Professional Documents

Culture Documents

Pole Assembly and Installation For Street Light Poles

Uploaded by

tsraj10Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pole Assembly and Installation For Street Light Poles

Uploaded by

tsraj10Copyright:

Available Formats

Doc.

No: 8.6.01

Revision: 0

Technical Instruction Date: 16-4-2013

Replaces: 8.4.2.1

Pole Assembly & Installation

For Street Light Poles

The purpose of this technical instruction is to detail those actions necessary to ensure that Street Lighting columns are joined in

compliance with the applicable design standards.

1.0 Check Procedure for Supplied Joined Sections

1.1 The pole sections may be supplied joined by INGAL EPS or may require on site joining. Generally, joined sections that are no longer than 12m in

overall length may be supplied joined by INGAL EPS; subject to contractual agreements or at the discretion of INGAL EPS.

1.2 Ascertain whether the poles supplied have been supplied joined by INGAL EPS. If supplied joined by a third party, ascertain that the correct joining

procedures, as below, have been followed.

1.3 Visually and physically check any supplied joined sections to ensure the slip joint is tight – if the method used to join the supplied sections can not

be determined (i.e. if joined by a third party and not by INGAL EPS) and/or the slip joint does not appear to be tight then re-apply the joining force

as per the joining procedure below.

Note: Physical checking will simply involve pulling and rocking the two sections by hand and is intended to identify any sections that have clearly not been

compressed together.

2.0 Joining Procedure

2.1 Arrange the sections on to packing so that the underside of the pole will be horizontal and the pole is adequately supported off the ground. Ensure

the height of the packing is compatible with the assembled pole to provide adequate ground clearance and that there is a minimum clearance of

300mm from the end of each nominal slip length.

2.2 Wedge the sections to prevent accidental rotation.

2.3 Ensure the sections are correctly aligned in relation to the doors, outreach, cable exits etc.

2.4 Sling the section for assembly at its centre of gravity and engage the sections, making sure that perfect alignment is maintained. Only one section at

a time is to be joined starting from the base section.

2.5 Make a temporary mark on the top face of the male section to indicate the specified slip length. Make an additional temporary mark 150mm

beyond the specified slip length, noting it as slip + 150.

2.6 Under strict supervision join the two sections together by applying a compressive force along the central axis of the two sections. Ensure that

telescoping of the sections proceeds evenly about the pole axis and no misalignment is present. Gradually increase the compressive force to 2,000

kg – at the same time the external surface of the slip joint shall be hammered via a wooden block to assist in achieving a good joint (care shall be

taken to ensure the pole surface/coating is not damaged). Release the compressive force.

Note: If a compressive force of 2,000 kg can not be achieved for a particular reason, contact INGAL EPS and advise the force achieved and the reason for

not achieving the required force – INGAL EPS will advise course of action).

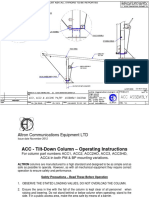

There are a number of different set-ups used to join pole sections – it is most important that the resultant compressive force is applied coincident

with the pole axis, as any eccentric loading may result in a misaligned joint and/or may damage the pole sections due to the additional bending

stresses. A particular set-up is shown in Figure 1.

Wire Rope Pulley Crossbeam clamped

Crossbeam clamped to bottom of section

to top of section

Pulley

5 Tonne Tirfor Load Cell. A measurement of 1000kg will result

in a 2000kg compressive force in the pole

Figure 1.

Note: Set-up to be symmetrical about the pole axis to

ensure resulting compressive force is along the pole axis

ingal eps Technical Instruction Street Light Poles Page 1

Doc. No: 8.4.3.1

Pole Assembly & Installation for Street Light Poles Revision: 0

Date: 03-10-2011

2.7 Record the slip length achieved by reference to the marking positions previously applied. If the slip length achieved is less than 1.35 times the

bottom internal dimension (across flats or internal diameter) of the female section, then notify INGAL EPS for course of action.

2.8 Before removing the crane sling, pack up the newly assembled section to the required level ensuring that the packing is at least 300mm clear of

the next joint to be made. At the same time re-pack and wedge under the new slip joint before removing the original packing and proceed in this

manner until completion of assembly, keeping a careful check on alignment.

3.0 Lifting Procedure

3.1 Ensure the column is correctly assembled prior to lifting (all necessary attachments/fittings are added and sections have been correctly joined).

3.2 Ensure all lifting tackle is checked for its capacity and adequacy for the weight of pole being lifted.

3.3 Attach a single loop sling around the pole at approximately two thirds of the overall height, taking care not to damage the pole finish (synthetic

slings should be used for painted product). The sling shall not be wrapped tight around the pole.

3.4 On the opposite side to the lifting side, attach a safety rope from the sling and attach the other end to a hook which is to be hooked into the

access door. Ensure the safety rope is taut at all times. Refer Figure 2.

The purpose of the above arrangement is to prevent the sling from slipping up the pole while at the same time transferring all force parallel to

the pole’s axis back through the base of the pole (preventing sections from accidentally slipping apart). It is important that the sling is not tightly

wrapped around the pole and that the safety rope remains taut at all times.

Note: It is the operator’s responsibility to ensure that the safety rope remains taut and the hook remains in position at all times until the pole is permanently

secured to the footing.

3.5 Begin lifting the pole. After lifting the top of the pole approximately 1m above the ground (base should still be supported on the ground), stop and

check the arrangement. Ensure that the safety rope is still taut and that the sling begins to rotate around in-line with the lift. Refer Figure 2.

3.6 Continue lifting the pole ensuring that the safety rope remains taut at all times and that the sling continues to rotate around. Refer Figure 3.

3.7 Carefully place the pole on the foundation bolts. DO NOT release the load from the crane (safety rope is to still remain taut) until washers and

nuts are placed on all threads and initially tightened.

3.8 Release the load from the lifting crane – the lifting sling should loosen and the safety rope can be

used to guide the lifting sling down the pole as the lifting crane cable is run down.

3.9 Remove lifting tackle.

Sling free to slide up

Single Loop Sling

Approximately

/3 x H

2

1000

Safety Rope

Ensure always taut

Ground Level

Figure 2. Check safety rope is taut Safety Rope Hook into door

before continuing lift Ensure always taut

Hook into door

Ground Level

Figure 3.

ingal eps Technical Instruction Street Light Poles Page 2

Pole Assembly & Installation for Street Light Poles

4.0 Plumbing and Grouting Procedure

4.1 Plumb the column using the adjusting nuts. It is more important to have the top of the vertical part of the pole in line with the base of the pole

rather than having the base plate level – particularly so for poles with single outreaches and loading on one side which will exhibit a natural ‘bowing’.

4.2 Tighten all nuts to the underside of the base plate and tighten down the corresponding nuts above the base plate.

4.3 Fill the space between the base plate and the foundation with a non-shrink general purpose construction grout – following the manufacturer’s

instructions.

4.4 Clean up area.

For more information please contact INGAL EPS:

Tel 1800 623 302 | Email sales@ingaleps.com.au

or visit www.ingaleps.com.au

Disclaimer The instructions included in this document have been written to provide guidance only for the assembly of the equipment therein described. Industrial Galvanizers

Corporation Pty Ltd is not liable for any direct, indirect or consequential loss or damage to property or personal injury that may arise in tort, equity or otherwise at

law as a result of following these instructions. | Copyright © 2013 Industrial Galvanizers Corporation Pty Ltd, trading as INGAL EPS.

You might also like

- Method Statement For Installation of Puddle Flange DN 500Document8 pagesMethod Statement For Installation of Puddle Flange DN 500Ahmed ImranNo ratings yet

- Method of Statement For Installation of Wires and Cables PDF FreeDocument6 pagesMethod of Statement For Installation of Wires and Cables PDF Freetristan guarinoNo ratings yet

- Installation of AMI/AMR CablesDocument9 pagesInstallation of AMI/AMR Cablessalman100% (1)

- Method Statement For On Site Installation of DiffusersDocument2 pagesMethod Statement For On Site Installation of Diffusersamg007No ratings yet

- Upstream Excavation Procedure Highlights Key StepsDocument37 pagesUpstream Excavation Procedure Highlights Key StepsabbNo ratings yet

- ED-P1 Licensing and Competency AuthorizationDocument22 pagesED-P1 Licensing and Competency AuthorizationMohammed Zubair0% (1)

- MS For Installation of GCBDocument10 pagesMS For Installation of GCBvarunNo ratings yet

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetYounis KhanNo ratings yet

- GRP Method StatementDocument33 pagesGRP Method StatementManiNo ratings yet

- Install HVAC Duct SystemDocument16 pagesInstall HVAC Duct SystemLouis ClarkNo ratings yet

- KEC International LTD.: RPG GroupDocument13 pagesKEC International LTD.: RPG GrouppopaminoNo ratings yet

- ADWEA's excavation guidelinesDocument22 pagesADWEA's excavation guidelinesRiyazuddin MahamadNo ratings yet

- EMP - Environmental Risk RegisterDocument23 pagesEMP - Environmental Risk RegisterNaveen ChaudharyNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe InstallationDocument35 pagesCgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe Installationdiki anggriawanNo ratings yet

- Main Building Raft Foundation MS-005 R1Document11 pagesMain Building Raft Foundation MS-005 R1Anonymous kWfNFbNo ratings yet

- Installation, Testing - Flushing of Firefighting SystemDocument7 pagesInstallation, Testing - Flushing of Firefighting SystemWahid Husain100% (1)

- Method Statement for Gypsum Panels InstallationDocument8 pagesMethod Statement for Gypsum Panels InstallationNikita KasyanovNo ratings yet

- Fabrication, Installation & Testing of 420m Compressed Air SystemDocument6 pagesFabrication, Installation & Testing of 420m Compressed Air Systemvishwas salunkheNo ratings yet

- Weida Subsoil PipeDocument4 pagesWeida Subsoil PipeOngNo ratings yet

- Progress Up To 05-Des-2013Document1 pageProgress Up To 05-Des-2013Asep MAkmurNo ratings yet

- M1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BDocument72 pagesM1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BAnandu AshokanNo ratings yet

- Check List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelDocument6 pagesCheck List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelAminovic PlusNo ratings yet

- PAL - Construction GuidelinesDocument28 pagesPAL - Construction GuidelinesCarew Mohammed AbayomiNo ratings yet

- DC Cable LayingDocument8 pagesDC Cable LayingAhamed UmarNo ratings yet

- NCR Action PlanDocument5 pagesNCR Action PlandasNo ratings yet

- Tech Gss & TssDocument218 pagesTech Gss & Tsser.ras.ma100% (1)

- KAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01Document10 pagesKAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01rickie7809No ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- SURFACE PREPARATION & PAINTING PROCEDURE FOR AIR RECEIVER TANKDocument4 pagesSURFACE PREPARATION & PAINTING PROCEDURE FOR AIR RECEIVER TANKWijayanto BekasiNo ratings yet

- Lifting & Installation Pipes Plan - Romp 05Document6 pagesLifting & Installation Pipes Plan - Romp 05syed khaja misbhuddinNo ratings yet

- Guangzhou Botny Chemical MSDS Aerosol PaintDocument5 pagesGuangzhou Botny Chemical MSDS Aerosol PaintpedroNo ratings yet

- NOVEC System - Commissioning and TestingDocument5 pagesNOVEC System - Commissioning and TestingSalim Bakhsh100% (1)

- Risk Assessment - Electrical WorksDocument1 pageRisk Assessment - Electrical WorksGenerdheil Dela CruzNo ratings yet

- Disinfection Procedure For Water Distribution LinesDocument3 pagesDisinfection Procedure For Water Distribution Linesfa forb100% (1)

- 052876-005 Patio Awning Installation ManualDocument8 pages052876-005 Patio Awning Installation ManualStacy OneillNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- Raychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVDocument4 pagesRaychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVgiovany_vq91No ratings yet

- Method Statement For Foundation ExcavatiDocument6 pagesMethod Statement For Foundation ExcavatiArianne Mae De Vera GallonNo ratings yet

- Draft Method Statement Decorative Tile Installation - RemovedDocument17 pagesDraft Method Statement Decorative Tile Installation - Removedyusuf anwerNo ratings yet

- Release Notes: RDL-3000 XP Edge v3.9Document8 pagesRelease Notes: RDL-3000 XP Edge v3.9alex BecerraNo ratings yet

- Fan Coil Unit Installation Check ListDocument5 pagesFan Coil Unit Installation Check ListAkshay GarudNo ratings yet

- 38 Through Installation Job Safe Practice Ladder and Rack InstallationDocument1 page38 Through Installation Job Safe Practice Ladder and Rack InstallationsalmanNo ratings yet

- TR-CA-MS-004 - B Shifting Concrete BarriersDocument14 pagesTR-CA-MS-004 - B Shifting Concrete Barrierssamer8saifNo ratings yet

- Excavation Method Statement for Schools Improvement ProjectDocument19 pagesExcavation Method Statement for Schools Improvement ProjectIrfan AliNo ratings yet

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDocument10 pagesSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanNo ratings yet

- Risk Assessment MV Power Cables & Accessories InstallationDocument10 pagesRisk Assessment MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument12 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- Compliance Statement for 4 Residential Building ProjectDocument1 pageCompliance Statement for 4 Residential Building ProjectAhmed HelmyNo ratings yet

- Method Statement Risk Assessment For Pump Installation 2 PDFDocument4 pagesMethod Statement Risk Assessment For Pump Installation 2 PDFALTHAF HUSSAINNo ratings yet

- Basra Multipurpose Terminal Construction Method StatementDocument26 pagesBasra Multipurpose Terminal Construction Method StatementMahmoud FakhereddinNo ratings yet

- Method Statement RISK ASSESSMENT For Mechanical Piping CompressDocument41 pagesMethod Statement RISK ASSESSMENT For Mechanical Piping CompressVlad KaroNo ratings yet

- UntitledDocument4 pagesUntitledJUANNo ratings yet

- HELIAX Coaxial CableDocument8 pagesHELIAX Coaxial CablehernanoygNo ratings yet

- Install and Operate Bucket Elevator ManualDocument12 pagesInstall and Operate Bucket Elevator ManualKoevoet1No ratings yet

- Instruction Manual: Spring BalancerDocument7 pagesInstruction Manual: Spring Balancerjaskaran singhNo ratings yet

- 999-998-423 - 425 InstructionsDocument4 pages999-998-423 - 425 InstructionsKimba WorthNo ratings yet

- Synchronous Drive InstallationDocument4 pagesSynchronous Drive InstallationryanmackintoshNo ratings yet

- Short Circuit Current CalculationDocument3 pagesShort Circuit Current CalculationDHAMIM ANSARI0% (1)

- RPG Cable GlandsDocument6 pagesRPG Cable GlandsAhamed AshithNo ratings yet

- Inspection and Testing Plan of Electrical Equipment Procedure May 2013 PDFDocument19 pagesInspection and Testing Plan of Electrical Equipment Procedure May 2013 PDFtsraj10No ratings yet

- Thesis Regarding Shortcircuit and ProtectionDocument197 pagesThesis Regarding Shortcircuit and ProtectionMandip Pokharel100% (1)

- Transformer Basics (Excellent For Practical Purpose)Document40 pagesTransformer Basics (Excellent For Practical Purpose)Sandeep Kumar100% (3)

- Central Battery System DesignDocument11 pagesCentral Battery System Designssatgr100% (1)

- Panel Design & Calculate Size of Bus Bar: 20 CommentsDocument9 pagesPanel Design & Calculate Size of Bus Bar: 20 CommentspvamanNo ratings yet

- PA Catalogue 2010 - WEBDocument28 pagesPA Catalogue 2010 - WEBelshoubryNo ratings yet

- Cable Tray Size CalculationDocument3 pagesCable Tray Size Calculationtsraj10No ratings yet

- Cable Joint Spec 02.9Document29 pagesCable Joint Spec 02.9nvinodn06100% (1)

- Pole Assembly and Installation For Street Light PolesDocument3 pagesPole Assembly and Installation For Street Light Polestsraj10No ratings yet

- Testing of Electrical Installations GuideDocument28 pagesTesting of Electrical Installations Guidetsraj10No ratings yet

- PST BSC 2009Document175 pagesPST BSC 2009manikantanNo ratings yet

- Qwest GuidelinesDocument297 pagesQwest GuidelinesGreg WilliamsNo ratings yet

- Technical Specification for 315kVA to 2500kVA Distribution TransformersDocument51 pagesTechnical Specification for 315kVA to 2500kVA Distribution Transformerstsraj1083% (6)

- Highbay GuideDocument8 pagesHighbay Guidehemantgupta226No ratings yet

- Power Ups PDFDocument7 pagesPower Ups PDFtsraj10No ratings yet

- Thesis Regarding Shortcircuit and ProtectionDocument197 pagesThesis Regarding Shortcircuit and ProtectionMandip Pokharel100% (1)

- Grace - SD 092810Document24 pagesGrace - SD 092810givepleaseNo ratings yet

- 4 Electric Lighting Design TechniquesDocument34 pages4 Electric Lighting Design TechniquesWaleed Mohammed Fekry100% (1)

- Mep Specs PDFDocument152 pagesMep Specs PDFtsraj10No ratings yet

- Abb AtsDocument156 pagesAbb AtsmherbakNo ratings yet

- MEP Guide For Planning Engineers DemoDocument11 pagesMEP Guide For Planning Engineers Demomohan_2710915067% (3)

- 14ld44 Strip LightDocument2 pages14ld44 Strip Lighttsraj10No ratings yet

- Siemens ElvDocument222 pagesSiemens Elvtsraj10No ratings yet

- LF LEOlight Installation GuideDocument3 pagesLF LEOlight Installation Guidetsraj10No ratings yet

- BICSI NG 15 Designing Integrated ELV Services OIukayode SodimuDocument19 pagesBICSI NG 15 Designing Integrated ELV Services OIukayode SodimuManjunath BeleriNo ratings yet

- HomeAutomation CatalogueDocument132 pagesHomeAutomation Cataloguetsraj10No ratings yet

- Door Entry Kit CatalogueDocument2 pagesDoor Entry Kit Cataloguetsraj10No ratings yet

- S10 Electric Power PackDocument12 pagesS10 Electric Power PackrolandNo ratings yet

- Kathleen Langreo Notes FB (Feb6)Document27 pagesKathleen Langreo Notes FB (Feb6)Kaycee Ayo100% (4)

- Inkontinensia Urin: Dr. Adhi Permana, SPPDDocument35 pagesInkontinensia Urin: Dr. Adhi Permana, SPPDTiara KhairinaNo ratings yet

- F588 PDFDocument8 pagesF588 PDFOscar Gutiérrez-JuncoNo ratings yet

- Guide to Conducting SAFOP StudiesDocument52 pagesGuide to Conducting SAFOP Studiesokemma79% (14)

- Sanoj Kumar - OriginalDocument5 pagesSanoj Kumar - OriginalHamid SaifNo ratings yet

- CDI-500 Specialized Crime Investigation and Legal MedicineDocument20 pagesCDI-500 Specialized Crime Investigation and Legal MedicineCherry Len FaroniloNo ratings yet

- Jurnal Risna YantiDocument14 pagesJurnal Risna YantiRisnayantiNo ratings yet

- Mar For M: I MMQ SeriesDocument28 pagesMar For M: I MMQ SeriesIpal Febri NartaNo ratings yet

- 1 s2.0 S2210803316300781 MainDocument8 pages1 s2.0 S2210803316300781 MainGilang Aji P. EmonNo ratings yet

- TICSA - Diesel Uno Petroleos Guatemala (13.01.23)Document1 pageTICSA - Diesel Uno Petroleos Guatemala (13.01.23)Luis M LópezNo ratings yet

- Ringing On A Transmission LineDocument33 pagesRinging On A Transmission LinePrem BhaskaraNo ratings yet

- ABYIPDocument18 pagesABYIP千住 マリエルNo ratings yet

- Type 2 Diabetes MellitusDocument6 pagesType 2 Diabetes MellitusJoy NisoladaNo ratings yet

- Mercedes ManDocument7 pagesMercedes Manien yeyenNo ratings yet

- Passive Filter vs. Active Filter: DefinitionsDocument3 pagesPassive Filter vs. Active Filter: DefinitionsAmit DebnathNo ratings yet

- Hyundai Elevator Manual Helmon 2000 InstructionDocument27 pagesHyundai Elevator Manual Helmon 2000 InstructionReynold Suarez100% (1)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech09920050% (2)

- Civil Engineering Subjects (1st - 5th Year) - 1Document5 pagesCivil Engineering Subjects (1st - 5th Year) - 1Vincent TayagNo ratings yet

- Gas Turbine Performance Enhancement Update: GE Energy ServicesDocument45 pagesGas Turbine Performance Enhancement Update: GE Energy Servicesesteban100% (1)

- Diesel HatchbackDocument14 pagesDiesel HatchbackloganathprasannaNo ratings yet

- Man FXM FKM Motors PDFDocument176 pagesMan FXM FKM Motors PDFRenato MeloNo ratings yet

- SI44M 60H 80H-DeN1730-V12web DownloadedDocument4 pagesSI44M 60H 80H-DeN1730-V12web DownloadedtauraimukumbaNo ratings yet

- I Wanna Be Yours Arctic Monkeys Love SongDocument3 pagesI Wanna Be Yours Arctic Monkeys Love SongAndréia E NiltonNo ratings yet

- Carl Sagan Wonder and Skepticism SecDocument13 pagesCarl Sagan Wonder and Skepticism SecAndreea BanagaNo ratings yet

- Nutrition Effects of VitaminsDocument21 pagesNutrition Effects of Vitaminsblessed cccNo ratings yet

- Plant LayoutDocument16 pagesPlant LayoutAli MahmoudNo ratings yet

- 1830PSS R36 QuickReferenceGuide 8DG60888JAAADocument66 pages1830PSS R36 QuickReferenceGuide 8DG60888JAAAFelippe CanatoNo ratings yet

- Integrating Kuleana Rights and Land Trust PrioritesDocument50 pagesIntegrating Kuleana Rights and Land Trust PrioritesKeala Rodenhurst-JamesNo ratings yet

- Motor Cat 924HZDocument6 pagesMotor Cat 924HZAdemilson Rangelvieira100% (1)