Professional Documents

Culture Documents

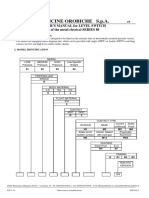

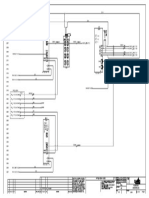

General Arrangement Model

Uploaded by

donaxtaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Arrangement Model

Uploaded by

donaxtaCopyright:

Available Formats

WEIGHT LOAD CHART MATERIALS

Empty Load With Fluid With Fluids & Product Total Fluid Volume 1764 Exchanger Plates 1.4404 / SS316L

F1=F2=F3=F4 15.8 kN 16.9 kN 35.4 kN Hoses & Fittings 1.4404 interior & 1.4301 braid

Total F1+F2+F3+F4 63.4 kN 67.6 kN 141.8 kN 1092 Springs 1.4310 / SS301

Manifolds 1.4307 / SS304L

912 Casing Contact 1.4307 / SS304L

Casing Non-Contact 1.4301 / SS304

Discharge Device Contact 1.4307 / SS304L

F4 Discharge Device Non-Contact 1.4301 / SS304

813

882 Assembly Bolts A2-70

736 A2 A4

Door Gasket Silicone Sponge/Foam /Food Grade

619

1516

1696

614 Mating Flange Gasket Silicone Caulking / Food Grade

F3 Nozzle Assembly Gasket: Silicone / Food Grade

229 B1 Fluid Flange Gasket: Klingersil

F1

813

0 A1 SURFACE PREPARATION & PAINT SPECIFICATIONS

Exchanger Plates Stainless Steel 2B Finish, Pickled & Passivated

F2 Door Swing 229 S1

Plate Bank / Inlet Cover Stainless Steel

384 L1 22

614 Ra,180 grit), Pickled & Passivated

Mounting

619 A3 B2

Holes Discharge Device Stainless Steel Interior Sloping Surfaces 2B Finish,

76 768 768 76 All Other Surfaces Mill Finish,

882

SECTION A-A grit), Pickled & Passivated

0

848

668

588

531

588

668

848

1312

Base Mounting Dimensions NOZZLE SCHEDULE

1:30 Mk Nozzle Function

A1 12mm Plate Flange( 12"- 150# ANSI LAYOUT) Product Inlet

A2 12mm Plate Flange( 6"- 150# ANSI LAYOUT) Purge Air Inlet

A3 4" RFSO 150# ANSI FLANGE Exchanger Fluid In

A4 12mm Plate Flange( 3"- 150# ANSI LAYOUT) Startup Air Inlet

B1 150 mm OD. Tube Vent

B2 4" RFSO 150# ANSI FLANGE Exchanger Fluid Out

B3 300 mm OD. Tube Product Outlet

L1 1 1/2" NPT Coupling (plugged) Level Probe

M1 3/4" NPT Coupling (plugged) Manifold Vent

M2 3/4" NPT Coupling (plugged) Manifold Drain

S1 1 1/2" NPT Coupling (plugged) Spare

S2 S3 S4 3/4" NPT Coupling (plugged) Spare

T1 3/4" NPT Coupling (plugged) Temperature Probe

Openings & Hatches (width x height)

H1 918 x 255 Opening Inspection Hatch

1500 Minimum H2 1200 x 912 Opening (x3) Full Size Access Door

450 Minimum 6481 B1 Clearance For

506

621 X 150 Opening (x2) Inspection Hatch

150

H3

Clearance For Probe Removal

Cover Swing 6148 A1 Z1 Z2 Z3 Tie Back Lugs

6000

Name Plate

H1

1200

Insulated THERMAL EXPANSION

Lifting 4982 T1 Nozzle: Max Vertical Movement (mm)

Lug 4910

4800 Z1 4845 A1 10

4750 Proposed

Platform M1 A2 4628 A2 8

4496 B2 Location A3 1

1650 Minimum M2

Tie Back Clearance For A4 0

Lug

1600

H2 B1 11

Plate Removal

And Door Swing B2 8

M1

200

B3 2

M2

Z1 8

3450 3400 Z2 6

3282 S2 Proposed Z2 3300

3150 3200 Z3 3

Platform M1

H2 Location

1650 Minimum M2

Clearance For

1600

7498

Plate Removal

And Door Swing

M1

200

1850 M2

H2 1800

1682 S3

Proposed Z3 1700

Grounding 1600 Purchase Order Number: 4500075496

1550 Platform

Lug Location

M1 Customer Job Number:

M2 Equipment Description: Sugar Cooler

1650 Minimum

H3 Clearance For Equipment Number: ---

1600

Plate Removal

Project Name: San Jacinto

And Door Swing

M1

200

Location: Ancash

432 A3

M2 Customer: San Jacinto, Ancash

250 200

112 S4 A4 74

Proposed

0

Platform A A 0

Location 1 General updates 2014/07/30 IW KK

0 Certified Issue 2014/07/08 IW KK

B Revised width of unit dimension 912 was 741 2014/07/04 IW KK

1348

625 Minimum A Issued for Approval 2014/06/24 IW VW KK

Clearance For Rev. Revision Description Date By Chk'd App'd

Motor Maintenace

& Removal

1348 B3

*THIS DOCUMENT IS THE PROPERTY OF SOLEX THERMAL SCIENCE, INC. THIRD-ANGLE

AND HAS BEEN RELEASED FOR CONFIDENTIAL USE ONLY. IT IS NOT TO BE PROJECTION

COMMUNICATED OR DISCLOSED TO OTHERS OR TO BE COPIED IN WHOLE

DIMENSIONS: MILLIMETERS

OR IN ANY PART EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF VALUES SHOWN ARE TO BE USED AS STANDARD

TOLERANCES UNLESS OTHERWISE NOTED

SOLEX THERMAL SCIENCE, INC.* APEGA PERMIT No: P07247

OVER TO

PROJECT Solex Project 763 0.5 3

3 6

DWG NAME GENERAL ARRANGEMENT 6 30

ANGLE:

30 120

120 400

DWG NO. 763-1010 400 1000

1000 2000

FINISH N/A 2000

SHEET NO. 1 OF 2 SCALE: 1:30 PLOT: A1 SIZE

You might also like

- SDW-10338830 015 01Document4 pagesSDW-10338830 015 01Tiagohowpy RamosNo ratings yet

- Type ISO-AB 2000: Plug Valve With PFA/FEP Lining and PTFE SleeveDocument2 pagesType ISO-AB 2000: Plug Valve With PFA/FEP Lining and PTFE SleeveandrebitaNo ratings yet

- Ball Valve 1-4464 Body and Stem - 3-Piece - RFDocument1 pageBall Valve 1-4464 Body and Stem - 3-Piece - RFruiz sumarNo ratings yet

- Endurace CF SL - CF SLX Disc r36-17 - R054-01-Am - Bom - MeDocument1 pageEndurace CF SL - CF SLX Disc r36-17 - R054-01-Am - Bom - MeRoberto EmmeNo ratings yet

- SERIE 80-IngleseDocument8 pagesSERIE 80-Ingleseshb soomroNo ratings yet

- AI195986432891en 000101Document2 pagesAI195986432891en 000101Peerasut ChaisrimaneepanNo ratings yet

- GAD - Gallaf - After TBC Revc PDFDocument58 pagesGAD - Gallaf - After TBC Revc PDFDaniel DuongNo ratings yet

- 2 Inch Demco Relief Valves Replacement PartsDocument1 page2 Inch Demco Relief Valves Replacement Partsjose villalbaNo ratings yet

- Endurace CF SL - CF SLX Disc R36-17 - R054-01-AM - BOM - EL PDFDocument1 pageEndurace CF SL - CF SLX Disc R36-17 - R054-01-AM - BOM - EL PDFRoberto EmmeNo ratings yet

- Synchro-Feed Welding System: Maximum Current Increased ToDocument2 pagesSynchro-Feed Welding System: Maximum Current Increased ToEdwin GeovannyNo ratings yet

- Air Inlet: General Tolerances Machining ISO 2768-c Welding: Flanges EN-ISO 13920-F 1 1Document1 pageAir Inlet: General Tolerances Machining ISO 2768-c Welding: Flanges EN-ISO 13920-F 1 1Ankit JainNo ratings yet

- FLO DS 0103 Valve Tek V2F Full Port Ball Valves PDFDocument1 pageFLO DS 0103 Valve Tek V2F Full Port Ball Valves PDFStuart MaleNo ratings yet

- PN16 Joints Dismantling: Ref.: JT4243 .Pas Rev.: Initial Date: 30/05/2016 Page: 1/1Document1 pagePN16 Joints Dismantling: Ref.: JT4243 .Pas Rev.: Initial Date: 30/05/2016 Page: 1/1edmar jay conchadaNo ratings yet

- Robinet SP Pn64 Cf. DIN 3202-F8Document2 pagesRobinet SP Pn64 Cf. DIN 3202-F8Radoo NephilaNo ratings yet

- Fittings Stopple: ASME B31.4Document2 pagesFittings Stopple: ASME B31.4Anonymous 7xbdR5100% (1)

- Pressure Safety ValveDocument1 pagePressure Safety ValveBaoLCNo ratings yet

- BR Ku 1101 enDocument4 pagesBR Ku 1101 enAkshay ValaNo ratings yet

- Valvulas SunDocument1 pageValvulas SunErickson AmpueroNo ratings yet

- FCV 1201 Hydrolic SystemDocument1 pageFCV 1201 Hydrolic SystemMouez DallelNo ratings yet

- Wurth Wit Pe 500Document1 pageWurth Wit Pe 500Bijaya RaulaNo ratings yet

- CKD-DWG-DD-PR-B1-PL-014 - REV H - PID - Blender 300KG (As Built Drawing) - ModelDocument1 pageCKD-DWG-DD-PR-B1-PL-014 - REV H - PID - Blender 300KG (As Built Drawing) - ModelParid SuwantoNo ratings yet

- S80 - Sales Borchure EnglishDocument2 pagesS80 - Sales Borchure Englishevilnemesis133No ratings yet

- Tank Drawing MarkupDocument2 pagesTank Drawing MarkupbharanidharanNo ratings yet

- Steam & Condensate Manifold: M4/SM/CMDocument2 pagesSteam & Condensate Manifold: M4/SM/CMBillal Al-ankarNo ratings yet

- RFE For Unit 21LAF10BR010 2016-12-28: Slope: 1.3% 183Document1 pageRFE For Unit 21LAF10BR010 2016-12-28: Slope: 1.3% 183ghgh100% (1)

- rj15020 OPS Data SumeDocument1 pagerj15020 OPS Data SumeSaimar Celeste Peñaloza GuanareNo ratings yet

- Vent Valve PDFDocument1 pageVent Valve PDFIqra AngelsNo ratings yet

- LF311 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF311 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- Bolt Torque SpreadsheetDocument1 pageBolt Torque Spreadsheetboo huNo ratings yet

- Phoenix Contact: Network Interfaces Network InterfacesDocument1 pagePhoenix Contact: Network Interfaces Network InterfacesZinou ZizouNo ratings yet

- Globe Valve 600Document1 pageGlobe Valve 600Tri SatrioNo ratings yet

- Giunti Di Smontaggio Pn10-Pn16 Dismantling Joints Pn10-Pn16: PN 10 - Art. N325 TIS1 PN 16 - Art. N326 TIS1Document1 pageGiunti Di Smontaggio Pn10-Pn16 Dismantling Joints Pn10-Pn16: PN 10 - Art. N325 TIS1 PN 16 - Art. N326 TIS1engyana engyyyNo ratings yet

- Van bi inox lắp bích điều khiển khí nénDocument1 pageVan bi inox lắp bích điều khiển khí nénAutoma Viet NamNo ratings yet

- Van bi inox tay gạt lắp bichDocument1 pageVan bi inox tay gạt lắp bichAutoma Viet NamNo ratings yet

- FOLS Quotation ON-OFF Type Electric Sanitary Butterfly ValveDocument5 pagesFOLS Quotation ON-OFF Type Electric Sanitary Butterfly ValveRodrigoNo ratings yet

- Auger Exploded View PDFDocument1 pageAuger Exploded View PDFSixtysix Baltimore100% (1)

- Wege-Magnetventil-Patronen NG 5Document4 pagesWege-Magnetventil-Patronen NG 5fahd kingNo ratings yet

- Asco 3 4 WayDocument42 pagesAsco 3 4 WayServitech SellNo ratings yet

- FITOK - Subsea - Check - Valves - ENDocument3 pagesFITOK - Subsea - Check - Valves - ENt.cardoso.verionNo ratings yet

- Dinghy S300-General-ViewDocument1 pageDinghy S300-General-ViewaudiosteveNo ratings yet

- ALUMAPRO TORCH Centerfire ConsumablesDocument1 pageALUMAPRO TORCH Centerfire ConsumablesJeff1012No ratings yet

- U.fl Catalog D31697 enDocument20 pagesU.fl Catalog D31697 entedi mardetaNo ratings yet

- Spa Jets: Your Global Partner in High Quality and Strong Innovation Since 1974Document3 pagesSpa Jets: Your Global Partner in High Quality and Strong Innovation Since 1974Sherwin CruzNo ratings yet

- F646G F641G F656G F651G F676G F671G Butterfly CFS DS 1021 p43Document1 pageF646G F641G F656G F651G F676G F671G Butterfly CFS DS 1021 p43Mahmoud KhirfanNo ratings yet

- DS5404 Standard US ENDocument4 pagesDS5404 Standard US ENkicsnerNo ratings yet

- Catalogue Web 43Document1 pageCatalogue Web 43Jose MarinNo ratings yet

- Denah Gardu PDFDocument1 pageDenah Gardu PDFharryNo ratings yet

- DBB (DN50 CL600)Document1 pageDBB (DN50 CL600)hameedNo ratings yet

- Scheda Tecnica: Etpv Anchor Anchor For Hollow Base MaterialsDocument1 pageScheda Tecnica: Etpv Anchor Anchor For Hollow Base MaterialsKasia GosławskaNo ratings yet

- Technical Service Information: ISUZU MEDIUM TRUCK A465/AS68RC 07-2014Document3 pagesTechnical Service Information: ISUZU MEDIUM TRUCK A465/AS68RC 07-2014Planta Damiana2No ratings yet

- F (X) 4Document4 pagesF (X) 4Parth PatelNo ratings yet

- 301外形尺寸图Document1 page301外形尺寸图Wbeimar Alexander Vargas AriasNo ratings yet

- Design & Drawing - RKD - 20.09.22Document23 pagesDesign & Drawing - RKD - 20.09.22lenkapradipta2011100% (1)

- Ball ValveDocument12 pagesBall ValveToty DzNo ratings yet

- 01Document1 page01Reno Reza GumilangNo ratings yet

- Tracker STI H250 - NCUDocument1 pageTracker STI H250 - NCUAlberto Duarte Rezende0% (1)

- High Pressure Tube Fittings and TubingDocument10 pagesHigh Pressure Tube Fittings and TubingsunanNo ratings yet

- 1013CCJ - T3 2019 - Assessment 2 - CompleteDocument5 pages1013CCJ - T3 2019 - Assessment 2 - CompleteGeorgie FriedrichsNo ratings yet

- Geology, Logging, Drilling ReportDocument53 pagesGeology, Logging, Drilling Reportwisam alkhooryNo ratings yet

- L Rexx PDFDocument9 pagesL Rexx PDFborisg3No ratings yet

- Mass and Heat Balance of Steelmaking in Bof As Compared To Eaf ProcessesDocument15 pagesMass and Heat Balance of Steelmaking in Bof As Compared To Eaf ProcessesAgil Setyawan100% (1)

- Inqlusive Newsrooms LGBTQIA Media Reference Guide English 2023 E1Document98 pagesInqlusive Newsrooms LGBTQIA Media Reference Guide English 2023 E1Disability Rights AllianceNo ratings yet

- NST 029Document123 pagesNST 029Riaz Ahmad BhattiNo ratings yet

- IJISRT23JUL645Document11 pagesIJISRT23JUL645International Journal of Innovative Science and Research TechnologyNo ratings yet

- System of Linear Equation and ApplicationDocument32 pagesSystem of Linear Equation and Applicationihsaanbava0% (1)

- MIDTERM Exam - Programming 2 - 2SEM 2020Document3 pagesMIDTERM Exam - Programming 2 - 2SEM 2020Bab bidiNo ratings yet

- CBLM - Interpreting Technical DrawingDocument18 pagesCBLM - Interpreting Technical DrawingGlenn F. Salandanan89% (45)

- AHU CatalogueDocument16 pagesAHU CatalogueWai Ee YapNo ratings yet

- Decision Tree AlgorithmDocument22 pagesDecision Tree Algorithmvani_V_prakashNo ratings yet

- Yaskawa V7 ManualsDocument155 pagesYaskawa V7 ManualsAnonymous GbfoQcCNo ratings yet

- Bleed Valve FunctionDocument7 pagesBleed Valve FunctionUWT10No ratings yet

- RRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestDocument46 pagesRRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestBharat KumarNo ratings yet

- Car Section 2 Series (H) Part-IiDocument6 pagesCar Section 2 Series (H) Part-Iipandurang nalawadeNo ratings yet

- Résumé Emily Martin FullDocument3 pagesRésumé Emily Martin FullEmily MartinNo ratings yet

- Busbusilak - ResearchPlan 3Document4 pagesBusbusilak - ResearchPlan 3zkcsswddh6No ratings yet

- Company Profile 4Document54 pagesCompany Profile 4Khuloud JamalNo ratings yet

- 3 - Risk Opportunity RegisterDocument4 pages3 - Risk Opportunity RegisterArmando CorboNo ratings yet

- Plantas Con Madre Plants That Teach and PDFDocument15 pagesPlantas Con Madre Plants That Teach and PDFJetNo ratings yet

- Ebook Computer Forensics Principles and Practices 1St Edition Volonino Test Bank Full Chapter PDFDocument29 pagesEbook Computer Forensics Principles and Practices 1St Edition Volonino Test Bank Full Chapter PDFmundifycoucheefnhgl100% (10)

- Week 2 - Sulphur DyesDocument5 pagesWeek 2 - Sulphur DyesRR TNo ratings yet

- RTD IncotestDocument2 pagesRTD IncotestJabari KaneNo ratings yet

- (Database Management Systems) : Biag, Marvin, B. BSIT - 202 September 6 2019Document7 pages(Database Management Systems) : Biag, Marvin, B. BSIT - 202 September 6 2019Marcos JeremyNo ratings yet

- Benchmark Leadership Philosphy Ead 501Document5 pagesBenchmark Leadership Philosphy Ead 501api-494301924No ratings yet

- Portland Cement: Standard Specification ForDocument9 pagesPortland Cement: Standard Specification ForHishmat Ezz AlarabNo ratings yet

- Angelina JolieDocument14 pagesAngelina Joliemaria joannah guanteroNo ratings yet

- Contract 1 ProjectDocument21 pagesContract 1 ProjectAditi BanerjeeNo ratings yet

- Principal Examiner Feedback Summer 2016: Pearson Edexcel GCSE in Statistics (2ST01) Higher Paper 1HDocument14 pagesPrincipal Examiner Feedback Summer 2016: Pearson Edexcel GCSE in Statistics (2ST01) Higher Paper 1HHeavenly SinNo ratings yet