Professional Documents

Culture Documents

Apds-Ra-011 Filtration Operation of Apds Filtration System Rev B

Uploaded by

Hua Tien DungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apds-Ra-011 Filtration Operation of Apds Filtration System Rev B

Uploaded by

Hua Tien DungCopyright:

Available Formats

Ref.

number APDS-RA-011 Rev B

Assessment of Risk in Relation to Filtration

Issue no: 00 APDS-VIETNAM LIMITED

Operation

Date : Jan- 2013

Description: Method Statement/ Installation Procedure No: Location of working Area

Assessment of Risk in relation to Filtration Operation Filtration Operation Procedure Offshore Rig – Main deck and Onshore Filtration

Special Equipment Required Personnel Protective Equipment Required

Filtration Unit Safety Hard Hats, Glasses, Boots, Gloves, Coveralls as identified by specific Risk Assessment

Persons Affected:

Filtration Crew

P = Probability S = Severity IR = Risk RP = Residual Probability RS = Residual Severity RR = Residual Risk (Add rows as required on next sheet, or expand row as required)

Task/step being

Ref Hazard Description Hazard Effect P S IR Control Measure RP RS RR

taken

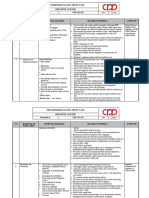

Pre- Operation/ Manual Handling-Lifting/ Failure of Lifting Slings Familiarization on site (working area) signs and barriers of the area

Prior running the transferring, Setting and & Accessories has the prior to operations commencement.

Filtration system replacing of consumables. potential to cause a Ensure usage of correct PPE used especially gloves and safety glasses

Slipping and tripping on range of personal Proper handling and stepping techniques.

restricted access/work injuries. Good communication between personnel involved.

area. Sprains, strains, Pay attention during the activity if accompanied with other

Pinch Points. Trapped dislocated limbs, cuts, personnel.

hands and fingers. bruises, broken bones, Ensure usage of proper tool for the specific job. Do not improvise.

Chemicals ( DE Powder) fatalities Be aware of potential pinch points and impact points whilst using

Asthma, skin irritation, hand tools

Issue 4: 23/04/09 Uncontrolled when printed

1 Etc. 2 2 4 Ensure good posture/position when performing an activity on 1 3 3

confined space to eliminate dislocated bones

All chemicals marked and clearly identified.

Material Safety Data Sheets available.

Use appropriate PPE in handling & mixing the DE powder such as

Basic PPE requirement, Mask, Scrub suite coverall & rubber gloves.

Proper waste disposal of consumables.

Appropriate Training, Supervision and Signage will be applied

to ensure that all implemented control measures are known

to all concerned parties and adhered to.

APDS-RA-Form: Risk Assessment Filtration Operation APDS-RA-010 Rev. B Page 1 of 4

Ref. number APDS-RA-011 Rev B

Assessment of Risk in Relation to Filtration

Issue no: 00 APDS-VIETNAM LIMITED

Operation

Date : Jan- 2013

Task/step being

Ref Hazard Description Hazard Effect P S IR Control Measure RP RS RR

taken

Ensure pre use inspection of Hoses prior usage.

During Filtration Hose bursting Unawareness to the

potential hazard may Use whip checks and Cotter pins.

Operation Malfunction of

cause a range of Remove potential element that will hit the hose.

Filtration unit due to

personal injuries Ensure proper connection of the hoses to filtration unit prior

exceeding work rating

Sprains, strains, operation.

Leaking pipes / dislocated limbs, cuts, Slow down operation capacity. Check equipment condition. Stop

connections. bruises and broken

2 operation if needed.

Crane Lifting operation bones.

Ensure repetitive checking on working pressure of the system.

Slip , Trip and Fall Clean the area.

Potential drop objects Awareness on the working area.

from ongoing lifting Do not leave the equipment unattended during operation.

operations on the

Main Deck.

Familiarization on site (working area) signs and barriers of the area

Post operation & Manual Handling-Lifting/ Unawareness may

transferring, Setting and cause a range of prior to operations commencement.

Maintenance of

replacing of consumables. personal injuries - Ensure usage of correct PPE used especially gloves and safety glasses

Filtration unit

Slipping and tripping on Sprains, strains, Proper handling and stepping techniques.

restricted access/work dislocated limbs, cuts, Good communication between personnel involved.

area. bruises and broken Pay attention during the activity if accompanied with other

Pinch Points. Trapped bones personnel.

hands and fingers. Ensure usage of proper tool for the specific job. Do not improvise.

Issue 4: 23/04/09 Uncontrolled when printed

Use of Hand Tools. Be aware of potential pinch points and impact points whilst using

3 hand tools

Ensure good posture/position when performing an activity on

confined space to eliminate dislocated bones.

Appropriate Training, Supervision and Signage will be

applied to ensure that all implemented control measures are

known to all concerned parties and adhered to.

APDS-RA-Form: Risk Assessment Filtration Operation APDS-RA-010 Rev. B Page 2 of 4

Ref. number APDS-RA-011 Rev B

Assessment of Risk in Relation to Filtration

Issue no: 00 APDS-VIETNAM LIMITED

Operation

Date : Jan- 2013

Task/step being

Ref Hazard Description Hazard Effect P S IR Control Measure RP RS RR

taken

Wet & Slippery Surface Slip , Trip and fall Always secure air hoses and water hoses with Whip checks and cotter

Housekeeping of

Area and Awareness of Crane Injury / fatality to a pins.

Equipment Lifting operation potential falling

Awareness in the working area for potential falling objects.

Air and water Pressure objects.

Injury Always clear the work area when there is a lifting operation.

4 Manual Lifting

Secure proper positioning and handling techniques.

“ALWAYS KEEP THE WORK AREA CLEAN”

Assessment Team: Approved by

Larry Adlawan / Paul Anthony Ganzon Colin Peart

Engineering APDS- Managing Director

Issue 4: 23/04/09 Uncontrolled when printed

APDS-RA-Form: Risk Assessment Filtration Operation APDS-RA-010 Rev. B Page 3 of 4

Ref. number APDS-RA-011 Rev B

Assessment of Risk in Relation to Filtration

Issue no: 00 APDS-VIETNAM LIMITED

Operation

Date : Jan- 2013

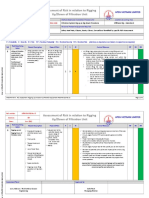

ASSESSMENT OF RISK MATRIX

Very unlikely Unlikely Possible Likely Very likely Certain

A freak, A rare combination Could happen when Not certain to happen Almost inevitable that Incident would

unforeseeable of factors would be additional factors are but an additional factor an incident would result definitely occur

combination of required for an present but otherwise may result in an incident or has happened more

factors would be incident to result unlikely to occur or has or has happened at the than once per year at

Safety Health Environment required for an or has been heard happened in our location or more than the location

incident to result and of in industry organization or more once per year in our

has never been heard than once per year in organization

of in industry the industry

0 1 2 3 4 5

Lung disease, Moderate or severe pollution

cancer, with long-term impact.

Multiple fatalities 5 0 5 10 15 20 25

permanent Breach of legal or contractual

disability, etc. requirements.

Poisoning, Severe pollution with short-

Permanent Total

sensitization, term localized impact.

Disablement or single 4 0 4 8 12 16 20

infectious Potential breach of legal

fatality

disease, etc. contractual requirements.

Major injury leading to

a lost time incident Dermatitis, acne, Moderate pollution with

3 0 3 6 9 12 15

(includes all RIDDOR asthma, etc. short-term localized impact.

reportable injuries).

Minor injury requiring

Issue 4: 23/04/09 Uncontrolled when printed

first aid or medical Minor illness,

Minor Short-term

treatment away from Longer-term

environmental damage with 2 0 2 4 6 8 10

worksite (i.e. hospital) headache,

reversible impact.

return to work on same Nausea, etc.

shift.

Slight Injury may involve

Slight illness, No

minor first aid Slight local, Short-term

absence from 1 0 1 2 3 4 5

treatment, No absence environmental damage.

work.

from work.

No injury or health

No health effect No effect 0 0 0 0 0 0 0

effect

APDS-RA-Form: Risk Assessment Filtration Operation APDS-RA-010 Rev. B Page 4 of 4

You might also like

- HIRA WaterproofingDocument16 pagesHIRA WaterproofingPRIYESH . K. PRIYANNo ratings yet

- Rebar InstallationDocument4 pagesRebar Installationmark jayson yabesNo ratings yet

- TA-Replacing Floor TilesDocument8 pagesTA-Replacing Floor TilesShannon MooreNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Risk Assessment For Fabrication & Installation of Tensile Fabric ShadesDocument4 pagesRisk Assessment For Fabrication & Installation of Tensile Fabric ShadesSun Shade67% (3)

- Backfilling Compaction JSADocument2 pagesBackfilling Compaction JSArashid zaman84% (25)

- TA-Replacing Floor TilesDocument8 pagesTA-Replacing Floor TilesShannon MooreNo ratings yet

- JHA Welding Pipe BenderDocument2 pagesJHA Welding Pipe Bendermohammad arshadNo ratings yet

- Fabrication WorksDocument4 pagesFabrication Worksmark jayson yabesNo ratings yet

- Joinery Carpentry Risk AssessmenmtDocument4 pagesJoinery Carpentry Risk Assessmenmtadeniyi abiolaNo ratings yet

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- Safety Officer Project SODocument2 pagesSafety Officer Project SODarwin De ChavezNo ratings yet

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- Hse Risk Assessment For Civil Works, Isolators and Duct InstallationDocument6 pagesHse Risk Assessment For Civil Works, Isolators and Duct Installationvenkatesh snkNo ratings yet

- Positif Jsa HMCFDDocument4 pagesPositif Jsa HMCFDBryant TorresNo ratings yet

- Workplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentDocument2 pagesWorkplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentMashur Al JunaibiNo ratings yet

- Safety Engineering and JhaDocument29 pagesSafety Engineering and JhaDarren Dela CruzNo ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- JHA Power Hand Tool Use - ROMODocument3 pagesJHA Power Hand Tool Use - ROMOMohd AleemNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- RA of Chlorination & Disinfection of Domestic Water Supply SystemDocument12 pagesRA of Chlorination & Disinfection of Domestic Water Supply SystemAhmad Omar50% (2)

- JSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestDocument5 pagesJSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestRajuNo ratings yet

- TTEC Fencing RADocument7 pagesTTEC Fencing RAGeml TrinidadNo ratings yet

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Rme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20Document1 pageRme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20nanthan06No ratings yet

- Coating and Painting Work.Document9 pagesCoating and Painting Work.MOHNISHKUMARJHANo ratings yet

- Jsa For Scaffolding ErectionDocument7 pagesJsa For Scaffolding Erectionnoorul IslamNo ratings yet

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- JSA of 33KV Bay - Rev001 - 15072020Document3 pagesJSA of 33KV Bay - Rev001 - 15072020Aradhya SinghNo ratings yet

- FRP Bonding CHESS - JSADocument6 pagesFRP Bonding CHESS - JSADanial AfandiNo ratings yet

- Duct InstallationDocument2 pagesDuct InstallationKrishna PatilNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument7 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNo ratings yet

- Risk Assessment For .Testing and Commissioning of Fire Rated Bus DuctDocument13 pagesRisk Assessment For .Testing and Commissioning of Fire Rated Bus Ductarun kurlanNo ratings yet

- SOP 15 - Hopper Cleaning ActivityDocument6 pagesSOP 15 - Hopper Cleaning Activityfaraz ahmed100% (2)

- Jsa RTDocument1 pageJsa RTGamma CompanyNo ratings yet

- Risk Assessment For .Testing and Commissioning of Fire DamperDocument9 pagesRisk Assessment For .Testing and Commissioning of Fire Damperarun kurlanNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Risk Assessment For BricklayingDocument7 pagesRisk Assessment For BricklayingSathishKumar SkNo ratings yet

- Job Safety Analysis: 10.06.2017 Page 1 of 7Document7 pagesJob Safety Analysis: 10.06.2017 Page 1 of 7Raghava RichhuNo ratings yet

- SOP 11 - Lime Stone Circuit OprationDocument9 pagesSOP 11 - Lime Stone Circuit Oprationfaraz ahmedNo ratings yet

- JHA Manual HandlingDocument5 pagesJHA Manual HandlingFatin Zulkifli100% (1)

- Risk AssessmentDocument7 pagesRisk AssessmentRenjith RaviNo ratings yet

- SOP 10 - Limestone Shifting Form YardDocument9 pagesSOP 10 - Limestone Shifting Form Yardfaraz ahmedNo ratings yet

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- Risk Assessment NO. 37 WASH PAINTING Rev 0Document2 pagesRisk Assessment NO. 37 WASH PAINTING Rev 0Lalit Choudhary0% (1)

- Hirac - Repair Damaged Asphalt Road - Blok 1Document14 pagesHirac - Repair Damaged Asphalt Road - Blok 1Widyardi SaputraNo ratings yet

- Jsa For Admin BuildingDocument5 pagesJsa For Admin Buildingmohamed yasinNo ratings yet

- Lecture 6 Job Hazard AnalysisDocument28 pagesLecture 6 Job Hazard AnalysisgatdulalanzNo ratings yet

- 1 SurveyDocument5 pages1 Survey王志伟0% (1)

- RA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualyDocument1 pageRA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualySaifulNo ratings yet

- JSEA042022001 - Aluminium WorksDocument6 pagesJSEA042022001 - Aluminium WorksWeru MorrisNo ratings yet

- Jsa PaintingDocument1 pageJsa Paintingclynne despiNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Physical Hazard Control: Preventing Injuries in the WorkplaceFrom EverandPhysical Hazard Control: Preventing Injuries in the WorkplaceNo ratings yet

- 0stprocess Flash CalculationDocument15 pages0stprocess Flash CalculationHua Tien DungNo ratings yet

- How To Write A ProofDocument16 pagesHow To Write A ProofJeff PrattNo ratings yet

- 0 HTD HEAT 23 November 2022Document2 pages0 HTD HEAT 23 November 2022Hua Tien DungNo ratings yet

- 0hp HTD BuddhismDocument4 pages0hp HTD BuddhismHua Tien DungNo ratings yet

- 0stprocess FugacityDocument36 pages0stprocess FugacityHua Tien DungNo ratings yet

- 0 SvbaDocument9 pages0 SvbaHua Tien DungNo ratings yet

- 0 Chinese Luyen Cau Dont DeleteDocument2 pages0 Chinese Luyen Cau Dont DeleteHua Tien DungNo ratings yet

- Math SGK Toan 6Document1 pageMath SGK Toan 6Hua Tien DungNo ratings yet

- Mas M Prog GuideDocument504 pagesMas M Prog GuideJulieta RoldánNo ratings yet

- zToC MATH AMA105Document3 pageszToC MATH AMA105Hua Tien DungNo ratings yet

- Godhavn - New Slug Control Strategies - Tuning RulesDocument11 pagesGodhavn - New Slug Control Strategies - Tuning RulesHua Tien DungNo ratings yet

- Cable Track RecordDocument3 pagesCable Track RecordHua Tien DungNo ratings yet

- Fundamentals of Orifice Measurement Techwpaper PDFDocument9 pagesFundamentals of Orifice Measurement Techwpaper PDFartletNo ratings yet

- Instrukciya 2019 EngDocument7 pagesInstrukciya 2019 EngHua Tien DungNo ratings yet

- Field Test Procedures Chemical Injection ValveDocument2 pagesField Test Procedures Chemical Injection ValveHua Tien Dung100% (1)

- Toan 9 PT Bac 2Document2 pagesToan 9 PT Bac 2Hua Tien DungNo ratings yet

- VBA WordDocument8 pagesVBA WordHua Tien DungNo ratings yet

- 0909-GS-P-CA-10057 - B1 - 3rd Stage Gas Export Comp. PSV 384,524 Sizing CalDocument14 pages0909-GS-P-CA-10057 - B1 - 3rd Stage Gas Export Comp. PSV 384,524 Sizing CalHua Tien DungNo ratings yet

- Schlumberger Brunei: 2-3/8" EUE Tubing ThreadDocument1 pageSchlumberger Brunei: 2-3/8" EUE Tubing ThreadHua Tien DungNo ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- Trang, Nguyen Nam (SR - Petroleum Engineer) : From: Sent: To: CC: Subject: AttachmentsDocument2 pagesTrang, Nguyen Nam (SR - Petroleum Engineer) : From: Sent: To: CC: Subject: AttachmentsHua Tien DungNo ratings yet

- 0909-GS-P-CA-10057 - B1 - 3rd Stage Gas Export Comp. PSV 384,524 Sizing CalDocument14 pages0909-GS-P-CA-10057 - B1 - 3rd Stage Gas Export Comp. PSV 384,524 Sizing CalHua Tien DungNo ratings yet

- Apds Filtration System Procedures Risk Assessments (For Lamson Joc)Document9 pagesApds Filtration System Procedures Risk Assessments (For Lamson Joc)Hua Tien DungNo ratings yet

- APDS-RA-010 Rig Up - Down of APDS Filtration System Rev BDocument3 pagesAPDS-RA-010 Rig Up - Down of APDS Filtration System Rev BHua Tien DungNo ratings yet

- Lam Son JOC: Completion Fluid For BasementDocument2 pagesLam Son JOC: Completion Fluid For BasementHua Tien DungNo ratings yet

- Lam Son JOC: Completion Fluid For BasementDocument2 pagesLam Son JOC: Completion Fluid For BasementHua Tien DungNo ratings yet

- Archer Point Casestudy Uknorthsea2 ScreenDocument2 pagesArcher Point Casestudy Uknorthsea2 ScreenHua Tien DungNo ratings yet

- Archer Point Casestudy Uae Fateh ScreenDocument2 pagesArcher Point Casestudy Uae Fateh ScreenHua Tien DungNo ratings yet

- Archer Point Casestudy Uknorthsea ScreenDocument2 pagesArcher Point Casestudy Uknorthsea ScreenHua Tien DungNo ratings yet

- Iron PillsDocument4 pagesIron PillsKundan KumawatNo ratings yet

- Access To Mammography in New York City'Document43 pagesAccess To Mammography in New York City'NYCCouncilNo ratings yet

- 10/03/2020 Asbestosis: Dr. A. Sau MBBS, MD (Gold Medalist) DD (Medical) 1Document20 pages10/03/2020 Asbestosis: Dr. A. Sau MBBS, MD (Gold Medalist) DD (Medical) 1puneet100% (1)

- Different Kinds of PhobiasDocument3 pagesDifferent Kinds of PhobiasLajila100% (1)

- Ii 2015 1Document266 pagesIi 2015 1tuni santeNo ratings yet

- Malaika Nakupenda MalaikaDocument11 pagesMalaika Nakupenda MalaikaMuhidin Issa MichuziNo ratings yet

- Сhronic pancreatitis: Lykhatska G.VDocument42 pagesСhronic pancreatitis: Lykhatska G.VOlga CîrsteaNo ratings yet

- Neurosurgery SOKDocument2 pagesNeurosurgery SOKMrS DNo ratings yet

- Case Report: Primary AnetodermaDocument3 pagesCase Report: Primary AnetodermaAizat KamalNo ratings yet

- Passive Voice-To Have Something Done PDFDocument2 pagesPassive Voice-To Have Something Done PDFAlberto Martínez CastañoNo ratings yet

- 5th MOSCON Agenda 1012Document4 pages5th MOSCON Agenda 1012drgarimaguptaNo ratings yet

- IT 16 - Neurogenic Bladder - SMDocument31 pagesIT 16 - Neurogenic Bladder - SMRurie Awalia SuhardiNo ratings yet

- Acute Leukemia: Basic PrinciplesDocument3 pagesAcute Leukemia: Basic PrinciplesPrabhat GuptaNo ratings yet

- JC Oncology55211005Document32 pagesJC Oncology55211005Neenuch ManeenuchNo ratings yet

- 1400 IMRT Impact of ICRU-83Document11 pages1400 IMRT Impact of ICRU-83cham_potterNo ratings yet

- Nutritional Management of Chyle Leaks: An Update: Nutrition Issues in Gastroenterology, Series #94Document13 pagesNutritional Management of Chyle Leaks: An Update: Nutrition Issues in Gastroenterology, Series #94mmmdeandradeNo ratings yet

- Jeopardy Questions OBGYNDocument4 pagesJeopardy Questions OBGYNjkj;jjNo ratings yet

- Skin Nail HairDocument48 pagesSkin Nail HairkitsilcNo ratings yet

- How To ZapDocument11 pagesHow To ZapMarkWoodxxxNo ratings yet

- Association Between Weight Gain and PCOSDocument3 pagesAssociation Between Weight Gain and PCOSAstrid SitohangNo ratings yet

- Course Syllabus-Maternity TheoryDocument6 pagesCourse Syllabus-Maternity TheoryannairishybNo ratings yet

- NCP Karl Jacon M. FerolinoDocument4 pagesNCP Karl Jacon M. FerolinoWhyng CabugayanNo ratings yet

- Abstrak Medika Mentosa PDFDocument3 pagesAbstrak Medika Mentosa PDFpawiroNo ratings yet

- ICD 9-10 - Common Codes For OBGYN-MI3859-042715Document4 pagesICD 9-10 - Common Codes For OBGYN-MI3859-042715Avicena M IqbalNo ratings yet

- Dosimetric Evaluation of PlansDocument8 pagesDosimetric Evaluation of PlansQuang-Vu TranNo ratings yet

- Percentages For MRCOG1Document3 pagesPercentages For MRCOG1jmoNo ratings yet

- Bone Mineral DensityDocument5 pagesBone Mineral DensityMd Ahsanuzzaman PinkuNo ratings yet

- Arab Board Final 2018 - 2Document12 pagesArab Board Final 2018 - 2lonsilord17No ratings yet

- Edema de ReinkeDocument9 pagesEdema de ReinkeDaniel SuárezNo ratings yet

- Parotid LabDocument11 pagesParotid Labapi-268707929No ratings yet