Professional Documents

Culture Documents

Pwps Asme Gtaw & Smaw

Uploaded by

Muhammad Fitransyah Syamsuar PutraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pwps Asme Gtaw & Smaw

Uploaded by

Muhammad Fitransyah Syamsuar PutraCopyright:

Available Formats

PT.

JASUMA AUSTINDO

Alamat : Jln. Agung Timur 9, Blok N3 No. 1B RT.10/RW. 11, Sunter Jaya, Tanjung Priok, Jakarta Utara, DKI Jakarta 14350

Fax : +62 21 6583 0301 : +62 21 651 2018Telephone

: marketing@jasuma.co.id/marketing.jasuma@gmail.com Email

: http://jasuma-austindo.comWebsite

Page 1 of 2

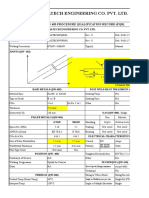

preliminary WELDING PROCEDURE SPECIFICATION (pWPS)

(Section IX, ASME Boiler and Pressure Vessel Code)

Company Name PT. Jasuma Austindo By : Welding Engineer

preliminary Welding Procedure Specification No. 03-pWPS-ASME-JA-17 Date Feb 27, 2017 Supporting PQR No. (s) - Date -

Revision No. 0

Welding Process (es) GTAW & SMAW Type(s) Manual

(Automatic, Manual, Machine, or Semi-Auto)

JOINTS (QW-402) Details

Joint Design As Per Details

Root Spacing As Per Details

Backing (Yes) ( No)

Backing Material (Type) Yes

(Refer to both backing and retainers)

Metal Nonfusing Metal

Nonmetallic Other (Weld Metal)

Sketches, Production Drawings, Weld Symbols or Written Description

shoul show the general arrangement of the parts to be welded. Where

applicable, the root spacing and details of weld groove may be specified.

(At the option of the Mfgr., sketches may be attached to illustrate joint design,

weld layers and bead sequence, e.g., for notch toughness procedures, for (Weld details shown are reference only, engineering design drawing

multiple process procedures, etc.) shall take precedence for production welding)

* BASE METALS (QW-403)

P-No. 1 Group No. All to P-No. 1 Group No. All

OR

Specification and type / grade or UNS Number SA 516 Gr. 70 (K02700)

to Specification and type / grade or UNS Number to SA 516 Gr.70 (K02700)

OR

Chem. Analysis and Mech. Prop. C–Mn–Si (70 ksi (485 MPa))

to Chem. Analysis and Mech. Prop. to C–Mn–Si (70 ksi (485 MPa))

Thickness Range :

Base Metal : Groove 1.5 mm up to 20 mm Fillet All Sizes & Diameters

Used Thickness 10 mm

Maximum Pass Thickness ≤ 1/2 in. (13mm) (Yes) (No)

Other None

* FILLER METALS (QW-404) GTAW SMAW

Spec. No. (SFA) 5.18 5.1

AWS No. (Class) ER 70S-6 E 7018

F-No. 6 4

A-No. 1 1

Size or Filler Metals 2.0 mm to 3.2 mm including 2.6 mm to 4.0 mm including

Filler Metal Product Form Solid N.A

Supplemental Filler Metal N.A N.A

Weld Metal

Thickness Range :

Groove Max. 10 mm Max. 10 mm

Fillet All Sizes & All Diameters All Sizes & All Diameters

Electrode-Flux (Class) N.A N.A

Flux Type N.A N.A

Flux Trade Name N.A N.A

Consumable Insert None N.A

Other / Trade name As Requirement As Requirement

* Each base metal-filler metal combination should be recorded individually.

PT. JASUMA AUSTINDO

Alamat : Jln. Agung Timur 9, Blok N3 No. 1B RT.10/RW. 11, Sunter Jaya, Tanjung Priok, Jakarta Utara, DKI Jakarta 14350

Fax : +62 21 6583 0301: +62 21 651 2018Telephone

: marketing@jasuma.co.id/marketing.jasuma@gmail.com Email

: http://jasuma-austindo.comWebsite

Page 2 of 2

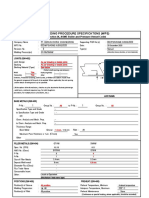

pWPS No.: 03-pWPS-ASME-JA-17 Rev.: 0

POSITION (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove All Positions Temperature Range None

Welding Progression : Up √ Down √ Time Range None

Position(s) of Fillet All Positions Other None

Other None

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temperature, Minimum 20 ⁰C Gas (es) (Mixture) Flow Rate

Interpass Temperature, Maximum 260 ⁰C Shielding Argon 99.997% 10 - 15 LPM

Preheat Maintenance None For SMAW Trailing None None None

Other None Backing None None None

(Continuous or special heating where applicable should be recorded) Other None None None

ELECTRICAL CHARACTERISTICS (QW-409)

Other

Filler Metal

Wire Feed Travel Speed (e.g., Remarks,

Weld Pass Current Type Amps Energy or Power

Process Speed Volts (Range), V (Range), Comments, Hot Wire

(s) Diameter and Polarity (Range),A (Range)

Classificatio (Range) mm/min Addition, Technique,

n Torch Angle, Etc.)

(mm)

As Req. GTAW ER 70S-6 2,0 DCEN 60-100 N.A N.A 10-20 50-150 None

As Req. GTAW ER 70S-6 2.6 DCEN 70-125 N.A N.A 10-20 50-150 None

As Req. GTAW ER 70S-6 3.2 DCEN 70-150 N.A N.A 5-25 50-150 None

As Req. SMAW E 7018 2.4 DCEP 70-150 N.A N.A 12-25 50-150 None

As Req. SMAW E 7018 3.2 DCEP 70-175 N.A N.A 15-30 50-150 None

As Req. SMAW E 7018 4.0 DCEP 80-225 N.A N.A 10-30 50-150 None

Amps and volts, or power or energy range, should be recorded for each electrode size, position, and thickness, etc

Pulsing Current None for GTAW Heat Input (max) 8100 J/mm

Tungsten Electrode Size and Type OD 2.4 mm 2 % Thoriated (WT20), AWS Class EWTH-2

Pure Tungsten, 2% Thoriated, etc

Mode of Metal Transfer for GMAW N.A

Spray arc, short circuiting arc, etc

Other Welding Parameters Maybe Used Recommended From Consumable Manufacturer

TECHNIQUE (QW -410) GTAW SMAW

String or Weave Bead String or Weave String or Weave

Orifice, Nozzle, or Gas Cup Size 1.6 mm to 10 mm N.A

Initial and Interpass Cleaning (Brushing, Grinding, etc.) Brushing, Grinding Brushing, Grinding

Method of Back Gouging Grinding or Air Arc Gouging Grinding or Air Arc Gouging

Oscillation None N.A

Contact Tube to Work Distance N.A N.A

Multiple or Single Pass (Per Side) Multiple Pass Multiple Pass

Multiple or Single Electrodes Single Electrode N.A

Electrode Spacing None N.A

Peening None None

Other None None

Prepared by, Acknowledge by,

Welding Engineer QA/QC Manager

You might also like

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- WPS-PQR Gmaw LtiDocument2 pagesWPS-PQR Gmaw Ltibgonzalez198150% (2)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Wps ModelDocument13 pagesWps ModelMuhammedShafeeq50% (2)

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Weld Fit Up Inspection Employee TrainingDocument10 pagesWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (1)

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- AWS D1.1 GuidesDocument7 pagesAWS D1.1 GuidesMuhammad FakhriNo ratings yet

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- Special Purpose DiodesDocument4 pagesSpecial Purpose DiodeslouiseNo ratings yet

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- San Salvador v1 InstructionsDocument11 pagesSan Salvador v1 InstructionsAtul SartapeNo ratings yet

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- John Bedini - My Work On Rife - HeterodyningDocument15 pagesJohn Bedini - My Work On Rife - HeterodyningoveryounityNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz Aydin100% (1)

- Pressure Vessel Dimension InspectionDocument10 pagesPressure Vessel Dimension InspectionYetkin ErdoğanNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- Night Vision TechnologyDocument27 pagesNight Vision TechnologyGagandeep Singh100% (1)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- SAIC-W-2081 Receiving Inspection of Welding Consumables (EE)Document2 pagesSAIC-W-2081 Receiving Inspection of Welding Consumables (EE)karioke mohaNo ratings yet

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDocument9 pagesASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- EQT ChecklistDocument5 pagesEQT Checklistvijayachidu100% (1)

- WPS-Tube To Tube Sheet (SS-SS)Document2 pagesWPS-Tube To Tube Sheet (SS-SS)suria qaqcNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- CMMDocument26 pagesCMMSanjeev kumar Verma100% (1)

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 06 GTAW Stainless SteelDocument4 pages06 GTAW Stainless SteelMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Young's Double Slit Experiment (Handout)Document3 pagesYoung's Double Slit Experiment (Handout)phydotsi100% (1)

- Fit-Up Inspection Report PDFDocument1 pageFit-Up Inspection Report PDFAlfian Imaduddin100% (1)

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam100% (3)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- Beers Law Lab Guidedinquiry Studenthandout Docx-AlexaguilarDocument4 pagesBeers Law Lab Guidedinquiry Studenthandout Docx-Alexaguilarapi-31071482660% (5)

- Defects Acceptance CriteriaDocument1 pageDefects Acceptance CriteriahakamaffaqNo ratings yet

- Wps Hzi SMAWDocument18 pagesWps Hzi SMAWMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Long Seam and Circumference Seam SetupDocument4 pagesLong Seam and Circumference Seam Setuppriti kumariNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportmohd as shahiddin jafriNo ratings yet

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDocument23 pagesSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNo ratings yet

- PWPS - 3G FCAWDocument2 pagesPWPS - 3G FCAWasrafiNo ratings yet

- PWPS - 2G SMAWDocument2 pagesPWPS - 2G SMAWasrafiNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- Tanda TerimaDocument2 pagesTanda TerimaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Program K3 2023Document2 pagesProgram K3 2023Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Employee Hours Worked Last Three YearsDocument1 pageEmployee Hours Worked Last Three YearsMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Transmittal FormDocument90 pagesTransmittal FormMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT BridonDocument1 pagePT BridonMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Manufacturing Data Record IndexDocument2 pagesManufacturing Data Record IndexMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Laporan PiketDocument12 pagesLaporan PiketMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Design Intermittent WeldingDocument5 pagesDesign Intermittent WeldingMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT DjabesmenDocument1 pagePT DjabesmenMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Method Statement For Prediction Weld Shrinkage On StructuralDocument4 pagesMethod Statement For Prediction Weld Shrinkage On StructuralMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PQR PT Bse WPS 07Document2 pagesPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraNo ratings yet

- PT DjabesmenDocument1 pagePT DjabesmenMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 7 Inspection and Repair: 3 Api S 2BDocument1 page7 Inspection and Repair: 3 Api S 2BMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Annex C Residual Stress Profiles: Fitnet Mk7Document62 pagesAnnex C Residual Stress Profiles: Fitnet Mk7Muhammad Fitransyah Syamsuar PutraNo ratings yet

- AMH Magz Vol 9Document40 pagesAMH Magz Vol 9Muhammad Fitransyah Syamsuar Putra0% (1)

- WPQTDocument18 pagesWPQTMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Designing and Manufacturing of Alloy Wheel Using 3d Printing TechnologyDocument6 pagesDesigning and Manufacturing of Alloy Wheel Using 3d Printing TechnologyEditor IJTSRDNo ratings yet

- EPMA Introduction To Additive Manufacturing Technology Second Edition PDFDocument56 pagesEPMA Introduction To Additive Manufacturing Technology Second Edition PDFFlávia CostaNo ratings yet

- Mitrc Refresher Course Radiowave Propagation & AntennaDocument5 pagesMitrc Refresher Course Radiowave Propagation & AntennaAlbert AlemaniaNo ratings yet

- Vcta-Z5 Off LineDocument3 pagesVcta-Z5 Off LineqwUENo ratings yet

- NR-410404 - Optical CommunicationsDocument9 pagesNR-410404 - Optical CommunicationsSrinivasa Rao GNo ratings yet

- 2007-AHS-Splst-Aerodynamic Efficiency of Micro RotorDocument19 pages2007-AHS-Splst-Aerodynamic Efficiency of Micro RotorManikandan RamasamyNo ratings yet

- 71-76 GHZ Grounded-coplanar-waveguide-To-rectangular-waveguide Transition With Integrated Planar Bias Tee For Quasi-Hermetic Radio-Over Fiber Wireless TransmitterDocument4 pages71-76 GHZ Grounded-coplanar-waveguide-To-rectangular-waveguide Transition With Integrated Planar Bias Tee For Quasi-Hermetic Radio-Over Fiber Wireless TransmitterJonNo ratings yet

- Solid Ground CuringDocument18 pagesSolid Ground CuringSreedhar Pugalendhi100% (1)

- Physiolaser EnglishDocument39 pagesPhysiolaser EnglishLiliana ŢehanciucNo ratings yet

- SecFlow-2Document350 pagesSecFlow-2Diego Germán Domínguez HurtadoNo ratings yet

- NanoparticlesDocument25 pagesNanoparticlesAnonymous oVd3php100% (1)

- Safran-Vectronix ULTISENSE Brochure 2023-04 EN WebDocument8 pagesSafran-Vectronix ULTISENSE Brochure 2023-04 EN WebZhuoqun DaiNo ratings yet

- Technical Insight Into Laser TrackerDocument26 pagesTechnical Insight Into Laser TrackerSuresh RajagopalNo ratings yet

- Batarang TemplatesDocument4 pagesBatarang TemplatesSİLENTNo ratings yet

- University of Technology Department of Electrical Engineering Final Examination 2019-2020Document3 pagesUniversity of Technology Department of Electrical Engineering Final Examination 2019-2020Xzxz WahshNo ratings yet

- Campbell 1989Document6 pagesCampbell 1989MJNo ratings yet

- State of The Art of MicromachiningDocument16 pagesState of The Art of MicromachiningMarcionilo NeriNo ratings yet

- Semiconductor Manufacturing ProcessesDocument32 pagesSemiconductor Manufacturing ProcessesmailstonaikNo ratings yet

- Introduction To Remote Sensing PDFDocument19 pagesIntroduction To Remote Sensing PDFErnawati SengajiNo ratings yet

- Night Vision Technology: by Mudit Deval Mudit RelanDocument28 pagesNight Vision Technology: by Mudit Deval Mudit RelanmuditrelanNo ratings yet

- Advanced Machining ProcessesDocument22 pagesAdvanced Machining ProcessesfaizNo ratings yet

- Square Drive Hydraulic Torque Wrench CatalogueDocument2 pagesSquare Drive Hydraulic Torque Wrench CataloguerealmofmysticNo ratings yet

- Field Welding of RailDocument4 pagesField Welding of Raildurandm10No ratings yet