Professional Documents

Culture Documents

IP210

Uploaded by

vniranjanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IP210

Uploaded by

vniranjanCopyright:

Available Formats

Current To Pressure

(I/P) Converter

Control Air

3-15 to 3-120 psi

IP210 Series

U Loop Powered

U Ideal for Pneumatic

Control Systems

U IP65 Sealed Case

U Zero and Span

Adjustments for Field

Calibration

U Rugged Zinc-Cast IP210-X15 shown

Housing actual size.

A “current to pressure” converter

(I/P) converts an analog signal

(4 to 20 mA) to a proportional linear

pneumatic output (3 to 15 psig). Its

purpose is to translate the analog

output from a control system into The IP210 provides a reliable,

a precise, repeatable pressure repeatable, accurate means of

value to control pneumatic actuators/ converting an electrical signal

operators, pneumatic valves, into pneumatic pressure. Its force

dampers, vanes, etc. balance principle is a coil suspended

The IP210 is a loop-powered in a magnetic field on a flexible

instrument, which eliminates the mount. At the lower end of the coil

need for an external power supply is a flapper valve that operates Zero adjustment of the unit is made

(except for IP210-X120). against a precision ground nozzle to by turning a screw that regulates the

create a backpressure on the servo distance between the flapper valve

Principle of Operation and the air nozzle. Span adjustment

OMEGA’s IP210 converts an analog diaphragm of a booster relay.

is made by varying a potentiometer,

signal (4 to 20 mA) to a proportional The input current flows in the coil which shunts input current past the

linear pneumatic output (3 to 15 psig). and produces a force between the coil. An integral volume flow booster

Its uncomplicated design and proven coil and the flapper valve, which provides adequate flow capacity,

electromagnetic force balance controls the servo pressure and the resulting in fast response time and

deliver consistently high performance. output pressure. accurate control.

L-9

(SUPPLY PRESSURE 7 bar)

5

OUTLET PRESSURE (bar)

4

LOOP-POWERED Electropneumatic Control 1

0

0 100 200 300 400 500 600

FLOW (N/MIN)

RELIEF FLOW CHARACTERISTICS

(SUPPLY PRESSURE 7 bar)

8

OUTLET PRESSURE (bar)

Dimensions: mm (inch) 6

8

(0.31)

FORWARD FLOW CHARACTERISTICS 4

(SUPPLY PRESSURE 7 bar)

5

=

OUTLET PRESSURE (bar)

54 2

(2.1) 4

= 3 0

-700 -600 -500 -400 -300 -200 -100 0

FLOW (N/MIN)

2

73 (2.9) SPAN/ZERO ADJUSTMENTS

1

= = 20% OF

PLUG ORIENTS 4 WAYS 0 MAX OUTPUT

0 100 200 300 400 500 600 RANGE

61.5 (2.4) 54 (2.1)

FLOW (N/MIN)

RANGE OR SPAN = =

OUTLET

(TYPICAL) RELIEF FLOW CHARACTERISTICS PRESSURE

2 HOLES 06.5 mm

(SUPPLY PRESSURE 7 bar)

8

OUTLET PRESSURE (bar)

MIN

6

120 MIN MAX

(4.7) 4 INPUT SIGNAL

RANGE ZERO

67 (2.6)

2

51 REMOVABLE ORIFICE

(2) SUPPLY IN OUTPUT 0

-700 -600 -500 -400 -300 -200 -100 0

FLOW (N/MIN)

FRONT VIEW

SPAN/ZERO ADJUSTMENTS

MAX

20% OF

OUTPUT

ARTWORK/PRODUCT ART/ IP210graphs

RANGE

VALVES AND REGULATORS

OUTLET

PRESSURE

SPECIFICATIONS Media: Oil-free,

ARTWORK/PRODUCT ART/ IP210 dimensionsMIN clean, dry air filtered Failure Mode: Upon electrical failure,

Accuracy: 0.5% FS to 25 µm the signal pressure falls to bleed

Supply Sensitivity: 0.025% span RecommendedMIN Supply

INPUTPressure:

SIGNAL

MAX pressure

per % supply pressure change 25 to 30 psig (filtered air) Pressure Port: 1⁄4 FNPT

Zero Adjustment: 5% FS Max Supply Pressure: 80 psig Electrical Connection: DIN 43650

Span Adjustment: 20% FS (for IP210-X120: 135 psi) with screw terminals included

Operating Temp: Min Supply Pressure: 10 psi above Housing: IP65 rated, epoxy-painted

-20 to 70°C (-5 to 160°F) maximum output pressure zinc die castings

Compensated Temp: Air Consumption (Leakage): 0.03 scfm Construction: Nitrile diaphragms,

ARTWORK/PRODUCT

Flow Rate: 10 scfm ≤60 psi; ART/ IP210graphs

stainless steel/nylon flapper, nozzle and

-10 to 60°C (15 to 140°F)

0.06 >60 psi supply valve, integral surface mounting

Thermal Effects: bracket included

<0.1%/°C over operating range Response Time: <30 psi

Input Resistance: <300 Ω [less than 0.5 s (10 to 90% step);

≥30 psi: 2 s]

Weight: 1.7 kg (3 lb)

L

To Order

MODEL NO. INPUT RANGE OUTPUT RANGE

IP210-X15 4 to 20 mA 3 to 15 psig

IP210-X30 4 to 20 mA 3 to 30 psig

IP210-X60 4 to 20 mA 3 to 60 psig

IP210-X120 4 to 20 mA* 3 to 120 psig

* 3-wire system. External 24 Vdc power supply required.

Comes complete with operator’s manual.

Ordering Examples: IP210-X15, I/P converter, takes a 4 to 20 mA control signal and converts it into 3 to 15 psig control air.

IP210-X60, I/P converter, takes a 4 to 20 mA control signal and converts it into 3 to 60 psig control air.

L-10

You might also like

- TYPE 100X/101X Electro Mechanical Converters Current To Pressure (I/P) and Voltage To Pressure (E/P)Document20 pagesTYPE 100X/101X Electro Mechanical Converters Current To Pressure (I/P) and Voltage To Pressure (E/P)JabraneFatimiNo ratings yet

- Modular ValvesDocument67 pagesModular Valvesrodruren01No ratings yet

- Directional Control Valve: V20 SeriesDocument8 pagesDirectional Control Valve: V20 SeriesRAYNo ratings yet

- Control LoopDocument40 pagesControl LoopMoiz SiddiquiNo ratings yet

- Series 140-080-1800-A-1: Fan Diameter 55.125 Inches Air Density 0.075 Lbs./cu. FTDocument1 pageSeries 140-080-1800-A-1: Fan Diameter 55.125 Inches Air Density 0.075 Lbs./cu. FTmauricioperezimmNo ratings yet

- Mpa 4150Document149 pagesMpa 4150GrahamNo ratings yet

- Typical 400kV TRF (HV) Bay View (GIS MODULE)Document1 pageTypical 400kV TRF (HV) Bay View (GIS MODULE)Amarjit KulkarniNo ratings yet

- 5-Senctronic Valvula Proporcional PDFDocument6 pages5-Senctronic Valvula Proporcional PDFNICOLAS AMAYA USECHENo ratings yet

- 2 - Circuit Diagram ELRiDocument13 pages2 - Circuit Diagram ELRironaldo cordeiroNo ratings yet

- Control LoopsDocument40 pagesControl LoopssaadNo ratings yet

- EMKODocument5 pagesEMKOwaqas afzalNo ratings yet

- Electro-Pneumatic I/P, Ep Transducer: Model T7800 SeriesDocument11 pagesElectro-Pneumatic I/P, Ep Transducer: Model T7800 SeriesGilberto Meneses NavarroNo ratings yet

- sc1088 PDFDocument7 pagessc1088 PDFMariuszChreptakNo ratings yet

- Hydraulic Room Drawing PDF 3 ColourDocument1 pageHydraulic Room Drawing PDF 3 ColourKarthii AjuNo ratings yet

- Basic Control Systems Equipment and Terms Used IT02 Curriculum ManualDocument1 pageBasic Control Systems Equipment and Terms Used IT02 Curriculum Manualbaboiu electricNo ratings yet

- Ip210a Ip210Document3 pagesIp210a Ip210Tudor SasuNo ratings yet

- Pipe Layout 1Document1 pagePipe Layout 1azkrazy1No ratings yet

- Manual TP 245 3 Etapas A Polea (Murphy Horizontal) - Skid Dual-InglesDocument28 pagesManual TP 245 3 Etapas A Polea (Murphy Horizontal) - Skid Dual-InglesTucho TuchoNo ratings yet

- Centrifugal PumpsDocument1 pageCentrifugal PumpsJayath BogahawatteNo ratings yet

- Solair 3350 (Brochure)Document2 pagesSolair 3350 (Brochure)Validaciones VicarNo ratings yet

- Series 152-091-1800-A-2: Fan Diameter 60 Inches Air Density 0.075 Lbs./cu. FTDocument1 pageSeries 152-091-1800-A-2: Fan Diameter 60 Inches Air Density 0.075 Lbs./cu. FTmauricioperezimmNo ratings yet

- Chapter 11: Poppet Style Flow Controls: ObjectivesDocument16 pagesChapter 11: Poppet Style Flow Controls: ObjectivesSangmin KimNo ratings yet

- Recommended Inlet Feed and Gas Outlet Nozzles Momentum + Liquid Outlet Nozzle Velocity LimitsDocument1 pageRecommended Inlet Feed and Gas Outlet Nozzles Momentum + Liquid Outlet Nozzle Velocity LimitsHadi VeyseNo ratings yet

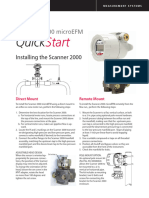

- Cameron Scanner 2000 Quick Start GuideDocument8 pagesCameron Scanner 2000 Quick Start GuidehectorivantovarjaimesNo ratings yet

- 100W Ultraminiature Open Frame Switching Power Supplies: SeriesDocument2 pages100W Ultraminiature Open Frame Switching Power Supplies: SeriesMartinNo ratings yet

- F125-3829 Hydraulic DiagramDocument3 pagesF125-3829 Hydraulic DiagramhacknoteNo ratings yet

- Industrial Peristaltic Pumps: RBT-25/B Data SheetDocument2 pagesIndustrial Peristaltic Pumps: RBT-25/B Data SheetSrpskiNo ratings yet

- ROLLER SHUTTER - 2WQWQW-ModelDocument1 pageROLLER SHUTTER - 2WQWQW-ModelSyed MuhammadNo ratings yet

- 789C Off-Highway Truck Hydraulic System: Tap Locations Pressure, Sampling and SensorDocument2 pages789C Off-Highway Truck Hydraulic System: Tap Locations Pressure, Sampling and SensorJuan Galleguillos VilchesNo ratings yet

- Sandvik: Control Circuit DiagramDocument1 pageSandvik: Control Circuit DiagramLUIS MICHAEL SUNI ILACHOQUENo ratings yet

- Regulators Edge 3 Series Regulators: Slam™Document1 pageRegulators Edge 3 Series Regulators: Slam™Dries VandezandeNo ratings yet

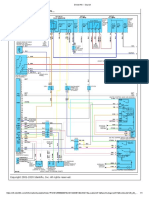

- 2020 I30 G 1.4 Mpi-DiagramDocument1 page2020 I30 G 1.4 Mpi-DiagramcarsexpressNo ratings yet

- ERA 340w PDFDocument1 pageERA 340w PDFSimon Aguado100% (1)

- Diagram 1 A/C AMPLIFIER ASSEM..Document2 pagesDiagram 1 A/C AMPLIFIER ASSEM..Jose HuescaNo ratings yet

- Lighting Layout Power Layout: Schedule of LoadsDocument1 pageLighting Layout Power Layout: Schedule of LoadsErnesto LopezNo ratings yet

- SENR33120001 - 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)Document2 pagesSENR33120001 - 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)CEVegaONo ratings yet

- SENR33120001 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)Document2 pagesSENR33120001 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)CEVegaONo ratings yet

- CPM1A-DA041: Operating ManualDocument2 pagesCPM1A-DA041: Operating Manualomnitech2No ratings yet

- Cat 226BDocument4 pagesCat 226BRajan MullappillyNo ratings yet

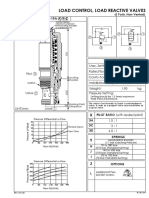

- Load Control, Load Reactive Valves: MB-19A-X-Y-ZDocument1 pageLoad Control, Load Reactive Valves: MB-19A-X-Y-ZIngenieriaNo ratings yet

- GROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVEDocument3 pagesGROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVERiahi RezegNo ratings yet

- Utility Service: Vicinity Map Service Entrance PoleDocument1 pageUtility Service: Vicinity Map Service Entrance Polejay vasquezNo ratings yet

- Flat Wakaf Mek Zainab P1Document1 pageFlat Wakaf Mek Zainab P1Nur NaziraNo ratings yet

- 700 Spec-1 PDFDocument2 pages700 Spec-1 PDFmarei mahgoobNo ratings yet

- Beffi @PERAT@ffi$ MWA: Il IlDocument5 pagesBeffi @PERAT@ffi$ MWA: Il IlAdam LimNo ratings yet

- Load Schedule: Ground Floor Lighting Layout Second Floor Lighting LayoutDocument1 pageLoad Schedule: Ground Floor Lighting Layout Second Floor Lighting Layoutnaynn.susuNo ratings yet

- Altima WiringDocument7 pagesAltima WiringwiccanwaysNo ratings yet

- Section-B: Fabricated Angle 44x37x5mmDocument4 pagesSection-B: Fabricated Angle 44x37x5mmshoebNo ratings yet

- 8M LP Design STRL+FDNDocument9 pages8M LP Design STRL+FDNSANJeEVNo ratings yet

- 303.5E2 CR EXCAVADORA Diagrama Electrico PDFDocument2 pages303.5E2 CR EXCAVADORA Diagrama Electrico PDFRICHARD100% (2)

- RBT 32B English PDFDocument2 pagesRBT 32B English PDF013Steeven RamzyNo ratings yet

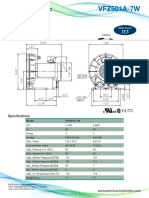

- Fuji Electric VFZ501A 7W DatasheetDocument2 pagesFuji Electric VFZ501A 7W Datasheetghmp123No ratings yet

- Accessories 7400Document4 pagesAccessories 7400Prakash KumarNo ratings yet

- Equalization Tank: Maynilad Water Services, IncDocument1 pageEqualization Tank: Maynilad Water Services, Inckaustavmukherjee1978No ratings yet

- DP40Document11 pagesDP40Yoyoo SusantoNo ratings yet

- Service Manual: KV-29FA350 KV-29FA350 KV-29FA750 KV-29FA750Document134 pagesService Manual: KV-29FA350 KV-29FA350 KV-29FA750 KV-29FA750CESARRRY72No ratings yet

- Sofar Data SheetDocument1 pageSofar Data SheetAB InteligentNo ratings yet

- Next Generation Robotics: Editorial Team: Henrik I Christensen, Allison Okamura, Maja Mataric, Vijay KumarDocument24 pagesNext Generation Robotics: Editorial Team: Henrik I Christensen, Allison Okamura, Maja Mataric, Vijay KumarvniranjanNo ratings yet

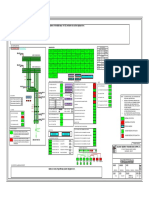

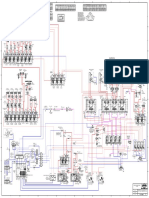

- Existing Air Line To 40psi Air Receiver 2Document3 pagesExisting Air Line To 40psi Air Receiver 2vniranjanNo ratings yet

- Introduction1989 Reprint PDFDocument15 pagesIntroduction1989 Reprint PDFvniranjanNo ratings yet

- Space ShuttleDocument28 pagesSpace ShuttlevniranjanNo ratings yet

- Space Plasma Physics: An Introduction: Basic Theoretical ConsiderationsDocument40 pagesSpace Plasma Physics: An Introduction: Basic Theoretical ConsiderationsvniranjanNo ratings yet

- Chapter 1. Collective Plasma PhenomenaDocument44 pagesChapter 1. Collective Plasma PhenomenavniranjanNo ratings yet

- Des Utility BMP Rev 3Document70 pagesDes Utility BMP Rev 3vniranjanNo ratings yet

- Piping Iso ChecklistDocument2 pagesPiping Iso Checklistvniranjan100% (1)

- Blower & ScrubberDocument15 pagesBlower & ScrubbervniranjanNo ratings yet

- Date L/T Content ResponsibleDocument20 pagesDate L/T Content ResponsiblevniranjanNo ratings yet

- Only.: Advanced ExcelDocument8 pagesOnly.: Advanced ExcelvniranjanNo ratings yet

- Thermodynamic Chart R22Document20 pagesThermodynamic Chart R22vniranjanNo ratings yet

- Wilf Book FlyerDocument4 pagesWilf Book FlyerEduardo Manuel Chávarry VelaNo ratings yet

- PanasonicBatteries NI-MH HandbookDocument25 pagesPanasonicBatteries NI-MH HandbooktlusinNo ratings yet

- DCPDocument3 pagesDCPAsima AtharNo ratings yet

- 01 IK IESYS e Communications OverviewDocument12 pages01 IK IESYS e Communications OverviewHernando AlborNo ratings yet

- Lit MotorsDocument11 pagesLit MotorsJohnson7893No ratings yet

- The Economic Essentials of Digital StrategyDocument13 pagesThe Economic Essentials of Digital StrategydhietakloseNo ratings yet

- Commissioning Template RevDocument17 pagesCommissioning Template Revelif maghfirohNo ratings yet

- American Panda Day 11 Lesson Condensed 2fadapted Eng482Document3 pagesAmerican Panda Day 11 Lesson Condensed 2fadapted Eng482api-296346559No ratings yet

- CH 01Document28 pagesCH 01Deepu MaroliNo ratings yet

- TripleA RuleBook PDFDocument52 pagesTripleA RuleBook PDFPete MousseauxNo ratings yet

- Error Rateio NorunDocument725 pagesError Rateio Norunmatheus felipeNo ratings yet

- CC 1352 PDocument61 pagesCC 1352 PGiampaolo CiardielloNo ratings yet

- TMB 60Document2 pagesTMB 60oac08No ratings yet

- t410 600w 4 Amp PDFDocument8 pagest410 600w 4 Amp PDFJose M PeresNo ratings yet

- Repair Manual For Claas Mega 202 218 Combine HarvesterDocument382 pagesRepair Manual For Claas Mega 202 218 Combine Harvesterramunas100% (7)

- OPA237Document21 pagesOPA237philprefNo ratings yet

- E DPT2020Document37 pagesE DPT2020arjuna naibahoNo ratings yet

- Recycled Concrete Roadbase Swis 4003Document45 pagesRecycled Concrete Roadbase Swis 4003Mircea BobarNo ratings yet

- WS 4 Minutes - 2.9.2019Document3 pagesWS 4 Minutes - 2.9.2019Andrea KakuruNo ratings yet

- Overheat Freeze Mechanisms of Solar CollectorsDocument5 pagesOverheat Freeze Mechanisms of Solar CollectorsJuli HasanajNo ratings yet

- 4 Power TransmissionDocument27 pages4 Power TransmissionMehmetNo ratings yet

- Senb8604 02 03 - 44607 PDFDocument125 pagesSenb8604 02 03 - 44607 PDFChristian BedoyaNo ratings yet

- Global Trends 2030 Preview: Interactive Le MenuDocument5 pagesGlobal Trends 2030 Preview: Interactive Le MenuOffice of the Director of National Intelligence100% (1)

- Technical Data: An Innovative & Cutting-Edge Digital Radiography SystemDocument12 pagesTechnical Data: An Innovative & Cutting-Edge Digital Radiography SystemJacques GamelinNo ratings yet

- MultimediaDocument4 pagesMultimediaMonica IsipNo ratings yet

- 010 Frank Sealing Systems 700BR01Document28 pages010 Frank Sealing Systems 700BR01Handy Han QuanNo ratings yet

- Shyla Jennings Ebook FinalDocument17 pagesShyla Jennings Ebook FinalChye Yong HockNo ratings yet

- Authentication MethodsDocument1 pageAuthentication MethodsmelocyNo ratings yet

- I Know Many BeginnersDocument5 pagesI Know Many BeginnersOsmar Tavares JuNo ratings yet

- It Implementation-Issues, Opportunities, Challenges, ProblemsDocument9 pagesIt Implementation-Issues, Opportunities, Challenges, ProblemsAnnonymous963258No ratings yet