Professional Documents

Culture Documents

Watanabe IHIMU

Uploaded by

thlim19078656Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Watanabe IHIMU

Uploaded by

thlim19078656Copyright:

Available Formats

IHI--SPB Tank System for FLNG

IHI

Kazuo WATANABE

IHI Marine United Inc.

IHI Corp./ IHI Marine United Inc. Proprietary

Page 1 Nov.02, 2012

Contents

• Outline of FLNG CCS – IHI-SPB System

• Key Factors for Selection of FLNG CCS

• IHI-SPB System

y Application

pp

IHI Corp./ IHI Marine United Inc. Proprietary

Page 2 Nov.02, 2012

Outline of SPB Cargo Tank System

Self

elf--supporting, Prismatic

rismatic--shape IMO type B

Structural concept based on long history and

experiences

i in

i marine

i technology

h l

Hull

u

¾ Robust & Reliable

¾ Best fit to hull form

Tank

¾ Restricts

R t i t motions

ti off

cargo liquid inside Insulation

Support

IHI Corp./ IHI Marine United Inc. Proprietary

Page 3 Nov.02, 2012

Tank and Tank Regions

Insulation Internal Bulkheads

Swash Bulkhead

H ll

Hull Centerline Bulkhead

Around Tank Tank

Walkwayy Tank Support

IHI Corp./ IHI Marine United Inc. Proprietary

Page 4 Nov.02, 2012

Hull and Tank Section

Chock

Hull Tank General View of Tank

Centerline BHD Swash BHD

Insulation

Support

IHI Corp./ IHI Marine United Inc. Proprietary

Page 5 Nov.02, 2012

Tank Support

Longitudinal Chock Vertical Support • Cargo tank is supported on the

bottom by specially reinforced

plywood

Tank Dome

• Chock constructions are

provided on top and bottom of

the tank

Transverse Chock

Tank top plan Tank bottom plan

Tank

Hull Inner Bottom stopper

Support Chock

IHI Corp./ IHI Marine United Inc. Proprietary

Page 6 Nov.02, 2012

T k IInsulation

Tank l ti

Insulation System:

• Pre-fabricated rigid PUF panels

• Cushion joints

No Thermal Stress Cushion Joint

Very Low Boil-Off Rate Best Insulation material

Special insulating support

Rod/Washer/Nut

Outer Cushion Joint

Joint Tape

Panel

Inner Cushion Joint Stud

Tank Skin

IHI Corp./ IHI Marine United Inc. Proprietary

Page 7 Nov.02, 2012

Key Factor for FLNG CCS

A) Wide and Flat Upper Deck

B) Any Level Loading without Sloshing

C) Hi

High

hRReliability

li bilit & Robustness

R b t

D) Easy operation, inspection & less maintenance on-site

IHI Corp./ IHI Marine United Inc. Proprietary

Page 8 Nov.02, 2012

A) Wide and Flat Upper

Upper--deck

- To install topside plant on upper deck

Wide and Flat Upper

Upper--deck is essential for

FLNG to mount Topside process plant

LPG FPSO with SPB tanks LNG Carrier with SPB tanks

IHI Corp./ IHI Marine United Inc. Proprietary

Page 9 Nov.02, 2012

B) Any Level Loading without Sloshing

- To produce LNG continuously by planned production rate

Sloshing is : Resonance of liquid in tank with the vessel motions

z Eliminate sloshing

g phenomenon

p itself by

y

providing internal bulkheads in both

transverse and longitudinal directions.

z Natural way in marine technology not to

generate sloshing by dividing liquid into

portions, exactly

y same approach to :

9 Crude oil tankers

9 LPG tankers

9 Chemical tankers, etc.

IHI Corp./ IHI Marine United Inc. Proprietary

Page 10 Nov.02, 2012

C) High Reliability and Robustness

• To operate continuously without dry dock during long life time

• To

T minimize

i i i risks

i k to stop FLNG operation

i

SPB designed

g based on No Leak Concept p

incorporating as-built conditions of tank

Complete fatigue analysis with conservatism

Probability of Fatigue Failure Maximum

a u

construction tolerance

P << 10-6 taken into design

Quality verification by 100% X-ray

IHI Corp./ IHI Marine United Inc. Proprietary

Page 11 Nov.02, 2012

Operation Records

• No trouble on the SPB tank

• No shutdown of floating terminals since start of

their operation

• No delay of LNG transportation even in very

harsh route, Alaska – Japan

LNG Carriers Floating LPG Terminals

(from 1993) (from 2005) (from 1997)

By courtesy of Single Buoy Moorings

IHI Corp./ IHI Marine United Inc. Proprietary

Page 12 Nov.02, 2012

D) Easy Operation & Less Maintenance

-Simple Pressure Control, Independence from Hull

Hull--

• To operate continuously without dry dock during long life time

• To minimize risks to stop FLNG operation

• No special pressure controls

Strong against OUTER and inner

pressure

• Free from inner hull damage

g

Seawater leakage from ballast tank, if

it should occur, can be treated safely

andd repaired.

i d

IHI Corp./ IHI Marine United Inc. Proprietary

Page 13 Nov.02, 2012

A

Access and

d Inspection

I ti

• Fault, if any, can be found before growing into trouble

Tanktop SPB Tank

Uniform space between hull

and tank system

Walkway Horizontal girders

provide permanent stages for

Tank access and/or work scaffolding

g

IHI Corp./ IHI Marine United Inc. Proprietary

Page 14 Nov.02, 2012

SPB Tank Application

Floating Terminal (FPSO) Floating Terminal (FSRU)

Onshore Power Plant

LNGC SPB Technology

LNGC

LNG Carrier (1993 -)

FPSO

FSRU

Land Storage Offshore GBS

LPG FPSO (2005 -)

IHI Corp./ IHI Marine United Inc. Proprietary

Page 15 February 29, 2012

LNG Fuel Gas Tank for various kinds of vessels

Reduction of;

CO2 emission

NOx, SOx emission

Effective use of ship’s space with any

Source: Wartsila shape of tank by SPB system

IHI Corp./ IHI Marine United Inc. Proprietary

Page 16 February 29, 2012

Thank y

you for y

your Attention!

IHI Corp./ IHI Marine United Inc. Proprietary

Page 17 Nov.02, 2012

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 11-8840 BLOWDOWN White Paper - FINAL PDFDocument13 pages11-8840 BLOWDOWN White Paper - FINAL PDFphantanthanhNo ratings yet

- MSDocument13 pagesMSthlim19078656No ratings yet

- En Innovative Precooling Strategies PDFDocument8 pagesEn Innovative Precooling Strategies PDFthlim19078656No ratings yet

- Deo 2014 Whole PDFDocument255 pagesDeo 2014 Whole PDFthlim19078656No ratings yet

- Gas Lift With Nitrogen Injection Generated in SituDocument10 pagesGas Lift With Nitrogen Injection Generated in SitutherockstarsunNo ratings yet

- 1 4041168Document37 pages1 4041168thlim19078656No ratings yet

- Thomas 2015Document20 pagesThomas 2015thlim19078656No ratings yet

- MsDocument10 pagesMsthlim19078656No ratings yet

- Kim 2016Document11 pagesKim 2016thlim19078656No ratings yet

- OMC2003 ABOFlowAssuranceDocument15 pagesOMC2003 ABOFlowAssurancethlim19078656No ratings yet

- Shane 2015Document15 pagesShane 2015thlim19078656No ratings yet

- dp393 PDFDocument29 pagesdp393 PDFthlim19078656No ratings yet

- 9 OverrideControlDocument10 pages9 OverrideControlsamiran21No ratings yet

- 133 1 132 1 10 20110530 PDFDocument11 pages133 1 132 1 10 20110530 PDFMurali DarenNo ratings yet

- 1 4003453Document5 pages1 4003453thlim19078656No ratings yet

- 1 4007730Document6 pages1 4007730thlim19078656No ratings yet

- 1 3445988Document2 pages1 3445988thlim19078656No ratings yet

- 1 4027187Document9 pages1 4027187thlim19078656No ratings yet

- 1 2132383Document12 pages1 2132383thlim19078656No ratings yet

- Water 10 01592Document16 pagesWater 10 01592thlim19078656No ratings yet

- Form Lopa Summary SheetDocument1 pageForm Lopa Summary Sheetthlim19078656No ratings yet

- Spe 155124 MS PDocument13 pagesSpe 155124 MS Pthlim19078656No ratings yet

- ECOS2015 Carranzaand Oliveira JRDocument14 pagesECOS2015 Carranzaand Oliveira JRthlim19078656No ratings yet

- PSAM13 Kim - 20160916Document35 pagesPSAM13 Kim - 20160916thlim19078656No ratings yet

- ECOS2015 Carranzaand Oliveira JRDocument14 pagesECOS2015 Carranzaand Oliveira JRthlim19078656No ratings yet

- Piping and Instrument Diagram (P&id) Standard Symbols Detailed DocumentationDocument15 pagesPiping and Instrument Diagram (P&id) Standard Symbols Detailed Documentationautomationforum92% (103)

- Otc 27288 MSDocument13 pagesOtc 27288 MSthlim19078656No ratings yet

- Esda2012 82986 PDFDocument11 pagesEsda2012 82986 PDFthlim19078656No ratings yet

- Esda2012 82986 PDFDocument11 pagesEsda2012 82986 PDFthlim19078656No ratings yet

- Form Lopa Summary SheetDocument1 pageForm Lopa Summary SheetguhadebasisNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Shop Manual 12V140E-3Document468 pagesShop Manual 12V140E-3josecall91% (11)

- 01 D155 IntroductionDocument22 pages01 D155 IntroductionMichael DavenportNo ratings yet

- 41.valve TypeDocument313 pages41.valve TypeSteve Wan100% (1)

- FOGO Mitshubishi SpecsDocument3 pagesFOGO Mitshubishi SpecsAli HussainNo ratings yet

- H2S Dispersion ModelDocument52 pagesH2S Dispersion Modelrsb_4192No ratings yet

- 2005 Air Emission Inventory for Puget Sound CountiesDocument223 pages2005 Air Emission Inventory for Puget Sound Countieswicca9brNo ratings yet

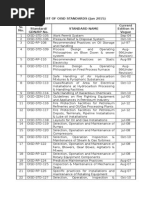

- OISD StandardsDocument6 pagesOISD Standardskakababa117No ratings yet

- TCS-PTG Savings With Extra PowerDocument9 pagesTCS-PTG Savings With Extra PowerfatboykrNo ratings yet

- ISKRA Starter MotorsDocument20 pagesISKRA Starter MotorsJuan Carlos BajoNo ratings yet

- Std-119 Selection, Operation & Maintance of PumpsDocument23 pagesStd-119 Selection, Operation & Maintance of PumpsRohit YadavNo ratings yet

- TCEQ Guidance on Emission Calculations for Rock Crushing PlantsDocument29 pagesTCEQ Guidance on Emission Calculations for Rock Crushing PlantsChristian MavarezNo ratings yet

- Model Nc-1 Neutrapal' Condensate Neutralization Kit: 1.6 Gal/hr (6.05l/hr)Document2 pagesModel Nc-1 Neutrapal' Condensate Neutralization Kit: 1.6 Gal/hr (6.05l/hr)Hot Water NowNo ratings yet

- Subiect 1Document2 pagesSubiect 1Cristina VargaNo ratings yet

- Ethylene Plus Benzene Design Project Reference (Partial Only)Document11 pagesEthylene Plus Benzene Design Project Reference (Partial Only)YueZhen ChuaNo ratings yet

- Api 619 SiDocument9 pagesApi 619 SitutuionutNo ratings yet

- COALIFICATION, RANK and TYPEDocument6 pagesCOALIFICATION, RANK and TYPEgujrati guyNo ratings yet

- ORAP Data Entry PresentationDocument18 pagesORAP Data Entry PresentationcastilvNo ratings yet

- Informacion Tecnica 3RZDocument8 pagesInformacion Tecnica 3RZjuan riveraNo ratings yet

- LPG Co-MinglingDocument17 pagesLPG Co-MinglingderhgawenrahulNo ratings yet

- Getting Strated With Aspen PIMS (1st Ed)Document180 pagesGetting Strated With Aspen PIMS (1st Ed)Ahsan Jalal89% (36)

- Installation and Operating Manual: T Turbo Coupling With Constant FillDocument134 pagesInstallation and Operating Manual: T Turbo Coupling With Constant FilludungeNo ratings yet

- 01 Dedusting EquipmentDocument40 pages01 Dedusting Equipmentrudye kardunNo ratings yet

- An Analysis of The Relationship Between Petroleum Prices and Inflation in NigeriaDocument7 pagesAn Analysis of The Relationship Between Petroleum Prices and Inflation in NigeriaChidinma Glory EjikeNo ratings yet

- M12 PDFDocument22 pagesM12 PDFAdrian GuzmanNo ratings yet

- Boiler and Steam SystemDocument33 pagesBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Off The Grid Independent Energy ProductionDocument31 pagesOff The Grid Independent Energy ProductionMoreMoseySpeedNo ratings yet

- M1 - Djonrae N. GalvezDocument5 pagesM1 - Djonrae N. GalvezDjonraeNarioGalvezNo ratings yet

- Pompa Namol Secundar - RefDocument3 pagesPompa Namol Secundar - RefCretu DanNo ratings yet

- Ignition LagDocument2 pagesIgnition Lageafz111No ratings yet

- EOR Methods GuideDocument109 pagesEOR Methods GuideKarwan DilmanyNo ratings yet