Professional Documents

Culture Documents

Estructuras de Protección Costera - Nota Técnica N°3

Uploaded by

Paula0 ratings0% found this document useful (0 votes)

20 views2 pagesCapitulo 3

Original Title

Estructuras de Protección Costera - Nota técnica n°3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCapitulo 3

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views2 pagesEstructuras de Protección Costera - Nota Técnica N°3

Uploaded by

PaulaCapitulo 3

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

CETN-III-3

2/80

PURPOSE: To call attention to the use of geotechnical fabrics as an alter-

native to sand and gravel filters for coastal structures.

BACKGROUND: Normally, filters to protect soils from surface erosion of pip-

ing losses are made-up of layers of graded sand, gravel, and stone materials

in various combinations and thicknesses. Often these materials are expensive

and, in some locations , proper materials are not economically available. Even

if the required materials are readily available, proper placement in the field,

particularly at inwater sites can be tedious and demands close inspection.

GEOTECHNICAL FABRICS: The term "Geotechnical Fabric" applies to a variety of

synthetic fiber textile products used in the construction of engineering works

including coastal engineering projects. These fabrics, both woven and non-

woven, have been used in projects involving quarrystone revetments, groins,

seawalls , jetties, and breakwaters. In these coastal structures the fabric

can replace one or more layers of a graded sand-and-gravel filter and is also

effective for erosion-control where the fabric can prevent piping and erosion

of cohesionless materials while allowing drainage and dissipation of excess

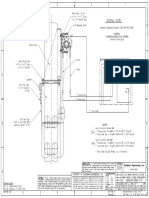

hydrostatic pore pressures. The seawall shown in the Figure was constructed

at the north end of Carolina Beach, North Carolina, in 1970, by the Corps of

Engineers, and utilizes a geotechnical fabric. Structures of a generally sim-

ilar cross section using these fabrics have been built along the Atlantic sea-

board since 1958. Stone weights, slopes, and elevations varied with local con-

ditions. More recently fabrics have been used behind steel, concrete, and timber‘

sheet-pile bulkheads in connection with french drains, weepholes, and joints.

A yn~: 3000-6000 Lbs.

B 500-2500 Lbs.

c stone: 2”-I2”Bed stone

Beach Fill

Geotechnical Fabric

- - - - - - - - - -

Figure - Use of Geotechnical Fabric in Seawall at Carolina

Beach, NC (Corps of Engineers project).

The great flexibility of these fabrics helps to assure the long-term con-

tinuity of the filter. While all of these fabrics will bend, crease, fold,

and stretch to some degree without rupturing, the relative performance of dif-

ferent proprietary fabrics are quite varied. However, it is important to

properly place the fabric loosely so that distortions that occur from place-

ment of heavy stones will not subject the fabric to stresses beyond its elas-

tic limits and to adequately overlap adjacent sections to insure continuity.

Over 30 different fabrics for coastal usage are commercially available in

the United States in either woven or nonwoven styles. In any given project

application it is important to consider which of these proprietary fabrics

will best meet the engineering design parameters. Before selection of a par-

ticular geotechnical fabric is made for its applicability to a specific de-

sign, it is important to determine the physical, chemical, and engineering

properties of commercially available filter fabrics with respect to design

criteria. There may be large variations in these properties (see Table) and

the cost can vary greatly.

TABLE

General Properties of Geotechnical Fabrics

ITEM REMARKS ANDREFERENCES

1. Weave. . . . . . . . . . . . . . . .Woven, Nonwoven, or Perforated

2. Thickness. . . . . . . . . . . . . ASTM-D-1777, Dimension of Fibers

3. Weight . . . . . . . . . . . . . . .ASTM-D-1910, Construction Character-

istics

4. Breaking Load and Elongation . . . .ASTM-D-1682, Grab and Strip Test

a. Warp Direction (length)

b . Fill Direction (width)

5. Bursting Strength. . . . . . . . . .ASTM-D-751, Testing of Fabrics

6. Puncture Test. . . . . . . . . . . ASTM-D-751, Modified

7. Abrasion Resistance. . . . . . . . .ASTM-D-1175

8. Abrasion Strength. . . . . . . . . .ASTM-D-1682

9. Equivalent Opening Size (EOS). . . .Care should be used to prevent clog-

(US Sieve No. Equivalent) ging by sediment or loss of fines

through the fabric.

10. Elastic Properties . . . . . . . . .ASTM-D-1774

11. -Water Permeability . . . . . . . . .Gradient-Ratio should not exceed 3

(see Guide Specifications, OCE, 1977)

12. Chemical Composition . . . . . . . .Fiber material could be: nylon,

polypropylene, polyamide, polyester,

olefine, fiber glass, etc.

13. Accelerated Aging. . . . . . . . . .Some deterioration after prolonged

exposure to sunlight if not buried

in structure. (See Fed. Stnd. 191.)

Guidelines for quality control can be found in the following reference:

U.S. ARMY, CORPS OF ENGINEERS, "Plastic Filter Cloth," Guide Specifications

CW-02215, Office of the Chief of Engineers, Washington, DC, November, 1977.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 000 Diseño Por Capacidad - 2003 - Myths and Fallacies in Earthquake Engineering - Priestley Pag20Document98 pages000 Diseño Por Capacidad - 2003 - Myths and Fallacies in Earthquake Engineering - Priestley Pag20Roberto UrrutiaNo ratings yet

- Rotary EvaporatorDocument4 pagesRotary EvaporatorArif FerdianNo ratings yet

- Free FEM Course Civil Exercise: Beam On Elastic Springs: IcaeecDocument19 pagesFree FEM Course Civil Exercise: Beam On Elastic Springs: IcaeecDanielRoblesTorresNo ratings yet

- Mechanistic Insights Into The Durability of Ancient Roman ConcreteDocument13 pagesMechanistic Insights Into The Durability of Ancient Roman ConcretePaulaNo ratings yet

- Two Dimensional TrussDocument2 pagesTwo Dimensional Trussgreat2007No ratings yet

- Criteria For The Design of Composite Slabs PDFDocument8 pagesCriteria For The Design of Composite Slabs PDFakhileshgojeNo ratings yet

- Two Dimensional TrussDocument2 pagesTwo Dimensional Trussgreat2007No ratings yet

- CFT Design Guide March 2014Document44 pagesCFT Design Guide March 2014Juan Castillo100% (2)

- Stability Publications FlexiFloatDocument19 pagesStability Publications FlexiFloatPaulaNo ratings yet

- Two Dimensional TrussDocument2 pagesTwo Dimensional Trussgreat2007No ratings yet

- Technical Bulletin No. 1: Basic Formulas of Static StabilityDocument8 pagesTechnical Bulletin No. 1: Basic Formulas of Static StabilityPaulaNo ratings yet

- Modular C5 FloatsDocument2 pagesModular C5 FloatsPaulaNo ratings yet

- Estructuras de Protección Costera - Nota Técnica N°2Document8 pagesEstructuras de Protección Costera - Nota Técnica N°2PaulaNo ratings yet

- Beam Tutorial 12 PDFDocument20 pagesBeam Tutorial 12 PDFAnand ShahNo ratings yet

- Stability Publications FlexiFloatDocument19 pagesStability Publications FlexiFloatPaulaNo ratings yet

- Hilti Instruction-for-use-HIT-MM-PLUS-Instruction-for-use-PUB-5204384-000 PDFDocument64 pagesHilti Instruction-for-use-HIT-MM-PLUS-Instruction-for-use-PUB-5204384-000 PDFcemadaroNo ratings yet

- Deck Cleat Working DrawingDocument1 pageDeck Cleat Working DrawingPaulaNo ratings yet

- S70 - FlexiboatDocument1 pageS70 - FlexiboatPaulaNo ratings yet

- Info LinuxDocument1 pageInfo LinuxPaulaNo ratings yet

- Preparing Your Computer For LFS101xDocument16 pagesPreparing Your Computer For LFS101xAnish RaoNo ratings yet

- Semana 2 PDFDocument1 pageSemana 2 PDFPaulaNo ratings yet

- Nocturne in B Flat Minor, Op. 9 No. 1Document4 pagesNocturne in B Flat Minor, Op. 9 No. 1PaulaNo ratings yet

- Enciclopedia SismicaDocument3,996 pagesEnciclopedia SismicaPaula100% (2)

- Linux Editores de Texto - IntroducciónDocument7 pagesLinux Editores de Texto - IntroducciónPaulaNo ratings yet

- Mapa Hidrografico CORFO 1971Document19 pagesMapa Hidrografico CORFO 1971PaulaNo ratings yet

- Estructuras de Protección CosterasDocument6 pagesEstructuras de Protección CosterasPaulaNo ratings yet

- Second Edition International Code Council 2006Document548 pagesSecond Edition International Code Council 2006ElgueVen82% (11)

- Bridge Design Eurocodes Worked ExamplesDocument438 pagesBridge Design Eurocodes Worked Examplespradeepjoshi007100% (4)

- AWC WCD1 ConventionalWoodFrame ViewOnly 0107 PDFDocument55 pagesAWC WCD1 ConventionalWoodFrame ViewOnly 0107 PDFjuan pringNo ratings yet

- Second Edition International Code Council 2006Document548 pagesSecond Edition International Code Council 2006ElgueVen82% (11)

- Cabochon Settings and Patterns UsingDocument27 pagesCabochon Settings and Patterns Usingodile lambNo ratings yet

- Astm G109Document6 pagesAstm G109AlbertoNo ratings yet

- Flexible PavementDocument28 pagesFlexible PavementbhanukerniNo ratings yet

- Spaghetti Challenge - 2022-0Document2 pagesSpaghetti Challenge - 2022-0diegoNo ratings yet

- Structure of WaterDocument5 pagesStructure of Waterapi-233981890No ratings yet

- UC XLPE CatalogueDocument80 pagesUC XLPE CatalogueNICHOLASNo ratings yet

- General - Chemistry 1 Module 2 AY 2022 2023Document17 pagesGeneral - Chemistry 1 Module 2 AY 2022 2023Yzac Barroga PascualNo ratings yet

- Waste ManagementDocument43 pagesWaste Managementالدنيا ساعة فاجعلها طاعةNo ratings yet

- 324-Chapter 1 Rock Bit Interactions PDFDocument42 pages324-Chapter 1 Rock Bit Interactions PDFBilge KaanNo ratings yet

- Loctite 401™: Technical Data SheetDocument3 pagesLoctite 401™: Technical Data Sheetehsan100% (1)

- Plasterers Bead and Mesh. PVC - OriginalDocument11 pagesPlasterers Bead and Mesh. PVC - OriginalSowmiya Rajagopal100% (1)

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Chem Paper 3 Salt AnalysisDocument6 pagesChem Paper 3 Salt AnalysisalphonsuswanjohiNo ratings yet

- Additive Sunset YellowDocument2 pagesAdditive Sunset YellowMohammad RofikNo ratings yet

- SQWTS PH3 Direct ManpowerDocument42 pagesSQWTS PH3 Direct ManpowerOsama AliNo ratings yet

- Chelating AgentDocument13 pagesChelating AgentHiba MusthafaNo ratings yet

- Assessment of Flaws in Pipe Girth WeldsDocument17 pagesAssessment of Flaws in Pipe Girth Weldssherviny100% (1)

- Hydraulic Ram Pump ReportDocument42 pagesHydraulic Ram Pump ReportliviciuklNo ratings yet

- Convection: Cooling TowersDocument11 pagesConvection: Cooling Towersantolincy6706No ratings yet

- A Database For Shot Peening ProcessDocument9 pagesA Database For Shot Peening Processkayasimge595No ratings yet

- TOMRA Catalouge 2022 EN LowResDocument31 pagesTOMRA Catalouge 2022 EN LowResdean.murray65No ratings yet

- Fundamentals of Pipeline Design, Hydraulics & PumpsDocument75 pagesFundamentals of Pipeline Design, Hydraulics & PumpsMIRACLE26No ratings yet

- Industrial Strainers Filters Y StrainerDocument1 pageIndustrial Strainers Filters Y StrainerEi Ei PhyoNo ratings yet

- Olivine Thin Section GuideDocument16 pagesOlivine Thin Section Guideishotthesherifswife100% (1)

- Traditional and Innovative Joints in Bamboo ConstructionDocument3 pagesTraditional and Innovative Joints in Bamboo ConstructionAulia Rahman FahmiliNo ratings yet

- Wye BranchesDocument8 pagesWye BranchesbarukomkssNo ratings yet

- Potasium Dichromate TitrationDocument4 pagesPotasium Dichromate TitrationChandran100% (1)

- CeramicsDocument21 pagesCeramics05DWI BILQIIS KHAIRUNNISANo ratings yet