Professional Documents

Culture Documents

4.4.2 Technical Specification

Uploaded by

Siji OktoberCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.4.2 Technical Specification

Uploaded by

Siji OktoberCopyright:

Available Formats

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

4.4.2. TECHNICAL SPECIFICATION

4.4.2.1 SOIL INVESTIGATION AND LABORATORY TESTING

4.4.2.1.1 SOIL INVESTIGATION

The scope of soil investigation including all tests shall, be performed by the

Contractor to clarify the soil conditions in order that satisfactory and

economical foundation can be designed and suitable foundation types can be

proposed for recommendations. Site investigation data is not provided on Bid

Document.

The Contractor shall submit to the Owner for approval the investigations

program including all tests to satisfy him self in preparing foundation design

for entire structures. The approved program shall not relieve the Bidder from

his obligation to undertake additional soil investigations based on the Owner

request at no additional cost to the Owner.

The following minimum of the investigations program are:

1. Sampling and coring

2. Standard penetration test

3. Physical property test

a. Moisture content

b. Specific gravity

c. Grain size analysis

d. Liquid limit, plastic limit

e. Chemical analysis of soil

4. Mechanical property test

a. Unconfined compression test

b. Direct shear test

c. Consolidation test

d. Permeability test

e. Standard Proctor Test

f. CBR Test

4.4.2.1.2 LABORATORY TESTING

The work includes performing laboratory tests on disturbed and relatively

undisturbed and remolded soil samples, and on rock cores obtained during

the subsurface investigations. All testing shall be performed as soon as

practical after receiving the samples.

PT Indo Ridlatama Power Part 4.4 - 12 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

All of the test performed shall be documented for evaluation and future

referencing and standard testing procedures applied shall be included in the

documentation. A listing of the number of required test, which are anticipated

for this Contract, shall be included in Bid Proposal.

The Bidder may consider performing additional tests which he believes are

necessary and appropriate for a proper evaluation of the characteristics of the

materials subject to approval by the Owner.

4.4.2.2 TOPOGRAPHY AND BATHIMETRY SURVEY

4.4.2.2.1 TOPOGRAPHY

The Contractor shall, as described in this section, perform all surveying and

setting out and calculations necessary to establish the accurate location of the

power plant structures. The survey area required for the power plant will not

less than the area indicated in the Owners location topo map as given in Bid.

Drawing.

The Contractor shall set out, construct and establish benchmarks at the site

for this work. The survey for this benchmark grid shall only be based on

approved points. The Contractor shall protect, preserve and keep accessible

the benchmark of the basic survey and any provided by him self. Any damage

or removal of benchmark shall be brought to the attention to the Owner and

shall be repaired on the Bidder cost.

The plane survey shall be performed and topographic maps shall be prepared

for his requirement in preparing of construction drawing. All this drawing shall

be submitted to the Owner for review and approval before used.

4.4.2.2.2 BATHYMETRIC SURVEY

As for reference, bathymetrical map of the river facing the proposed power

plant site is provided by the Owner. The Owner shall not accept any

responsibility for the integrity of the data nor any interpretation upon it.

Accordingly, a bathymetry surveys shall be carried out by the Bidder up to

approximately at 5 m depth from LLWL to ensure that the 5.000 DWT flat barge

for coal transportation is able to unload and maneuver safely,

PT Indo Ridlatama Power Part 4.4 - 13 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

1. The Contractor shall submit the plan and method of the survey, including

all equipment used and workers for the works including their

experiences.

2. Bar checking shall be carried out at 1 m intervals so as derive 1 meter

contour intervals having 0.1 meter accuracy, line spacing shall be at 5 m

intervals except shore line sounding area, preferably perpendicular to the

shore line.

3. The river water level shall be observed during the sounding survey and

start from and return to the datum level with direct leveling.

Reference point for Bathymetric survey shall be in one system with reference

point for Topographical mapping.

HHWL, MWL, LLWL survey and analysis shall be carried out as the above

Bathymetric survey works.

The bathymetric survey area required for the power plant shall be sufficient for

Wharf design.

4.4.2.3 EXCAVATION WORK

4.4.2.3.1 COMMON EXCAVATION WORK

Common excavation includes excavation in all materials other than rock.

Excavation shall include excavation and disposal of excavated materials, all

protection need, sheeting, shoring, bracing and cofferdams, dewatering of

excavation at work areas as required to properly install and complete the work,

regardless of the nature of materials encountered in excavation, including

construction of temporary diversion ditches, culverts, temporary access road

etc, where required.

Excavation means excavation of material, which may be removed by hand

tools, dozers or other moving equipment. Excavation may be accomplished by

any method and by the use of any excavation and hauling equipment suitable

for the work.

The Contractor shall analyze the potential sliding of plant site area before

execution of the work. Unused excavated material shall be disposed to a spoil

bank area approved by the Owner with the best dumping and compacting

method.

PT Indo Ridlatama Power Part 4.4 - 14 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

In case that excavation shall not be carried out to specified levels as indicated

on the approved drawings and the natural foundation material is disturbed or

loosened for any reason, the foundation shall be improved by compaction or

replaced with approved fill and compacted, as directed by the Owner.

4.4.2.3.2 ROCK EXCAVATION WORK

Rock excavation includes excavation in all materials other than common

excavation which can not be removed by a ripper.

When blasting work for rock excavation is carried out, the Contractor shall

ensure that the blasting method applied shall not disturb the surrounding

areas. The blasting system applied shall be proved that the ground

acceleration impact shall not exceed the allowable value for the surrounding

building.

Loose and fractures rock surface shall be protected properly to avoid any

sliding or movement and endanger the working environment.

4.4.2.3.3 FILL

The Contractor shall perform filling and backfilling work in accordance with this

section and as shown on the approved drawings or as directed by the Owner.

The sources of material shall be well graded, no more than 15% passing

No.200 screen, maximum particle size 75 mm.

Compaction Densities Material shall be brought up to grade elevation

indicated on the approved drawings, with suitable moisture control and

compaction throughout placement, to produce to 90 % of maximum dry

density per ASTM D 1557 Test Method indicated.

4.4.2.3.4 RECLAMATION WORK (NA)

4.4.2.4 STRUCTURAL FOUNDATIONS

The Contractor shall design, supply and install complete reinforced concrete

mat/floor, rock dowel, anchor bolt, grouting and foundation piles (newly

manufactured) required to support buildings, major structures and equipment.

The subsoil engineering property as the results of a detailed geotechnical

investigation performed by the Contractor shall be as design basis to

PT Indo Ridlatama Power Part 4.4 - 15 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

determine the amount and length of the piles. Lightly loaded structures and

other facilities not sensitive to settlement may be founded on shallow

foundations or alternatively ground improvement techniques may be

employed in conjunction with the Site development works.

Foundations shall be capable of withstanding all the applied loadings during

construction, operation and maintenance of the plant without any distress,

failure or settlement causing loss of function, damage or durability problems

for the whole of the operating life of the station.

Before driving of pile, Contractor shall pre-boring or pre-coring in order to

penetrate cemented layer, if necessary, at no extra cost to the Owner.

If bored piles are required the Contractor shall design and provide 300 mm

and 600 mm bored piles for light structures and heavy structures respectively.

12 m depth for both types of pile as the basis of the bidding.

4.4.2.4.1 PRE-STRESS CONCRETE SPUN PILE (NA)

Form Work

Form facing shall produce acceptable finished surfaces with the required

profile and within tolerances given in PCI MNL – 1 16.

Pre-stressing Tendons

Pre-stressing tendons shall conform to the requirements as specified below :

Grade 250 K (1724MPa), seven wire, uncoated, stress-relieved steel

strands in conformance with ASTM-A416 or

Minimum tensile strength 1655 MPa, wire, uncoated stress/-relieved steel,

for pre-stressed concrete in conformance with ASTM A421 or

Minimum tensile strength 1586 MPa, steel bars in conformance with ASTM

A322 and A29.

Reinforcing Steel

Reinforced steel shall be deformed and plain billet-steel bars in conformance

with ASTM-A615. Spiral reinforcing shall conform to the requirements of ASTM-

A82.

Concrete Materials

PT Indo Ridlatama Power Part 4.4 - 16 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Minimum cylinder concrete comprehensive strength shall be 500 kg/cm2 at 28

days.

Fabrication

Piles shall be fabricated in compliance with the applicable provisions of

“Specification for Concrete Work”, ACI 543R and PCI NML-116.

Pre-tensioning stress shall be transferred to the concrete pile until a minimum

strength of 400 kg/cm2 is reached in the concrete.

The Bidder shall submit with the bid proposal full, details of the proposed pile

driving equipment and the method of carrying out the work.

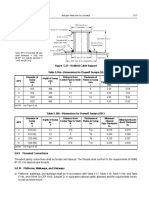

4.4.2.4.2 STEEL PIPE PILE

The steel pipe piles shall be spiral welded with nominal size 609.6 mm outer

diameter, meeting at least one of the following specifications:

1. API 5L

2. ASTM A53 (with mill certificates to confirm minimum yield strength).

3. ASTM A252 with the following provisions :

a. Chemical analysis of material shall show that both the equivalent

carbon content and total carbon content are less than 0.30%.

b. Unless spiral welds are certified as conforming to the requirements

of ASTM A53 or API 5L-1980 to the satisfaction of the Owner, welds

shall be 100 percent inspected by ultrasonic or electromagnetic

inspection according to the requirements of ASTM A53. This

inspection shall be conducted at the Bidder’s expense.

c. The pipes joint shall be fully penetration weld. All welds shall be

inspected by ultrasonic or electromagnetic inspection with 100%

for the first 3 m of weld for each position for each welder.

Thereafter, shall be 1 random spot examination of 1 pile joints for

each additional 10 piles joint of weld. If any random spot fails to

meet the acceptance standard, 2 additional random spots shall be

examined at locations on each pile joints from the failure random

spot, if still fail to meet the acceptance standard, the entire welds

of 10 pile joints shall be completely examined.

d. The Contractor shall bear the expense of repairing and re-

inspecting all rejected welds.

PT Indo Ridlatama Power Part 4.4 - 17 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

The Contractor shall provide necessary certified mill test reports to

demonstrate the material meets the above standards.

Welding practice and qualifications of fabricators and erectors of welded

construction shall conform to the requirements of American Welding Society

(AWS) Welding Code AWS D1.1-86.

The driven piles shall have a maximum tolerance of 2 % from intended batter,

1% from intended verticality and its location at the cut off elevation within 75

mm of the true position as shown on the Drawings. Variation of pile elevation

shall not be more than 25 mm plus or minus.

If the pile location is not within the above specified limits, the Bidder shall be

liable for correction measures as directed by the Owner at no cost to Owner.

The steel pile shall be driven until the required final set. If piles do not achieve

the required final set at the specified depth, pile shall be driven deeper until

the requirement is met.

The upper part of all piles shall be filled with reinforced concrete as indicated

on the approved drawings.

4.4.2.4.3 BORED PILES

Piles shall be capable to withstand all the applied loadings during

construction, operation and maintenance of the plant and for the whole of the

operating life of the station.

The concrete for piles shall use the Portland cement type II ASTM Standard. All

details with respect to the pile dimensions, length, shall be shown on the

Bidder’s proposed drawings, and shall be subject to approval by the Owner.

All piles shall satisfy the tolerances for position, the deviation in position of pile

center line from the pile center point as shown on the setting out drawing shall

not exceed 75 mm in any direction from the true position of the same pile.

4.4.2.4.4 PRE-STRESS CONCRETE SHEET PILE

4.4.2.4.5. PILE TESTING

Prior to construction of working piles, a number of trial piles shall be

constructed and load tested (up to 3 times working load, called as excessive

loading test as ASTM standard) as follows:

PT Indo Ridlatama Power Part 4.4 - 18 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

1. Chimney area: 1 conventional compressive test, 1 lateral test, 1 tensile

test and 1 High Strain Dynamic Test.

2. Boiler area: 1 conventional compressive test, 1 lateral test and 1 High

Strain Dynamic Test.

3. Steam Turbine Building area: 1 conventional compressive test, 1 lateral

test and 1 High Strain Dynamic Test.

4. Switchyard area: 1 conventional compressive test, 1 lateral test. 1 tensile

test and 1 High Strain Dynamic Test.

5. Wharf area: 1 conventional compressive test, 1 lateral test and 1 High

Strain Dynamic Test.

All tests shall demonstrate that the pilling system meets the design criteria

including adequate bearing capacity and immediate settlement characteristics

and that the level of workmanship given in the construction proposals can be

achieved.

During the works, 3% of the total number of working piles shall be load tested

by High Strain Dynamic Test Method to demonstrate that the behavior of the

constructed piles correlates with the trial pilling tests and complies with the

design basis. Full recording and monitoring shall be carried out during pilling

as relevant to the pile type.

4.4.2.5 CONCRETE, FORMWORK AND REINFORCEMENT

All concrete, sampling and testing shall comply with the relevant American

Standard (ASTM & ACI).

The bidder shall perform concrete mixed design for each proposed mixture at

least 3 (three) compressive cylinder test for each age shall be made and cured

in accordance with ASTM C-192. The cylinders shall be tested for strength in

accordance with ASTM C-39 at 3, 7 and 28 days.

Minimum of concrete samples for cylinder test during construction as follow:

Total cylinders required from a sample Cylinders for strength test at

representing each 50 m3 of concrete, or 28

3

from each days pour if less then 50 m 3 days 7 days days

3 sets of 3 each (total 9) 3 3 3

PT Indo Ridlatama Power Part 4.4 - 19 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Grades of Concrete

The concrete shall have the minimum compressive strengths shown below:

MINIMUM

CLASS

COMPRESSIVE STRENGTH (Kg/cm2)

C50 500

C30 300

C25 250

C15 150

Unless otherwise specified, concrete of the various classes shall be used as

follows :

Class C50 : For pres-tress concrete structures ( eg. spun piles, sheet

piles)*.

Class C30 : For important structures (chimney windshield structure and

foundation, T/G pedestal, wharf, steam turbine building

foundation, boiler structure foundation, CW pump house).

Class C25 : For all concrete work in the common buildings and

structures of the power plant, unless otherwise specified.

Class C15 : For lean concrete as specified and for un-reinforced

concrete or otherwise noted.

Note : *) The bidder is responsible for any modification of dimension and

concrete grade, if necessary, for driving sound piles in

accordance with site condition at no extra cost to the Owner.

Cement type I shall be used for above grade work, cement type II for sub

structure and all structure directs contact with water including wharf, intake

and outfall structure.

When cement type II is difficult to find in the local market, cement type I with

silica fume admixture of 92% SIO2 conform to ASTM C 1240 is recommended

or PPC cement are another alternative.

PT Indo Ridlatama Power Part 4.4 - 20 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Polypropylene fiber with 0.905 g/ml specific gravity and of 3.5 KN/mm2

Modulus Young shall be used for all important structures.

All cement and reinforcement used in the works shall generally be produced of

local factories and be obtained from a registered firm.

Super sulphate, high alumina cements and admixtures containing calcium

chloride shall not be used. Admixtures shall comply with an approved

standard and shall require evidence of previous acceptable use.

The total chloride content of the concrete mix shall not exceed 0.15% by

weight of cement in accordance with ASTM D512.

The total acid soluble sulphate content of the concrete mix expressed as SO3,

shall not exceed 4%, by mass of the cement in the mix. The cement content of

any mix shall not be less than 160 kg/m3 or greater than 550 kg/m3.

Aggregates shall be specified and tested in accordance with ASTM C 33. The

water cement ratio of any mix shall not be less than 0.5 for characteristic

strengths equal or more than 25 N/mm2. Extra water or other material shall not

be added to mixes after they have left the batching plant.

All false work, formwork and safety standards shall comply with an appropriate

Code of Practice for false work and in compliance with the occupational Safety

and Health Act & Regulations.

The Bidder shall make due allowance for hot weather concreting to the

relevant International standard at no extra cost to the Owner.

4.4.2.6 GROUT WORK

Installation of grout shall be in strict accordance with the manufacturer’s

printed instructions. Wherever requirements for grout and grout installation

differ between this specification and equipment manufacturer’s requirements,

the equipment manufacturers requirement’s shall be applied, subject to the

approval of the Owner.

PT Indo Ridlatama Power Part 4.4 - 21 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Type and Specific Uses of Grout

Type of Grout Specific Use (Grouting)

a) Plastic grout (Regular (1) Conduit, piping etc. Through concrete floors or walls

sand and cement grout) (2) Anchor bolts in drilled holes in concrete

b) Non Shrink Precision (1) Anchor bolts in drilled holes in concrete

Grout (2) Equipment bases where required by manufacturer

or subject to high precision and ultimate strength

(3) Anchor bolts including sleeves, and column base

plates

(4) Pre-stressed anchor hales (Chimney & Transformer

area)

c) Non shrink Inert Iron (1) Anchor bolts in drilled holes in concrete

Reinforced Precision (2) Equipment bases where required by manufacturer or

Grout subject to high repetitive and dynamic loads

PT Indo Ridlatama Power Part 4.4 - 22 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Grout Components and Products

Type of Admixture Grout

Cement Aggregate Mixing Water

Grout (if used) Product

a. Plastic a.1 Portland a.1.1 Grout 75 Conforming a..4 Clean, Not

grout cement, mm thick or to ASTM potable, specified

(Regular ASTM less Fine C494, Type A and free

sand and C150 aggregate, water- from

cement ASTM C33 reducing injurious of

grout) a.2 Type II or a.1.2 Grout admixtures; oil, acid,

III unless thicker than and salt, alkali,

otherwise 75 mm Fine containing organic

indicated aggregate, chloride not matter and

ASTM C33, more than 1% other

or coarse by weight deleterious

aggregate, (Use only if substances

Size No. 7 reviewed by

or 8, ASTM the Owner

C33

b. Non Manufacturer’s standards (this grout shall not contain Same as Item a Not

Shrink oxidizing and gas producing agents, catalysts, specified

Precision inorganic accelerators and chlorides) conforming to

Grout ASTM C1107 Type C

c. Non Manufacturer’s standards (this grout shall contain Inert Same as Item a Not

shrink Iron aggregates, not contain oxidizing and gas specified

Inert Iron producing agents, catalysts, and chloride) ASTM C1107

Reinforce Type C

d

Precision

Grout

PT Indo Ridlatama Power Part 4.4 - 23 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Property Requirement for Placed Grout

Compressive

Type of Grout Flow ability Expansion Bleeding Segregation

strength

a. Plastic grout 250 kg/cm2 at Plastic with No No No visible

28 days maximum requirement requirement bleedings

unless slump 125 mm

otherwise for grout 75

specified mm thick or

less; and

maximum

slump 75 mm

for grout thicker

than 75 mm

b. Non Shrink 700 kg/cm2 at Flow able with Not more No bleeding No

Precision Grout 28 days ASTM Flow Trough than 0.4% at segregation

– C109 at 35-55 cm 7, 14 or 28

Flowable lateral flow at days CRD621

consistency 22 - 30 C

c. Non Shrink 880 kg/cm2 at Flow able with Not more No bleeding No

Inert Iron 28 days ASTM Flow Trough than 0.4% at segregation

Reinforced – C109 at 35-55 cm 7.14 or 28

Precision Grout Flow able lateral flow at days CRD621

Consistency 22 - 30 C

4.4.2.7 BRICKWORK AND MASONRY

Brickwork and masonry shall comply with ASTM C 55 ACI 531.1. Marine sand

shall not be used for brick and masonry works. Calcium chloride shall not be

used for mortar.

All materials and components shall comply with the relevant standards for

mortars. Bricks shall be tested for absorption percentage, soluble salt content,

drying shrinkage, moisture expansion, density and dimensional tolerance.

4.4.2.8 DREDGING

The Contractor shall perform all dredging operations necessary to complete

the power station project implementation throughout the construction period

so far as they relate to the construction of the power plant in particular the

water intake structures and wharf constructions if required.

PT Indo Ridlatama Power Part 4.4 - 24 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

The Bidder shall indicate as applicable, the extent to which dredging is

proposed for both the temporary and permanent works (areas, locations and

volumes).

The Contractor shall furnish, establish and maintain in good order marks,

stakes, gauges, sounding equipment, boats and buoys required for the proper

execution of dredging.

The Contractor shall design and execute the dredging within the plan

indicated on the approved drawing or as directed by the Owner, and ensure

that no portion of the finished dredged work shall, at the time of acceptance,

be higher than the level or levels shown on the approved drawings or as

directed by the Owner. The bidder shall propose the disposal area for unused

material to the Owner for approval.

4.4.2.9 SLOPE PROTECTION

4.4.2.9.1 RIP RAP

The riprap material in relation with their common engineering functions is

stone with sound rock with the size range of stones shall be 15 – 60 cm

diameter.

Contractor shall propose the materials suitable for each engineering function,

location and type of the works to the Owner for approval.

Material properties such as density, hardness and type of rock, shall be

determined by the Bidder and submitted to the Owner for approval.

Riprap shall be furnished and placed to the lines and grades as shown on

approved drawing or as directed by the Owner.

4.4.2.9.2 Shotcrete (NA)

4.4.2.9.3 Gabions

The standard type gabions shall be a flexible hot-dip galvanized gabion with

PVC coated of the type and size comply to SNI 03-0090-1999, as specified

below.

The mesh shall be hexagonal woven mesh, the joints formed by twisting each

pair of wires through three half turns.

PT Indo Ridlatama Power Part 4.4 - 25 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

The size of mesh conforms to standard specification issued by the factory and

shall be not greater then 2/3 of the smallest stone filled in the gabion.

All wire used in the fabrication of the gabions shall be mild steel galvanized

wire, diameter not less than 3.8 mm with an average tensile strength of 44

kg/sq.mm.

Broken rocks for gabions have 150 mm minimum size and 300 mm maximum

size.

The Contractor shall propose the materials suitable for each engineering

function, location and type of the works to the Owner for approval.

Gabions shall be constructed to the shapes and dimension as shown on the

approved drawing or as instructed by the Owner. Hand made gabion shall not

be allowed.

4.4.2.9.4 Reno Matters

1. Mattress

If required, the matters shall be a mechanically fabricated type, made up

of a flexmat or equally approved and provide sufficient strength

requirement and shall be installed as manufacturer recommendation and

approved by the Owner.

The materials used shall conform to the following specification.

a. Raw material Polyester

b. B/Strength warp 1.2 tonnes/m2

c. B/Strength weft 5.6 tonnes/m2

d. Weight 420 gram/m2

e. Slab Size 1.0 x 1.0 m

f. Nominal thickness 100 mm

g. Loom with 3.75 m

PT Indo Ridlatama Power Part 4.4 - 26 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

2. Concrete

Concrete mix proportions shall conform to the following requirements:

a. Cement: 600 kg

b. Sand: 1200 kg shall be washed, zone 3-4, 95% passing mesh 14,

consisting hard dense, durable uncoated rock particles. It shall be

free from injurious amounts of silt, loam, lumps, soft or flaky

particles, shall be such as will not remove desirable fines and the

sand shall subsequently free moisture is uniform and stable.

c. Water: 360 kg (w/c ratio 0.6)

d. Compressive strength at 28 days: 300 kg/cm2

The laying and filling operation shall be limited to an amount that can be

working shift. Only the zip panel of each mattress should. Remain empty

ready for next shift to zip on a subsequence mattress before

recommencing the filling operation.

4.4.2.9.5 Anchoring Works

If required, the anchor bars and grouting shall conform to ASTM F.432

Anchor Bars shall be deformed steel bars of minimum 32-mm diameter.

Anchor shall be supplied free from rust, scale and dirt or other foreign

substances. This anchor could be tensioned or un-tension, depend on the

requirement of the anchors. All the anchors shall pushed into the grouted hole.

Grouting anchor bars shall conform to ASTM F.432

This tensioned anchor is a reinforcement element consisting of a rod,

mechanical or grout anchorage, plate and nut for tensioning by torqueing the

nut or for retaining tension applied by direct pull

4.4.2.9.6 Stone Masonry

The stone for rubble masonry shall be natural or crushed stone.

The stoned used shall be clean and must be washed if necessary in the

opinion of the Owner.

Unless otherwise shown on the approved drawings, stones shall have

minimum size not less than 25 cm.

PT Indo Ridlatama Power Part 4.4 - 27 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

For facework the stones shall show a face of not less than 0.03 m2 and not

more than 0.10 m2 in area and more none shall be less than 125 mm in depth,

they shall be laid to give a uniformly random appearance and shall be

selected in laying so as to present at even distribution of large and small

stones on the face.

The stone shall be placed with 1 Pc : 3 sand after having joints thoroughly

moistened the spaces between the stone and the surface joint shall be filled

with 1 Pc : 3 sand.

4.4.2.9.7 Sod Facing

The Contractor shall responsible to protect earth fill slope from erode caused

by rum off. Sodding material shall be proposed and approved by the Owner.

Maintenance period of sodding shall be 3 months.

4.4.2.10 ROAD AND PARKING.

4.4.2.10.1. SUB GRADE PREPARATION

Excavate sub grade or fill to its proper level or as required, and then grade and

compact to provide a firm foundation of uniform density throughout. Complete

sub grade shall be true to alignment, grade and cross-section, including the

required crown as shown on the approved drawings.

CBR test on the finished level of completed sub grade shall have a minimum

value of 6 in the 98% dry density compacted condition, as per ASTM D698,

Method D.

Prior to placing of any fill material required to bring the sub grade to its proper

level, strip or clean the areas to be covered from any loose or unapproved

materials, organic materials, or any deleterious matter.

Fill holes, ruts and similar defects with approved fill materials as approved by

the Owner. Unstable areas, projecting stone or rock, and similar defects shall

be cut and the areas filled. Round shaped gravel shall categorically not be

used.

The Bidder shall provide temporary drainage as required to facilitate his work

activities during the wet season.

PT Indo Ridlatama Power Part 4.4 - 28 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

4.4.2.10.2. ROAD WORK

The Contractor shall perform all-phases of road construction work per the

requirements stated in this specification and in accordance with the approved

drawings.

Materials used for the sub-base, base and surface courses shall consist of

materials approved by the Owner as specified herein under:

Sub-base Course Material

This material shall consist of well graded material with hard, strong, durable

rock pieces having the following gradation.

Sieve size Percentage Passing by Weight

37.50 mm 100

25.00 mm 90 – 100

19.00 mm 40 – 75

12.50 mm 15 – 35

9.50 mm 0 – 15

4.75 mm 0- 5

Base Course Material

This material shall consist of well graded crushed stone with hard, strong,

durable pieces having the following gradation:

ASTM Standard Sieve Percentage Passing by Weight

1.51” (31.5 mm) 100

1.0” (26.5 mm) 60 – 100

¾” (9.0 mm) 55 – 85

4 (9.5 mm) 35 – 60

10 (4.75 mm) 25 - 50

40 (3.36 mm) 15 – 30

200 (1.18 mm) 8 - 15

Surface Course Material (Hot Asphalt Concrete Paving)

Material for asphalt paving shall conform to the following:

PT Indo Ridlatama Power Part 4.4 - 29 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Asphalt primer ASTM D2027, Grade MC-70 or equivalent

Asphaltic concrete ASTM D3515, job mix formula acceptable to the Owner,

design density between 94 and percent density of

voidless mixture determined by Hubbard-Field test or

ASTM D.1074 or equivalent.

Asphalt cement ASTM D946, Penetration Grade 85-100 or AASHTO

M20, Penetration Grade 85-100 or equivalent.

Coarse aggregate ASTM D692, Size No. 67 or 68 or equivalent.

Fine aggregate ASTM D1073 or equivalent, add mineral filter as

required to provide at least 5 percent of total aggregate

passing No. 200 sieve for surface course.

Construction of Sub base course shall be of minimum of 30 cm thick.

The sub base material shall be rolled and compacted as determined by the

method specified in ASTM D698, Method D.

Any surface if disturbed, for any reason, shall be re-compacted at the

Contractor’s expense before or during the placing of the base coarse material

Construction of Base Course shall be of minimum of 20 cm thick.

After the sub base course for the road has been completed, the base course

shall be placed in layers not less than 10 cm of compacted thickness.

Road bases and surfaces shall be compacted to a dry density as specified in

ASTM D698, Method D. Water shall be added during compaction as required

to achieve the specified dry density.

Asphalt Primer/Primer Coat

The crushed rock base course shall be dried, swept clean of all dust, dirt and

looses particles.

A prime coat of asphalt primer ASTM D2027 GRADE MC70 shall be sprayed

uniformly at rate of 0.90 liter per m2 as required to fill all voids and interstices.

PT Indo Ridlatama Power Part 4.4 - 30 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

The asphalt prime coat shall be placed when the compacted base course

layer are acceptable, as approved by the Owner.

Hot Asphalt Concrete Paving (minimum of 7.5 cm thick)

Asphaltic concrete shall be placed when the humidity, air temperature, general

weather conditions of the compacted base course are suitable, as approved

by the Owner.

The paving shall be laid in two layer of 37.5 mm thickness (compacted) and

shall be laid hot using a mechanical spreader.

The asphalt paving shall be compacted continuously to obtain the specified

density without causing undue displacement. The completed paving shall

have a density equal to or greater than 95 per cent of the density of a

laboratory specimen made in the proportions of the job mix formula.

Curbs, sidewalks, buildings, and other surfaces shall be protected from

damage by paving equipment and from deposits of asphalt materials.

Deposits of asphalt materials on such surfaces shall be considered as

permanent damage and shall be repaired by the Contractor as directed by the

Owner at no cost to the Owner.

Testing of Hot Asphalt Concrete Paving

The job mix formula, aggregate requirement, and compaction density

requirement for asphaltic concrete paving shall be determined prior to the start

of the paving work by an independent testing laboratory. The laboratory shall

be retained by the Contractor.

4.4.2.10.3 PARKING

Concrete Paving Block

The nominal size of each block shall be 210 mm long x 105 mm wide 100 mm

thick.

The average compressive strength of block shall not be less than 49 N/mm2,

however no individual block strength shall be below 40 N/mm2.

Laying coarse material shall be natural sand, or crushed rock fines and

passing the 5 mm BS sieved and have the following grading:

PT Indo Ridlatama Power Part 4.4 - 31 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

The natural sand filler shall be grades with maximum particle size no greater

than 1.18 mm and containing approximately 10 % by weight passing the 75

microns sieve.

The laying course of sand bedding layer shall be such that, after compaction,

it forms a nominal uniform 50 mm thick layer under the blocks.

This layer shall be lightly compacted by means of the vibrating plate

compactor similar to that used for compacting the block paving course. A

further layer of loose material shall be spread and screened to create a loose

surface on to which the block can be placed.

The surface course shall be compacted by approved plate compactors in

order to ensure the filling of the lower portion of the block-to-block joint by the

laying materials. Two or three passes of the compaction equipment will

normally be required to achieve this condition.

The plate compactor shall have a plan area of not less than 0.25 m2 .

The block paved area shall be then be re-vibrated as before in order to

encourage the filling of the upper part of the block-to-block joint by the

surface-applied material. Top filling and final compaction shall be completed

as soon as practicable after laying and in any case prior to the termination of

work on that day.

4.4.2.9.4 CURB AND GUTTER

Concrete for curbs and gutters shall be class C25 refer to this specification.

4.4.2.11 STRUCTURAL STEEL WORK

4.4.2.11.1 ANCHOR BOLTS, NUTS AND WASHERS

Nominal : ASTM A36 for threaded rods and ASTM A307 for headed bolts and

for all nuts.

High Strength: ASTM A 325 for threaded rods and headed bolt. Hardened

washers shall be provided with high strength anchor bolts.

Anchor bolts, nuts and washers for galvanized structures shall be galvanized

in conformance with ASTM Specification A153.

PT Indo Ridlatama Power Part 4.4 - 32 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Anchor Bolt Sleeves

Anchor bolts sleeves shall be made of standard weight steel pipe conforming

to ASTM A120 or made of polyethylene plastic.

Plastic Plugs: For anchor bolts with pipe sleeves, provide plastic plugs at top

of sleeves.

Column anchor bolts shall be erected to the following tolerance:

Individual anchor Bolts : 3 mm

Anchor Bolt Group : 6 mm

4.4.2.11.2 CONCRETE EXPANSION ANCHOR BOLTS

Concrete expansion anchors and accessories shall be made of carbon steel

with zinc plated finish. Stainless steel may be used in place of this zinc coated

carbon steel.

The material shall have minimum yield strength of 4220 kg / cm2 for wedge

type anchors, and 3515 kg per cm2 for sleeve type anchors. The material shall

have a minimum tensile strength of 5270 kg per sq. cm for all anchors.

All concrete expansion anchors shall be installed in accordance with the

manufacturer’s specifications and recommendations and the requirements of

this Specification. In case of conflict, the requirements of this specification

shall govern. The locations where expansion anchors will be installed and the

sizes of these anchors shall be as indicated on approved drawings.

4.4.2.11.3 FABRICATION OF STRUCTURAL STEEL

Provide new fabrication materials which conform to the specifications

indicated and the types as specified.

Mill test reports for steel material shall conform to the applicable ASTM or

other approved equal material specifications and makes them available for

Owner’s review. Material shall have certificates of compliance for bolts, nuts,

washers, filler material, shear connectors, welding electrodes, and the other

material specifications and make them available for Owner’s review.

PT Indo Ridlatama Power Part 4.4 - 33 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

MATERIAL FOR STRUCTURAL STEEL WORK

ITEM ASTM STANDARDS

UTILIZATION

NO. UNLESS NOTED

1. Rolled beams, bars channels, plates and angles, A36

bracing, structural steel

2. Plate girders A36

A572 Grade 50

A588 Grade 46

A588 Grade 42

3. Column A36 or

A572 or A588

4. Covers plates A36 or

A572 Grade 50

A588 Grade 50

5. Column base plates and splice plates A36

6. Connection bolts A325, A490 or A307

7. Welding AWS D1.1

8. Round tubular bracing A53

9. Square and rectangular tubing A500 Grade B or A501

10. Castings A27 Grade 65-35 or

A148 Grade 80-50

11. Forgings A668 Classes C, E and F

12. Shear connectors A106

PT Indo Ridlatama Power Part 4.4 - 34 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

ADDITIONAL REQUIREMENTS FOR STRUCTURAL STEEL MATERIAL

Material Item Standards Additional Requirements

1. Low-sulfur High- ASTM A588 Grade A or B, a. The sulfur content of the steel shall

Strength Steel (for plates A572 Grade 50 or equivalent be 0.01% maximum, and the

over 12 mm in thickness with special process (such sulfides shall be in globular form.

when shown on). as vacuum degassing).

b. The steel shall have the following

properties in through-thickness

direction.

b.1 Reduction of area under tensile

test shall be 25% minimum

b.2 The yield and tensile strengths

shall not be less than 75% of

specified strengths of original

A588 or A572.

For plates thicker than 56 mm,

yield tests shall be performed with

test specimens conforming to

ASTM A370 Figure 5 for 12 mm

diameter specimens.

c. The steel shall be 100%

ultrasonically tested, per ASTM

A572 Level 1 for plate thickness of

19 mm and greater, and level II for

plate thickness less than 19 mm

diameter circle, and scanning shall

be continued over 100% of the

plate surface.

d. The steel shall be tested for charpy

V-notch impact, in accordance

with ASTM A370 with frequency (P)

indicated in ASTM A673; and shall

meet the following requirements:

PT Indo Ridlatama Power Part 4.4 - 35 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Material Item Standards Additional Requirements

Direction Charpy Value

(Mills-lateral

Expansion)

at 0°C

Longitudinal 70

Transverse 60

Through-thickness 30

e. Use : Where indicated, especially for

plates loaded or stressed in through-

thickness direction.

2. Tubular members

2.1 Round Tubular Bracing ASTM A53 of the following Use standard, extra strong or double

type and grade: extra strong weight.

a. Type E or S, open-

hearth or basic oxygen

steel only, with sulphur

content not exceeding

0.05%).

b. Grade B only (2,460

kg/cm² yield).

2.2 Rectangular or square ASTM A500 Grade B or

tubing A501 For tubular framing.

3. High-Strength Bolts AISC Specification for a. Bolts and Nuts : Use the following

Structural Joints Using materials unless otherwise indicated.

ASTM A325.

a.1 For bolt size through 22 mm

diameter, use A325 Type I steel.

a.2 For other size bolts, use steel as

indicated in the bid document.

b. Washers

A325 bolts one washer under the

head or nut whichever is the clement

turned in tightening

PT Indo Ridlatama Power Part 4.4 - 36 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Material Item Standards Additional Requirements

4. Shoulder bolts for

slotted sliding

connections

4.1 Bolts ASTM A325, Type I 22 mm diameter shank; grip length of

bolt shall equal the thickness of the

mated parts plus two 3 mm thick

washers plus 3 mm. Bolt threads shall

be 19 mm diameter and the length

shall equal the thickness of two nuts

plus 6 mm.

4.2 Nuts ASTM A563, Grade C Two required per bolt.

5. Washers ASTM F436 Two 22 mm diameter washers

required. One washer under the bolt

head and one under the nut.

6. Castings a. ASTM A27, Grade 65-35 Use for all castings under otherwise

indicated

b. ASTM A148, Grade 80-

50 Use only where high-strength steel

castings are required.

7. Forgings ASTM A668, Class C Use for all forgings unless otherwise

indicated.

8. Stock material As specified in Item 1 Mill test reports for applicable material,

through 10 shall ordinarily constitute sufficient

record, but separate tests may be

required on pieces selected from any

shipment.

9. Crane rails-weigh 50 ASTM A1, No. 1, rails with a. Length: Standard 12 m, subject

kg/m or more (Lighter carbon content 0.67-0.82% tolerances of ASTM A1.

rails shall conform to or manufacturers standards

manufacturer standards) meeting the same b. Size: As indicated on the design

requirements drawings.

c. End drilling; Three holes each end,

spaced to suit specified joint bars

and as required for tight end joints.

d. Marking: As specified in ASTM A1.

PT Indo Ridlatama Power Part 4.4 - 37 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Material Item Standards Additional Requirements

10. Crane Rail Accessories As indicated Accessories shall be as made by, or as

furnished by, one of the rail

manufacturers indicated in item 9 in

accordance with their Standard

Specifications for rail accessories, for

the specified rails and in accordance

with the requirements of this Item 10.

11. Joint bars ASTM A3 Low-carbon steel, with 6 holes and

with size and shape of bars and

spacing of holes as required for tight

end joints.

12. Bolts and Nuts ASTM A325 and ANSI B18.2 Heat-treated, with finished hexagon

heads in accordance with ANSI B18.2.

13. Spring Washers AREA Specification for Alloy steel with one washer for each

Spring Washers bolt

14. Rail Clips ASTM A36 or better Shall be “Tight Fit” type, made of

pressed steel plate with reversible steel

filters and 2 holes each clip.

Connections

For shop connection provide bolted or equivalent welded connections.

For field connections, provide bolted connection unless shown otherwise on

the approved drawings. Field welded connections are permitted only where

shown on the approved drawings or specifically authorized by the Owner.

Use Friction type bolted connections with ASTM A325 bolts.

Where required by magnitude of reactions or space considerations, use ASTM

A490 bolts.

Bolts conforming to ASTM A 307 may be used for girts, purlins, doors, window

framing, and for fabrications, assembly, and erection at the jobsite. The

number of each size of loose nuts, bolts, washers, and fittings furnished for

PT Indo Ridlatama Power Part 4.4 - 38 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

field erection shall be 5 percent more than the numbers indicated as required

on the drawings.

Use the Turn-of-Nut Tightening or Calibrated Wrench Tightening method, as

specified in the AISC “Specification for Structural Joints Using ASTM A325

Bolts”.

Unless special protection against corrosion is provided by other means, the

interior of any hollow member, whether a structural hollow section or a

fabricated member, shall be sealed so as prevent the ingress of moisture.

4.4.2.11.4 PRIME COAT, SHOP PAINTING AND FIELD PAINTING

Paints, including types, colors, products and manufacturers shall be suitable

for the environmental conditions. Use of all components of the same

manufacturer’s system is mandatory.

All operations covered by this section shall be adequately controlled and

supervised by operators adequately skilled in them.

The Bidder shall submit for approval the method of painting including types,

colors, and surface preparation he proposes to adopt and the locations where

he proposes to carry out the works. The Bidder shall keep the Owner informed

of the proposed work’s programmed and if called upon to do so he shall

assist the Owner with inspections at all reasonable time.

Application of paint shall conform to the applicable requirements of SSPC

Paint Application Specification No.1 “Shop, Field and Maintenance Painting”,

or manufacturer’s instructions.

Paint shall not be applied on surfaces which are at a temperature of over 500

C unless the paint is specifically formulated for application at the proposed

temperature. When a surface is painted in hot weather, precautions shall be

taken to ensure that the specified dry micron thickness of paint is obtained.

All surfaces shall be perfectly dry before and while being painted.

PT Indo Ridlatama Power Part 4.4 - 39 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

PAINT SYSTEM FOR STEEL SURFACES

Item Coat-Type-DFT Paint System

Shop-Prime Coat :

SHOP 1 (inorganic zinc 85 to 89 % zinc by weight) A

Shop-Intermediate Coat :

(two-component polyamide epoxy)

SHOP2 B

125 to 175 microns

Primer-Intermediate Coat :

(Touch-up and Total Coating)

FIELD PAINT 3 Aluminum-Epoxy-Mastic) C

125 to 175 microns

Field Finish Coat :

(Apliphatic Polyurethane)

FIELD 4 D

50 to 75 microns

PAINT SYSTEM FOR BUILDING SURFACES

Item Coat-Type-DFT Paint System

One Latex Sealer

1 12.5 to 25 microns E

Intermediate Coat :

Latex Flat Finish

2 F

25 to 50 microns

Finish Coat

Latex Flat Finish

3 G

25 to 50 microns

Notes :

1. All paint shall be met the performance requirements.

2. The use all components of the same manufacture’s paint system is

mandatory.

3. Owner will select the color scheme of field finish painting work to complement

the building color at a later date after the award of the Contract at no extra

cost to Owner.

PT Indo Ridlatama Power Part 4.4 - 40 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

EXTENT OF PRIME COAT AND RELATED PAINTING

Item Surface Preparation Painting Paint System

1. Structural and miscellaneous

ferrous steel members

(a) All surfaces including

columns, beams, girder Solvent & Near 1 shop prime coat A

girt, hangers, struts, tie White Blast Cleaning of paint.

rods, plates, risers, stair

strangers, washers, etc. 1 shop intermediate

unless otherwise coat

indicated.

(b) Inaccessible Steel Solvent & Near

Surfaces and Girt. White Blast 1 shop prime coat A for prime coat

Cleaning. and 2 shop and B for second

intermediate coats coats.

of paint.

(c) Milled, embedded, contact None (Unless

and welded surfaces, etc. otherwise indicated No painting (milled

herein). surface protected

with lacquer. All

other surfaces

protected with

antirust compound

unless otherwise

c.1 Milled and machined indicated herein).

surfaces (as on base

plate).

c.2 Anchor bolts, bolts, nuts

c.3 Embedded surfaces

Solvent & Near 1 shop prime coat

White Blast Cleaning of paint A

PT Indo Ridlatama Power Part 4.4 - 41 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

EXTENT OF PRIME COAT AND RELATED PAINTING

(Continued)

Item Surface Preparation Painting Paint System

c.4 Contact surfaces (as Solvent & Near 1 shop primer coat A (for friction type

surfaces under column White Blast of paint. connection,

and beam cover plates, Cleaning for faying painting system

faying surfaces under surfaces & splices shall be proposed

connection angles, splice plates. by Bidder and shall

plates). meet the

requirement of

AISC).

1 shop intermediate B (for friction type

coat paint for faying connection,

surface and splice painting system

plates. shall be proposed

by Bidder and shall

meet the

requirement of

AISC).

c.5 Top flanges of beams Solvent & Near 1 shop prime coat A

and girders to support White Blast of paint

metal decking or welding Cleaning.

studs.

c.6 Welded surfaces (a 75 Solvent & Near

mm strip wide on each White Blast

side of a joint to be field Cleaning.

welded).

(d) Marred painted areas, bolt Solvent Cleaning 1 or 2 field touch-up A for prime coat,

heads, nuts, washers, and Hand Tool coats of matching and B for second

unprotected fasteners Cleaning, if required paint. coat.

field welds, adjacent Power Tool

unpainted areas and Cleaning.

strips, unless otherwise

indicated.

(e) Marred galvanized areas Hand or Power Tool 1 field touch-up C

and field welds on Cleaning. coat of paint.

galvanized surfaces.

PT Indo Ridlatama Power Part 4.4 - 42 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

EXTENT OF PRIME COAT AND RELATED PAINTING

(Continued)

Item Surface Preparation Painting Paint System

2. Surfaces to be in contact with

aluminum, or aluminum

surfaces :

(1) Surfaces of non aluminum Solvent & 1 shop of field C for prime coat,

metals incompatible with Commercial Blast prime coat & 1 field D for second coat.

aluminum, to be in Cleaning second coat of

contact with aluminum, or paint for ferrous

aluminum surfaces to be metals, and 2 coats

in contact with of paint for non

incompatible non ferrous metals

aluminum metal surfaces.

(2) Concrete and masonry

surfaces to be in contact As specified in 2 field coats of paint

with aluminum, or manufacturers

aluminum surfaces to be standards.

in contact with other

structures.

3. Welded steel ducts Solvent and Near 1 shop prime coat

A

White Blast of paint on exterior

Cleaning on exterior surfaces, of the duct

surfaces of the duct if there is no lagging

to be painted unless outside these

otherwise indicated surfaces.

4. Metal doors and door channel

frame :

(1) Channel frames. Solvent & 1 prime coat, 1

A and B

Commercial Blast intermediate coat

Cleaning. and field touch-up

paint.

(2) Exterior doors Solvent Cleaning. 1 prime coat, 1

(galvanized) intermediate coat

and field touch-up

paint.

PT Indo Ridlatama Power Part 4.4 - 43 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

EXTENT OF PRIME COAT AND RELATED PAINTING

(Continued)

Item Surface Preparation Painting Paint System

(3) Interior doors (sheet Solvent Cleaning 1 prime coat A

metal). and Hand Tool

Cleaning.

5. Exposed steel piping for Solvent Hand Power 1 prime coat, 1 A and B

plumbing. Tool & Commercial intermediate coat

Blast Cleaning and touch-up with

paint on outside

surfaces, touch-up

75 mm wide

welding bands.

PT Indo Ridlatama Power Part 4.4 - 44 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

SCHEDULE FIELD FINISH PAINTING

SURFACE

PREPARATION

ITEM SPECIFIED AREAS AND PRESENT

ON PAINT SYSTEM

NO. SPECIFIED SURFACES FINISH

REQUIREMENTS

(MINIMUM)

1. Class SSS

Specified Structural Surfaces

1.1 All structural steel, auxiliary

steel, miscellaneous steel,

galleries, trolley, stairs,

ladders, cages, handrails,

exterior doors, etc. as

furnished by the Bidder.

1.1.1 Indoor Shop prime SL-SP3 C, D

painted

1.1.2 Indoor Bare metal SL-SP4 A, B, C, D

1.1.3 Outdoor Shop prime SL-SP3 C, D

painted

A, B, C, D

1.1.4 Outdoor Bare metal SL-SP4

C, D

1.1.5 All exposed steel surfaces, Shop prime SL-SP3

supports, etc. painted

2. Class SBS

Specified Building Surfaces

2.1 All concrete and plastered Bare Per paint E, F, G

surfaces Manufacturer’s

Standard

Per paint

2.2 All interior door and rolling Shop prime Per paint

Manufacturer’s

door Manufacturer’s

Standard

Standard

2.3 All wood work Bare Per paint

Varnish or oil paint

Manufacturer’s

Standard

Note :

1. The Owner will select the color of finish coat after the award of the

Contract at no extra cost to the Owner.

PT Indo Ridlatama Power Part 4.4 - 45 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

2. Bare metal surfaces shall receive both shop and field coat paints as

indicated in the table. Field touch up of primed metal surfaces shall be

done using field coat paints as indicated in the table.

3. Field touch up of primed metal surfaces shall be done using field coat

paints as indicated in the table.

4. Do not paint thiokol base or silicone base rubber sealant caulking. Paint

all other caulking with same paint as adjacent or surrounding areas.

5. Safety color painting shall be as approved by the Owner.

4.4.2.11.5 ERECTION OF STRUCTURAL STEEL

Erect structural steel in accordance with the AISC Code of standard practice

and the AISC Specification for Design, Fabrication and Erection of Structural

Steel for Buildings. Erection of Steel coal silos in conformance with API

Standard 650, parts 3,4,5, and 7, unless otherwise specified or shown as

follow.

Erection Tolerances

Set steelwork accurately to the established lines and grades and erect is

plumbed and leveled such that the deviations in all completed work are within

the tolerance limits and meet the requirements as specified in the AISC Code

of Standard Practice in the following subsection of this specification.

Position

Permissible deviation between designed and

actual position of the erected column 10 mm

Linear Dimensions

Permissible deviation from the design length

or width of any member or structure overall:

Up to and including 8 m 10 mm

Over 8 m up to including 15 m 15 mm

Over 15 m up to and including 25 m 20 mm

Over 25 m 25 mm

PT Indo Ridlatama Power Part 4.4 - 46 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Plumb

Permission deviation above base of 15 mm

column 0.05% of the height with

maximum of

Levels

Unless otherwise specified, the level of

a beam, girder or truss shall be taken

on the top of upper flange.

Permissible deviation between the 5 mm

design and actual levels of the base

of the first column to be erected

Permissible deviation between the 5 mm

design and actual levels of the upper

or lower surfaces of two or more beams at a column

Difference in levels of ends of beams,

girders or trusses relative to the above :

Up to 8 m long 5 mm

From 8 m to 15 long 10 mm

From 15 to 25 long 15 mm

Over 25 m long 20 mm

Crane Rails

Span between rails 10 mm

Level between rails 15 mm

Straightness about any line 1/3000

out of alignment at rail-joint

Upper and side surfaces 0.5 mm

Elevator Hoist way

For elevator hoist way, do not deviate more than 25 mm for plumb for the

entire height of the hoist way.

Column Base Plates

PT Indo Ridlatama Power Part 4.4 - 47 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Set column base plates at the specified elevations within the tolerance of 1.5

mm and level them within the same tolerance.

4.4.2.11.6 WELDING OF STRUCTURAL STEEL

All welding electrodes shall conform to the applicable provision of the AWS

Structural Welding code AWS D1.1. For welding of steel materials with special

properties such as resistance of brittle fracture, corrosion – resistant steel,

stainless – clad steels and stainless steel, the recommendations of both the

steel and electrode manufacturers shall be obtained and followed.

Low hydrogen electrodes shall be used for SMA when welding of carbon

steels not listed in AWS D1.1 and that have a specified allowable carbon

above 0.90 percent.

Type 309, 3092, or NiCrFe 3 filter materials shall be used when welding carbon

or low alloy steels to austenitic stainless steel.

For types 309 and 309L stainless steel, welding materials, range of delta ferrite

materials shall be limited from 5 to 15 to percent.

All welding, including stud welding, shall conform to the requirements of AWS

D1.1 unless otherwise indicated. Welding shall be performed using Shielded

Metal Arc of Submerged Arc Welding Process.

All welding shall be inspected and examined by the Bidder’s Certified Welding

Inspector in accordance with AWS D1.1. Inspection and examination reports

shall be submitted to Owner.

PT Indo Ridlatama Power Part 4.4 - 48 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

EXTENT AND METHODS OF NONDESTRUCTIVE EXAMINATION

FOR WELDING IN STEEL CONSTRUCTION WORK

Method of

Item Extent of Examination Remarks

Examination

1. Structural Steel

1.1 Built-up Girders and

Columns:

(a) All complete 100 % Radiograph Weld impractical to be

penetration groove radiographed shall be

welds. examined 100 % by

both Ultrasonic and

either Magnetic

Particle or Liquid

Penetrant methods

(b) All other weld joining 100 % Visual

flanges, webs,

plates, stiffeners,

connections, base

plate details, etc.

1.2 Rolled Beams and

Columns:

(a) All complete 100 % Radiograph

penetration groove Same as 1.1a.

welds

(b) All other welds 100 % Visual

joining cover plates

stiffeners,

connections, base

plate details, etc,

2. Tank, Duct Work, etc.

2.1 All complete penetration 100 % for the first 3 m Radiograph

groove welds of welds, in horizontal Welds impractical to

and vertical welds be radiographed shall

respectively, for each be examined by both

welder or welding Ultrasonic and either

operator (Any weld Magnetic Particle or

which fails to meet the Liquid Penetrant

acceptance standard, Methods.

shall be replace and

reexamined 100 %).

PT Indo Ridlatama Power Part 4.4 - 49 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Method of

Item Extent of Examination Remarks

Examination

(a) Thereafter, 1 % : 1 Spot Radiograph (b) The 1 % spot

spot examination 30 radiographed

cm long for each shall include 25 %

additional 33 m of of junctions of

welds (if any spot vertical and

fails to meet the horizontal welds.

acceptance

standard, 2

additional spots

shall be examined at

locations at least 30

cm on each side

from failure spot, if

either of the 2

additional meet the

acceptance

standard the entire

unit of the 33 m

welds shall be

completely

examined).

2.2 Fillet welds between Same as Item 1 Visual

plates and stiffeners

2.3 Welds for supporting Same as Item 1 Same as Item 1

Structural Steel

3. Welding Studs

3.1 Composite Beam Shear (a) The first two studs

Connectors welded on each

beam, through

metal deck where

applicable, after

being allowed to

cool, shall be bent

to an angle of 30 °C

from their original

axes by being struck

with a hammer (if

failure occurs in

either stud, the

procedure shall be

corrected and two

more shall be

welded to the beam

and tested. If either

of the second pair of

studs fails,

additional welding

shall be continued

on separate plates

until two

consecutive studs

are tested and

found to be

satisfactory).

PT Indo Ridlatama Power Part 4.4 - 50 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Method of

Item Extent of Examination Remarks

Examination

(b) 100 % of all studs Visual Any stud which does

not show a 360 ° weld

under visual

examination is subject

to the bend test.

3.2 All other studs (a) Before the start of Visual Any stud which does

welding operations not show a 360 ° weld

on each day for under visual

each welding gun examination is subject

and associated to the bend test.

power source, two

studs shall be

welded to separate

material in the

same general

position (flat,

vertical, overhead

sloping) and of

similar thickness

and material. After

being allowed to

cool, each stud

shall be bent to an

angle of 30 ° from

its original axis with

a hammer (if failure

occures in either

stud, the

procedure shall be

corrected and

repeated until two

consecutive studs

have been

successfully

welded and tested

before any studs

are welded to the

member).

(b) 100 % of all studs

PT Indo Ridlatama Power Part 4.4 - 51 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Method of

Item Extent of Examination Remarks

Examination

(c) At leas one stud in Bend test Additional acceptance

every 100 shall be (Torque Test for standard indicated in

bent to an angle of threaded studs) AWS D.1.1.

15 ° from its

original axis by

being struck with a

hammer. If

threaded, the stud

shall be torque

tested with a

calibrated torque

wrench (if the stud

fails, the procedure

shall be checked in

accordance with

(a) above, and two

more existing

studs shall be

bend or torque

tested. If either of

these two studs

fails, all the studs

represented by the

tests shall be

tested).

Notes :

1. Extent of examination (1 %, etc.) shall be applied equally to shop welding

and field welding.

2. Magnetic Particle method is for ferritic materials, and liquid Penetrant

method is for austenitic materials.

4.4.2.11.7 MISCELLANEOUS METAL WORK

1. Steel plates, sections and bars

Structural steel and all other steel including floor plates, ladders, and

cages, guard plates etc shall conform to applicable requirements of

ASTM A36 – Standard Specification for Structural Steel.

PT Indo Ridlatama Power Part 4.4 - 52 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

2. Bolts

Bolts, nuts and washers shall conform to ASTM A 307, Grade A and

ASTM A 563, Grade C (except round washers which shall conform to

ANSI B27.2). High strength bolts shall conform to ASTM A 325 or ASTM

A 490

3. Welded Grating

Steel grating shall be fabricated from welding quality steel conforming to

SAE1015 and SAE 1010 for bearing bar and cross bar respectively.

Grating shall be galvanized steel unless otherwise specified and shall be

the standard rectangular-opening type, electro-forged. All grating shall

be banded at each ladder entrance and exit.

Area exposed to chemical attack shall have Fiberglass Reinforced

Polyester (FRP) grating with FR gray grit top.

4. Checkered Steel Floor plates

Checkered steel floor plate shall be of standard manufacture with the

standard two-way raised pattern. The thickness shown is nominal and

does not include the height of the raised pattern.

5. Handrails

Handrails and posts shall be butt-welded or otherwise noted made of

steel pipe of standard weight (schedule 40) or steel structural tubing of

equal or greater weight. The pipe shall conform to ASTM A 120. The

structural tubing shall conform to ASTM A501, A-36 or better material. All

handrails shall be shop prime and field finish painted.

6. Stainless Steel

Stainless steel grating, plate, bars, rolled shapes, and shims shall

conform to ASTM A 167 and ASTM A 276 as applicable.

7. Galvanized coating

Galvanized coatings shall conform to ASTM A 123, ASTM A 153, ASTM A

386 and AASHTO M 111 as applicable.

PT Indo Ridlatama Power Part 4.4 - 53 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

4.4.2.11.8 METAL DECKING

Sheet Material

ASTM A446, Grade A (minimum yield strength 2320 kg per sq. cm)

Finish

Hot-dip galvanized, ASTM A525, Coating Designation G90 (minimum).

Design

Deck type and size shall be designed and detailed by the Bidder and shall be

used only for formwork for cast-in-place concrete. The deck shall be suitable

for the span and the construction loads.

The Contractor is not allowed to consider the deck as part of reinforcing steel

for the concrete slab.

Decks acting as formwork for cast-in-place concrete shall be design for the

wet weight of concrete plus a minimum 100 kg/m2 construction live loads.

4.4.2.12 METAL ROOFING AND CLADDING

1. Exterior Steel Sheet

Material: shall be galvanized steel complying in all respects with ASTM

A653 Coating designation G 90.

Metal thickness: shall be fluted as required for loading and span, but not

less than 0.70 mm.

Finish: shall be finished with high built urethane top coat on both

surfaces.

Texture: smooth

Color & Profile: Owners approval is required.

2. Interior Steel Sheet

Material: shall be galvanized steel flat finer panels, complying in all

respects with ASTM A653, Coating designation G 90.

Steel thickness: shall be as required for loading and span but minimum

of 0.95 mm for 60 cm wide sheets and 0.79 mm for 30 cm wide sheets.

PT Indo Ridlatama Power Part 4.4 - 54 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Acoustic treatment: where an acoustic treatment is required for insulated

siding, the interior sheets shall be perforated with holes of size and

spacing that will provide a NRC value of not less than 0.85.

Finish: shall be finished with a silicone polyester coat finish.

Color: Owner’s approval is required.

3. Insulation

Where insulated siding and roof (external wall & electrical room) is

indicated, the insulated shall conform to the following requirements:

Material: shall be fibrous glass, rock or slag with minimum density of

25.3 kg/m3.

The roof insulation shall be reinforced on down face with vinyl or

aluminum foil. The thickness of vinyl shall not be less than 0.01 mm and

the thickness of aluminum shall not be less than 0.0025 mm.

The wall insulation shall be completely enclosed with 150 micron thick

polyethylene protective cover.

Thickness of insulation: shall be a minimum of 3.37 cm.

4. Fasteners

Fastener sizes and types shall be provided in accordance with the

requirement and as recommended by the manufacturer.

Material : shall be type 305 stainless steel with cadmium plated finish.

Size of Fasteners : No. 12 or larger.

Coating of Metal Roofing and Cladding

Type of coating shall be of prime quality; and color, processing system

shall be as manufacturer recommendation and approved by the Owner.

Test procedure to metal painted shall conform to requirement as follow:

PT Indo Ridlatama Power Part 4.4 - 55 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Organic Coating for Metal Siding, Roofs and Accessories

Item Requirements

1. Exterior/Interior

Sheet

1.1. Base Metal Material : Galvanized steel, ASTM A 653, G90 Coating 275 g/m2

1.2. Coating 1.2.1. Barrier Coal : Manufacturer’s Standard

1.2.2. Prime Coat : Manufacturer Standard

1.2.3. Finish Coat : Urethane or PVF2 Kynar 500 top coat.

1.2.4. Dry Film Thickness

1.2.4.1. Barrier Coat : as manufacturer Standard

1.2.4.2. Prime Coat (front side) : 5 microns

1.2.4.3. Finish Coat: 38 microns

1.2.4.4. Finish Coat (Reverse Side) : 10 microns

1.3. Curing Oven baked in accordance with Manufacture’s standard

2. Tests Tests shall conform to or better the following tests requirements :

2.1. Pencil Hardness (ASTM D3363) : Shall be F Minimum

2.2. Salt Spray (ASTM B117): After testing 1000 hours in 5 % salt fog

at 350C, samples area shall have no blisters.

2.3. Humidity (ASTM D2247): After 1000 hours testing at 100% relative

humidity and 380C, samples at least 95% shall have no blisters.

2.4. Weatherometer (ASTM G23) : After 5000 hours exposure in

Sunshine Arc Weatherometer or Atlas Twin Weatherometer, no

chalk in excess of No. 8 per ASTM D659 and no color fade more

than 5 NBS units per ASTM D2244, as operated under Dew Cycle

condition using 60/60 cycle.

PT Indo Ridlatama Power Part 4.4 - 56 Muara Jawa CFSPP

BOOK III A

PART 4.4 Civil Works

4.4.2 Technical Specification

Item Requirements

2.5. Flexibility (ASTM D1737) : Withstand 1T – 2T bends.

2.6. Gloss (ASTM D523) : 25 – 35% reflectivity measured on 600C

gloss meter.

2.7. Impact : No removal of finish when tested as follows :

2.7.1. Using a sharp knife, make 6 or, more parallel cuts at 1.5 mm

intervals through finish to bare metal. Cross hatch similarly.

2.7.2. Reserve impact to at least 92 cm – kg or to point of metal rupture.

2.7.3. Apply Scotch cellophane tape firmly to scribed impacted area.

Remove tape with sharp pull. There shall be no loss of adhesion.

2.8. Abrasion (ASTM D968) : The average coefficient of abrasion

shall not be less than 70, with the lowest value not less than 60.

3. Warranty The Bidder shall furnish the Owner, upon acceptance installation, a

written warranty that coating has been applied in accordance with

license Manufacture’s process instructions and under normal

conditions; and that it shall meet the following standards for a minimum

period of ten (10) years (the Bidder shall state the number of years

warranty, and also the number of times he will replace any defective

panels without charges of any kind):

3.1. Will not chalk in excess of ASTM D659 No. 8 rating. Chalk rating

shall be determined by the procedure outlined in ASTM D659.

3.2. Will not change color more than 5 NBS units as determined in

accordance with procedures set forth in ASTM D2244, after

removal of external deposits chalk.

3.3. Will not crack, check or peel (lose adhesion).

4.4.2.13 MISCELLANOUS ARCHITECTURAL WORK

4.4.2.13.1 Plastering Works

Gypsum plasters shall conform to ASTM C 28

Portland cement for Portland Cement plasters shall conform to ASTM C 150

Type (I).

Aggregates for Portland cement plasters shall conform to ASTM C 144