Professional Documents

Culture Documents

Ultra low sulphur diesel fuel impacts on availability of other fuels

Uploaded by

Dia Fatima MaguikayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultra low sulphur diesel fuel impacts on availability of other fuels

Uploaded by

Dia Fatima MaguikayCopyright:

Available Formats

Ultra low sulphur diesel fuel

impacts on availability of other

fuels

G. R. Hadder, S. Das, R. Lee, N. Domingo and R. M. Davis

Legislation for ultra low sulphur (ULS) diesel particulate limitations would require the use of traps

fuel, with a greatly reduced allowable sulphur on the vehicle exhaust system. The industry express-

content and a new limit on aromatics content, is ed concern that these traps might be ineffective with

expected to be in place in the USA by 1995. The present day sulphur levels in diesel fuel because of

ULS diesel fuel has been specified to satisfy US the trap plugging by sulphates in the engine exhaust

standards for particulate emissions from heavy- and the generation of increased sulphur emissions

duty diesel engines. The Navy Mobility Fuels catalyzed by the traps. Commenters recommended

Forecasting System has been used to study the that EPA reduce the allowable sulphur in diesel fuel.

impacts of ULS diesel fuel production on other EPA responded that it would continue to study the

refined petroleum products. The study predicts issue and, if warranted, would consider so doing. 3

that to produce ULS diesel fuel, US Gulf and While addressing the issue of diesel fuel sulphur,

west coast refiners will have to invest about $4.4 EPA investigated the emission effects of other diesel

billion in new processing capacity. Refiners will fuel properties such as aromatics content. 4 Aromatic

shift aromatics from No 2 diesel fuel to jet fuel compounds in fuel contribute significantly to both

and to No 2 fuel oil. Therefore, particulate the carbonaceous fraction of particulate emissions as

emissions could be transferred from highways to well as hydrocarbon emissions from heavy-duty

airways and to communities which use No 2 fuel diesel engines under transient conditions. 5

oil for residential and commercial heating. The Various studies were conducted to estimate the

study also predicts that there will be an increase cost to cut diesel fuel sulphur content to 0.05 weight

in the aromatics content of Navy JP-5 jet fuel and percent 6 and to limit diesel aromatics content to a

F-76 marine diesel fuel produced in the USA. maximum of 20 volume percent. 7 EPA now esti-

The gum-forming tendencies of F-76 and F-77 mates that the cost to produce this ultra low sulphur

burner fuel oil will increase in most cases. The (ULS) diesel fuel will be equivalent to 7 c/g of diesel

freezing point of JP-5 will improve. There will fuel, with an industry investment of $2.7 billion, s

be minor changes in the cost of JP-5, but sizable Based on an independent survey, the petroleum

reductions in the cost of F-76 and F-77. refining industry has estimated that the cost to

produce ULS diesel fuel will be equivalent to 15.5

Keywords:Diesel fuel; Jet fuel; Environmentalregulations c/g, with an industry investment of $6.7 billion. 9

Industry analysts believe that legislation covering

the levels of diesel sulphur and aromatics is likely to

On 15 March 1985, the USA Environmental Protec- be in place by 1995.1°

tion Agency (EPA) established particulate standards A plausible impact of the production of ULS

for heavy-duty diesel engines. 1 These standards diesel fuel would be that some of the high sulphur

were to go into effect for 1988 model year vehicles, and high aromatics stocks currently blended to diesel

and were to follow with progressively more stringent fuel would be diverted to products with relatively

regulations. 2 In response to these regulations, the high allowable levels of sulphur and aromatics. For

diesel engine manufacturing industry stated that the example, F-76 marine diesel might be a good dis-

position for high sulphur stocks, since the limit on

The authors are members of the Energy Division, Oak sulphur in F-76 is 1.0 weight percent or 20 times the

Ridge National Laboratory, PO Box 2008, Oak Ridge, limit for ULS diesel fuel. The purpose of this report

Tenessee, TN 37831, USA. is to discuss the application of the Navy Mobility

488 0301-4215/91/050488-06 0 1991 Butterworth-Heinemann Ltd

Ultra low sulphur diesel fuel impacts on other fuels

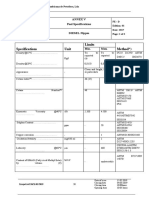

Table 1. Key specifications for navy fuels.

JP-5 F-76 F-77

API gravity 36-48 11.5 minimum

Flash point, °F, minimum 140 140 150

Freezing point, °F, maximum -51

Smoke point, mm, minimum 19

Cetane number, minimum 45

Sulphur, wt %, maximum 0.4 1.0 3.5

Pour point, °F, maximum 20 15

Particulate matter, mg/L, maximum 1.0

Accelerated stability, mg/100 ml, maximum 1.5

Fuels Forecasting System in the assessment of such models: the oil market simulation model; the pet-

impacts of ULS diesel fuel production on the availa- roleum allocation model; and the refinery yield

bility and quality of other fuels, with emphasis on model.

Navy jet and marine fuels.

The oil market simulation model

The econometric oil market simulation (OMS)

Model analysis of domestic production of model 11 estimates the price at which global supply

fuels and demand for oil are in balance. Aggregate sup-

The Navy Mobility Fuels Forecasting System has ply, demand and price data from the OMS model are

been used to predict the impacts of the production of used for some of the input data requirements of the

ULS diesel fuel on the production of other refined other two models of the forecasting system.

petroleum products. The study focuses on the effects The methodology of the OMS model consists of a

of ULS diesel fuel production on the availability and specific set of behavioural rules for three groups of

quality of Navy JP-5 jet fuel, F-76 marine diesel fuel, market participants who have different objectives:

and F-77 burner fuel oil. Key specifications for these oil consumers, OPEC oil producers, and non-OPEC

fuels are summarized in Table 1. oil producers.

The forecasting system, shown conceptually in The oil demand equations for the six regions of

Figure 1, consists of three Department of Energy the consumer group are expressed in terms of four

FORECASTINGSYSTEM

I

CRUDE ? I

AND SYNCRUDE I

CHARACTERISTICS .L . . . .

l- . . . .

I SUPPLYDISRUPTION

"1 SCENARIOS

L

WORLD

CONVERSION DISTRIBUTION

TECHNOLOGY CRUDE,PRODUCT

TRENDS (PAL)

REGIONAL

.EF,NERY I REFINERY

TRENDS ] MODELLING

-I (REMS/RYM)

±

T

REFINEDPRODUCT(FUELS)QUANTITY,

QUALITY,COST

Figure 1. Navy Mobility Fuels Forecasting System and supporting activities.

Source: S. Das et al, Navy Mobility Fuels Forecasting System Phase IV Report,

ORNL-6517, Oak Ridge National Laboratory, Oak Ridge, TN, USA, 1988.

E N E R G Y P O L I C Y June 1991 489

Ultra low sulphur dieselfuel impacts on other fuels

variables: the world oil price; regional income; the Each regional RYM determines the optimal solu-

economic feedback effect of world oil price on tion which maximizes the gross refinery margin.

regional income; and regional oil demand in the Because of the detailed refinery technology repre-

previous year. sented within RYM, the model can be used to

For the group of OPEC oil producers, the OMS perform a host of impact analyses by estimating the

model incorporates a theory of pricing behaviour changes in product yields given changes in input

that maintains that the higher the demand for OPEC variables. These variables include capacity, utiliza-

oil relative to the OPEC maximum sustainable oil tion and yield structure for more than 20 refinery

production capacity, the greater will be the increase processes; refinery slates which can contain over 30

in the world oil price. The pricing theory, repre- products; product prices; detailed blending speci-

sented mathematically in a price reaction function, fications for most products; availability and cost of

assumes that the OPEC pricing objective is to main- more than 100 crude oils; crude oil assays; and cost

tain a target percentage of OPEC oil production of utilities.

capacity utilization. If the percentage falls below the RYM is idealized in that it assumes 'connected

target level, OPEC reduces the world oil price to refinery pipelines' within a large region. Conse-

encourage increased demand for OPEC oil and quently, RYM has a tendency to over-optimize

movement toward the target level. Conversely, refinery operations. In a verification study to deter-

when the actual capacity utilization rises above the mine how closely RYM could simulate refinery

target level, OPEC raises the world oil price in order activities in 1982, it was estimated that regional

to reduce demand and utilization of oil production refinery aggregation could have caused the model to

capacity. overestimate light product yields by about 3% of

The supplies of oil from the five regions in the total gasoline and distillate yields. 14 The over-

non-OPEC producer group are determined by the optimization problem can be mitigated by focusing

world oil price and the regional oil supplies in the on scenario-induced changes in refining operations,

previous year. The required relationship in an OMS rather than relying on the model to predict the exact

model solution is that the free world quantity of oil values of refining variables for a particular scenario.

demanded equals the quantity supplied. The OMS and PAL models produce an aggre-

gated picture of regional refining under different

The petroleum allocation model market scenarios. Although regional refinery yield

The petroleum allocation (PAL) model 12 is a linear models are embedded within the PAL model, they

programme that estimates global petroleum move- do not explicitly represent the production of impor-

ments for different market scenarios. Crude oil tant military fuels such as JP-5. Therefore, RYM,

supplies and the production of refined products, which contains enhanced descriptions of military

such as motor gasoline, are forecast by the PAL fuel production, uses some key results of the PAL

model for input to the refinery yield model. model but is executed independently of it. The

Two basic assumptions underlie the PAL model stand-alone RYM can be used efficiently to evaluate

objective function. First, the distribution of crude oil many variations of the refining environment. For

from supply points to refinery regions, and the example, RYM is used to estimate investment in

distribution of refined products from refinery re- domestic refining capacity and to produce detailed

gions to refined product demand regions will tend to reports on the effects of changing refined product

follow historical movements. Second, when supply prices and specifications.

conditions are such that these historical movements Given the global petroleum market analyses of the

cannot be satisfied, crude and refined products will OMS and PAL models, RYM has been used to

be distributed according to the pattern that mini- analyse the impact of ULS diesel fuel production. A

mizes total costs. Within the PAL model, there are region was selected for study if it had a recent history

33 crude oil supply regions; over 50 crude oil types; of production of Navy mobility fuels. The selected

37 refinery regions; 33 refined product demand regions were:

regions; and modes of petroleum transportation • US Bureau of Mines (BOM) Districts 7 and 11

including tanker, pipeline, rail and truck. (Inland Texas and New Mexico);

• BOM District 8 (Texas Gulf Coast, which

The refinery yield model contains over 85% of Texas's crude oil distilla-

The refinery yield model (RYM) is a linear tion capacity);

programme 13 that represents regional refining op- • BOM Districts 9 and 10 (Louisiana, Mississip-

erations. pi, Alabama and Arkansas); and

490 ENERGY POLICY June 1991

Ultra low sulphur diesel fuel impacts on other fuels

• BOM District 13 (Alaska, California, Hawaii, invest about $4.4 billion, according to the Navy

Nevada, Oregon and Washington). Mobility Fuels Forecasting System. is The invest-

ment will be primarily for the processes of distillate

Scenarios for production of current-quality diesel

deep hydrotreating, naphtha hydrotreating and gas

and ULS diesel were studied for petroleum markets

oil hydrocracking.

in the year 1995. In both scenarios, it was assumed

The production of ULS diesel fuel results in a shift

that motor gasoline will be unleaded and that the

of aromatics to civilian jet fuel and to No 2 fuel oil as

Reid vapour pressure of summertime motor gasoline

summarized in Table 2.

will be reduced by about 25% relative to the present

Table 3 shows some of the key effects of ULS

motor gasoline. 15

diesel fuel on JP-5:

Business-as-usual market conditions, which were

estimated with the OMS and PAL models, are • ULS diesel production causes an increase in

described in detail by Das et al. 16 A map which the aromatics content of JP-5 in all study

summarizes the projected business-as-usual free- regions.

world distribution of petroleum is shown in Figure 2. • Increases in aromatics content would be ex-

pected to result in decreases in smoke point.

However, the only substantial decrease in

Impacts of ULS diesel fuel production smoke point is in BOMs 9 and 10.

Of the nation's total crude oil distillation capacity • The forecasting system predicts substantial im-

66% is located in the Gulf and west coast study provements in the freezing point of JP-5 in

regions of BOMs 7, 8, 9, 10, 11 and 13.17 To produce BOMs 7, 8, 11 and 13. The improvement of

ULS No 2 diesel fuel rather than current-quality freezing point is consistent with the fact that

diesel, refiners in these study regions will have to freezing point improves substantially as the

Figure 2. Business-as-usual free-world petroleum (crude oil and refined product) distribution in 1995.

Source: S. Das et al, Navy Mobility Fuels Forecasting System Phase IV Report, ORNL-6517,Oak RidgeNationalLaboratory,Oak Ridge,

TN, USA, September 1988.

ENERGY POLICY June 199! 491

Ultra low sulphur diesel fuel impacts on other fuels

Table 2. Civilian product quality changes associated with change to ultra low sulphur diesel

specifications.

BOM 7/11 BOM 8 BOM 9/10 BOM 13

Jet A aromatics (vol %) +2.0 0 +3.6 0

No 2 diesel aromatics (vol %) -9.8 -13.8 -12.0 -17.9

No 2 diesel cetane index (number) +3.9 +8.3 +0.7 +3.6

No 2 diesel sulphur (wt %) -0.4 -0.4 -0.4 -0.3

No 2 fuel oil aromatics (vol %) +24.7 +25.9 +15.5 +16.2

No 2 fuel oil sulphur (wt %) 0 -0.2 0 -0.2

characterization factor of a fuel decreases (ie, Observations and recommendations

the fuel becomes more aromatic), for a con-

stant 50% recovery temperature. 19 The forecasting system predicts that the production

The change in cost of JP-5 ranges from -2.3 to of ULS diesel fuel will cause an increase in the

+1.4 c/g. aromatics content of domestically produced JP-5. It

is recommended that the impact of higher aromatics

Table 4 shows some of the key effects of ULS content in JP-5 be reviewed with respect to compara-

diesel fuel on F-76. bility with materials such as elastomers and with

respect to engine performance characteristics, such

• ULS diesel fuel production causes large in- as smoking.

creases in the aromatics content of F-76 in It is also predicted that the production of ULS

BOMs 8 and 13. diesel fuel will cause an improvement in the freezing

• In BOM 13, the cetane index of F-76 drops by point of domestically produced JP-5. It is recom-

9 numbers. mended that future research focus on the extension

• There are increases in light cycle oil blended to of JP-5 supplies, during market disruptions or mili-

F-76 in all regions of production of this fuel. tary mobilization, by blending higher freezing point

Light cycle oils have inferior stability, with stocks.

tendencies to produce gums and other particu- The production of ULS diesel fuel is predicted to

lates, resulting from complex interactions be- cause an increase in the aromatics content of domes-

tween molecular oxygen, organocompounds of tically produced F-76. It is recommended that the

nitrogen, sulphur and oxygen, and the more impact of higher F-76 aromatics content be reviewed

reactive hydrocarbon species such as olefins with respect to ignition and particulate formation

and aromatics. The resulting particulates and characteristics.

gums can cause plugging of diesel engine filters The forecasting system predicts that the produc-

and fouling of fuel injectors. 2° Studies have tion of ULS diesel fuel will cause an increase in the

shown rapid degradation in the stability of percentage of light cycle oil blended to domestically

fuels blended with more than 30% light cycle produced F-76 and an increase in the percentage of

oil in virgin distillate. 21 Hardy et al cite the light cycle oil blended to F-77 produced in BOM 13.

marked instability of a blend of 70% good It is recommended that because of potential fuel

quality F-76 with 30% light cycle oil. 22 stability problems, the possibility of high percen-

• The cost of F-76 is reduced in all study regions. tages of light cycle oil in F-76 and F-77 should be

discussed with refiners. These discussions could

The quality of F-77 produced in BOM 8 is not identify the need for follow-up investigations on the

affected by ULS diesel fuel production. However, in stability and power system impacts of such blends.

BOM 13 the sulphur content of F-77 increases Finally, it is predicted that the production of ULS

substantially and the change in light cycle oil diesel fuel will cause a shift of aromatics from No 2

blended to F-77 is +60 volume percent. In both diesel fuel to jet fuel and to No 2 fuel oil. Since

regions, the cost of F-77 is substantially reduced. aromatics tend to produce more smoke in the com-

Table 3. Key effects of ultra low sulphur diesel specifications on JP-5.

BOM 7/11 BOM 8 BOM 9/10 BOM 13

Aromatics content (vol % change) +1.6 +2.2 +1.2 +1.0

Smoke point (mm change) -0.5 +0.2 -5.2 -0.1

Freezing point (degrees F change) -25.0 -42.0 +2.0 -24.0

Cost (c/g change) +1.1 0 +1.4 -2.3

492 ENERGY POLICY June 1991

Ultra low sulphur diesel fuel impacts on other fuels

man shows a relationship in which a minimum cetane number of

Table 4. Key effects of ultra low sulphur diesel specifications on 40 (for a blend of light cycle oils and virgin distillates) corresponds

F-76. to a maximum aromatics content of about 38 volume percent. See

G. H. Unzelman, 'Higher diesel quality would constrict refining',

BOM 8 BOM 9/10 BOM 13 Oil & Gas Journal, 29 June 1987, pp 55-59.

Aromatics content (vol % change) +7.8 -1.2 +20.6 8Bob Williams, 'US refiners may face gasoline supply crunch in

Cetane index (number change) 0 0 -9.0 driving season', Oil & Gas Journal, 5 June 1989, pp 23-28

Light cycle oil (vol % change) +13.5 +10.0 +35.4 90p cit, Ref 6.

Cost (c/g change) -4.0 -2.4 -9.6 l°Op cit, Ref 7.

HSystem Science Inc, The Oil Market Simulation Model, Model

Documentation Report DOE/EIA/19656-2, Department of Ener-

gy, Washington, DC, USA, 1985.

bustion of jet fuels and fuel oils, 23 the net reduction 1ZA.F. Turhollow, T.R. Curlee and Sujit Das, Documentation of

in particulate emissions may be less than anticipated the Petroleum Allocation (PAL) Model, Oak Ridge National

by environmental planners. The final recommenda- Laboratory, Oak Ridge, TN, USA, 5 March 1987.

13Refinery Evaluation Modeling System (REMS) Documentation,

tion is that the proposals for ULS diesel fuel be DOE/EIA-0460, Energy Information Administration, October

assessed for the net reduction in particulate emis- 1984; Refinery Evaluation Modeling System (REMS) Documenta-

sions, accounting for the potential transfer of the tion, DOE/EIA-0461, Energy Information Administration, Octo-

ber 1984.

particulate emissions from highways to airways and a4REMS 1982 Verification Test Results, working paper prepared

to communities which use No 2 fuel oil for residen- for US Energy Information Administration and the Strategic

tial and commercial heating. Petroleum Reserve Office of the US Department of Energy by

Decision Analysis Corporation with Sobotka and Company,

under subcontract with Computer Data Systems, November 1983.

Research sponsored by the Mobility Fuels Technology Program 15G.T. Kinney, 'EPA to limit summertime gasoline RVP', Oil &

of the US Navy Energy and Natural Resources Office, Office of Gas Journal, 27 March 1989, p 79.

Naval Research, Interagency Agreement No 40-1391-83 under 16S. Das et al, Navy Mobility Fuels Forecasting System Phase IV

Martin Marietta Energy Systems Inc, Contract No. DE-AC05- Report, ORNL-6517, Oak Ridge National Laboratory, Oak

84OR21400 with the US Department of Energy. Ridge, TN, USA, September 1988.

17Energy Information Administration, US Department of Ener-

1Federal Register, Vol 50, No 51, 15 March 1985, p 10606. gy, Petroleum Supply Annual 1988, DOE/EIA-0340(88)/1,

2The particulate emission standards, which apply only to heavy- Washington, DC, USA, May 1989.

duty diesel engines are: 0.6 grams per brake horsepower-hour for ]SWhen extrapolated by the distillation capacity of the entire

1988 and later model years, 0.25 grams per brake horsepower- USA relative to the study regions (ie, 1/0.66), the investment

hour (0.1 grams per brake horsepower-hour for urban buses) for estimate of the study supports the investment determined in the

1991 and later model years, and 0.1 grams per brake horsepower- petroleum refining industry survey (op cit, Ref 6). The extrapola-

hour for 1994 and later model years. Tile rule is in response to the tion, which does not account for important factors such as the

requirements of section 202(a)(3) of the Clean Air Act as total refinery process configuration, provides only a rough appro-

amended in 1977. ximation.

3Federal Register, Vol 51, No 124, 27 June 1986, p 23437. ~gW.L. Nelson, Petroleum Refining Engineering, McGraw-Hill,

4The back-end distillation temperature has also been directly NY, USA, 1958, p 139.

correlated with diesel fuel particulate emissions. 2°L.D. Palmer and B.V. Copson, 'Hydrotreatment of light cycle

50p cit, Ref 3. oil for stabilization of automotive diesel fuel', in Conference

6In a 1986 survey of 139 refineries, representing 98% of the Proceedings, 2nd International Conference on Long-Term Storage

nation's crude oil refining capacity, the average diesel fuel sulphur Stabilities of Liquid Fuels, Southwest Research Institute, San

content was 0.27 weight percent. A relatively small volume of Antonio, TX, USA, 29 July-1 August 1986, pp 902-914.

diesel fuel, which was primarily consumed in the Los Angeles 21M.W. Schrepfer, R.J. Arnold and C.A. Stansky, 'Distillate

basin area, met a 0.05 weight percent maximum sulphur specifica- stability ensured by testing, treatment', Oil & Gas Journal, 16

tion. For diesel fuels sold in accordance with the ASTM D 975 January 1984, pp 79-84.

standard, the maximum sulphur content is 0.5 weight percent. See 22D.R. Hardy, R.N. Hazlett and E.W. White, 'Assessment of

National Petroleum Refiners Association, US Refining Industry storage stability additives for naval distillate fuel', Conference

Capability to Manufacture Ultra Low Sulfur Diesel Fuels: NPRA Proceedings, 2nd International Conference on Long-Term Storage

Survey 1986, National Petroleum Refiners Association, Suite Stabilities of Liquid Fuels, Southwest Research Institute, San

1000, 1899 L Street, NW, Washington, DC 20036, USA, 1986. Antonio, TX, USA, 29 July-1 August, pp 887-901.

7The average aromatics content of diesel fuel produced by the 23See, for example, D.W. Naegeli and C.A. Moses, 'Effects of

refineries surveyed by the NPRA (op cit, Ref 6) was 34 volume fuel properties on soot formation in turbine combustion,' Society

percent. ASTM D 975 has no aromatics specification but requires of Automotive Engineers Paper No 781026, Aerospace Meeting,

a minimum cetane number of 40. Cetane number and aromatics San Diego, CA, USA, 27-30 November 1978, p 5; and V.B.

content are inversely related, and, in effect, the cetane specifica- Guthrie, Petroleum Products Handbook, McGraw-Hill, NY,

tion limits the amount of aromatics that can be blended. Unzel- USA, 1960, pp 7-29.

ENERGY POLICY June 1991 493

You might also like

- Short-Term Analysis of Refinery Costs and Supply: Appendix DDocument9 pagesShort-Term Analysis of Refinery Costs and Supply: Appendix DgenergiaNo ratings yet

- Paper No.: 13 Marine Distillate Fuels Specifications - Today and TomorrowDocument10 pagesPaper No.: 13 Marine Distillate Fuels Specifications - Today and TomorrowAnonymous 8qUHG4SlNo ratings yet

- World Jet Fuel Specifications 2005Document51 pagesWorld Jet Fuel Specifications 2005Richo Crb100% (2)

- Fundamentals of ULSD ProductionDocument6 pagesFundamentals of ULSD Productionsaleh4060No ratings yet

- Properties of Crude Oil ExplainedDocument15 pagesProperties of Crude Oil ExplainedAkol MajookNo ratings yet

- Desulfurization of Diesel Like Fuel Produced From Waste Lubrication OilDocument8 pagesDesulfurization of Diesel Like Fuel Produced From Waste Lubrication OilSanchez Martinez Hugo De DiosNo ratings yet

- Ruler Vs Rpvot Fluitec Doc1003Document3 pagesRuler Vs Rpvot Fluitec Doc1003api-221802169100% (1)

- Policy Analysis: Environmental Assessment of Used Oil Management MethodsDocument6 pagesPolicy Analysis: Environmental Assessment of Used Oil Management Methodsjhonqwerty111No ratings yet

- Effect of Petroleum Condensate on Automotive EnginesDocument7 pagesEffect of Petroleum Condensate on Automotive EnginesMas KumambangNo ratings yet

- World Jet Fuel Specifications: EditionDocument45 pagesWorld Jet Fuel Specifications: EditionAdu Ansere FokuoNo ratings yet

- Diesel TechnologyDocument70 pagesDiesel TechnologyJeremy Diaz100% (1)

- Diesel FuelDocument70 pagesDiesel FuelFra Fra100% (2)

- Cat DEO ULS Moves To API CK 4 in December 2016Document4 pagesCat DEO ULS Moves To API CK 4 in December 2016Gracia SediNo ratings yet

- Simple & Complex RefineriesDocument6 pagesSimple & Complex RefineriesFernanda Guerrero100% (1)

- Crude Assay - Lecture NotesDocument18 pagesCrude Assay - Lecture Notessam joseph100% (1)

- LeibyEtAl2015 ORNL - Drawdown Capability Study For DOE EPSA - Final - 20150414Document51 pagesLeibyEtAl2015 ORNL - Drawdown Capability Study For DOE EPSA - Final - 20150414ridgepabloNo ratings yet

- World Jet Fuel Specifications 2005Document51 pagesWorld Jet Fuel Specifications 2005BaronNo ratings yet

- Pros and Cons Using PAG in Engine OilsDocument14 pagesPros and Cons Using PAG in Engine OilsSounak SasmalNo ratings yet

- Lubricant Performance and Turbochargers Analysis For Alternate Fuel TestsDocument16 pagesLubricant Performance and Turbochargers Analysis For Alternate Fuel Testsgigi23901No ratings yet

- 7 US Refining Cash Margin TrendsDocument20 pages7 US Refining Cash Margin TrendsAbraham Juarez Luis100% (1)

- Astm d975 2007Document36 pagesAstm d975 2007Osama FouadNo ratings yet

- TLT Techbeat 9 06Document9 pagesTLT Techbeat 9 06alexsv_17No ratings yet

- Impact of Engine Oil Consumption On Particulate Emissions: Southwest Research Institute GE Global Research CenterDocument11 pagesImpact of Engine Oil Consumption On Particulate Emissions: Southwest Research Institute GE Global Research CenteriitabhiandrohitNo ratings yet

- CIMAC WG08 2014 05 Guideline Fuel Scenarios Impact LubricationDocument19 pagesCIMAC WG08 2014 05 Guideline Fuel Scenarios Impact LubricationozakyusNo ratings yet

- Diesel LubricityDocument14 pagesDiesel LubricityLordENo ratings yet

- Used Oil Recycling and Treatment in The United AraDocument11 pagesUsed Oil Recycling and Treatment in The United AraEssam AlharthyNo ratings yet

- Mina Abdulla Refinery Experience With Atmospheric Residue Desulfurization (Ards)Document10 pagesMina Abdulla Refinery Experience With Atmospheric Residue Desulfurization (Ards)Owais AhmedNo ratings yet

- RVP SaftDocument11 pagesRVP SaftGustav MolMedNo ratings yet

- Atık Yağın Diğer ProsesleriDocument10 pagesAtık Yağın Diğer ProsesleriBurak Barış AtalıkNo ratings yet

- "What About Heavy Duty Diesel Engine Oils?": Ray Garvey/CSI@CSIDocument2 pages"What About Heavy Duty Diesel Engine Oils?": Ray Garvey/CSI@CSIsatya_chagantiNo ratings yet

- Product Specifications & Usage, Quality Checks & QC Indexing ForDocument69 pagesProduct Specifications & Usage, Quality Checks & QC Indexing ForAshwani Singh BaghelNo ratings yet

- Density and Values of Crude Oil PDFDocument9 pagesDensity and Values of Crude Oil PDFRichard Amorin0% (1)

- D6448Document5 pagesD6448rimi7alNo ratings yet

- EOR Screening CriteriaDocument7 pagesEOR Screening CriteriaMuhammad WibisonoNo ratings yet

- EOR Screening Part 2 Taber-MartinDocument7 pagesEOR Screening Part 2 Taber-MartinPerwira HandhikoNo ratings yet

- Economics (MCX)Document6 pagesEconomics (MCX)Abhi SharmaNo ratings yet

- Petroleum Refining-The Basics Petroleum Refining-The BasicsDocument18 pagesPetroleum Refining-The Basics Petroleum Refining-The Basicsoneofone100% (1)

- Iodine ValueDocument6 pagesIodine ValueSandesh HakkiNo ratings yet

- Micellar/Polymer Flooding - An Overview: SPE-AIME, Marathon Oil CoDocument13 pagesMicellar/Polymer Flooding - An Overview: SPE-AIME, Marathon Oil Coorenji nimong crossNo ratings yet

- FT-IR Analysis of Used Lubricating OilsDocument4 pagesFT-IR Analysis of Used Lubricating OilsMeetika GuptaNo ratings yet

- Ftir Analysis of Used Lubricating OilsDocument4 pagesFtir Analysis of Used Lubricating Oilsjuli_radNo ratings yet

- Diesel FuelsDocument116 pagesDiesel FuelsTimothy Rowe100% (1)

- Diesel Flash Point StudyDocument5 pagesDiesel Flash Point StudyAdamNo ratings yet

- Nitrile Rubber Jet A-1Document13 pagesNitrile Rubber Jet A-1Nguyên NguyễnNo ratings yet

- LNG As Marine FuelDocument10 pagesLNG As Marine FuelJames RobbinsNo ratings yet

- Torres Jimenez2011Document8 pagesTorres Jimenez2011RahulRajNo ratings yet

- 0 50 S Fuel OperationDocument56 pages0 50 S Fuel Operationargentum19619692No ratings yet

- Passivator and Gas Formation at TransformatorDocument11 pagesPassivator and Gas Formation at TransformatorHelmy Nur Efendi YusufNo ratings yet

- Some Technical and Economic Aspects of Residual Fuel Oil DesulfurizationDocument5 pagesSome Technical and Economic Aspects of Residual Fuel Oil Desulfurizationmohsen miandehiNo ratings yet

- CCAIDocument0 pagesCCAIshishir4870No ratings yet

- Astm D975Document19 pagesAstm D975JohnNo ratings yet

- Visible Alpha Guide To Oil and Gas E&P KPIsDocument29 pagesVisible Alpha Guide To Oil and Gas E&P KPIsdeepikaNo ratings yet

- Liquid Fuels: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Metallurgy DivisionFrom EverandLiquid Fuels: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Metallurgy DivisionRating: 4.5 out of 5 stars4.5/5 (2)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- The Role of Engine Oil Viscosity in Low Temperature Cranking and Starting: Prepared Under the Auspices of the SAE Fuels and Lubricants ActivityFrom EverandThe Role of Engine Oil Viscosity in Low Temperature Cranking and Starting: Prepared Under the Auspices of the SAE Fuels and Lubricants ActivityNo ratings yet

- Proposed Wastewater Treatment Facility For King's Quality Food Incorporated - A Meat Processing and Packaging CompanyDocument77 pagesProposed Wastewater Treatment Facility For King's Quality Food Incorporated - A Meat Processing and Packaging CompanyDia Fatima MaguikayNo ratings yet

- Waste Final Written Report 2 15 2017Document76 pagesWaste Final Written Report 2 15 2017Dia Fatima MaguikayNo ratings yet

- 1083ch8 37Document6 pages1083ch8 37Dia Fatima MaguikayNo ratings yet

- Conversion FactorsDocument3 pagesConversion FactorsDia Fatima MaguikayNo ratings yet

- HYSYS Tutorial 2014Document36 pagesHYSYS Tutorial 2014ridhajamelNo ratings yet

- RA6969Document8 pagesRA6969Gino Luna CondecionNo ratings yet

- AspenPlusPetroleumV7 1 StartDocument45 pagesAspenPlusPetroleumV7 1 StartLuis Eduardo Plazas100% (1)

- ASME B16.5 Pipe Flanges and Flanged Fittings Published InterpretationsDocument71 pagesASME B16.5 Pipe Flanges and Flanged Fittings Published InterpretationsAymen HileliNo ratings yet

- Heat Exchanger Types and CalculationsDocument16 pagesHeat Exchanger Types and CalculationsAudrey Patrick KallaNo ratings yet

- AspenPlusPetroleumV7 1 StartDocument45 pagesAspenPlusPetroleumV7 1 StartLuis Eduardo Plazas100% (1)

- (D) PHD Thesis - Naveen Bhutani PDFDocument252 pages(D) PHD Thesis - Naveen Bhutani PDFDia Fatima Maguikay100% (1)

- 314Document620 pages314Dia Fatima MaguikayNo ratings yet

- 002 HydroprocessingDocument35 pages002 HydroprocessingDia Fatima MaguikayNo ratings yet

- E04413040 PDFDocument11 pagesE04413040 PDFjoseNo ratings yet

- AspenTech Announces Availability of AspenONE V8 FINAL - For at - Com 12-10-2012Document3 pagesAspenTech Announces Availability of AspenONE V8 FINAL - For at - Com 12-10-2012imoomexNo ratings yet

- Maples, Robert E.-Petroleum Refinery Process Economics-PennWell (2000)Document491 pagesMaples, Robert E.-Petroleum Refinery Process Economics-PennWell (2000)janandcpcl100% (4)

- Sap5 Mkeu PerbankanDocument28 pagesSap5 Mkeu PerbankangustidhewiNo ratings yet

- Modern Petroleum Refinery Engineering Bhaskar RaoDocument208 pagesModern Petroleum Refinery Engineering Bhaskar RaoAman Dhanani71% (21)

- Plume BehaviourDocument8 pagesPlume Behaviourfaridkhan100% (6)

- Design and Fabrication of Crude Distillation Unit Components For A Mini Petroleum RefineryDocument269 pagesDesign and Fabrication of Crude Distillation Unit Components For A Mini Petroleum RefineryDia Fatima MaguikayNo ratings yet

- Thesis Rasmus R. Boesen 2010 FinalDocument167 pagesThesis Rasmus R. Boesen 2010 FinalDia Fatima MaguikayNo ratings yet

- 02 Feedstocks & ProductsDocument133 pages02 Feedstocks & ProductsverdugrNo ratings yet

- 10.1007/s13203 012 0006 6Document17 pages10.1007/s13203 012 0006 6Dia Fatima MaguikayNo ratings yet

- 49 2 Philadelphia 10-04 1055 PDFDocument3 pages49 2 Philadelphia 10-04 1055 PDFDia Fatima MaguikayNo ratings yet

- Kinetic Modeling and Reactor Simulation for Diesel HydrodesulfurizationDocument14 pagesKinetic Modeling and Reactor Simulation for Diesel HydrodesulfurizationDia Fatima MaguikayNo ratings yet

- Destructive Mining Set in Most Bio-Diverse Zone - Opinion, News, The Philippine Star - PhilstarDocument3 pagesDestructive Mining Set in Most Bio-Diverse Zone - Opinion, News, The Philippine Star - PhilstarDia Fatima MaguikayNo ratings yet

- Hydro Treating CompleteDocument19 pagesHydro Treating CompleteFaiq Ahmad Khan100% (3)

- 2015 EnergyScienceandTechnology OilandNaturalGas2015304 328Document28 pages2015 EnergyScienceandTechnology OilandNaturalGas2015304 328Dia Fatima MaguikayNo ratings yet

- Air Pollution Dispersion Processes and Atmospheric StabilityDocument43 pagesAir Pollution Dispersion Processes and Atmospheric StabilityDia Fatima MaguikayNo ratings yet

- C.I. Engine - Unit 3Document234 pagesC.I. Engine - Unit 3vaibhav ghogareNo ratings yet

- Petroleum Refinery Powerpoint SlideDocument22 pagesPetroleum Refinery Powerpoint SlideBharat BajajNo ratings yet

- Diesel Nox Reduction TechnologiesDocument11 pagesDiesel Nox Reduction TechnologiesHasan Kayhan KayadelenNo ratings yet

- FVMQDocument115 pagesFVMQNguyên NguyễnNo ratings yet

- Astm D613-13Document17 pagesAstm D613-13Ruben Perez AyoNo ratings yet

- Exp 3 - Carbon Residue TestDocument15 pagesExp 3 - Carbon Residue TestMark Cortez92% (12)

- Production of Biofuel Mini Project PreseDocument18 pagesProduction of Biofuel Mini Project PreseMalike ShamelNo ratings yet

- Unit - 5-Cy19241Document45 pagesUnit - 5-Cy19241Suresh Kumar A PNo ratings yet

- FFFFDocument25 pagesFFFFJunior Paolo Mas AguilarNo ratings yet

- Hxh En590 Jurong Fob Icpo 富吉拉港口Document4 pagesHxh En590 Jurong Fob Icpo 富吉拉港口tsng812No ratings yet

- Fuels and Combustion GuideDocument102 pagesFuels and Combustion GuideMohanSharmaNo ratings yet

- (CH-4) Fuel PropertiesDocument35 pages(CH-4) Fuel Propertiesxan pitchuNo ratings yet

- Astm D613Document19 pagesAstm D613Eder Fajardo ValenciaNo ratings yet

- Analysis On Synthesis, Storage & Combustion Characteristics of DME As Fuel in CI EnginesDocument8 pagesAnalysis On Synthesis, Storage & Combustion Characteristics of DME As Fuel in CI EnginesTanu SharmaNo ratings yet

- Farm Machinery and PowerDocument111 pagesFarm Machinery and PowerGary Bhullar83% (12)

- Immersion Test For ElastomerDocument13 pagesImmersion Test For ElastomerChandra KusaristiantoNo ratings yet

- Specifications Unit Limits Method ) : Annex V Fuel SpecificationsDocument3 pagesSpecifications Unit Limits Method ) : Annex V Fuel Specificationsbasharat121No ratings yet

- Product Passport (Quantity & Quality Dip Test Analysis Report)Document1 pageProduct Passport (Quantity & Quality Dip Test Analysis Report)spetsoilgroupNo ratings yet

- Diesel Generator Operation and Maintenance ManualDocument39 pagesDiesel Generator Operation and Maintenance ManualAuliamNo ratings yet

- Handbook of Petroleum Product Analysis by JAMES SPEIGHT PDFDocument164 pagesHandbook of Petroleum Product Analysis by JAMES SPEIGHT PDFamiestudentNo ratings yet

- ASTM D613 18ae1Document11 pagesASTM D613 18ae1ammarNo ratings yet

- Chapter 3 explores conventional and alternative fuelsDocument49 pagesChapter 3 explores conventional and alternative fuelsmharitmsNo ratings yet

- 5-Knocking, Octane - Cetane NumbersDocument38 pages5-Knocking, Octane - Cetane NumbersPravin EswaramoorthyNo ratings yet

- Volvo A40E Operator ManualDocument200 pagesVolvo A40E Operator ManualWa Toke92% (13)

- Dja3032 Chapter3 151217030704Document38 pagesDja3032 Chapter3 151217030704handwiNo ratings yet

- Philippine National Standard For Petroleum Products & Other Fuel Related ProductsDocument1 pagePhilippine National Standard For Petroleum Products & Other Fuel Related ProductsRay RomeyNo ratings yet

- CFR Engine Cetane Number LabDocument22 pagesCFR Engine Cetane Number LabAbhishekRajNo ratings yet

- 09.40 10.00 G. K. Acharya Deputy General Manager IOC Indian Oil Corporation 1Document36 pages09.40 10.00 G. K. Acharya Deputy General Manager IOC Indian Oil Corporation 1ra1958jaNo ratings yet

- Series: Service ManualDocument10 pagesSeries: Service Manualhasan siraitNo ratings yet

- CHEG421 Petroleum Refining and Processin PDFDocument416 pagesCHEG421 Petroleum Refining and Processin PDFJoseNo ratings yet