Professional Documents

Culture Documents

BS 8110-97 PT-SL-001

Uploaded by

Bunkun15Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS 8110-97 PT-SL-001

Uploaded by

Bunkun15Copyright:

Available Formats

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

EXAMPLE BS 8110-97 PT-SL-001

Post-Tensioned Slab Design

PROBLEM DESCRIPTION

The purpose of this example is to verify the slab stresses and the required area of

mild steel strength reinforcing for a post-tensioned slab.

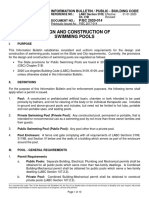

A one-way, simply supported slab is modeled in SAFE. The modeled slab is 254

mm thick by 914 mm wide and spans 9754 mm, as shown in shown in Figure 1.

Prestressing tendon, Ap

Mild Steel, As

229 mm

254 mm

25 mm

Length, L = 9754 mm 914 mm

Elevation Section

Figure 1 One-Way Slab

EXAMPLE BS 8110-97 PT-SL-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

A 254-mm-wide design strip is centered along the length of the slab and has been

defined as an A-Strip. B-strips have been placed at each end of the span,

perpendicular to Strip-A (the B-Strips are necessary to define the tendon profile).

A tendon with two strands, each having an area of 99 mm2, was added to the A-

Strip. The self-weight and live loads were added to the slab. The loads and post-

tensioning forces are as follows.

Loads: Dead = self weight, Live = 4.788 kN/m2

The total factored strip moments, required area of mild steel reinforcement, and

slab stresses are reported at the midspan of the slab. Independent hand calculations

have been compared with the SAFE results and summarized for verification and

validation of the SAFE results.

GEOMETRY, PROPERTIES AND LOADING

Thickness T, h = 254 mm

Effective depth d = 229 mm

Clear span L = 9754 mm

Concrete strength f 'c = 30 MPa

Yield strength of steel fy = 400 MPa

Prestressing, ultimate f pu = 1862 MPa

Prestressing, effective fe = 1210 MPa

Area of Prestress (single strand) Ap = 198 mm2

Concrete unit weight wc = 23.56 kN/m3

Modulus of elasticity Ec = 25000 N/mm3

Modulus of elasticity Es = 200,000 N/mm3

Poisson’s ratio ν = 0

Dead load wd = self kN/m2

Live load wl = 4.788 kN/m2

TECHNICAL FEATURES OF SAFE TESTED

Calculation of the required flexural reinforcement

Check of slab stresses due to the application of dead, live, and post-tensioning

loads.

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE total factored moments, required mild

steel reinforcing, and slab stresses with the independent hand calculations.

EXAMPLE BS 8110-97 PT-SL-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

Table 1 Comparison of Results

INDEPENDENT SAFE

FEATURE TESTED DIFFERENCE

RESULTS RESULTS

Factored moment,

174.4 174.4 0.00%

Mu (Ultimate) (kN-m)

Area of Mild Steel req’d,

19.65 19.79 0.71%

As (sq-cm)

Transfer Conc. Stress, top

−5.058 −5.057 0.02%

(D+PTI), MPa

Transfer Conc. Stress, bot

2.839 2.839 0.00%

(D+PTI), MPa

Normal Conc. Stress, top

−10.460 −10.465 0. 50%

(D+L+PTF), MPa

Normal Conc. Stress, bot

8.402 8.407 0.06%

(D+L+PTF), MPa

COMPUTER FILE: BS 8110-97 PT-SL-001.FDB

CONCLUSION

The SAFE results show an acceptable comparison with the independent results.

EXAMPLE BS 8110-97 PT-SL-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

HAND CALCULATIONS:

Design Parameters:

Mild Steel Reinforcing Post-Tensioning

f cu = 30 MPa f pu = 1862 MPa

fy = 400 MPa f py = 1675 MPa

Stressing Loss = 186 MPa

Long-Term Loss = 94 MPa

f i = 1490 MPa

f e = 1210 MPa

γm, steel = 1.15

γm, concrete = 1.50

Prestressing tendon, Ap

Mild Steel, As

229 mm

254 mm

25 mm

Length, L = 9754 mm 914 mm

Elevation Section

Loads:

Dead, self-wt = 0.254 m x 23.56 kN/m3 = 5.984 kN/m2 (D) x 1.4 = 8.378 kN/m2 (D u )

Live, = 4.788 kN/m2 (L) x 1.6 = 7.661 kN/m2 (Lu )

Total = 10.772 kN/m2 (D+L) = 16.039 kN/m2 (D+L)ult

ω =10.772 kN/m2 x 0.914m = 9.846 kN/m, ωu = 16.039 kN/m2 x 0.914m = 14.659 kN/m

wl12

Ultimate Moment, M U = = 14.659 x (9.754)2/8 = 174.4 kN-m

8

7000 f pu Ap

Ultimate Stress in strand, f pb =+

f pe 1 − 1.7

l/d f cu bd

7000 1862(198)

=

1210 + 1 − 1.7

9.754 / 0.229 30(914)(229)

= 1358 MPa ≤ 0.7 f pu

= 1303 MPa

EXAMPLE BS 8110-97 PT-SL-001 - 4

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

K factor used to determine the effective depth is given as:

M 174.4

K= = = 0.1213 < 0.156

30000 ( 0.914 )( 0.229 )

2 2

f cu bd

K

z = d 0.5 + 0.25 − ≤ 0.95d = 192.2 mm

0 . 9

Ultimate force in PT, =Fult , PT A=

P ( f PS ) 197.4 (1303=) 1000 257.2 KN

=

Ultimate moment due to PT, ult , PT ( z ) / γ

M ult , PT F= 257.2 ( 0.192

= ) 1.15 43.00 kN-m

= MU − M PT

Net Moment to be resisted by As, M NET

= 174.4 − 43.00 = 131.40 kN-m

The area of tensile steel reinforcement is then given by:

M NET 131.4

As = = (1e6 ) = 1965 mm 2

0.87 f y z 0.87 ( 400 )(192 )

Check of Concrete Stresses at Midspan:

Initial Condition (Transfer), load combination (D+PT i ) = 1.0D+0.0L+1.0PT I

Tendon stress at transfer = jacking stress − stressing losses = 1490 − 186 = 1304 MPa

The force in the tendon at transfer, = 1304 (197.4 ) 1000 = 257.4 kN

Moment= =

due to dead load, M D 5.984 ( 0.914 )( 9.754 ) 8 65.04 kN-m

2

Moment due to PT, = M PT F=

PTI (sag) 257.4 (102mm =) 1000 26.25 kN-m

FPTI M D − M PT −257.4 65.04 − 26.23

Stress in concrete, f = ± = ±

A S 0.254 ( 0.914 ) 0.00983

where S=0.00983m3

f = −1.109 ± 3.948 MPa

f = −5.058(Comp) max, 2.839(Tension) max

Normal Condition, load combinations: (D+L+PT F ) = 1.0D+1.0L+1.0PT F

Tendon stress at Normal = jacking − stressing − long-term = 1490 − 186 − 94= 1210 MPa

The force in tendon at Normal, = 1210 (197.4 ) 1000 = 238.9 kN

Moment= =

due to dead load, M D 5.984 ( 0.914 )( 9.754 )2 8 65.04 kN-m

Moment= =

due to live load, M L 4.788 ( 0.914 )( 9.754 )2 8 52.04 kN-m

Moment due to PT, =

M PT F=

PTI (sag) 238.9 (102 mm

= ) 1000 24.37 kN-m

EXAMPLE BS 8110-97 PT-SL-001 - 5

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

Stress in concrete for (D+L+PT F ),

FPTI M D + L − M PT −238.8 117.08 − 24.37

f = ± = ±

A S 0.254 ( 0.914 ) 0.00983

f = −1.029 ± 9.431

f = −10.460(Comp) max, 8.402(Tension) max

EXAMPLE BS 8110-97 PT-SL-001 - 6

You might also like

- Intake Tower Existing DamDocument3 pagesIntake Tower Existing DamBunkun15No ratings yet

- How To Construct A Concrete Swimming Pool - (PDF) - The ConstructorDocument13 pagesHow To Construct A Concrete Swimming Pool - (PDF) - The ConstructorBunkun15No ratings yet

- Guide To Standards-Pools and SpasDocument15 pagesGuide To Standards-Pools and SpasMIguel HazNo ratings yet

- Swimming Pool Details Structures SampleDocument1 pageSwimming Pool Details Structures SampleBunkun15100% (3)

- Industrial BuildingsDocument2 pagesIndustrial BuildingsBunkun15No ratings yet

- Design and Construction of Swimming Pools-Ib-P-Bc2017 014Document10 pagesDesign and Construction of Swimming Pools-Ib-P-Bc2017 014Luffy11No ratings yet

- Checklist ResPoolsDocument7 pagesChecklist ResPoolsBunkun15No ratings yet

- Swimming Pool Roofing OptionsDocument2 pagesSwimming Pool Roofing OptionsBunkun15100% (1)

- Basic Requirements in Swimming Pool Construction - The ConstructorDocument10 pagesBasic Requirements in Swimming Pool Construction - The ConstructorBunkun15No ratings yet

- Title - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsDocument24 pagesTitle - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsBunkun15No ratings yet

- Swimming Pool Site PlanDocument1 pageSwimming Pool Site PlanBunkun15No ratings yet

- Swimming Pool Sample LayoutsDocument1 pageSwimming Pool Sample LayoutsBunkun15No ratings yet

- Basements For HousingDocument2 pagesBasements For HousingBunkun15No ratings yet

- HealthcareDocument3 pagesHealthcareBunkun15No ratings yet

- Swimming Pool & Spa Safety: PurposeDocument12 pagesSwimming Pool & Spa Safety: PurposekenNo ratings yet

- University OrganogramDocument1 pageUniversity OrganogramBunkun15No ratings yet

- HotelsDocument2 pagesHotelsBunkun15No ratings yet

- EducationDocument3 pagesEducationBunkun15No ratings yet

- Pc-I (Infrastructure-Proforma For Development Projects)Document12 pagesPc-I (Infrastructure-Proforma For Development Projects)Haider IqbalNo ratings yet

- Designing Resilient HomesDocument2 pagesDesigning Resilient HomesBunkun15No ratings yet

- Residential - Low-RiseDocument4 pagesResidential - Low-RiseBunkun15No ratings yet

- CommercialDocument3 pagesCommercialBunkun15No ratings yet

- Starting A Bookstore BusinessDocument11 pagesStarting A Bookstore BusinessBunkun15No ratings yet

- Stable Sprayed ConcreteDocument2 pagesStable Sprayed ConcreteBunkun15No ratings yet

- How To Start A Bookstore BusinessDocument5 pagesHow To Start A Bookstore BusinessBunkun15No ratings yet

- Imperial College of Business Studies Employment Application FormDocument3 pagesImperial College of Business Studies Employment Application FormBunkun15No ratings yet

- 4 Ways To Book PublishingDocument7 pages4 Ways To Book PublishingBunkun15No ratings yet

- ICBS Faculty Positions in Engineering, Business, SciencesDocument1 pageICBS Faculty Positions in Engineering, Business, SciencesBunkun15No ratings yet

- Anchorage Detail of Column at Top FloorDocument5 pagesAnchorage Detail of Column at Top FloorBunkun15No ratings yet

- Unifrom Load Partially Distributed at Left EndDocument1 pageUnifrom Load Partially Distributed at Left EndBunkun15No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Engineering Calculations SpreadsheetDocument2 pagesEngineering Calculations Spreadsheetraghav abudhabiNo ratings yet

- Tube FlaringDocument7 pagesTube FlaringDan WolfNo ratings yet

- Peng2019 PDFDocument7 pagesPeng2019 PDFRoja AllampallyNo ratings yet

- C9 PDFDocument36 pagesC9 PDFpaulkohanNo ratings yet

- Kolej Yayasan Pelajaran Johor Assignment 3 Sesi Ogos/September 2021Document8 pagesKolej Yayasan Pelajaran Johor Assignment 3 Sesi Ogos/September 2021koko sampNo ratings yet

- ASTM D 2899 - 01 Establishing Allowable Stresses For Round Timber PilesDocument6 pagesASTM D 2899 - 01 Establishing Allowable Stresses For Round Timber Pilesalin2005No ratings yet

- 4-Bending of Straight Beams PDFDocument39 pages4-Bending of Straight Beams PDFMohamad ZaidNo ratings yet

- Experiment No: - 03 Name of Experiment: - The Torsion System. ObjectivesDocument7 pagesExperiment No: - 03 Name of Experiment: - The Torsion System. ObjectivesNewton ShikderNo ratings yet

- BTCVC701 - 1 Question PaperDocument1 pageBTCVC701 - 1 Question Paperस्नेहल पिंपळे शेळकेNo ratings yet

- Waves in Three-Dimensional Solid: A ElasticDocument22 pagesWaves in Three-Dimensional Solid: A ElasticaguiiahimNo ratings yet

- Flexural and Shear Performance of HFRC Beams with Steel, Glass, and Polypropylene FibersDocument5 pagesFlexural and Shear Performance of HFRC Beams with Steel, Glass, and Polypropylene FibersStephenNo ratings yet

- Thick Walled Cylinders (Plane Stress)Document16 pagesThick Walled Cylinders (Plane Stress)Alvaro FabianNo ratings yet

- Chapterwise Question bank-DSR-22502Document5 pagesChapterwise Question bank-DSR-22502soumyasonawane100% (1)

- Design 200x300 Column Flat FootingDocument5 pagesDesign 200x300 Column Flat FootingVAIBHAV KASHYAP U ce16b062No ratings yet

- Shear Connectors On Concrete-To-Concrete Interface Surfaces: A Numerical Investigation On 3D FramesDocument13 pagesShear Connectors On Concrete-To-Concrete Interface Surfaces: A Numerical Investigation On 3D FramesPedro SantosNo ratings yet

- Behaviour of Piles in Landslides and Slope ProtectionDocument27 pagesBehaviour of Piles in Landslides and Slope ProtectionAdityaputera WirawanNo ratings yet

- Welded FatigueDocument6 pagesWelded FatigueAlok SinghNo ratings yet

- Weld Stress UW-15 UW-18Document1 pageWeld Stress UW-15 UW-18muhammad hadiNo ratings yet

- External FrictionDocument2 pagesExternal FrictionRo AnNo ratings yet

- Earthpressures 2013 UpdatedDocument38 pagesEarthpressures 2013 UpdatedkartikkeyyanNo ratings yet

- Cost Estimate of Retaining Wall OptionsDocument3 pagesCost Estimate of Retaining Wall OptionsHoihogo HoiNo ratings yet

- Types of Deep FoundationsDocument98 pagesTypes of Deep FoundationsRuli Aprillianto67% (3)

- Design of Masonry Structures EC6Document136 pagesDesign of Masonry Structures EC6roscii100% (4)

- Spandrel Flexural Design: Technical NoteDocument11 pagesSpandrel Flexural Design: Technical Notetomxxx34No ratings yet

- Rotary kiln stressDocument6 pagesRotary kiln stressRachid Kheir100% (1)

- 3D Plane Stresses and Strains - QProducersDocument14 pages3D Plane Stresses and Strains - QProducersvickywce JadhavNo ratings yet

- CH 6Document25 pagesCH 6Bill WilliamsNo ratings yet

- Civil Engineering SyllabusDocument172 pagesCivil Engineering SyllabusGeorgy XavierNo ratings yet

- Material Requirements for Steel and Concrete StructuresDocument38 pagesMaterial Requirements for Steel and Concrete StructuresSimon LsmNo ratings yet