Professional Documents

Culture Documents

Installation Wiring Diagram for SD119 Series Smoke Detectors

Uploaded by

Victor PatsiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Wiring Diagram for SD119 Series Smoke Detectors

Uploaded by

Victor PatsiCopyright:

Available Formats

Photoelectric SD119 series

Smoke Detector Installation Wiring Diagram

TYPICAL WIRING DIAGRAM intended for mounting on a ceiling no less than 6

Figure 1.a shows the typical wiring diagram of 2-wire inches from a wall or mounting on a wall than no less

multiple-station smoke detector system. than 4 inches and no more than 12 inches from a

ceiling.

5. The base of smoke detector can be mounted directly

onto electrical junction box such as octagonal (3”, 3.5”

or 4”), round (3”), and square (4” length) box without

using any type of mechanical adapter.

INSTALLING THE HEAD

1. Align the components as shown in Figure 2.

2. Mate the detector head onto the base and twist

clockwise to secure it.

3. Do not install the detector head until the area is

thoroughly cleaned of construction debris, dusts, etc.

The maximum number of smoke detector installed in

the same loop is 30 units.

DO NOT USE LOOPED WIRE UNDER

TERMINALS 2 AND 5 BREAK WIRE RUN TO

PROVIDE SUPERVISION OF CONNECTIONS

Figure 1.b shows the typical wiring diagram of 4-wire

multiple-station smoke detector system.

Fig. 2 Mating detector head onto base

ADJUSTMENT OF THE RELAY POSITION

4-wire type: Adjust the relay set-position for wiring unit to

the security monitoring system by the following steps:

1. The reset position for the relays is at “normal open”

DO NOT USE LOOPED WIRE UNDER (NO) position, when energizing all the relays.

2. If one needs to adjust the relay set point, use a

TERMINALS 2 AND 5 BREAK WIRE RUN TO

screwdriver to loose two screws on the back of the

PROVIDE SUPERVISION OF CONNECTIONS base. See Figure 3, there is a jump head next to the

relay on the PCB, adjust it to select set point either

WARNING “normal close” (NC) or “normal open” (NO) position.

TO PREVENT DETECTOR CONTAMINATION 3. Relay contact rating:

1A @30VDC,

AND SUBSEQUENT WARRANTY 0.5A @125VAC.

CANCELL-TION, SMOKE DETECTOR MUST

REMAIN COVERED UNTIL AREA IS CLEAN

AND DUST FREE.

INSTALLING THE BASE

1. To insure proper installation of the detector head to the Fig. 3 Schematic of detector structure

base, all the wires should be properly addressed at When front cover is open

installation: TESTING

(A)Position all the wires flat against terminals. 1. All the alarm signal services, releasing device and

(B)Fasten the wires away from connector terminals. extinguisher system should be disengaged during the

2. If you use the jumper wire to connect the poles of test period and must be re-engaged immediately at the

terminal 2 and 5 when testing the detector loop conclusion of testing.

continuity, be sure to remove the jumper wire prior to

the installation of the detector head. 2. After energizing the detector head for approximately

3. The end-of-line device shown in Figure 1.a & 1.b one minute, check to see the indicator red LED

should be compatible with the control unit. The flashing once every 1~3 seconds. If red LED fails to

end-of-line supervisory relay used should list the rated flash, it indicates the non-functioning of the detector or

DC power voltage used. faulty wiring. Re-check the wiring or replace the

4. Per UL listing, open area smoke detectors are detector if necessary.

3. Allow smoke from a cotton wick or a punk to enter the NOTES FOR USING DETECTOR

detector’s sensing chamber for at least 10 seconds. The National Fire Protection Association (NFPA)

When sufficient smoke has entered the chamber, an states that duct smoke detector must not used as a

alarm signal will take place by indicating with a substitute for open area smoke detector. Duct smoke

continuous illumination of the LED. After it alarms, detector is solely intended to use in the air handing

Reset each detector and/or control unit before

equipments for such purposes like dampers or

attempting to test the additional detectors in the same

zone. If the alarm fails in this step, it indicates a

shutting down the air handing units.

defective unit, which requires service. NOT SUITABLE FOR INSTALLATION IN

AREAS WHERE AIR VELOCITIES EXCEED

HEAT SENSOR TESTING 300 ft/min.

The detector to be tested should be subject to a flow of

warm air at a temperature between 140℉ and 180℉. MAINTENANCE

Some domestic hair dryers can meet such requirement. The recommended minimum requirement for detector

Proceed as follows: maintenance consists of an annual cleaning of dust from

1. Switch on the warm airflow and check that temperature the detector head by using a vacuum cleaner cleaning

is correct and stable. program should be agreed to the individual environment

2. From a distance of inches, direct the airflow at the in conformance with NFPA-72A standard.

guard protecting the thermistor. The detector should

alarm within 30 seconds. CAUTION: DO NOT ATTEMPT TO REMOVE THE

3. When alarm is on, immediately remove the heat

SCREWS, WHICH HOLD THE ASSEMBLY OF

source and check that the detector’s red LED is lit.

SMOKE-SENSING CHAMBER AND PRINTED CIRCUIT

Reset the detector from the control panel.

BOARD (PCB). THIS ASSEMBLY IS SEALED FOR

4. If the detector fails to go into alarm within 30 seconds it

YOUR PROTECTION AND IS NOT INTENDED TO BE

is too insensitive and needs to be returned to the

distributor for servicing. SEPARATED FOR SERVICING BY USERS. OPENING

5. After testing check that the system is set for normal SUCH ASSEMBLY WILL VOID THE WARRANTY.

operation and notify the appropriate authorities that the

testing operation is complete and the system is active REFER TO THE TECHNICAL BULTTIN ISSUE NO.

again. STSD20080702S01, REV.D, July 02, 2008

SPECIFICATION

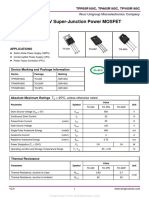

2/4 Heat Voltage Standby Alarm Surge Start-Up Permissible Cycle Alarm Base

Model wire Sensor DC Current Current Current Time Current Time contact Model No.

Setting (Min./Max.) (Max.) (12/24V) (Max.) (Max.) (Max.)

SD119-4H(12V) 4 135±5℉ 12V 80μA 30mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SD119-4H(24V) 4 135±5℉ 24V 80μA 45mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SD119-4 (12V) 4 - 12V 80μA 30mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SD119-4 (24V) 4 - 24V 80μA 45mA - 30 Sec. - 1-3 Sec. Form A P/N854001

SD119-2HL 2 135±5℉ 10.8~33V 80μA 22/55mA 160μA 30 Sec. 80mA 1-3 Sec. — P/N854001

SD119-2L 2 - 10.8~33V 80μA 22/55mA 160μA 30 Sec. 80mA 1-3 Sec. — P/N854001

SD119-2H 2 135±5℉ 10.8~33V 80μA 22/55mA 160μA 30 Sec. 80mA 1-3 Sec. — P/N852001

SD119-2 2 - 10.8~33V 80μA 22/55mA 160μA 30 Sec. 80mA 1-3 Sec. — P/N852001

Remark: L- remote indicator output; H-Heat sensor; AR-Auto-reset; B-Sound

2-wire devices are UL Recognized, the 4-wire devices are UL Listed

LIMITED WARRANTY STATEMENT

SENTEK ELECTRONICS INC. declares that this product is free from defects in material and workmanship. And it will repair

or replace any product or part thereof which proves to be defective in workmanship or material for a period of twelve (12)

months from the date of purchase but not to exceed eighteen (18) months after shipment by the manufacturer. For a full

description of SENTEK’S LIMITED WARRANTY, which, among other things, limits the duration of warranties of

merchantability and fitness for a particular purpose and excludes liability for consequential damages. Please read the entire

LIMITED WARRANTY on the SENTEK quotation. Acceptance of order and/or original invoice which will become part of your

sales agreement. Please contact SENTEK directly for a return merchandise authorization (RMA) number before returning

goods to the factory, Shipment must be prepaid and SENTEK will repair or replace your returned detector.

SDMI119080702, REV C

You might also like

- Highly accurate dual channel AC millivoltmeter for stereo audio measurementsDocument1 pageHighly accurate dual channel AC millivoltmeter for stereo audio measurementsazamamaNo ratings yet

- KOCOM Manual KVS-A4P+&+A8PDocument6 pagesKOCOM Manual KVS-A4P+&+A8Parranguezjr5991No ratings yet

- LG BH5140S PDFDocument109 pagesLG BH5140S PDFboroda2410100% (5)

- Solutions: Power ProtectionDocument47 pagesSolutions: Power Protectionkamil arnous100% (1)

- Spec For AS3693B1Document33 pagesSpec For AS3693B1tomlee888No ratings yet

- Specification and Functions of 15S Lithium Battery BMSDocument18 pagesSpecification and Functions of 15S Lithium Battery BMSRoberto Antonio Yance Hemer100% (2)

- Manual Usuario Rokonet Orbit ProDocument34 pagesManual Usuario Rokonet Orbit ProManuel Pezoa LacomaNo ratings yet

- Arduino Webserver DS18B20 POE ZABBIX Data LoggingDocument3 pagesArduino Webserver DS18B20 POE ZABBIX Data Loggingosadeamos8684No ratings yet

- Manual de Instalacion PC5108Document2 pagesManual de Instalacion PC5108Jairo Antonio Orellano ArbelaezNo ratings yet

- Led TV: Service ManualDocument53 pagesLed TV: Service ManualMauricio PérezNo ratings yet

- Marti RPT-30 User ManualDocument43 pagesMarti RPT-30 User ManualJose Carlos SoaresNo ratings yet

- Delixi Catalogue 2009Document112 pagesDelixi Catalogue 2009Radu_ISNo ratings yet

- Schneider Electronics Manual Provides Safety InstructionsDocument60 pagesSchneider Electronics Manual Provides Safety Instructionsjose4445No ratings yet

- A Survey of Neutral Currents in Three-PhaseDocument9 pagesA Survey of Neutral Currents in Three-PhaseImranul KarimNo ratings yet

- Catalogo Actualizado ChintDocument39 pagesCatalogo Actualizado Chint12dante1767% (3)

- Rhode5G+ - 22 (Moto g82 5G, XT2225) - Trouble-Shooting GuideDocument39 pagesRhode5G+ - 22 (Moto g82 5G, XT2225) - Trouble-Shooting GuideIgnacio Scalisi0% (1)

- Linear Integrated Circuit Tone RingerDocument3 pagesLinear Integrated Circuit Tone RingerLenon Salazar100% (1)

- 650V Super-Junction Power MOSFET: FeaturesDocument9 pages650V Super-Junction Power MOSFET: FeaturesAdalbertoRoque100% (1)

- PowerBeam PBE-5AC-620 QSGDocument28 pagesPowerBeam PBE-5AC-620 QSGJohan SatariNo ratings yet

- Catalogo He 2004Document85 pagesCatalogo He 2004ferenscribd0% (1)

- 0d347 Compal LA-6752P LA-6754P PDFDocument52 pages0d347 Compal LA-6752P LA-6754P PDFFrancisco FreemanNo ratings yet

- Sony BDP-S3100, S1100, BX110, BX310 PDFDocument68 pagesSony BDP-S3100, S1100, BX110, BX310 PDFboroda2410100% (1)

- Manual Teclado Ligthsys - RiscoDocument32 pagesManual Teclado Ligthsys - RiscoLuis Oliver Neciosup VasquezNo ratings yet

- PVM500/DIDRIVE10 Instructions For Conventional and Resonant LoadsDocument9 pagesPVM500/DIDRIVE10 Instructions For Conventional and Resonant Loadsmostafa1alaahobaNo ratings yet

- Mikroc GLCD Library PDFDocument12 pagesMikroc GLCD Library PDFKenaiNo ratings yet

- 8dtek KingkongDocument43 pages8dtek KingkongJuan ZapataNo ratings yet

- Samsung UN32D4000ND UN32D4010ND Chasis U59A PDFDocument26 pagesSamsung UN32D4000ND UN32D4010ND Chasis U59A PDFczarbrrj0% (1)

- Metercat 3.5.0.1 - Release Notes: Elster Solutions, LLCDocument7 pagesMetercat 3.5.0.1 - Release Notes: Elster Solutions, LLCLander Chavez SoplaNo ratings yet

- 01 EST3X Logical Addressing v6Document3 pages01 EST3X Logical Addressing v6Ahmed SweetNo ratings yet

- Nvf300 ManualDocument5 pagesNvf300 Manualjohnny paredes100% (2)

- PL10S - PL32S Solar Powered Low Intensity Single Obstruction Light - Datasheet - v202008v2Document2 pagesPL10S - PL32S Solar Powered Low Intensity Single Obstruction Light - Datasheet - v202008v2REDDOT SIGNALNo ratings yet

- Paso A Paso Radio ZteDocument31 pagesPaso A Paso Radio Ztecapulina1234+No ratings yet

- 9a6l4 A5 Vi 1000 Cable Futp SiemonDocument4 pages9a6l4 A5 Vi 1000 Cable Futp SiemonGabriel HaroNo ratings yet

- Nokia 220 Schematics v1.0Document8 pagesNokia 220 Schematics v1.0Riza Virsada100% (2)

- 4007-9810 Network Interface PDFDocument32 pages4007-9810 Network Interface PDFNarciso TorresNo ratings yet

- Yagi Antenna PaperDocument4 pagesYagi Antenna PaperJean Franco SánchezNo ratings yet

- Pioneer M-La21 SMDocument26 pagesPioneer M-La21 SMRichard100% (1)

- Manual de Reparacion Horno de Microondas Daewoo Smkor630&860aDocument33 pagesManual de Reparacion Horno de Microondas Daewoo Smkor630&860aErick Rodriguez100% (1)

- SIC9556ADocument9 pagesSIC9556AErik Dany LNo ratings yet

- TCL L55C1US Service ManualDocument30 pagesTCL L55C1US Service Manualpepe2176No ratings yet

- Wireless Alarm Hub with 32 Zones and Wi-Fi ConnectivityDocument1 pageWireless Alarm Hub with 32 Zones and Wi-Fi ConnectivityMinh TuNo ratings yet

- Sika Co.,Limited: Rs12Xxhxf Series 12A TriacsDocument4 pagesSika Co.,Limited: Rs12Xxhxf Series 12A TriacsPablo GuerraNo ratings yet

- HBD-TZ140 - (DAV-TZ140) Diagrama FuenteDocument1 pageHBD-TZ140 - (DAV-TZ140) Diagrama FuenteIngeniero Uvm100% (1)

- Kerberos TPB-E01 E02Document2 pagesKerberos TPB-E01 E02berkahharianNo ratings yet

- Gamewell 7100 Manual PDFDocument50 pagesGamewell 7100 Manual PDFHenrySiviraNo ratings yet

- User Configuration Manual Digital Relay ICS-W0813A V1Document17 pagesUser Configuration Manual Digital Relay ICS-W0813A V1Diego NavarreteNo ratings yet

- PM500 Datasheet PDFDocument8 pagesPM500 Datasheet PDFNASSERNo ratings yet

- Manual de Control Remoto Universal Rca en EspañolDocument2 pagesManual de Control Remoto Universal Rca en EspañolLivan Perez50% (2)

- Rane Ac23Document18 pagesRane Ac23dxnxbNo ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- DMAX DH-4326 ManualDocument2 pagesDMAX DH-4326 ManualMarcelo MachadoNo ratings yet

- Installation Wiring Diagram: DetectorDocument2 pagesInstallation Wiring Diagram: Detectorparallax1957No ratings yet

- TG - NB326 - S - Smoke DetectorDocument2 pagesTG - NB326 - S - Smoke DetectordepozitankoNo ratings yet

- Hd912 ManualDocument2 pagesHd912 ManualrhomadonaNo ratings yet

- RE316 Smoke and Heat Detector Wiring DiagramDocument2 pagesRE316 Smoke and Heat Detector Wiring DiagrammadhuNo ratings yet

- RE316 Smoke and Heat Detector Wiring DiagramDocument2 pagesRE316 Smoke and Heat Detector Wiring Diagramedwin_serpas2894No ratings yet

- GFE H ManualDocument2 pagesGFE H Manualparallax1957No ratings yet

- Smoke DetectorDocument2 pagesSmoke DetectoratharvawazurkarNo ratings yet

- Wizmart: Installation Wiring DiagramDocument2 pagesWizmart: Installation Wiring DiagramAlejandro CabreraNo ratings yet

- Class A Wiring Diagram PDFDocument2 pagesClass A Wiring Diagram PDFRodel D Dosano100% (2)

- Wireless Fixed Temperature Heat Alarm MODEL: WH588P-AF2/ WH588P-V3EDocument6 pagesWireless Fixed Temperature Heat Alarm MODEL: WH588P-AF2/ WH588P-V3EVictor PatsiNo ratings yet

- CETI UMSA 2-1 1era TareaDocument2 pagesCETI UMSA 2-1 1era TareaVictor PatsiNo ratings yet

- LH1000 FDocument1 pageLH1000 FVictor PatsiNo ratings yet

- IP Installer ManualDocument30 pagesIP Installer ManualOmar T. ALazzawiNo ratings yet

- Read MeDocument1 pageRead MeJessy RamirezNo ratings yet

- F6 Installation Guide V1.2-20120322 PDFDocument2 pagesF6 Installation Guide V1.2-20120322 PDFVictor PatsiNo ratings yet

- TFT Fingerprint V6 - 4 PDFDocument195 pagesTFT Fingerprint V6 - 4 PDFVictor PatsiNo ratings yet

- IN03、IN04 User Manual V1.0 PDFDocument82 pagesIN03、IN04 User Manual V1.0 PDFVictor PatsiNo ratings yet

- Voip BrochureDocument10 pagesVoip BrochureVictor PatsiNo ratings yet

- Mensaje ModeDocument2 pagesMensaje ModeVictor PatsiNo ratings yet

- ULN2004AC-inversor LvadoraDocument8 pagesULN2004AC-inversor Lvadoraarturo_hernandez_78No ratings yet

- Manual para Diebold Opteva ATMDocument26 pagesManual para Diebold Opteva ATMVictor Patsi100% (1)

- Robo Box3 ContructionEDocument36 pagesRobo Box3 ContructionEPato AcevedoNo ratings yet

- 01 - Gei-100472Document18 pages01 - Gei-100472abderrahmaneNo ratings yet

- 1 - Installation Manual - OTS3-LHD3 PDFDocument68 pages1 - Installation Manual - OTS3-LHD3 PDFMartin Basurto100% (1)

- International CatalogDocument16 pagesInternational CatalogDesmond KhorNo ratings yet

- Proline Prosonic Flow I 400 Ultrasonic Flowmeter for Water and WastewaterDocument4 pagesProline Prosonic Flow I 400 Ultrasonic Flowmeter for Water and WastewaterFun TonNo ratings yet

- Tse-A100 1-2002 PDFDocument2 pagesTse-A100 1-2002 PDFRegina OrtízNo ratings yet

- Pressure-Resistant Position Sensors From Ifm 2016 EnglishDocument4 pagesPressure-Resistant Position Sensors From Ifm 2016 Englishifm electronicNo ratings yet

- Ze03 Electrochemical Module Manualv2 - 5Document7 pagesZe03 Electrochemical Module Manualv2 - 5Ильнур ТагировNo ratings yet

- Olympus Thickness GagesDocument8 pagesOlympus Thickness GagessukimeNo ratings yet

- Search Point Optima Plus BrochureDocument6 pagesSearch Point Optima Plus BrochureAdam SaufiNo ratings yet

- Oven Setup Wizard ConfigurationDocument30 pagesOven Setup Wizard Configurationgsus kraz100% (1)

- Digiscan DS-324Document4 pagesDigiscan DS-324Nitesh SrivastavaNo ratings yet

- LPG Leakage Detector using Arduino SMS AlertDocument22 pagesLPG Leakage Detector using Arduino SMS Alertsifat islamNo ratings yet

- Explo ScanDocument4 pagesExplo ScanEngHusamAlhasaniNo ratings yet

- Ionocaloric Cooling and BiosensorsDocument13 pagesIonocaloric Cooling and Biosensorssrinath parvatineNo ratings yet

- A2 Ref 1Document8 pagesA2 Ref 1Alya WorkerNo ratings yet

- Hexoskin Patent PDFDocument34 pagesHexoskin Patent PDFSayantan RahaNo ratings yet

- Water Jacket Incubator Installation and Operation ManualDocument35 pagesWater Jacket Incubator Installation and Operation ManualCeleynes RTNo ratings yet

- Fire Detecting Robots PPT SeminarsDocument17 pagesFire Detecting Robots PPT Seminarssatyam_venkat02350% (2)

- Murphy - Controlador EMS 447 - Sales BulletinDocument2 pagesMurphy - Controlador EMS 447 - Sales BulletinJohn Jairo Simanca CastilloNo ratings yet

- Tekmar 1773 - 2Document16 pagesTekmar 1773 - 2Danko ErićNo ratings yet

- Brosur Heart-Lung Machine + Heater Cooler Unit + Hemofiltration SetDocument22 pagesBrosur Heart-Lung Machine + Heater Cooler Unit + Hemofiltration SetadefcesyoNo ratings yet

- P and ID HandsbookDocument30 pagesP and ID HandsbookYohannes GebreNo ratings yet

- Sushi Sensor Rd-Te-R06101-003 PDFDocument4 pagesSushi Sensor Rd-Te-R06101-003 PDFRiki HermansyahNo ratings yet

- Manual - SMU01 Controller V4.1GDocument30 pagesManual - SMU01 Controller V4.1Gjoel ramosNo ratings yet

- AX PRO Brochure 433Document27 pagesAX PRO Brochure 433lutz1502No ratings yet

- Application of Oscilloscope Technology in The Early 21st Century: A Systematic Literature ReviewDocument15 pagesApplication of Oscilloscope Technology in The Early 21st Century: A Systematic Literature Reviewjudej8905No ratings yet

- Updated Notes Unit-1Document23 pagesUpdated Notes Unit-1Rahul KumarNo ratings yet

- Ecdis Plan PDFDocument39 pagesEcdis Plan PDFL.A. Fodulla100% (3)

- Current Sensors: Dinesh Gopinath Department of Electrical Engineering College of Engineering Trivandrum Dinesh@cet - Ac.inDocument41 pagesCurrent Sensors: Dinesh Gopinath Department of Electrical Engineering College of Engineering Trivandrum Dinesh@cet - Ac.inakhilnandanNo ratings yet