Professional Documents

Culture Documents

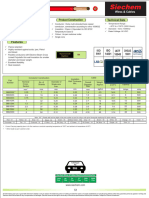

Voestalpine Wire Prestressing Wire Strand Folder

Uploaded by

arunt_19Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Voestalpine Wire Prestressing Wire Strand Folder

Uploaded by

arunt_19Copyright:

Available Formats

Wire Drawn Special

Rod Wire Wire

Special testing

Special tests are carried out in our accredited laboratories:

Deflective tensile test

Relaxation test

NH4SCN corrosion test

Fatigue test frequency range 10 - 120 Hz

That is what our customers can build on:

Quality management Highest quality for our customers

EN ISO 9001:2008 Our prestressing steels are the first

ISO/TS 16949:2009

For detailed information regarding our certifications visit our webpage choice wherever major forces have to

www.voestalpine.com/wire be transferred or absorbed reliably and

Special steel grades efficiently

We specialize in customer-oriented wire products. Due to the steel production possibilities Surface coating and corrosion protection

within our group, we can manufacture special steel grades according to customer

requirements. (zinc coating, plastic coating)

Various surface types (smooth, indented)

Special tests are carried out in our

accredited laboratories

Special applications: LNG Tanks, Stay

Cable Systems

03/2016

Prestressing strand

Safety builds on quality

voestalpine Wire Technology GmbH

Bahnhofstraße 2, 8600 Bruck a. d. Mur, Austria

T. +43/50304/22-0

wire@voestalpine.com voestalpine Wire Technology GmbH

www.voestalpine.com/wire www.voestalpine.com/wire

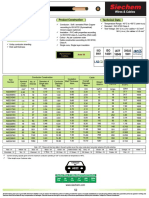

Prestressing steel 7 wire strand compacted in acc. with FprEN 10138-3

Diameter Tensile strength Cross sectional area Mass Characteristic value of max. force Max. value of max. force Value of 0,1% proof force

D Rm Sn M Fm Fm,max Fp0,1

mm N/mm² mm² g/m kN kN kN

15.2 1820 165 1289 300 354.0 264.0

15.2 1860 165 1289 307 353.0 270.0

Advantages of the compacted strand compared to standard strand

+ 18% more steel crosssection for the same outer strand diameter

+ 13% higher nominal breaking load and 3% smaller outer diameter compared to strand 150mm2 - 1770 N/mm2

+ 8% higher breaking load and 3% smaller outer diameter compared to strand 150mm2 - 1860N/mm2

More effective anchoring, due to higher grip-area of wedges

Lower surface pressure on HDPE-duct in deflection area, with applicaton of unbounded tendons

Prestressing steel 7 wire strand in acc. with FprEN 10138-3

Diameter Tensile strength Cross sectional area Mass Characteristic value of max. force Max. value of max. force Value of 0.1% proof force

D Rm Sn M Fm Fm,max Fp0,1

mm N/mm² mm² g/m kN kN kN

Prestressing steel 7 wire strand galvanized, waxed, HDPE sheathed 6.9 1860 29 226.5 51.3 60.5 45.1

Nominal diameter strand Total mass Mass of components

9.3 1860 52 406.1 92.0 109.0 81.0

DL M Steel HDPE Wax

9.3 1960 52 406.1 102.0 120.0 90.8

mm kg/1000m kg/1000 m

9.6 1860 55 429.6 97.4 115.0 85.7

15.3 ≥ 1224 1093 ≥ 82 ≥ 12

12.5 1860 93 726.3 173.0 204.0 152.0

15.7 ≥ 1303 1172 ≥ 82 ≥ 12

12.9 1860 100 781.0 186.0 220.0 164.0

Prestressing 7 wire strand galvanzized, waxed, HDPE sheathed for stay cable systems 15.2 1770 139 1086.0 246.0 283.0 216.0

Standard: FprEn 10337 or NF A35-035 15.2 1860 139 1086.0 259.0 298.0 228.0

Mass of zinc: 190 - 350 g/m2 or 220 - 350 g/m2 15.3 1770 140 1093.0 248.0 285.0 218.0

Type of HDPE: HDPE80 / HDPE100 / HDPE100+, different types upon request 15.3 1860 140 1093.0 260.0 299.0 229.0

Minimum sheathing thickness: 1.5 mm 15.7 1770 150 1172.0 266.0 306.0 234.0

Special types upon request 15.7 1860 150 1172.0 279.0 321.0 246.0

Please contact us for special requirements.

Surface quality Prestressing steel 7 wire strand galvanized

Smooth Diameter:

Indented 9.3 mm - 15.7 mm

Surface quality: smooth

Prestressing steel 7 wire strand in acc. with FprEN 10138-3 for application under cryogenic conditions

Diameter Tensile strength Cross section Mass Characteristic value of max. force Max. value of max. force Characteristic value of 0.1% proof force Elongation at max. load

D Rm Sn M Fm Fm,max Fp0,1 Agt

mm N/mm² mm² g/m kN kN kN % Prestressing steel 7 wire strand greased and HDPE sheathed

Strand diameter Mass Mass of components

15.7 1860 150 1172 279 329 246 > 3.5

DL M Steel HDPE Grease

Prestressing strand for applications under cryogenic conditions mm kg/1000m kg/1000 m

(LNG Tanks) 12.5 ≥ 825 ≥ 849 730 ≥ 65 ≥ 89 ≥ 30

Standards and rules: fip SR 88/2, ETAG 013, BS 7777-3 12.9 ≥ 885 ≥ 908 785 ≥ 68 ≥ 91 ≥ 32

Results of tensile tests under cryogenic conditions available 15.3 ≥ 1218 ≥ 1242 1099 ≥ 79 ≥ 103 ≥ 40

15.7 ≥ 1303 ≥ 1335 1178 ≥ 82 ≥ 114 ≥ 43

Prestressing steel 7 wire strand compacted and HDPE sheathed

Strand diameter Mass Mass of components

DL M Steel HDPE Grease

mm kg/1000m kg/1000 m

15.2 ≥ 1403 ≥ 1427 1289 ≥ 79 ≥ 103 ≥ 35

Standard minimum HDPE sheath: 1.5 mm or 2.0 mm

Other HDPE coating thickness upon request

Waxed version upon request

Same mechanical characteristics as the wire strand

Extraction load of straight tendons max. 60 N/m.

Multiple sheathed strands upon request

You might also like

- Cordaflex (SMK) - V (N) Shtoeu EnglDocument3 pagesCordaflex (SMK) - V (N) Shtoeu EnglrachidNo ratings yet

- CatalougeDocument15 pagesCatalougeBarbara OrtigozaNo ratings yet

- FLR2X11Y CablesDocument1 pageFLR2X11Y CablesKristaNo ratings yet

- FLR2X11Y CablesDocument1 pageFLR2X11Y CablesVijay KarthikeyanNo ratings yet

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- FLRY11Y CablesDocument1 pageFLRY11Y CablesKristaNo ratings yet

- FLRYWK CablesDocument1 pageFLRYWK CablesKristaNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- EV CablesDocument1 pageEV CablesVijay KarthikeyanNo ratings yet

- 1696 - Enduring-Versatile-And Tough-As-Steel - ENDocument12 pages1696 - Enduring-Versatile-And Tough-As-Steel - ENmohammadNo ratings yet

- Part II PDFDocument28 pagesPart II PDFAdrian OprisanNo ratings yet

- What's New - PV Elite 2018Document28 pagesWhat's New - PV Elite 2018SathiyaseelanNo ratings yet

- Cable-Gland-Catalogue CMPDocument1 pageCable-Gland-Catalogue CMPKaustabha DasNo ratings yet

- EU Data Sheet Chainflex CFSOFT2Document7 pagesEU Data Sheet Chainflex CFSOFT2Jérôme MeugnierNo ratings yet

- Auto 100 CableDocument1 pageAuto 100 CableVijay KarthikeyanNo ratings yet

- Bezinal XPDocument2 pagesBezinal XPHeca WahyuniNo ratings yet

- Postensioning TIANJINDocument25 pagesPostensioning TIANJINViviana Sofia100% (1)

- Hoist Chains: For Manual and Motor-Driven HoistsDocument12 pagesHoist Chains: For Manual and Motor-Driven HoistsjoosuasinagaNo ratings yet

- Airmaster HVAC Ducting BrochureDocument12 pagesAirmaster HVAC Ducting BrochureWaseem NaamoNo ratings yet

- Armouring For Copper CablesDocument2 pagesArmouring For Copper Cablestwo travellerNo ratings yet

- Auto 150 CableDocument1 pageAuto 150 CableVijay KarthikeyanNo ratings yet

- Bumax Material Presentation - 04!05!16Document49 pagesBumax Material Presentation - 04!05!16matteo_1234No ratings yet

- Technical Standard Data of Litz Wire Products: Home About Us Products FAQ Contact UsDocument3 pagesTechnical Standard Data of Litz Wire Products: Home About Us Products FAQ Contact UsRaghu LethwalaNo ratings yet

- Consol Steel Belt - 2018Document12 pagesConsol Steel Belt - 2018Lavender ShenNo ratings yet

- Brosur Concrete PipeDocument20 pagesBrosur Concrete PipegneissetiagrahaNo ratings yet

- Membrane Lined Insulated Gutter - BrochureDocument8 pagesMembrane Lined Insulated Gutter - BrochureAThaddeusAntonioNo ratings yet

- OS1LTSTA12UBKDocument2 pagesOS1LTSTA12UBKShimahNo ratings yet

- ZTT CableDocument20 pagesZTT CableMochammad Rochim PratamaNo ratings yet

- Tensile Fabric Is A Multi-Layer Composite Material WithDocument4 pagesTensile Fabric Is A Multi-Layer Composite Material WithDen BillNo ratings yet

- Sika Anchorfix 2 PDFDocument7 pagesSika Anchorfix 2 PDFUnited Construction Est. TechnicalNo ratings yet

- CapacitorDocument17 pagesCapacitorjuliolocNo ratings yet

- Annex 02-Technical Specfication for MV FSY-YJLSY63-15KV技术规格书菲律宾6.6Document3 pagesAnnex 02-Technical Specfication for MV FSY-YJLSY63-15KV技术规格书菲律宾6.6carlremNo ratings yet

- 1DB - 49821 - enDocument1 page1DB - 49821 - enFreddy MormontoyNo ratings yet

- Ficha Técnica - XABO 500 - ThyssenkruppDocument3 pagesFicha Técnica - XABO 500 - ThyssenkruppDiego Ramírez ParraNo ratings yet

- Cnwiremachine en Made in China Com Product vnmpKVqOCIcg ChinDocument7 pagesCnwiremachine en Made in China Com Product vnmpKVqOCIcg ChinwonosarijayasurabayaNo ratings yet

- Customized Bearings and Racks - Product Catalog ENDocument8 pagesCustomized Bearings and Racks - Product Catalog ENbekirrrrNo ratings yet

- R4 CableDocument1 pageR4 CableVijay KarthikeyanNo ratings yet

- Concrete Pipe Brosur 1Document20 pagesConcrete Pipe Brosur 1Toni SosantoNo ratings yet

- Lysaght Klip Lok 406 2011Document12 pagesLysaght Klip Lok 406 2011Zuhal ZaeemNo ratings yet

- Bridge Technology: Post-Tensioning Tendon Installation and Grouting ManualDocument91 pagesBridge Technology: Post-Tensioning Tendon Installation and Grouting Manualvikasharma_eeNo ratings yet

- 1095 Davers Bar Cable Low Res PDFDocument13 pages1095 Davers Bar Cable Low Res PDFjoseataviNo ratings yet

- ABB - Filament Wound ComponentDocument4 pagesABB - Filament Wound ComponentAbu Haydar Amin MustanginNo ratings yet

- Quend 700Document2 pagesQuend 700planningNo ratings yet

- Familydatasheet 29907 enDocument4 pagesFamilydatasheet 29907 enGajanan GaikwadNo ratings yet

- KSH International Continuously Transposed Cables - Conductors (CTC) BrochureDocument4 pagesKSH International Continuously Transposed Cables - Conductors (CTC) Brochurekshintl100% (3)

- Auto 85 CableDocument1 pageAuto 85 CableVijay KarthikeyanNo ratings yet

- Sikawrap®-300 C: Product Data SheetDocument4 pagesSikawrap®-300 C: Product Data SheetHenri DormoyNo ratings yet

- Indeco Welding Cable WS-105 600 V: DescriptionDocument3 pagesIndeco Welding Cable WS-105 600 V: DescriptionElmer Leodan Rojas CachayNo ratings yet

- Nitrile Rubber InsulationDocument2 pagesNitrile Rubber InsulationSushil WadiyeNo ratings yet

- Cross Limit Switch Lambda / AlphaDocument8 pagesCross Limit Switch Lambda / AlphaKhaled RabeaNo ratings yet

- AVSS CablesDocument1 pageAVSS CablesVijay KarthikeyanNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- E1FW/M: CMP Products Cable Gland CatalogueDocument1 pageE1FW/M: CMP Products Cable Gland CataloguesubramanyaNo ratings yet

- VSL SlabDocument12 pagesVSL SlabhazemNo ratings yet

- Customized Bearings and Racks - Product Catalog ENDocument8 pagesCustomized Bearings and Racks - Product Catalog ENDidi MoacaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNo ratings yet

- Video and Camcorder Servicing and TechnologyFrom EverandVideo and Camcorder Servicing and TechnologyRating: 4 out of 5 stars4/5 (1)

- Future of LNG - Arup - April17 PDFDocument21 pagesFuture of LNG - Arup - April17 PDF123habib123fikriNo ratings yet

- 2222222222Document42 pages2222222222KRRAJANBHUNo ratings yet

- MARKETING STRATEGY FOR The Resource Information Serving Everyone (R.I.S.E.) Project General OverviewDocument3 pagesMARKETING STRATEGY FOR The Resource Information Serving Everyone (R.I.S.E.) Project General Overviewarunt_19No ratings yet

- What Is A Feasibility StudyDocument5 pagesWhat Is A Feasibility Studyarunt_19No ratings yet

- Sanjay Dixit: TH TH TH THDocument5 pagesSanjay Dixit: TH TH TH THerroshanNo ratings yet

- Current MinistryDocument10 pagesCurrent Ministryarunt_19No ratings yet

- Iron Total High Level - AP-16 - 900Document4 pagesIron Total High Level - AP-16 - 900wulalan wulanNo ratings yet

- Product DatasheetDocument1 pageProduct Datasheetأبو أميرNo ratings yet

- Schéma Poste 225/20kV LydecDocument15 pagesSchéma Poste 225/20kV LydecOMARNo ratings yet

- ITEM 404 - BluebookDocument4 pagesITEM 404 - BluebookEster MarianNo ratings yet

- Anodizing Color Sample SheetDocument2 pagesAnodizing Color Sample SheetJason DesouzaNo ratings yet

- Borax 01 PDFDocument2 pagesBorax 01 PDFAbram Louies Hanna100% (1)

- Fine Print of Metallurgy Part 1 Optimieren PDFDocument5 pagesFine Print of Metallurgy Part 1 Optimieren PDFdhruvNo ratings yet

- Principle of Enhanced Oil Recovery: Chapter 5 Alkaline FloodingDocument13 pagesPrinciple of Enhanced Oil Recovery: Chapter 5 Alkaline FloodingNgapene MichelharisNo ratings yet

- Vinyl Acetate Production: Chemical CharacterizationDocument3 pagesVinyl Acetate Production: Chemical CharacterizationHamzah A. LaftaNo ratings yet

- Chem 1 PDFDocument33 pagesChem 1 PDFJelena ZdravkovicNo ratings yet

- Hydrogen EmbittlementDocument8 pagesHydrogen EmbittlementManoj SahuNo ratings yet

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDocument1 pageCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNo ratings yet

- High Strength Low Alloy Steels in Naval Construction PDFDocument18 pagesHigh Strength Low Alloy Steels in Naval Construction PDFbiancogallazzi100% (1)

- E TextilesDocument20 pagesE TextilesKhadeeja Ashna0% (1)

- HomeGuard Installation Manual 5C 2015Document112 pagesHomeGuard Installation Manual 5C 2015_Asylum_No ratings yet

- Article - CO2 Diffusion From PET Bottles - For Packaging India April 19Document8 pagesArticle - CO2 Diffusion From PET Bottles - For Packaging India April 19Darshan VartakNo ratings yet

- w0167 PreDocument1 pagew0167 PreKandeke DaviesNo ratings yet

- ASME B31.3 Process Piping: 13. Inspection, Examination & TestingDocument37 pagesASME B31.3 Process Piping: 13. Inspection, Examination & TestingMohamed Al-OdatNo ratings yet

- En bf880 PDFDocument1 pageEn bf880 PDFshaonaaNo ratings yet

- Kerto® LVL Q-Panels Combine Excellent Technical Performance With Ease of UseDocument3 pagesKerto® LVL Q-Panels Combine Excellent Technical Performance With Ease of UseMatheus FlorianiNo ratings yet

- ITP For Painting WorksDocument27 pagesITP For Painting Workssree50% (2)

- Salt and Miscellaneous Sodium CompoundsDocument13 pagesSalt and Miscellaneous Sodium CompoundsBrent FajardoNo ratings yet

- Textile Basic SpinningDocument21 pagesTextile Basic SpinningAnonymous Pt7NHkat9100% (1)

- Korasit Ks2 TM CLP 2017-02 enDocument4 pagesKorasit Ks2 TM CLP 2017-02 enBruno AlmeidaNo ratings yet

- Periodic TableDocument125 pagesPeriodic TablechristabelNo ratings yet

- Hilti HIT-RE 500 V3 Mortar With Rebar (As Post-Installed Connection)Document17 pagesHilti HIT-RE 500 V3 Mortar With Rebar (As Post-Installed Connection)Farly VergelNo ratings yet

- Durability of ConcreteDocument89 pagesDurability of ConcreteRamu NeupaneNo ratings yet

- Triple and Critical PointsDocument1 pageTriple and Critical PointsGarcia AzirNo ratings yet

- API 526 - Spring Loaded Material TableDocument1 pageAPI 526 - Spring Loaded Material TableGanda SamosirNo ratings yet

- Refrateck SolutionsDocument8 pagesRefrateck SolutionsMagesh Kumar0% (1)