Professional Documents

Culture Documents

Piping Engineering - Tank Nozzle Loads 9

Uploaded by

Nasrul AdliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Engineering - Tank Nozzle Loads 9

Uploaded by

Nasrul AdliCopyright:

Available Formats

2/1/2018 Piping engineering | Tank nozzle loads

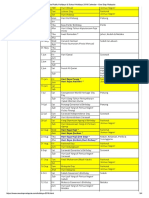

The following notes should be considered when using those formulas:

The minimum value of which is 0.1 occurs outside of the discontinuity area where the chocking

effect diminishes and so the whole stress capacity is used for hoop stress.

When the circumferential membrane stresses due to external loads are compressive, hoop stress doesn’t provide

any margin for allowable loads. So should not be considered in equation (53) and equation (53) changes to:

(60)

Piping stress engineers may use the nomograms which are mentioned on figures P-5A and P-5B in appendix P of

API 650.

4-Tank settlement

Settlement of storage tanks are usually considerable comparing to settlement of other equipment. Settlement highly

depends on tank dimensions and soil conditions. Depending on the connected piping flexibility, it may cause some

problems to connecting pipes and nozzles. During settlement a connected pipe tends to be pulled down by the tank.

If the piping system has enough flexibility to accommodate the settlement, it will not lead to a dangerous situation.

Moreover, usually pipes connecting to storage tanks have a heavy isolating valve near nozzles. So stress engineer

should find a solution to deal with not only piping flexibility but sustained stresses.

4-1-Solutions

4-1-1-Reducing of settlement

One of the best solutions is settlement reduction which can be achieved by connecting pipes after hydro test when

the tank is not empty, preferably half-full tank. Therefore only settlement that the pipes incorporate is long term

settlement. Civil engineers are expected to give the long term settlement to stress engineers.

4-1-2-Supporting

Obviously type of supports which are placed at near nozzles affects stresses caused by settlement in following ways:

Common foundation: Pipes which are supported on tank foundation have the same displacement as the tank

settlement has. Consequently it results in a lower stress.

Adjusting support: If settlement profiles versus time are available, some adjustable supports can be used. The

supports should be adjusted in field.

Spring Hangers: Spring hangers make the connected pipes more flexible and consequently it leads to lower

stresses at nozzles. Most of the time it is considered the best way because it sustains the heavy valve weight.

4-1-3-Piping Routes

Stress engineers may resort to this method to make the piping system more flexible. The solution may bring up two

problems: firstly this method requires enough room especially for large bore pipes. Moreover it makes the pipe more

vulnerable to vibration and dynamic loads by reducing natural frequency of the piping system. Secondly this solution

leads to an increase in sustained stress because rout change implies adding some piping components. As said before,

heavy isolating valves deteriorate the situation more.

To sum up, stress engineers should be aware of the solutions and select the best one depending on the situation.

4-2- Category of stresses caused by settlement

It is important to know which stress category should be assigned for stresses caused by settlement. Generally

primary stress is more dangerous and critical than secondary stress because the primary one is not reduced after

going beyond yielding points. So primary stresses should be checked against lower allowable stresses. Regarding the

mentioned explanation, putting settlement stress in primary category makes intensity stress more difficult to satisfy

its stress criteria. The nature of settlement loading is similar to secondary loading because it disappears after

http://www.calcstress.com/tank-nozzle-loads 9/11

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- (Ebook - SEX) Penis Enlargement ManualDocument52 pages(Ebook - SEX) Penis Enlargement Manualvano53% (30)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Faisal Awad - January 2012Document42 pagesFaisal Awad - January 2012eng_far0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- BASF Engineered Pipe Support CatalogueDocument108 pagesBASF Engineered Pipe Support CatalogueHITESH100% (1)

- Sct1375 Technical SpecDocument315 pagesSct1375 Technical SpecMUTHUKKUMARAMNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- Retroexcavadora WB146Document586 pagesRetroexcavadora WB146olaff jardinez moreno100% (7)

- Recommended Procedure For Alkali Boil OutDocument18 pagesRecommended Procedure For Alkali Boil OutsprotkarNo ratings yet

- Method Statement For Installation of Pipes and FittingsDocument4 pagesMethod Statement For Installation of Pipes and Fittingsadeniyi abiolaNo ratings yet

- PDMS 2Document1 pagePDMS 2Nasrul AdliNo ratings yet

- Cost Renovation RumahDocument3 pagesCost Renovation RumahNasrul AdliNo ratings yet

- Sow A2 Mopu Sepat2Document1 pageSow A2 Mopu Sepat2Nasrul Adli0% (1)

- Piping Engineering - Tank Nozzle Loads 3Document1 pagePiping Engineering - Tank Nozzle Loads 3Nasrul AdliNo ratings yet

- Job Information: Engineer Checked Approved Name: Date: Structure TypeDocument2 pagesJob Information: Engineer Checked Approved Name: Date: Structure TypeNasrul AdliNo ratings yet

- Asme Sect8 Div1 - SAMPLE Calculation-COVERDocument1 pageAsme Sect8 Div1 - SAMPLE Calculation-COVERNasrul AdliNo ratings yet

- PDMS 3Document1 pagePDMS 3Nasrul AdliNo ratings yet

- PDMS 4Document1 pagePDMS 4Nasrul AdliNo ratings yet

- Malaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFDocument4 pagesMalaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFNasrul AdliNo ratings yet

- Exhibit II Compliance To Technical RequirementsDocument1 pageExhibit II Compliance To Technical RequirementsNasrul AdliNo ratings yet

- Pipes. Maxi 8 PDFDocument1 pagePipes. Maxi 8 PDFNasrul AdliNo ratings yet

- Malaysia Public Holidays & School Holidays 2018 CalendaR-ALL 3Document1 pageMalaysia Public Holidays & School Holidays 2018 CalendaR-ALL 3Nasrul AdliNo ratings yet

- Class1 Div2 PDFDocument1 pageClass1 Div2 PDFNasrul AdliNo ratings yet

- What Is Piping 2Document1 pageWhat Is Piping 2Nasrul AdliNo ratings yet

- Solved - Stress Analysis - AutocCeasar II - Autodesk Community 3Document1 pageSolved - Stress Analysis - AutocCeasar II - Autodesk Community 3Nasrul AdliNo ratings yet

- B31 3 (Mygaz) - 1Document1 pageB31 3 (Mygaz) - 1Nasrul AdliNo ratings yet

- Table 1: bottom Range a/b 0.9500 btmwl αDocument1 pageTable 1: bottom Range a/b 0.9500 btmwl αNasrul AdliNo ratings yet

- Aig Tower 3/F To 5/F Transfer Truss Type A Joint Connection CalculationDocument1 pageAig Tower 3/F To 5/F Transfer Truss Type A Joint Connection CalculationNasrul AdliNo ratings yet

- PDMS 2Document1 pagePDMS 2Nasrul AdliNo ratings yet

- Pipes. Maxi 8 PDFDocument1 pagePipes. Maxi 8 PDFNasrul AdliNo ratings yet

- Shear Lug Verification Example 11Document1 pageShear Lug Verification Example 11Nasrul AdliNo ratings yet

- Edes Clip 2016 ModelDocument1 pageEdes Clip 2016 ModelNasrul AdliNo ratings yet

- Wind LoadDocument2 pagesWind LoadNasrul AdliNo ratings yet

- 40S Gives A Thickness: NG Thickness Less Than RequiredDocument1 page40S Gives A Thickness: NG Thickness Less Than RequiredNasrul AdliNo ratings yet

- Shear Lug Verification Example 12Document1 pageShear Lug Verification Example 12Nasrul AdliNo ratings yet

- Pipes. Maxi 6 PDFDocument1 pagePipes. Maxi 6 PDFNasrul AdliNo ratings yet

- TC 1.59 MM The Schedule Is To Be Determined Thread Depth TD 0 MM Mill Tolerance MT 12.5 %Document1 pageTC 1.59 MM The Schedule Is To Be Determined Thread Depth TD 0 MM Mill Tolerance MT 12.5 %Nasrul AdliNo ratings yet

- Pipes. Maxi 4 PDFDocument1 pagePipes. Maxi 4 PDFNasrul AdliNo ratings yet

- Stripper Efficiency Calculationfor Ammonia CO2 Stripping ProcessDocument10 pagesStripper Efficiency Calculationfor Ammonia CO2 Stripping ProcessRaga BimaNo ratings yet

- Ej800ahfph (2016-2017) W800 PDFDocument86 pagesEj800ahfph (2016-2017) W800 PDFAlbert DepanoNo ratings yet

- Mot So Loai Van Hay DungDocument14 pagesMot So Loai Van Hay DungNguyễn Xuân NamNo ratings yet

- Manual Aire Acondicionado Infiniti q50Document102 pagesManual Aire Acondicionado Infiniti q50David LópezNo ratings yet

- Screw Conv Comp WebDocument92 pagesScrew Conv Comp WebHannan yusuf KhanNo ratings yet

- Heat NoDocument234 pagesHeat NoDARMANo ratings yet

- QAQC WE 20 and 27th December 07Document3 pagesQAQC WE 20 and 27th December 07MarkyNo ratings yet

- SN 200 - May 2016Document136 pagesSN 200 - May 2016Dhaivat KoraNo ratings yet

- 2021-11 2021-12 Drive JD Piping-Stress-EngineerDocument2 pages2021-11 2021-12 Drive JD Piping-Stress-EngineerSomnath LahaNo ratings yet

- Scope of Works, Technical Specifications AND Bill of MaterialsDocument16 pagesScope of Works, Technical Specifications AND Bill of MaterialsRoi KimssiNo ratings yet

- Acoustics - Knowledge BookletDocument92 pagesAcoustics - Knowledge BookletShyam KumarNo ratings yet

- 2015 CatalogueDocument48 pages2015 CatalogueSouhardh K SNo ratings yet

- Tetra PakDocument13 pagesTetra PakPriya Subramanian0% (1)

- Astm C599 (1991) PDFDocument11 pagesAstm C599 (1991) PDFamusumuseeNo ratings yet

- Tubing Data SheetDocument8 pagesTubing Data Sheetksivakumar09No ratings yet

- DP-40 Aln Manual (MM10 R3)Document10 pagesDP-40 Aln Manual (MM10 R3)Amit ChourasiaNo ratings yet

- Ficha Tecnica Iloform RS 5116Document2 pagesFicha Tecnica Iloform RS 5116Victor Manuel Gonzalez PerezNo ratings yet

- PV SeriesDocument43 pagesPV SeriesramabhplNo ratings yet

- W200 Manual enDocument48 pagesW200 Manual enkhangduongda2No ratings yet

- Ws & Sanitary Works SORDocument267 pagesWs & Sanitary Works SORGurucharan Prajapati78% (9)

- Consolidated Piping Boq For Grade-Cs-Rev-01 PDFDocument4 pagesConsolidated Piping Boq For Grade-Cs-Rev-01 PDFSalz EngineeringNo ratings yet

- Dynaflex CatalogDocument99 pagesDynaflex CatalogLuis Carlos MayorgaNo ratings yet

- Trusted Protective Coatings: The Onshore Oil and Gas IndustryDocument7 pagesTrusted Protective Coatings: The Onshore Oil and Gas IndustryPretech AnandNo ratings yet