Professional Documents

Culture Documents

Productive Jobsite Layout PDF

Uploaded by

ParthJain0 ratings0% found this document useful (0 votes)

39 views3 pagesOriginal Title

1. Productive Jobsite Layout.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views3 pagesProductive Jobsite Layout PDF

Uploaded by

ParthJainCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Planning a productive

jobsite layout

For a given construction job, there’s only one optimal layout.

Here are some tips for coming up with the best plan.

BY JAMES J. ADRIAN ne of the most important but Consider, for example, what would

O often overlooked organiza-

tional tasks of a construction

supervisor is planning a lay-

out for the project site. Many

decisions must be made such as

where to place office trailers, where

to store onsite materials, and where

happen to the productivity of a form-

ing crew if the supervisor located

storage for form lumber on one side

of the jobsite and the staging area on

the opposite side. Not only would

workers have to walk long distances

to retrieve needed materials and haul

to keep equipment when not in use. them to the assembly area, they

Unfortunately, supervisors often take would also end up lifting materials

a haphazard approach to the layout more than necessary.

task, not realizing the effects their Although increasing jobsite

plans can have on productivity. productivity is one of the best rea-

sons for plotting an efficient lay-

out, it’s not the only one. Mini-

Objectives of a good jobsite layout mizing the potential for worker

accidents, and reducing material

1 Eliminate repeated handling of materials.

and equipment theft are other im-

2 Minimize the distance that workers must transport stored materials portant goals (see “Objectives of a

to the point of use. Good Jobsite Layout”).

3 Minimize the need to store materials. Planning checklist

4 Provide a uniform flow of materials about the site, free of bottlenecks. Though each project is unique,

the layout for most jobs must in-

5 Provide adequate controls on material waste, breakage, and theft.

clude similar elements: staging

6 Provide adequate controls on equipment theft. areas, access roads for equipment

and materials, office trailers, materi-

7 Facilitate movement of equipment on the jobsite.

als and equipment storage, and

8 Provide for controls on worker tardiness. toilet facilities and parking areas for

workers. You can use the following

9 Promote a safe working environment.

checklist to verify that the layout

10 Provide safe, nondisruptive access to the jobsite for visitors. sufficiently accounts for these

critical elements.

Staging areas

UMake staging areas accessible to

□

Main entrance cranes and handling devices.

ULocate staging activities near

□

materials storage and where

Wire Reinforcing

storage materials will be installed.

Equipment Staging

location area

Equipment

TF

UProvide for unobstructed entry of

□

equipment onto the jobsite.

URemove any obstacles or

□

Form New building foundation

lumber bottlenecks to equipment

to construct

storage Fabricated movement around the site.

forms UMake sure cranes are accessible to

□

Cars storage

staging and building areas but

TF

TF clear of overhead power lines and

other utilities.

Misc. Trailer-Sub ULocate equipment when not in

□

storage operation near staging areas and

Trailer-Sub Trailer-GC

materials storage but away from

overhead wires.

Haul roads

Site haul roads

UProvide a turnaround area for

□

BEFORE haul vehicles.

UProvide for security at entrances

□

to minimize theft.

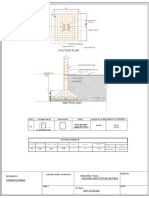

This preliminary sketch of a jobsite layout for a building foundation project

has several problems. A power line runs above the equipment location and Materials hauling and storage

main entrance, trailers and toilet facilities (TF) are far from the entrance, ma- ULocate the drop-off for materials

□

terials storage is on both sides of the project, and the area provided for close to the intended work area.

worker parking is far from the entrance. UGroup similar materials and

□

materials used by specific trades.

The modified layout includes the

Main entrance following improvements:

Gate

n Office trailers and the parking

Trailer-GC Bulletin board lot for workers are closer to the

Cars Wire main entrance.

TF

n Equipment storage is away from

Trailer-Sub

TF the overhead power line and

near staging and materials stor-

New building foundation

age areas.

Equipment n The materials storage areas are

to construct location

Trailer-Sub

grouped at the back of the job-

site, closer to the haul road.

TF

n The staging area is closer to the

TF Staging materials.

Turnaround

area n Security gates are installed at the

Form

Misc. Reinforcing lumber area Fabricated main and haul-road entrances.

storage storage forms n A bulletin board for posting

storage

TF storage project progress and important

Gate messages is located near the

main entrance, where workers

Haul roads

are sure to see it.

n A turnaround area for haul

AFTER vehicles has been established.

□

UPlace storage trailers as close as

possible to stockpiled materials.

□

UStore materials in the order in

which they will be used.

Office trailers

□

UPlace trailers near the main

entrance to limit visitor access

and to monitor worker entry

and exit.

□

UMake sure first-aid facilities are

nearby and easily accessible.

Toilet facilities and parking areas

□

UPlace toilet facilities in easily

accessible areas, away from

operating machinery.

□

ULocate parking for workers close

to the main entrance.

Set aside ample time before the

start of the project to plan the

layout. Draw preliminary sketches

and have the entire construction

team critique them, keeping the

10 objectives of a good jobsite layout

in mind. Incorporate suggestions

for improvement into the final plan

(see example “before” and “after”

sketches). The time spent analyzing

and revising the layout before the

project begins can yield big benefits

in jobsite productivity, safety,

efficiency, and economy. m

James J. Adrian is a professor of civil

engineering and construction at

Bradley University, Peoria, Ill., and

president of Adrian International,

a firm providing management con-

sulting services to the construction

industry.

Publication #C99L038

Copyright© 1999, The Aberdeen Group

a division of Hanley-Wood, Inc.

All rights reserved

You might also like

- 168 Sample ChapterDocument1 page168 Sample ChapterParthJainNo ratings yet

- Metric Tables 2012Document2 pagesMetric Tables 2012ParthJainNo ratings yet

- Faye C. McQuiston, Jerald D. Parker, Jeffrey D. SDocument14 pagesFaye C. McQuiston, Jerald D. Parker, Jeffrey D. SParthJainNo ratings yet

- Economic Order QuantityDocument10 pagesEconomic Order QuantityZafar IqbalNo ratings yet

- MS For Installtion of HVAC Duct WorkDocument11 pagesMS For Installtion of HVAC Duct WorkMohamed ElarabiNo ratings yet

- Method Statement For Installation of Ahu FahuDocument12 pagesMethod Statement For Installation of Ahu FahuRoger Akl75% (4)

- 168 Sample ChapterDocument14 pages168 Sample ChapterMishi Bhatnagar100% (1)

- Footing ConcreteDocument10 pagesFooting ConcreteParthJainNo ratings yet

- Slipform 151016093807 Lva1 App6891 160907075120Document13 pagesSlipform 151016093807 Lva1 App6891 160907075120ParthJainNo ratings yet

- 9 Education Installation Procedure of Split AirconditionersDocument35 pages9 Education Installation Procedure of Split AirconditionersParthJain100% (1)

- Wbs Refrnece ZZZDocument3 pagesWbs Refrnece ZZZParthJainNo ratings yet

- Installation Manual: WarningDocument16 pagesInstallation Manual: WarningParthJainNo ratings yet

- 14g09-1 - Sanbi Kirstenboch - New Offices Building - Ground Storey Hvac Bo...Document6 pages14g09-1 - Sanbi Kirstenboch - New Offices Building - Ground Storey Hvac Bo...ParthJainNo ratings yet

- RateDocument332 pagesRateParthJainNo ratings yet

- Wbs Refrnece ZZZDocument3 pagesWbs Refrnece ZZZParthJainNo ratings yet

- HVAC Tender For ACDocument54 pagesHVAC Tender For ACParthJainNo ratings yet

- Shaunak "B": Basement DATE-15/02/2018Document6 pagesShaunak "B": Basement DATE-15/02/2018ParthJainNo ratings yet

- Air Handling UnitDocument15 pagesAir Handling UnitParthJainNo ratings yet

- Installation Manuel Bs 30 43 EngDocument20 pagesInstallation Manuel Bs 30 43 EngParthJainNo ratings yet

- Flow Chart TemplateDocument13 pagesFlow Chart TemplateParthJainNo ratings yet

- Metric Tables 2012Document2 pagesMetric Tables 2012ParthJainNo ratings yet

- IMP Video ConceptDocument56 pagesIMP Video ConceptParthJainNo ratings yet

- Single Disc Floor Scrubber and PolisherDocument1 pageSingle Disc Floor Scrubber and PolisherParthJainNo ratings yet

- CDC UP WBS Template Style-1Document1 pageCDC UP WBS Template Style-1Koko PopoNo ratings yet

- Construction Site Safety RulesDocument3 pagesConstruction Site Safety RulesshollyeshoNo ratings yet

- Template Equipment Maintenance LogbookDocument4 pagesTemplate Equipment Maintenance LogbookParthJainNo ratings yet

- Sale of Goods Act 1930Document21 pagesSale of Goods Act 1930Gerald GarciaNo ratings yet

- Experiment No: 06: To Determine The Slump of Concrete by Slump-TestDocument6 pagesExperiment No: 06: To Determine The Slump of Concrete by Slump-TestParthJainNo ratings yet

- City of Vista Soils Report ChecklistDocument1 pageCity of Vista Soils Report ChecklistParthJainNo ratings yet

- D8 Visitor Log BookDocument2 pagesD8 Visitor Log BookParthJainNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HRISDocument13 pagesHRISAkash BansalNo ratings yet

- Ford Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Document8 pagesFord Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Alex CastilloNo ratings yet

- Catalogo UNITDocument226 pagesCatalogo UNIThareudangNo ratings yet

- E2S Guide For Hazardous AreasDocument9 pagesE2S Guide For Hazardous AreasRam KumarNo ratings yet

- Benchmarking Study of Strategic Sourcing PracticesDocument2 pagesBenchmarking Study of Strategic Sourcing PracticesPepe CMNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie1Document4 pagesCaterpillar Performance Handbook 49 62020 Partie1ali alilouNo ratings yet

- Column Detail PDFDocument1 pageColumn Detail PDFShubham KushwahaNo ratings yet

- 13 Organization Challenges of AgileDocument9 pages13 Organization Challenges of AgileroxrNo ratings yet

- Technical Sheet of EI2 60 Handed DoorDocument1 pageTechnical Sheet of EI2 60 Handed DoorTaoufikAzarkanNo ratings yet

- Actividades - Grupo Diana MabelDocument22 pagesActividades - Grupo Diana MabelJhon Alejandro Hurtado ValenciaNo ratings yet

- MAXvent OwletDocument66 pagesMAXvent Owletemanuelluca@yahoo.comNo ratings yet

- DK Da AdsorbtionDocument2 pagesDK Da AdsorbtionLevan KikacheishviliNo ratings yet

- MS ProjectDocument11 pagesMS ProjectSuneet SharmaNo ratings yet

- Properties of FluidsDocument21 pagesProperties of FluidsJhay-Pee QueliopeNo ratings yet

- This Lesson PDF - 7.2.3 - Internal Auditor CompetencyDocument10 pagesThis Lesson PDF - 7.2.3 - Internal Auditor CompetencyThee BouyyNo ratings yet

- Docit - Tips Contoh Manajemen Resikoxls Personal Protective EquipmentDocument12 pagesDocit - Tips Contoh Manajemen Resikoxls Personal Protective EquipmentBambang SumantriNo ratings yet

- Scrisoare de RecomandareDocument2 pagesScrisoare de RecomandareAndra GeanguNo ratings yet

- LAUDA Overall Brochure Constant Temperature Equipment en 2020-2021Document151 pagesLAUDA Overall Brochure Constant Temperature Equipment en 2020-2021FithriyyahningsihNo ratings yet

- Afico Liner CatalogueDocument4 pagesAfico Liner CatalogueChris SolonNo ratings yet

- The Three Steps of Thermodynamic Analysis of IC Engines AreDocument42 pagesThe Three Steps of Thermodynamic Analysis of IC Engines AreGODNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalNo ratings yet

- Warner Emails The Pirate Bay Re: Billy CorganDocument4 pagesWarner Emails The Pirate Bay Re: Billy Corganmary engNo ratings yet

- Engineering CommunicationDocument1 pageEngineering CommunicationwowomNo ratings yet

- Sieve Analysis Data Sheet: ASTM D422-63 (2007)Document1 pageSieve Analysis Data Sheet: ASTM D422-63 (2007)Bart LuceñaNo ratings yet

- Making Premium Alky LateDocument25 pagesMaking Premium Alky LateChristianGuerreroNo ratings yet

- 2080 rm001 - en eDocument752 pages2080 rm001 - en eCuong PhamNo ratings yet

- Eisen: 618B / 818B Series Precision Surface GrindersDocument2 pagesEisen: 618B / 818B Series Precision Surface GrindersRam ViswanathanNo ratings yet

- Dear White People Rhetorical AnalysisDocument9 pagesDear White People Rhetorical AnalysisClaire LangenhorstNo ratings yet

- Operations ManagementDocument57 pagesOperations Managementnasirmalik72No ratings yet

- University of Hyderabad Post Graduate Diploma in Business Management (PGDBM) I Term Assignment (2016) Dbm-416: Quantitative and Research MethodsDocument4 pagesUniversity of Hyderabad Post Graduate Diploma in Business Management (PGDBM) I Term Assignment (2016) Dbm-416: Quantitative and Research Methodsrao_nari8305No ratings yet