Professional Documents

Culture Documents

PJN3-1000 Assy8

Uploaded by

Charlie CB PortnerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PJN3-1000 Assy8

Uploaded by

Charlie CB PortnerCopyright:

Available Formats

PJN3 Series

Assembly Instructions

US PATENTS: 4,577,351 4,637299 4,793,100 4,895,400

SPECIFICATIONS

DIMENSION IMPERIAL METRIC

Exterior Height 91.0 in 231 cm

Interior Height 82.0 in 208 cm

Exterior Width 43.5 in 110 cm

Interior Width 41.0 in 104 cm

Exterior Length 47.0 in 119 cm

Interior Length 41.0 in 104 cm

Holding Tank 60.0 gal 227 ltr

Seat Height 19.0 in 48 cm

Weight (plastic base skid) 165.0 lb 74.25 kg

Side Panel Decal Area 12 in x 22.75 in 30 cm x 58 cm

Door Panel Decal Area 16 in x 21 in 40 cm x 53 cm

Optional Sink Tank Capacity 15 gal 56.8 ltr

Optional Recirculating Flush

Tank Capacity 35 gal 132 ltr

For product identification, the serial number is located on the left inside surface

(as viewed from the front) of the door jamb, near the door closure clip.

We recommend reading through the entire Assembly Instructions prior to proceeding with installation, service or maintenance.

All references to left and right throughout this guide are as viewed from the front.

POLYJOHN POLYJOHN POLYJOHN

USA WORLDWIDE CANADA

PolyJohn Enterprises Corp PolyJohn (UK) Ltd. PolyJohn Canada

2500 Gaspar Ave. Equinox 1 Audby Lane P.O. Box 2300

Whiting, IN 46394 Wetherby, England LS22 7RD 199 Forest Plain Rd.

Phone: 800-292-1305 Phone: 44 (0) 1937-583333 Orillia, Ontario LV3 6S2

Fax: 219-659-0625 Fax: 44 (0) 1937-583322 Phone: 800-465-9590

www.polyjohn.com www.polyjohn.co.uk Fax: 705-325-8250

info@polyjohn.com sales@polyjohn.co.uk www.polyjohncanada.ca

info@polyjohncanada.ca

PJN3 Assembly - April 2017

Page 1 of 12

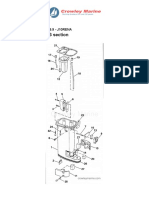

PJN3-1000 PARTS DIAGRAM

PJ03-0007

http: - Roof

//www.polyjohn.com/pj03-0007/

(20) PC-000100 - Rivet

http://www.polyjohn.com/pc-000531/ (20) PC-000106 - Washer

PC-000531 - Vent Stack

PC-000117 - Rivet

(6)http://www.polyjohn.com/pc-000570/

PC-000570 - Screen

(9) PC-000100 - Rivet

(9) PC-000106 - Washer

PC-000495

http: - Urinal

//www.polyjohn.com/pc-000495

(2) PC-000102 - Rivet PC-000204 - Toilet Seat

http://www.polyjohn.com/pc-000204/

(2) PC-000106 - Washer

PC-000490 - T.P. Dispenser

http://www.polyjohn.com/pc-000490/

(4) PC-000100 - Rivet

(4) PC-000106 - Washer

PC-000760 - Rod

PC-000205M - Lock

Page 2 of 12

PJN3 Assembly - April 2017

PJN3-0008 - Waste Tank

http://www.polyjohn.com/pjn3-0008/

(8) PC-000103 - Rivet

(8) PC-000106 - Washer

PJN3-0003 - Front Assembly

http://www.polyjohn.com/pjn3-0003/ PJN3-0001 - Complete Base

http://www.polyjohn.com/pjn3-0001/

(4) PC-000174 - 1/4-20 x 1-1/4” Screw (5) PC-000117 - Rivet

(4) PC-000123 - Washer PJN3-0001T - Floor

(4) PC-000140 - 1/4-20 Nylon Lock Nut

(4) PC-000192 - Lag Screw (3)

http://www.polyjohn.com/pj03-0002/

PJ03-0002 - Side Panel

(4) PJ03-0011 - Corner Molding

http://www.polyjohn.com/pj03-0011/ (15) PC-000192 - Lag Screw

(36) PC-000100 - Rivet

(36) PC-000106 - Washer

PJN3-0003 FRONT ASSEMBLY

http://www.polyjohn.com/pc-- Door

**PC-000200 000200/ Check Cable

(2) PC-000102 - Rivet (Clip to Door)

(1) PC-000104 - Rivet (Cable to Door Jamb)

http://www.polyjohn.com/pjn3-0006/

PJN3-0006 - Door Jamb (1) PC-000168 - 5/16” x 7/8” Washer (Cable to Door Jamb)

(8) PC-000104 - Rivet (1) PC-000106 - Washer (Cable to Door Jamb)

PC-000798 - Serial I.D. Plate

PJN3-0004

http://www.polyjohn.com/pjn3-0004/

- Front Wall Panel

http://www.polyjohn.com/tm01-0003/

TM01-0003 - Mirror

(4) PC-000367 - Nylon Fastener

** http: //www.polyjohn.com/pc-

PC-000223 000233/

- Handle

(2) PC-000105 - Rivet

http://www.polyjohn.com/pc-

** PC-000800 - Door000800/Spring Closure

http://www.polyjohn.com/pj-nSlide

** PJN3-0038 3-0038/ Latch w/Decal

http://www.polyjohn.com/pjn3-0043/

** PJN3-0043 - Door Pull

http://www.polyjohn.com/pj-n3-Door

PJN3-0005 0005/

(Includes Door w/Hinges Only)

(4) PC-000170 - 3“ Hinges

(12) PC-000104 - Rivet (Hinge to Door Jamb)

(12) PC-000102 - Rivet (Hinge to Door)

http://www.polyjohn.c-om/pc-000181/

PC-000181 Cable Clip

(2) PC-000104 - Rivet

http://www.polyjohn.com/pc-

** PC-000806 - Door000806/Closure Clip

(2) PC-000105 - Rivet

** Items are not included with PJN3-0003 Front Assembly.

Parts bag PJN3-0201 is available for replacement purposes.

PJN3 Assembly - April 2017

Page 3 of 12

PSN1 Sink

PC-000581G

http: - Sink Tap

//www.polyjohn.com/pc-000581g/

Optional (2) PC-000104 - Rivet

(2) PC-000106 - Washer 3/16”

http://www. polyjohn.com/pc-000339/

PC-000339 - Elbow 3/8”

PSN1 Sink Exploded View

Sink Bowl Fasteners

(2) PC-000107 - Rivet

http:PC-000310

//www.polyjohn.com/pc-000310/- Rubber Washer

See Page 11 for Installation (2) PC-000106 - Washer 3/16”

1” x 2” x .031

htPC-000308

tp:/ www.polyjohn.com/pc-000308/

Sink Strainer

htPC-000225

tp:/ www.polyjohn.com/pc-000225/ - Catch Lock

(2) PC-000110 - Rivet

(2) PC-000111 - Washer

htPC-000322

tp:/ www.polyjohn.com/pc-000322/ - Elbow 3/4” Fpt

http:/PC-000351

/www.polyjohn.com/pc-000351/ http:/CT38-049

www.polyjohn.com/ct38-049/- Tube 3/8” x 49” Long

#10 Hose Clamp

htPC-000224

tp:/ www.polyjohn.com/pc-000224/- Spring Lock

(2) PC-000110 - Rivet **NOT SHOWN

(2) PC-000111 - Washer

http: //www.polyjohn.com/ch075-041/- Drain Hose 3/4” x 41” Long

CH075-041

htPC-000351

tp:/ www.polyjohn.com/pc-000351/ - #10 Hose Clamp

htPC-000782

tp:/ www.polyjohn.com/pc-000782/ - Decal Not for Drinking or Cooking

http: //www.polyjohn.com/pc-000783/- Decal Transport

PC-000783

htPC-000790

tp:/ www.polyjohn.com/pc-000790/ - Decal Foot Pump

http://www.CT38-003

polyjohn.com/ct38-003/ http://www.PC-000339

polyjohn.com/pc-000339/- Elbow 3/8”

Tube 3/8” x 3” Long

http:/ PC-000305

www.polyjohn.com/pc-000305/ - Plastic Filter

htPC-000600

tp:/ www.polyjohn.com/pc-000600/

- Baby Foot Pump

(4) PC-000102 - Rivet

(4) PC-000106 - 3/16” - Washer

http:/PC-000418

www.polyjohn.com/pc-000418/- 1” Uniseal

PJN3 Recirc Tank

http:/ www.polyjohn.com/psn1-0050/- Mounting Plate

PSN1-0050

http:PC-100421B

/ www.polyjohn.com/pc-000421b/ - Drain Plug Body

FT02-1000 (2) PC-000135 - Screw

http://www.polyjohn.com/ft02-1000/

http:/ wPC-000241

ww.polyjohn.com/pc-000241/ - O-Ring

PC-000204

http://www.polyjohn.com/pc-000204/

htPC-100421P

tp:/ www.polyjohn.com/pc-000421p/ - Drain Plug

Toilet Seat

FT02-0003

http://www.polyjohn.com/ft02-0003/

PJN3 Recirc Lid

PC-000233 - Nut

http://www.polyjohn.com/pc-000233/

10-32 Nylon Lock S.S.

SG1-0013

http://www.polyjohn.com/sg1-0013/

- Cup Flapper Valve PC-000232 -Screw

http://www.polyjohn.com/pc-000232/

PC-100620 - Counterweight

(2) PC-000155 - Screw 10-32 x 1” S.S. FT02-0011

http://www.polyjohn.com/ft02-0011/

- Prop Rod

Optional

(2) PC-000233 - Nut 10-32 Nylon Lock S.S.

PC-100611 - Shaft

http://www.polyjohn.com/pc-100611/

FT02-1000 Recirculating

Flush Tank Exploded View

PC-000352

http://www.polyjohn.com/pc-000352/

Hose Clamp S.S. #12

FT02-0002

http://www.polyjohn.com/ft02-0002/

Recirc Waste Tank PC-100372B

http://www.polyjohn.com/pc-100372b/

- Nozzle See Page 7 for Installation

(2) PC-000102 Rivet

(2) PC-000106 Washer

PC-000304

http://www.polyjohn.com/pc-000304/

Secondary Filter

http://www.polyjohn.com/pc-000604/

PC-000604

PC-000303

http://www.polyjohn.com/pc-000303/ Rubber Dust Cover

Primary Filter

PC-000416 - Uniseal

http://www.polyjohn.com/pc-000416/ FT02-0010

http://www.polyjohn.com/FT02-0010/

Foot Pump Plate

CP050-40003

http://www.polyjohn.com/cp050-40003/

1/2” x 3” PVC Pipe CH100-050 - Discharge

http://www.polyjohn.com/ch100-050/

http://www.polyjohn.com/pc-100316/ Hose 1” x 50” Long

PC-100316 - Elbow

1” Barb x 1” Barb

PC-000352

http://www.polyjohn.com/pc-000352/

Hose Clamp S.S. #12 PC-000352

http://www.polyjohn.com/pc-000352/

CH100-0165 - Intake

http://www.polyjohn.com/ch100-0165/ Hose Clamp S.S. #12

PC-000352

http://www.polyjohn.com/pc-000352/

Hose 1” x 16.5” Long

Hose Clamp S.S. #12

PC-000603 - Pump

http://www.polyjohn.com/pc-000603/

(6) PC-000231 - Screw

(6) PC-000106 - Washer

PJN3 Assembly - April 2017

Page 4 of 12

GENERAL OVERVIEW

• When using air operated screw drivers or impact wrenches, be sure that the torque setting does not exceed 28 inch pounds.

• When using a battery-operated drill, set it to the lowest torque setting.

• Please follow the instructions in the order they are presented. It is suggested that you read through the entire assembly

instructions prior to proceeding with the assembly.

• All references to left, right, front and rear throughout the entire assembly instructions are as viewed from the front of the

restroom.

• All rivet holes drilled 13/64” dia.

• Use 1/4” disposable shim strips.

• The PJN3 Model restroom assembly will require two people.

• These instructions are for restrooms shipped unassembled. If you receive assembled units, please retain these instructions

for maintenance and repair purposes.

• We strongly suggest that these restrooms, as with all portable structures, be transported and handled with care. Dropping

the restroom when loading and unloading could cause damage to the door jamb and other components.

FULL SIZE SCALE FASTENER DRAWINGS

(80) PC-000106 Washer

3/16” Back-up

(69) PC-000100 Rivet (2) PC-000104 Rivet

Large Flange, Short Small Flange, Long

(4) PC-000123 Washer

1/4” x 5/8” Flat

(4) PC-000105 Rivet

(4) PC-000102 Rivet

Small Flange, Hollow Wall

Small Flange, Short

(1) PC-000117 Rivet

(1) PC-000168 Washer

(8) PC-000103 Rivet Small Flange, Long Hollow Wall

5/16” x 7/8” Flat

Large Flange, Medium

Optional - PC-000158 (4) PC-000367 Fastener

Self Tapping Screw Nylon Push

(1) Used in PSN1 Sink

(19) PC-000192 Sems Assembly

1/4” x 1-1/4” Self Tapping

(4) PC-000174 Screw

(4) PC-000140 Nut 1/4”-20 x 1-1/4” Long

1/4”-20 Nylok Optional - (1 ) Used in

FT02-1000 Recirculating Tank

~~TOOLS REQUIRED FOR ASSEMBLY~~

• Drill • Rivet Gun with 3/16” tip • Hammer • Socket Wrench

• 13/64” Drill Bit • Phillips Cross-head Screwdriver • Pliers • Vise-Grips

• Marker • Carpenters’ Square • Tape Measure • 7/16” Socket

PJN3 Assembly - April 2017

Page 5 of 12

ASSEMBLY INSTRUCTIONS

STEP 1. DOOR JAMB AND FRONT ASSEMBLY TO BASE SKID:

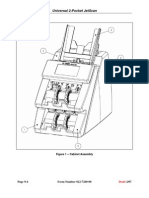

Refer to Figure 1. To assemble the door jamb to the skid, stand

two waste tanks on end about four feet apart (as shown). Stand a

base skid with the tank space toward the ground and the four holes

on the floor side of the base skid up. Position the front assembly on

top of the tanks with the bottom of the front assembly resting on

the base skid. (You may need to add a 4" x 4" on the tank at the top of

the front assembly to level the top with the base skid). Cut the strap

holding the door closed. Open the door and install a PC-000104 rivet

into the hole where the cut strap went through the door jamb. Use

a carpenters’ square to align the hinged leg of the door jamb with

the base skid so the door hangs square. The distance between the Figure 1

two legs of the door jamb is 24". Match up the four holes in the door

jamb with the four slots in the base skid. Fasten the door jamb to the

base skid with (4) PC-000174 screws, (4) PC-000123 washers, and (4)

PC-000140 nuts using a Phillips cross-head screwdriver and a 7/16" socket wrench.

Drive (4) PC-000192 sems lag screws through the two holes on the left and right sides of the

front panel into the base skid. CAUTION: DO NOT OVER-TIGHTEN; TIGHTEN ONLY UNTIL

SNUG. Stand the skid and front assembly upright.

PC-000140 Nut

PC-000174 Screw 4 Used in this step

4 Used in this step

PC-000192 Sems

4 Used in this step

PC-000104 Rivet PC-000123 Washer

1 Used in this step 4 Used in this step

STEP 2. CORNER MOLDINGS TO SIDE PANELS:

Refer to Figure 2. Place a wall panel on top, and on the sides of the

tanks. The mitre cut end of the corner moldings go towards the

top of the side panel. Slip the corner moldings onto the edges

of the side panel. Lift and insert an edge of a side panel into the

grooves of the corner moldings. Insert awls into the second hole

of the top and bottom edges to hold the panel and moldings

in place. (The corner moldings and each edge of the side panels

have nine holes. The center hole is 1/4" diameter and the remaining

holes are 5/16" diameter. The bodies of the rivets are 3/16" diameter.

This allows for thermal expansion and contraction of the cabana

during outdoor temperature fluctuations.) NOTE: Drive all rivet

heads from the front of the restroom, to give the unit a uniform

visual appearance. Rivet the 1/4” center hole first using a PC-

000100 rivet and a PC-000106 back-up washer. Repeat for the

remaining holes, then stand the three side panels and two corner

Figure 2

moldings upright.

PC-000100 Rivet PC-000106 Washer

18 Used in this step 18 Used in this step

PJN3 Assembly - April 2017

Page 6 of 12

STEP 3. CABANA ASSEMBLY:

Position the three side panels and corner molding sub-assembly around the base skid. IMPORTANT - The walls of

the cabana should be approximately 1/4" from the top surfaces of the base skid. Place 1/4" thick shims between

the rear corners of the cabana, and the base skid; this will make the cabana structure level with the front assembly

and allow for thermal expansion and contraction during outdoor temperature fluctuations. To connect the front

assembly, corner moldings, and side panels, begin at the front of the restroom. Insert a PC-000100 rivet through the

center hole, while attaching a PC-000106 back-up washer from the back. Repeat for the remaining holes. (For a uniform

visual appearance, drive all rivet heads from the front). CAUTION: DO NOT PRE-DRILL HOLES IN THE BASE SKID; THE

PC-000192 SEMS LAG SCREWS ARE SELF-THREADING. DO NOT OVER-TIGHTEN THE SEMS LAG SCREWS; TIGHTEN

ONLY UNTIL SNUG. On the bottom of each wall panel, there are five predrilled holes, begin at the center hole of the

rear panel. Use a 7/16” socket wrench, while pushing the rear wall panel against the base skid, drive-in the lag screws.

Then continue with the side wall panels, starting with the front edge of each side, working towards the back.

PC-000100 Rivet PC-000106 Washer PC-000192 Sems

18 Used in this step 18 Used in this step 15 Used in this step

STEP 4. WASTE HOLDING TANK INSTALLATION:

ASSEMBLY OF OPTIONAL RECIRCULATING TANK: For shipping pur-

poses, the pump is fastened under the lid with the necessary parts for

final assembly and installation. Use a 7/16” socket wrench to remove

the pump from the lid. Attach it to its proper location as illustrated 3

1

in the exploded view, and attach hoses with #12 hose clamps. The

CHI00-050 hose connects to the out port on the pump. The CH100-

4

0165 hose connects to the in port on the pump. 2

INSTALLATION OF STATIC OR RECIRCULATING WASTE TANK:

Refer to Figure 3. Position the tank so that it is centered between the

left and right side wall panels and pushed up to the floor plate. There 5 6 7 8

are drill spots on each of the side wall panels. The top four in-line drill

spots on the rear wall panel are used to rivet the back of the holding

tank to the rear wall panel. Of the top four drill spots on each of the

side wall panels, only the two closest to the rear are used to rivet the

sides of the holding tank to the side wall panels. While pushing the

wall panels in flat against the tank, use a 13/64" drill bit. Drill through

the specified drill spots of the wall panels into the outer walls of the

tank. CAUTION: DRILL ONLY THROUGH THE OUTER WALL OF

THE HOLDING TANK. DO NOT DRILL THROUGH THE INSIDE TOP

SURFACES OF THE TANK. From the outside of the restroom one per- Figure 3

son will rivet through the drilled holes with PC-000103 rivets, while

another person inside the restroom puts PC-000106 back-up washers

on the rivet stems.

PC-000106 Washer PC-000103 Rivet

8 Used in this step 8 Used in this step

PJN3 Assembly - April 2017

Page 7 of 12

STEP 5. ROOF INSTALLATION:

Position the roof over the wall panels, make sure the hole for the tank ventilation tube is above the corresponding hole

in the holding tank. (The front and three side panels are supplied with predrilled holes at the top center of each panel. The

roof is supplied with five predrilled holes on each of the four edges.) Start with the front of the unit. Align the predrilled

top center roof holes to the center holes of the wall panels and front assembly. From the outside of the restroom one

person will rivet PC-000100 rivets through each of the four top center holes, while another person inside the restroom

puts PC-000106 back-up washers on the rivet stems. Next, holding the roof firmly down, using the remaining predrilled

holes in the roof, drill 13/64” holes through to the wall panels and front assembly. The person on the outside will again,

rivet the PC-000100 rivets through the drilled holes while another person puts the PC-000106 back-up washers on the

rivet stems.

PC-000100 Rivet PC-000106 Washer

20 Used in this step 20 Used in this step

STEP 6: FLY SCREEN INSTALLATION:

(Each of the three sidewall panels has two vent screens.

On the surface of each vent screen there is a date stamp

symbol. The symbol goes toward the center of the side-

wall panel, facing the inside.)

For each of the three sidewalls, insert one screen

from each side of the vent slot and overlap the center

holes at the date stamp symbol (as shown in Figure 4).

IMPORTANT - Make sure both screens together are

centered in the vent slots. Drill a 13/64” hole through

the center hole of the screen and into the sidewall.

Rivet the screen in place from the outside using a

PC-000100 rivet with a PC-000106 back-up washer on Figure 4

the inside. Using the hole at each end of the screen

as a guide, drill 13/64” holes through the vent screens

and into the sidewall panels. Rivet the screens in place

using PC-000100 rivets on the outside with PC-000106

back-up washers on the inside.

PC-000100 Rivet PC-000106 Washer

9 Used in this step 9 Used in this step

STEP 7. VENTILATION STACK INSTALLATION:

Force the vent stack up through the 4" diameter hole in the roof. (This is intended to be a tight fit.) Slide the vent stack

down and into the 4" diameter recessed hole in the holding tank so that it rests on the round ledge of the hole in the

tank. Drill a 13/64" hole through the boss and vent stack. Fasten the vent stack in place with a PC-000117 rivet.

PC-000117 Rivet

1 Used in this step

PJN3 Assembly - April 2017

Page 8 of 12

STEP 8. SLIDE LATCH, DOOR PULL INSTALLATION:

Refer to Figure 5. Follow steps as illustrated.

Figure 5

INSERT DOOR PULL INTO SLOT USING 2 INSERT SLIDE LATCH

1 INTO DOOR PULL

NOTCHES TO GUIDE DOOR PULL USE SCREWDRIVER TO ASSIST

IN SLIDING THE LATCH

COMPLETELY INTO THE DOOR PULL

STEP 9. DOOR CHECK CABLE:

There are two holes located on the right inside surface of the door toward the top. Position the metal bracket on the

end of the cable so the angle points toward the interior of the restroom. Align the two outer holes of the bracket with

the two holes in the door, rivet in place with (2) PC-000102 rivets. Locate the hole at the top, in the middle of the door

jamb and from the outside insert a PC-000104 rivet through the jamb. Attach the loop end of the cable, a PC-000168

washer, and a PC-000106 back-up washer on the rivet stem and rivet in place.

PC-000102 Rivet PC-000104 Rivet PC-000168 Washer PC-000106 Washer

2 Used in this step 1 Used in this step 1 Used in this step 1 Used in this step

STEP 10. DOOR CLOSURE INSTALLATION:

Refer to Figures 6, 7 and 8. Place the door closure in the molded channel located at the center of the door and push it into

the molded pocket. Thread the ball end of the cable through the hole in the door closure retainer clip. Position the

door closure retainer clip (as shown in Figure 6). Rivet in place with (2) PC-000105 bulbex rivets. Go into the restroom

and close the door. Place the top of a hammer against the PC-000181 spring cable clip (as shown in Figure 7). Place

the end of the spring cable in the claw of the hammer. Open the door while holding the hammer in position. Hold

the door open with your foot and clamp a vice-grips pliers on the cable where it comes out of the door (as shown in

Figure 8). BE SURE TO CLAMP DOWN TIGHT. Remove the cable from the claw of the hammer, close the door, and

place the end of the cable into the slot of the cable clip. Open the door and remove the vice-grips.

PC-000105 Rivet

2 Used in this step

Figure 6

Figure 7 Figure 8

PJN3 Assembly - April 2017

Page 9 of 12

STEP 11. TOILET SEAT INSTALLATION: TS1-0002 - Lid

Push the lid onto the seat (lining up the holes of the lid with those (2) - Pin

in the seat). Line up the holes of the hinge bolts with those in the

seat/lid. From the outer edge, push the pins through the holes

until flush. Place the seat/lid on to the tank (inserting the bolts

through the holes in the tank). Use pliers to tighten the nuts. TS1-0001

Seat

(2) Hinge Bolt

(2) - Nut

STEP 12. URINAL INSTALLATION:

OMIT THIS STEP IF OPTIONAL SINK IS BEING INSTALLED ON

THE LEFT SIDE WALL. Refer to Figure 9. Insert the drain spigot

of the urinal into the hole on the left top surface of the holding

tank. Position the urinal so that it is level. There are two holes

at the top of the urinal. Drill 13/64" holes through those holes

and through the side wall panel. From inside of the restroom

one person will rivet through the drilled holes with PC-000102

rivets, while another person outside the restroom places PC-

000106 back-up washers on the rivet stems.

Figure 9

PC-000102 Rivet

PC-000106 Washer

2 Used in this step

2 Used in this step

STEP 13. TOILET PAPER DISPENSER INSTALLATION:

The double roll dispenser is mounted up on the right wall

panel. Position the dispenser on the top edge of the second

raised panel directly below the fly screens at the desired loca-

tion. (If sink is installed on the right wall, position the dispenser

towards the rear of the panel). CAUTION: BE SURE THE LOCA-

TION OF THE DISPENSER IS NOT IN THE WAY OF PERSONS US- PC-000100 Rivet PC-000106 Washer

ING THE RESTROOM. Level the dispenser on the wall. Using 4 Used in this step 4 Used in this step

the holes in the back of the dispenser as a guide, mark the

locations for the drill holes with a marker. Drill four 13/64”

holes into the drill spots marked. From the outside rivet into

the holes just drilled with (4) PC-000100 rivets while someone

places (4) PC-000106 back-up washers onto the rivet stems

on the inside.

STEP 14. MIRROR:

The mirror is mounted into the square recess on the inside

of the door with (4) PC-000367 nylon push rivets.

PC-000367 Fastener

4 Used in this step

STEP 15. CONVENIENCE HOVER HANDLE:

The convenience handle is mounted into the two square

recesses on the inside of the door with (2) PC-000105 bulbex

rivets. PC-000105 Rivet

2 Used in this step

PJN3 Assembly - April 2017

Page 10 of 12

Overview of Optional Sink Installation 1. APPLY DOWNWARD

PRESSURE ON LID

The sink bowl is attached to the sink tank with (2) PC-000107 rivets that act

as hinges. There is an internal spring snap button located on the top right

side of the bowl, which will hold the bowl in the up position for service and

maintenance. To lower the bowl, simply depress the snap button.

To Open the Sink Top (follow instructions as illustrated on the right) 2. INSERT OBJECT INTO HOLE.

(THIS WILL PUSH LOCKING TAB ALLOWING

ACCESS TO INNER TANK FOR MAINTENANCE.)

3.OPEN SINK LID

OPTIONAL SINK - INSTALLATION

Left Wall Installation

17” Refer to Illustrations. Before installing the sink, a

1-1/8” drain hole that will accept the drain hose

must be cut in the waste tank. This hole should

be located on the top left front edge of the waste

tank approximately 16-1/2” up from the floor.

(As shown on the right, a 2-1/2” plug PC-000557,

is available to cover the urinal drain hole.) NOTE:

2” Make sure the drain hole your cutting as indicated

above is just below the urinal hole. From the ex-

terior, drill two 13/64” holes (as shown on the left)

through the sidewall and the back of the sink, be

sure the sink is pressed flat against the sidewall.

43-1/4”

Fasten the sink to the side from the exterior with

40-1/2” (2) PC-000103 rivets and (2) PC-000106 back-up

washers on the inside of the sink. Attach sink to

base skid: Drive (1) PC-000158 self-tapping screw

in the pre-drilled hole in the sink mounting plate.

Perform a system check by adding a few gallons

of water to the sink. Depress the pump a few

times to “prime” it. The pump has a built in check

valve that will hold the prime between uses.

7”

Right Wall Installation

Before installing the sink, a 1-1/8” drain hole that

will accept the drain hose must be cut in the waste

tank. This hole should be located on the top right

front edge of the waste tank approximately 15-

1/2” up from the floor.

From the exterior, drill two 13/64” holes through

2” the sidewall and the back of the sink (as shown on

the left) be sure the sink is pressed flat against the

sidewall.

Fasten the sink to the side from the exterior with

42-3/4”

(2) PC-000103 rivets and (2) PC-000106 back-up

43-1/4” washers on the inside of the sink. Attach sink to

base skid: Drive (1) PC-000158 self-tapping screw

in the predrilled hole in the sink mounting plate.

Perform a system check by adding a few gallons

of water to the sink. Depress the pump a few

times to “prime” it. The pump has a built in check

valve that will hold the prime between uses.

PJN3 Assembly - April 2017

Page 11 of 12

Winterizing Sink (if installed)

• Drain all water from the tanks.

• Flush tank with a solution of chlorine and water.

• Depress the foot pump to clear lines.

Optional Accessories

CK01-0164 - Hand Sanitizing Dispenser FD1-1000 - Hand Foam Dispenser FT02-1000 - Recirculating Flushing System

LK04-1000 - Door Lock Clip & Hasp Kit LS04-0001 - Liquid Soap Dispenser MS02-1000 - Lifting Sling Set for Plastic Skid

PSN1-1000 - Single User Hand Wash Sink PT01-1000 - Toilet “Tug-A-Long” SU01-0001 - Convenience Shelf w/Coat Hook

TD04-1000 - PJ Paper Towel Dispenser TU01-1000 - Single Trailer TU02-1000 - Double Trailer

CLEANING AND MAINTENANCE

Use a mild soap to clean all surfaces and component parts.

Minor scratches and abrasions can be lightly sanded or scrubbed with a mild abrasive cleaner (such as “Soft Scrub”) that contains

calcium carbonate, hypochlorIte bleach and detergents. Be sure to follow the cleaning product directions since these ingredients

may cause hazardous gases when mixed with other chemicals. Rinse the cleaned area and buff with a conventional wax.

Some light scratches may also be hidden by using an industrial hot air gun.

If sink is installed add a “Fresh Sink Tablet” (chlorinated tablet) each time the sink is filled with water to keep the water fresh.

For a source of cleaning, deodorizing and paper products contact:

COOPER’S OWN

2500 GASPAR AVE.

WHITING, IN 46394-2175

800-292-1305

We highly recommend membership in the Portable Sanitation Association International (PSAI); the worldwide authority on portable

sanitation services. The PSAI, “Portable Sanitation Industry Certification Program” manual contains a wealth of information on standards

and service procedures. For more information contact the PSAI:

PORTABLE SANITATION ASSOCIATION INTERNATIONAL (PSAI)

7800 METRO PARKWAY, SUITE 104

BLOOMINGTON, MINNESOTA 55425 USA

800-822-3020 / 612-854-8300 FAX 612-854-7560

www.psai.org

OUR MISSION STATEMENT

“PolyJohn is a family owned, state of the art, plastics manufacturing company dedicated to providing its employees with a work

environment committed to excellence, and its customers with innovative products, services and technology that meet or exceed

their requirements.”

THANK YOU FOR PURCHASING POLYJOHN PRODUCTS!

Look for us on the Web @ www.PolyJohn.com

PJN3 Assembly - April 2017

Page 12 of 12

You might also like

- Banheiro 2 VistaDocument20 pagesBanheiro 2 VistaIlton Mendes da SilvaNo ratings yet

- Whirlpool WFC682CLWDocument15 pagesWhirlpool WFC682CLWalNo ratings yet

- 007 (Update, Po Belum) - ST-Q PT - ARTAJAYA - Ejf IndoramaDocument1 page007 (Update, Po Belum) - ST-Q PT - ARTAJAYA - Ejf IndoramaHoirunnisaNo ratings yet

- Abs PVC PipeDocument44 pagesAbs PVC PipeAdanaNo ratings yet

- 045 BD Borders Metal Panels 3x2700 (h1400) - 2018-10-09Document9 pages045 BD Borders Metal Panels 3x2700 (h1400) - 2018-10-09johnNo ratings yet

- Quantity Up To 30: Original Shipment: ETA MLE Is 8Document8 pagesQuantity Up To 30: Original Shipment: ETA MLE Is 8Top world rankingsNo ratings yet

- Tara Hand Pump BrochureDocument6 pagesTara Hand Pump BrochuremboolaNo ratings yet

- Plantadeiras Jd. Tt. Smt. Cs.Document2 pagesPlantadeiras Jd. Tt. Smt. Cs.Fernando IncopartsNo ratings yet

- 8 1 Caravan Prospekt ENDocument4 pages8 1 Caravan Prospekt ENPetko TsochevNo ratings yet

- Petrospection Calibration Tables (Report)Document11 pagesPetrospection Calibration Tables (Report)Abo Ali100% (1)

- Cargas Maximas Permitidas em Bocais de VasosDocument4 pagesCargas Maximas Permitidas em Bocais de VasosEd BarrosNo ratings yet

- Duct Weight 28Document16 pagesDuct Weight 28STANDARD EDUCATION ACADEMY M.E.P CENTERNo ratings yet

- Danby Dac7037m User ManualDocument12 pagesDanby Dac7037m User ManualElla MariaNo ratings yet

- 950 HD Parts Manual 1Document44 pages950 HD Parts Manual 1Rene Ramos MenesesNo ratings yet

- 3 Analisis de Opciones y Propuesta Financiera (Ingles)Document6 pages3 Analisis de Opciones y Propuesta Financiera (Ingles)Jair Fajrdo LopezNo ratings yet

- Diepa Χ43Document2 pagesDiepa Χ43Konstantinos SynodinosNo ratings yet

- Id Jimhouse 06-080223Document35 pagesId Jimhouse 06-080223Cynthia PhungkyNo ratings yet

- Calculation Sheet For Tank - API 620 12th EdDocument48 pagesCalculation Sheet For Tank - API 620 12th EdHamid Mansouri71% (17)

- Hazardous Waste Filtration System User Guide: Millipore Cat. No. YT30 142 HWDocument11 pagesHazardous Waste Filtration System User Guide: Millipore Cat. No. YT30 142 HWJUAN RAMIREZ MARTINEZNo ratings yet

- 64 PajeroDocument2 pages64 Pajerotsanjuna6623No ratings yet

- UYP-CH-ACI-001 Rev - 2 YCHICAWA PARURODocument22 pagesUYP-CH-ACI-001 Rev - 2 YCHICAWA PARUROTomas Alberto Garcia Puente ArnaoNo ratings yet

- MaxPure 2017 CATALOG PDFDocument56 pagesMaxPure 2017 CATALOG PDFChirag SolankiNo ratings yet

- Diepa B50 - High Performance Rotation Resistant Steel Wire RopeDocument1 pageDiepa B50 - High Performance Rotation Resistant Steel Wire RopeKonstantinos SynodinosNo ratings yet

- Rottler Manufacturing Company: Performance Racing & Engine Rebuilding Machinery & EquipmentDocument2 pagesRottler Manufacturing Company: Performance Racing & Engine Rebuilding Machinery & EquipmentJesus D. Gutierrez G.No ratings yet

- Project: Training Building Owner: PT Agincourt Resources Area: Laydown Workshop Procesing Location: Martabe Year: 2020Document7 pagesProject: Training Building Owner: PT Agincourt Resources Area: Laydown Workshop Procesing Location: Martabe Year: 2020rahmat huseinNo ratings yet

- Task Card JT8D (Install Fan Blade)Document3 pagesTask Card JT8D (Install Fan Blade)Raden BurhanNo ratings yet

- PVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogDocument44 pagesPVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogMohamed AtefNo ratings yet

- Caterpillar C10 02 19 20221388Document15 pagesCaterpillar C10 02 19 20221388CARLOSNo ratings yet

- 4 de 5) VÁLVULA MARIPOSA Marca NIBCO (Inglés)Document12 pages4 de 5) VÁLVULA MARIPOSA Marca NIBCO (Inglés)Maximiliano StaitiNo ratings yet

- Quotation # SO354: Invoicing and Shipping AddressDocument3 pagesQuotation # SO354: Invoicing and Shipping AddressDatashield InfoNo ratings yet

- Cummins 4196 GrisDocument51 pagesCummins 4196 GrisAlberto Ortega OrtegaNo ratings yet

- ComparisonDocument1 pageComparisonamir amiriNo ratings yet

- B 50 (D 1315 Z) B 53 (D 1315 ZP) B 55 (D 1315 CZ) B 58 (D 1315 CZP)Document4 pagesB 50 (D 1315 Z) B 53 (D 1315 ZP) B 55 (D 1315 CZ) B 58 (D 1315 CZP)Fernando LaraNo ratings yet

- Summary Doc (Issue 4)Document2 pagesSummary Doc (Issue 4)hanane sellamNo ratings yet

- Solder Balls or Solder Balling On A PCB - Wave Soldering DefectsDocument5 pagesSolder Balls or Solder Balling On A PCB - Wave Soldering DefectsasdfNo ratings yet

- Force Calculation Using ILDDocument6 pagesForce Calculation Using ILDdotamirNo ratings yet

- 0291 - Analisa Struktur Baja Untuk Pemasangan Solar Cell R1Document43 pages0291 - Analisa Struktur Baja Untuk Pemasangan Solar Cell R1Teguh DwiyantoNo ratings yet

- Memoria de Agua PotableDocument11 pagesMemoria de Agua PotableBenito Antonio ANo ratings yet

- Poultry Project: Officine Facco C. S.P.ADocument12 pagesPoultry Project: Officine Facco C. S.P.AMd. Syful AlamNo ratings yet

- Traditional Crane Parts Manual: This Manual Has Been Prepared For and Is Considered Part ofDocument380 pagesTraditional Crane Parts Manual: This Manual Has Been Prepared For and Is Considered Part ofReza SalimiNo ratings yet

- Sunon: Specification For ApprovalDocument16 pagesSunon: Specification For ApprovalManuelLentiNo ratings yet

- Group Bonomi 2017 EngDocument24 pagesGroup Bonomi 2017 EngAfrizal RivaNo ratings yet

- 1998-2004 MB SLK Parts CatalogDocument128 pages1998-2004 MB SLK Parts Catalogsmithm007100% (1)

- Sahara SAH31WHBL Tech Sheet 240221 HRDocument2 pagesSahara SAH31WHBL Tech Sheet 240221 HRDamien PollockTSANo ratings yet

- CONNECTION: UB305X165X40BS5950 - Base Plate: AdminDocument3 pagesCONNECTION: UB305X165X40BS5950 - Base Plate: AdminPNo ratings yet

- 2B-Anchor Bolt CapcityDocument9 pages2B-Anchor Bolt Capcityrao_vinay8296No ratings yet

- Vietnam Secureman Co., Ltd. Packing ListDocument6 pagesVietnam Secureman Co., Ltd. Packing Listapi-3704492No ratings yet

- Work Order: 1. Order Status (Sample, Production, Claim) (Diecut, Molded)Document1 pageWork Order: 1. Order Status (Sample, Production, Claim) (Diecut, Molded)Finda PutriNo ratings yet

- DS600-130 FRH340005 Water Drain ValveDocument2 pagesDS600-130 FRH340005 Water Drain ValvecaigaNo ratings yet

- 078 129 BedfordDocument58 pages078 129 BedfordSami AjNo ratings yet

- Packman Coal Fuel Hot Water BoilerDocument8 pagesPackman Coal Fuel Hot Water BoilerAmir ShamshiriNo ratings yet

- XCMG Trailer PIDocument5 pagesXCMG Trailer PIfzuniga.matricardiNo ratings yet

- Liquidacion Y Proyeccion de Ventas CO-034 Costo Unit. Credito FiscalDocument1 pageLiquidacion Y Proyeccion de Ventas CO-034 Costo Unit. Credito FiscalGrimsonJaurapomaNo ratings yet

- Cable-Cutting Tool - CUTFOX 52 - 1212133: Key Commercial DataDocument3 pagesCable-Cutting Tool - CUTFOX 52 - 1212133: Key Commercial DataDkalestNo ratings yet

- Installation Manual: Document TitleDocument14 pagesInstallation Manual: Document TitlehussamNo ratings yet

- Whirlpool Adg 789Document22 pagesWhirlpool Adg 789Joe ErdődyNo ratings yet

- Dressing Halal Oh2 - 2Document12 pagesDressing Halal Oh2 - 2Jovani G. BallonNo ratings yet

- 620CT - A Exploded ViewDocument17 pages620CT - A Exploded Viewmedabee200060No ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Steering Handle & Throttle Control - 1992 Johnson Outboards 9.9 J10rena Crowley MarineDocument7 pagesSteering Handle & Throttle Control - 1992 Johnson Outboards 9.9 J10rena Crowley MarineCharlie CB PortnerNo ratings yet

- MOTOR CABLE - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineDocument3 pagesMOTOR CABLE - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineCharlie CB PortnerNo ratings yet

- Exhaust Housing - 1992 Johnson Outboards 9.9 J10renaDocument7 pagesExhaust Housing - 1992 Johnson Outboards 9.9 J10renaCharlie CB PortnerNo ratings yet

- ELECTRIC PRIMER SYSTEM - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineDocument7 pagesELECTRIC PRIMER SYSTEM - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineCharlie CB PortnerNo ratings yet

- MIDSECTION (10SEL ONLY) - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineDocument19 pagesMIDSECTION (10SEL ONLY) - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineCharlie CB PortnerNo ratings yet

- Seborg, Mellichamp, Edgar, Doyle: Process Dynamics and Control, 3 Edition Edgar, Himmelblau, Lasdon: Optimization of Chemical Processes, 2 EditionDocument17 pagesSeborg, Mellichamp, Edgar, Doyle: Process Dynamics and Control, 3 Edition Edgar, Himmelblau, Lasdon: Optimization of Chemical Processes, 2 EditionCharlie CB PortnerNo ratings yet

- CARBURETOR - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineDocument8 pagesCARBURETOR - 1992 Johnson Outboards 9.9 J10RENA Crowley MarineCharlie CB PortnerNo ratings yet

- Chemistry and Technology of Rubber PDFDocument215 pagesChemistry and Technology of Rubber PDFCharlie CB Portner100% (1)

- ENCH 442: Chemical Process Control and SafetyDocument16 pagesENCH 442: Chemical Process Control and SafetyCharlie CB PortnerNo ratings yet

- Seborg, Mellichamp, Edgar, Doyle: Process Dynamics and Control, 3 Edition Edgar, Himmelblau, Lasdon: Optimization of Chemical Processes, 2 EditionDocument21 pagesSeborg, Mellichamp, Edgar, Doyle: Process Dynamics and Control, 3 Edition Edgar, Himmelblau, Lasdon: Optimization of Chemical Processes, 2 EditionCharlie CB PortnerNo ratings yet

- Baltimore City Bureau of Water and WastewaterDocument29 pagesBaltimore City Bureau of Water and WastewaterCharlie CB PortnerNo ratings yet

- GPSS3Document82 pagesGPSS3Charlie CB PortnerNo ratings yet

- 02 Overview of Drinking Water TreatmentDocument36 pages02 Overview of Drinking Water TreatmentCharlie CB PortnerNo ratings yet

- Final Lab Report Group 1 Flow Through Fluidized BedsDocument47 pagesFinal Lab Report Group 1 Flow Through Fluidized BedsCharlie CB Portner100% (2)

- ENCH 474 / ENCE 660 - Air Pollution The Big PictureDocument18 pagesENCH 474 / ENCE 660 - Air Pollution The Big PictureCharlie CB PortnerNo ratings yet

- Lab Guide 2017Document48 pagesLab Guide 2017Charlie CB PortnerNo ratings yet

- ENCH 225 Spring 2015 Course PacketDocument185 pagesENCH 225 Spring 2015 Course PacketCharlie CB PortnerNo ratings yet

- Tdmis 1510Document3 pagesTdmis 1510suman mollickNo ratings yet

- Chem Lab Report 9:26:18Document3 pagesChem Lab Report 9:26:18Andrew SmithNo ratings yet

- Project New Naushad PDFDocument83 pagesProject New Naushad PDFClick PickNo ratings yet

- SN200Document111 pagesSN200tajinder231280% (5)

- Natural VentilationDocument6 pagesNatural VentilationSumit Raina100% (1)

- ASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance AlloysDocument2 pagesASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloysanon_5892313360% (2)

- Technical Data Sheet LG11 ENG 2021Document2 pagesTechnical Data Sheet LG11 ENG 2021KEMPCHEN COMDIFLEXNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Basic Water ChemistryDocument4 pagesBasic Water ChemistryZAHID HUSSAINNo ratings yet

- Green Diesel Production From Upgrading of Cashew Nut Shell Liquid PDFDocument11 pagesGreen Diesel Production From Upgrading of Cashew Nut Shell Liquid PDFDaniela J. TitusNo ratings yet

- 20180310022848ega BrochureDocument24 pages20180310022848ega Brochuremoss .bNo ratings yet

- SSC 6mo Spec Sheet PDFDocument2 pagesSSC 6mo Spec Sheet PDFsiswoutNo ratings yet

- LEVA Parts Catalog V1.4 COLORDocument84 pagesLEVA Parts Catalog V1.4 COLORMionnix KM-Service-premiumNo ratings yet

- Structural Testing of Steel Fibre Reinforced Concrete Tunnel Lining Segments in SingaporeDocument17 pagesStructural Testing of Steel Fibre Reinforced Concrete Tunnel Lining Segments in Singaporethauwui86No ratings yet

- DOT Pipeline RepairsDocument18 pagesDOT Pipeline RepairsSeng HeangNo ratings yet

- Dr. Kirti Chandra Sahu Department of Chemical Engineering IIT HyderabadDocument15 pagesDr. Kirti Chandra Sahu Department of Chemical Engineering IIT HyderabadAnonymous P7J7V4No ratings yet

- Fabrication of Seed Sowing Machine: Bachelor of Technology in Mechanical EngineeringDocument31 pagesFabrication of Seed Sowing Machine: Bachelor of Technology in Mechanical EngineeringPrasanthi TalariNo ratings yet

- Rev 8Document2 pagesRev 8api-273257329No ratings yet

- Kodak X-Omat M35-A - User ManualDocument22 pagesKodak X-Omat M35-A - User ManualMilton CameraNo ratings yet

- CEM-1206S Datasheet - Magnetic Buzzer - CUI Inc PDFDocument5 pagesCEM-1206S Datasheet - Magnetic Buzzer - CUI Inc PDFLUDWINGNo ratings yet

- ACI - 2019 Arabic - p490-521Document32 pagesACI - 2019 Arabic - p490-521Mustafa Al-QawasmehNo ratings yet

- POLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESDocument3 pagesPOLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESPhuoc Thinh TruongNo ratings yet

- GL XX Primetals Gear Oil SeriesDocument3 pagesGL XX Primetals Gear Oil SeriesChérubinNo ratings yet

- FM5178R6 TBM Series EnglishDocument2 pagesFM5178R6 TBM Series EnglishalejgonzNo ratings yet

- CV Hadj Yahia Seba 2023Document5 pagesCV Hadj Yahia Seba 2023Yahia SebaNo ratings yet

- ExercisesDocument4 pagesExercisesStudent555No ratings yet

- Food Technology and Biotechnology - StrawberryDocument8 pagesFood Technology and Biotechnology - StrawberryIfenza HernandaNo ratings yet

- After Ultra CoolantDocument8 pagesAfter Ultra CoolantEmrah KutluNo ratings yet

- XRAY NT18 Engine Instruction & Safety ManualDocument26 pagesXRAY NT18 Engine Instruction & Safety ManualAsierReloopNo ratings yet

- Spot Learning (Autosaved) (Autosaved) PDFDocument159 pagesSpot Learning (Autosaved) (Autosaved) PDFaraz_1985No ratings yet