

– Replacing the battery incorrectly may result in explosion. Only use batteries recommended by the supplier. Display

Stranded 30-12 7-8 mm 4.5 lb-in

3. The PWS must be installed within an angle of 0° to 135° as shown above.

8 Description of Parts 9 Product Specifications 10 Communication Ports 11 Dip Switches

– COM 1 is a 9-pin female connector used to connect PLC via RS232, RS422, RS485 individually or sim-

Fixture Mounting Holes Item PWS5610T-S PWS5610S-S ulataneously in accordance with pin definition as "connection I" or "connection II". Dip Switches Function

Display Type Color STN LCD Mono STN LCD Please make sure that the connection is in accordance with the setting of the dip switches. For illustration on SW 1 Reserved

Display Color 256 colors 16 shades of blue the connection between the PWS and a controller, please consult the information on the controller. SW 2 Reserved

Display size 5.7” SW 3 SW 4 Operation Mode

Active area of display 115.2 x 86.4 mm Connection I: ON ON Runs user application

Display resolution 320 x 240, Number of 8 x 8 characters displayable 40 x 30 ON OFF Runs burn-in test program

Display adjustment - Via touch panel OFF ON Updates BIOS

Brightness adjustment Via touch panel OFF OFF Runs bench test program

Back light LED, Lifetime 50,000 hours @ 25°C LED, Lifetime 20,000 hours @ 25°C COM 1 SW 5 Communication Parameters

Touch Screen Analog ON The PWS uses parameters defined on the Configuration Screen for controller communica-

5 4 3 2 1

Input Power 24 V DC +-15%, less than 8W tions

Power Lamp Flash ROM 2 MB

9 8 7 6 OFF The PWS uses parameters defined in ADP for controller communications

RAM 512 KB SW 6 Password

CPU 32 bits RISC ON The PWS asks the operator to enter a password after power-on self-test

PIN Function

RTC YES OFF No password is required to start the PWS

1 RS422 TX+ (RS485 +) SW 7 System Menu

Data/Recipe 256 KB

2 RS232 RXD ON The PWS displays System Menu

COM1 9-pin female connector,(RS232/RS485/RS422 without RTS/CTS) or (RS232,COM2

RS422/RS485without RTS/CTS) 3 RS232 TXD OFF The PWS runs user application without displaying System Menu

Network Lamp 4 RS422 RX+

Front Panel seal IP65 SW 8 Default user level

Display 5 Signal ground

Ambient 0°C - 50°C ON The default user level is set to 1 if the PWS requires no password to start its opera-

temperature 6 RS422 TX- (RS485 -) tion(SW6 OFF)

Storage -10°C - 60°C 7 RS232 RTS OFF The default user level is set to 9 if the PWS requires no password to start its opera-

temperature 8 RS232 CTS tion(SW6 OFF)

Ambient humidity 10-90% RH(0°C~40°C),10-60% RH(41°C~50°C), non-condensing 9 RS422 RX- SW 9 COM 1 Port

Vibration endurance 0.5 mm displacement, 10-55 Hz, 2 hours per X, Y, Z axis directions ON For RS485 this switch has to be set ON

Shock endurance 10 G, 11 ms three times in each direction of X, Y, Z axes OFF For RS422 this switch has to be set OFF

Connection II:

CE EN61000-6-4,EN61000-6-2 SW 10 Reserved

External dimensions 195.0 x 145.0 x 40.2 mm

Dip Switches Cut-out dimensions 185.8 x 135.8 mm COM 1 COM 2

1-9 Weight 0.5 kg 0.55 kg

Cooling Natural cooling 5 4 3 2 1 5 4 3 2 1

9 8 7 6 9 8 7 6

Note:

When using the PWS for the first time, remember to reset Real Time Clock (RTC). PIN Function PIN Function

1 NC 1 RS422 TX+ (RS485 +)

2 RS232 RXD 2 NC

3 RS232 TXD 3 NC

4 NC 4 RS422 RX+

5 GND 5 GND

Beijer Electronics AB Beijer Electronics Corp.

6 NC 6 RS422 TX- (RS485 -) Box 426

DC Power 7&8F, No.108, Minquan Rd., Xindian City,

Outlet COM1 (RS232, RS422, RS485) 7 RS232 RTS 7 NC SE-201 24 Malmö, Sweden

Taipei County, Taiwan 23141

8 RS232 CTS 8 NC Tel: +46 40 35 86 00

Tel: +886-2-2218-3600

Fax: +46 40 93 23 01

9 NC 9 RS422 RX- Fax: +886-2-2218-9547

www.beijerelectronics.com www.beijerelectronics.com.tw

09/09/2010/V.1 561018+01

You might also like

- Rechargeable Battery UnitDocument24 pagesRechargeable Battery Unitprsking187No ratings yet

- Fan Uc Manuals 1790Document213 pagesFan Uc Manuals 1790Somchai SompongpuangNo ratings yet

- 6es7134 4GB11 0ab0 PDFDocument24 pages6es7134 4GB11 0ab0 PDFDeyanira Guzman EscobarNo ratings yet

- Power Mate H Motion CntrollerDocument448 pagesPower Mate H Motion CntrollerViru ShahNo ratings yet

- Fbox Series Instruction Manual: 二、InstallationDocument6 pagesFbox Series Instruction Manual: 二、Installationbassit82No ratings yet

- Ge Fanuc Automation: Powermotion ProductsDocument113 pagesGe Fanuc Automation: Powermotion ProductsEDUARDO PERFECTONo ratings yet

- F A N U C 5t 5mDocument5 pagesF A N U C 5t 5mmradivojeNo ratings yet

- THGT Series: Cylindrical Cased Axial Flow FansDocument42 pagesTHGT Series: Cylindrical Cased Axial Flow Fanszeljkogr100% (1)

- T B S G I M: IE AR Train AGE Nstruction AnualDocument22 pagesT B S G I M: IE AR Train AGE Nstruction Anualgilbert_28No ratings yet

- M.RT2261 (Without Audio) PDFDocument9 pagesM.RT2261 (Without Audio) PDFНиколайNo ratings yet

- JJ/JJJ-3x8000-XXX-KT-RDB G25-16-130211-8: Project Description Drawing Number Company / CustomerDocument23 pagesJJ/JJJ-3x8000-XXX-KT-RDB G25-16-130211-8: Project Description Drawing Number Company / CustomerМилен НиколовNo ratings yet

- Manual Prompt ErosionDocument118 pagesManual Prompt Erosionluis100% (1)

- SGDJ PDFDocument334 pagesSGDJ PDFDouglas Rogério de CastroNo ratings yet

- 63003en-1 01Document1,417 pages63003en-1 01Bobert HNo ratings yet

- Details PDF: Image Part Number Description Manufacturer QtyDocument1 pageDetails PDF: Image Part Number Description Manufacturer QtyPaulo Henrique Valério100% (1)

- Man Dds HardDocument418 pagesMan Dds HardVladNo ratings yet

- B-62114en 03 050120Document183 pagesB-62114en 03 050120CONG TRAN NGOCNo ratings yet

- CSD3 User ManualDocument294 pagesCSD3 User Manualcatur skak100% (1)

- capto主轴标准Document87 pagescapto主轴标准中国心No ratings yet

- ALARM 998 (Rom Parity Error) : Cause and Corrective ActionDocument1 pageALARM 998 (Rom Parity Error) : Cause and Corrective ActionPalaniappan SolaiyanNo ratings yet

- CACR-SR Alarm TroubleshootingDocument2 pagesCACR-SR Alarm TroubleshootingMladen Vujicic100% (1)

- Cncturret ManualDocument119 pagesCncturret Manualhariharan haranNo ratings yet

- Fronius Transtig 450Document53 pagesFronius Transtig 450dinescNo ratings yet

- Manual KeyenseDocument3 pagesManual KeyenseSergio Romano PadillaNo ratings yet

- Compatibility 5 4 3 0 Simotion Scout TiaDocument36 pagesCompatibility 5 4 3 0 Simotion Scout TiaRIDA EL-GHMARINo ratings yet

- PDFDocument224 pagesPDFSharkypeckyNo ratings yet

- B-64302en 01 100111 PDFDocument412 pagesB-64302en 01 100111 PDFDaud SaberNo ratings yet

- MELSEC-Q L Serial Communication Module User's Manual (Application) Dec 2014 PDFDocument422 pagesMELSEC-Q L Serial Communication Module User's Manual (Application) Dec 2014 PDFHoangTuanAnhNo ratings yet

- 3.24 980MD EnglishDocument348 pages3.24 980MD EnglishAbraham Tellez Flores100% (1)

- AC Servo Motor, Spindle, Amplifier βi PDFDocument222 pagesAC Servo Motor, Spindle, Amplifier βi PDFSang Nguyễn Bá100% (1)

- J4 Alarm ListDocument174 pagesJ4 Alarm ListElvira Nisa SNo ratings yet

- JR2000N BasicDocument44 pagesJR2000N BasicguillermoNo ratings yet

- Warner Bernstein 801 1Document4 pagesWarner Bernstein 801 1Juan Carlos EchevesteNo ratings yet

- 61393e OModelCD (107 197)Document91 pages61393e OModelCD (107 197)25 HanhaNo ratings yet

- Dell Inspiron 8200 SchematicsDocument51 pagesDell Inspiron 8200 SchematicscastelectorNo ratings yet

- Technical Manual: TNC 426 CB/PB/M TNC 430 CA/PA/MDocument1,129 pagesTechnical Manual: TNC 426 CB/PB/M TNC 430 CA/PA/MRafal FoxNo ratings yet

- 1hu3056 0af01 Z 8b93286701002imb5 DC Servo Motor Siemens Manual PDFDocument62 pages1hu3056 0af01 Z 8b93286701002imb5 DC Servo Motor Siemens Manual PDFEdwin RodríguezNo ratings yet

- Kent USA KGS818 1020AH AHD Operation ManualDocument75 pagesKent USA KGS818 1020AH AHD Operation ManualMohamed Shaban100% (1)

- Satchwell Unifact Pro Terminal Unit Controller For Sigma Systems Wiring & Commissioning Guide PDFDocument34 pagesSatchwell Unifact Pro Terminal Unit Controller For Sigma Systems Wiring & Commissioning Guide PDFGabor KomuvesNo ratings yet

- SMD-24B-2020-00 Driver: Basic Installation InstructionsDocument3 pagesSMD-24B-2020-00 Driver: Basic Installation InstructionsKien Nguyen TrungNo ratings yet

- EP3 Use ManualDocument321 pagesEP3 Use Manualalejandro becerraNo ratings yet

- Inverter Sumitomo Af3100Document20 pagesInverter Sumitomo Af3100FarizNo ratings yet

- Bobcat - tl360 TL470Document16 pagesBobcat - tl360 TL470YakupovmmNo ratings yet

- JP4 PDFDocument50 pagesJP4 PDFCarlos LourençoNo ratings yet

- VM1 PLWD r02x2-304Document241 pagesVM1 PLWD r02x2-304ag cnc & wedm machining shopNo ratings yet

- 896096-25 iTNC530 OEM HSCI PDFDocument112 pages896096-25 iTNC530 OEM HSCI PDFalanrinNo ratings yet

- Gorenje Tiki TGRDocument32 pagesGorenje Tiki TGRmiroslavNo ratings yet

- 6089-6090 Alarm List FanucDocument6 pages6089-6090 Alarm List FanucRicardo Jose PirelaNo ratings yet

- Ac70 Manual V1.0Document142 pagesAc70 Manual V1.0Thiện Lương MinhNo ratings yet

- Manual-DAIKIN Oil Cooling Unit AKZ9 Series - AKZ9 Manual - English PIM00318 - ADocument48 pagesManual-DAIKIN Oil Cooling Unit AKZ9 Series - AKZ9 Manual - English PIM00318 - AZoran VujadinovicNo ratings yet

- M00016896 取扱説明書(英文)Document81 pagesM00016896 取扱説明書(英文)brayan dearmasNo ratings yet

- Operators Manual: Victor 2 / Victor 2 Plus / Victor 2 SuperDocument55 pagesOperators Manual: Victor 2 / Victor 2 Plus / Victor 2 SuperToniNo ratings yet

- DCE Appendix BDocument19 pagesDCE Appendix Bnobamo100% (1)

- Kinco HMIware User ManualDocument536 pagesKinco HMIware User ManualRichard AvilezNo ratings yet

- Model PA1/PA3/SA1/SA2/SA3/SA5/ SB/SB2/SB3/SB4/SB5/SB6/SB7/ SC/SC3/SC4/NB/NB2/NB6Document506 pagesModel PA1/PA3/SA1/SA2/SA3/SA5/ SB/SB2/SB3/SB4/SB5/SB6/SB7/ SC/SC3/SC4/NB/NB2/NB6Mr TechNo ratings yet

- Service Manual: ModelDocument120 pagesService Manual: ModelRodolfo PinedaNo ratings yet

- B-65012E03 AC Spindle Motor Series (SPVH) Descriptions 1987Document322 pagesB-65012E03 AC Spindle Motor Series (SPVH) Descriptions 1987John BacsikNo ratings yet

- pws6600s SDocument1 pagepws6600s Spaino.paino67No ratings yet

- 1 Safety Precautions 4 Grounding 6 External and Cut-Out DimensionsDocument2 pages1 Safety Precautions 4 Grounding 6 External and Cut-Out DimensionsshankarNo ratings yet

- AS300 Operation ManualDocument422 pagesAS300 Operation ManualÁgó AttilaNo ratings yet

- AS300 Programming ManualDocument1,010 pagesAS300 Programming ManualÁgó AttilaNo ratings yet

- WEG Guia de Operacao Pws5610 Quick Guide EnglishDocument1 pageWEG Guia de Operacao Pws5610 Quick Guide EnglishÁgó AttilaNo ratings yet

- w342 E1 15+Cs CJ CP Nsj+ComrefmanualDocument268 pagesw342 E1 15+Cs CJ CP Nsj+ComrefmanualÁgó AttilaNo ratings yet

- VW Passat B5 Self Study Guide SP191Document122 pagesVW Passat B5 Self Study Guide SP191vasicata100% (5)

- Fec fc34Document76 pagesFec fc34Osvaldo GonzalezNo ratings yet

- AGC IPC Slash Sheet ReferenceDocument4 pagesAGC IPC Slash Sheet ReferenceSelvakumar NatarajanNo ratings yet

- Impact of Computer On SocietyDocument4 pagesImpact of Computer On SocietyraheelNo ratings yet

- MF 3854 WDDocument96 pagesMF 3854 WDRizwanAli100% (1)

- G M CryocoolerDocument22 pagesG M CryocoolerJaydeep PonkiyaNo ratings yet

- Statement of Purpose China PDFDocument2 pagesStatement of Purpose China PDFShannon RutanNo ratings yet

- Sensus WP Dynamic Cold Water Meter (DN40-300)Document4 pagesSensus WP Dynamic Cold Water Meter (DN40-300)Roderikus Rendy MNo ratings yet

- Guidelines For Hall IC SubassemblyDocument9 pagesGuidelines For Hall IC SubassemblyvkmsNo ratings yet

- Spam DetectionDocument142 pagesSpam DetectionRahul GantaNo ratings yet

- A Handbook of Livestock and Poultry Best Management PracticeDocument87 pagesA Handbook of Livestock and Poultry Best Management PracticeRaymond Katabazi100% (2)

- Manual de Serviço PDFDocument394 pagesManual de Serviço PDFMarcos Antonio de Souza JuniorNo ratings yet

- 26-789 Eng Manual Pcd3Document133 pages26-789 Eng Manual Pcd3Antun KoricNo ratings yet

- Guidelines For Xii Plan: Ther Backward Classes (Obc)Document15 pagesGuidelines For Xii Plan: Ther Backward Classes (Obc)SACHCHIDANAND PRASADNo ratings yet

- 1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)Document84 pages1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)khanh phanNo ratings yet

- 2006 AcrotechDocument32 pages2006 Acrotechkaniappan sakthivelNo ratings yet

- Manual de TallerDocument252 pagesManual de TallerEdison RodriguezNo ratings yet

- STLD Website User GuideDocument9 pagesSTLD Website User GuidemrmarcoscruzNo ratings yet

- Procedure Checklist For Fm200 InstallationDocument2 pagesProcedure Checklist For Fm200 InstallationJibril Lamai0% (1)

- Bobcat 3 Phase: Quick SpecsDocument4 pagesBobcat 3 Phase: Quick SpecsAnonymous SDeSP1No ratings yet

- Desktop 10 QA Exam Prep Guide PDFDocument16 pagesDesktop 10 QA Exam Prep Guide PDFShiva RungtaNo ratings yet

- Esu Tester WhoDocument5 pagesEsu Tester WhoquezonNo ratings yet

- JUNOS Cheat SheetDocument2 pagesJUNOS Cheat SheetJaeson VelascoNo ratings yet

- Trasdata HelpDocument4,852 pagesTrasdata HelpPaul Galwez75% (4)

- MSC BMT Excel Spreadsheet For Salmon FisheriesDocument10 pagesMSC BMT Excel Spreadsheet For Salmon FisheriesYamith.8210hotmail.com PedrozaNo ratings yet

- Customers at SurveyDocument10 pagesCustomers at Surveynaren000No ratings yet

- Advanced Plate Fin Heat Sink Calculator - MyHeatSinksDocument2 pagesAdvanced Plate Fin Heat Sink Calculator - MyHeatSinksHarsh BhardwajNo ratings yet

- JNTU Anantapur M.tech Syllabus For CSE CSDocument27 pagesJNTU Anantapur M.tech Syllabus For CSE CSRajkishore Reddy0% (1)

- BAERD GEN-007 Rev CDocument27 pagesBAERD GEN-007 Rev CPaulNo ratings yet

- Is Iec 60534 2 1 1998Document48 pagesIs Iec 60534 2 1 1998Sreeram PanigrahiNo ratings yet

- Course Recorder (Paperless) MDR290Document4 pagesCourse Recorder (Paperless) MDR290Jay SanchaniyaNo ratings yet

- Tiger SharkDocument2 pagesTiger Sharkstefanpl94No ratings yet