Professional Documents

Culture Documents

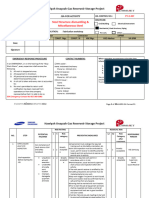

SWP Air Compressor Fixed - AS501

Uploaded by

Perwez21Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWP Air Compressor Fixed - AS501

Uploaded by

Perwez21Copyright:

Available Formats

(DESCON Engineering Limited) – Safe Work Procedure

FIXED AIR COMPRESSOR

DO NOT use this machine unless you have been instructed

in its safe use and operation and have been given permission

PERSONAL PROTECTIVE EQUIPMENT

Safety glasses must be worn at Long and loose hair must be Ensure all flammable

all times in work areas. contained. materials are safely stored.

Sturdy footwear must be worn Close fitting/protective Rings and jewellery must not

at all times in work areas. clothing must be worn. be worn.

PRE-OPERATIONAL SAFETY CHECKS

Locate and ensure you are familiar with all machine

operations and controls.

Check workspaces and walkways to ensure no

slip/trip hazards are present.

Put the compressor in a suitable location for safe

operation.

Lock the wheels on the base of the compressor to

prevent movement.

Check that all fittings and connections are in good

condition.

Check all fittings are securely connected before

being pressurised.

OPERATIONAL SAFETY CHECKS

Start the compressor, noting pressure increase and

cut-out /cut-in pressure.

Listen for any air leaks from any flexible airlines and

immediately report if any leaks are found.

Adjust pressure regulator to suit work requirements.

Check the compressor at regular intervals.

ENDING OPERATIONS AND CLEANING UP

Switch off machine when work completed.

Leave the machine, hose and work area in a safe,

clean and tidy state.

POTENTIAL HAZARDS

Unsecured hoses whipping under pressure.

Compressed air

DON’T

Do not use faulty equipment. Immediately report

suspect machinery. This SWP does not necessarily cover all possible hazards

Do not blow compressed air onto the skin.

associated with this equipment and should be used in

conjunction with other references. It is designed as a guide

to be used to compliment training and as a reminder to

users prior to equipment use.

You might also like

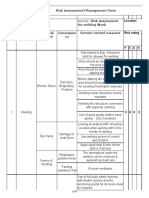

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- Shop Safety Safe Work Procedure DRILL PRESSDocument1 pageShop Safety Safe Work Procedure DRILL PRESSTamoy CooreNo ratings yet

- Risk Assessment GRP Tank InstallationDocument19 pagesRisk Assessment GRP Tank Installationanwer.ahmadNo ratings yet

- Conjuring For Amateurs (1901)Document138 pagesConjuring For Amateurs (1901)jgokey100% (1)

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Kids Fun FeetDocument4 pagesKids Fun FeetGabrijela FlopNo ratings yet

- PaintingDocument1 pagePaintingReynaldo PesqueraNo ratings yet

- RA0128 - Installation of UPS SystemDocument17 pagesRA0128 - Installation of UPS SystemExplore the world TodayNo ratings yet

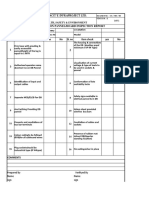

- JSA For KAHSDocument6 pagesJSA For KAHSFrancis Enriquez TanNo ratings yet

- HSE-SOP-14 Transportation Logistics Safety ManagementDocument29 pagesHSE-SOP-14 Transportation Logistics Safety ManagementPerwez2190% (10)

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

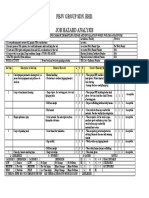

- Jobs Safety Analysis: Start DateDocument2 pagesJobs Safety Analysis: Start Dater afriantoNo ratings yet

- Health and Safety Induction - ChecklistDocument3 pagesHealth and Safety Induction - ChecklistPerwez210% (1)

- PT. Leighton Contractors Indonesia: Risk Assessment ReportDocument6 pagesPT. Leighton Contractors Indonesia: Risk Assessment ReportJohn KalvinNo ratings yet

- 7105 JHRA 008 12 Pneumatic Testing ActivitiesDocument7 pages7105 JHRA 008 12 Pneumatic Testing Activitiesarnel sungkipNo ratings yet

- Construction Safety Budget BreakdownDocument3 pagesConstruction Safety Budget BreakdownPerwez2150% (2)

- JSA Pressure TestingDocument1 pageJSA Pressure TestingScott Mills100% (1)

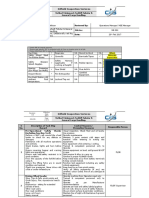

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementsimoneNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHeNo ratings yet

- Vehicle Hoist Safe Work ProcedureDocument2 pagesVehicle Hoist Safe Work ProcedureWiwinIndahSariEffendiNo ratings yet

- Changing Hydroulic Pump An Equipment (WS)Document6 pagesChanging Hydroulic Pump An Equipment (WS)John KalvinNo ratings yet

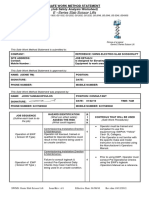

- TOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEDocument5 pagesTOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEazerNo ratings yet

- Sop OPOP - 050 - Breath Analyser, Alcohol and DrugsDocument5 pagesSop OPOP - 050 - Breath Analyser, Alcohol and Drugscontrax8100% (1)

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Hydrostatic Pressure Testing Procedure1 PWLDocument6 pagesHydrostatic Pressure Testing Procedure1 PWLYavannaNo ratings yet

- Abrasive Blasting ProgramDocument6 pagesAbrasive Blasting ProgramAditya Raj MishraNo ratings yet

- Oilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDocument6 pagesOilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDheeraj MenonNo ratings yet

- HSE guidance on safety devices for rapid roller doorsDocument11 pagesHSE guidance on safety devices for rapid roller doorsmsc920138No ratings yet

- Unsafe MEWP Operation ReviewDocument2 pagesUnsafe MEWP Operation ReviewAbdulKatherNo ratings yet

- Grounding Rod Installation SafetyDocument5 pagesGrounding Rod Installation SafetyHow Chin Engineering Sdn BhdNo ratings yet

- DK - Chocolate FiLELiSTDocument226 pagesDK - Chocolate FiLELiSTPaul95% (22)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Guide to Selecting and Purchasing Hammer CrushersDocument24 pagesGuide to Selecting and Purchasing Hammer CrushersPerwez21100% (1)

- Ginger RecipeDocument3 pagesGinger RecipeJane HomenaNo ratings yet

- EHS Alert 010 - Concrete Placing Boom OperationDocument1 pageEHS Alert 010 - Concrete Placing Boom OperationAbdulKatherNo ratings yet

- Duhok Polytechnic University College of Technical Engineering Department of PetrochemicalDocument17 pagesDuhok Polytechnic University College of Technical Engineering Department of PetrochemicalDll ZarNo ratings yet

- Health and Safety Induction - ChecklistDocument3 pagesHealth and Safety Induction - ChecklistPerwez21100% (1)

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- HSE Flyer On Falling Objects April 2018Document4 pagesHSE Flyer On Falling Objects April 2018Perwez21No ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- Hazard Identification & Risk Assessment Sheet ForDocument6 pagesHazard Identification & Risk Assessment Sheet Forasathish.eee100% (1)

- HSE Professionals - Fall Protection and PreventionDocument8 pagesHSE Professionals - Fall Protection and Preventionchinne046No ratings yet

- NEF Pre Int Wordlist FrenchDocument27 pagesNEF Pre Int Wordlist Frenchbleuet29No ratings yet

- Fixed Air Compressor: Do NotDocument1 pageFixed Air Compressor: Do NothainguyenbkvhvNo ratings yet

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- Electrical Inspection Color CodeDocument3 pagesElectrical Inspection Color CodePerwez21No ratings yet

- Textile Testing and Quality ControlDocument25 pagesTextile Testing and Quality ControlGreen University Textile100% (2)

- Crochet Koala Kevin PDF Amigurumi Free PatternDocument7 pagesCrochet Koala Kevin PDF Amigurumi Free PatternMargarita López Medina100% (1)

- BbsDocument23 pagesBbsPerwez21No ratings yet

- Standard SOP Recruitment ProcedureDocument3 pagesStandard SOP Recruitment ProcedurePerwez21No ratings yet

- RA - SandblastingDocument2 pagesRA - Sandblasting721917114 47No ratings yet

- 14 - Method Statements For Erection of Steel PDFDocument1 page14 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- SOP For Tree Cutting at HPCL UNNAODocument3 pagesSOP For Tree Cutting at HPCL UNNAOamankumar100% (1)

- Safety Topic 863 - Working Under Suspended LoadsDocument2 pagesSafety Topic 863 - Working Under Suspended LoadsAshishNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- Job Safety Analysis Sheet: Manual ExcavationDocument1 pageJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalNo ratings yet

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocument5 pagesLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasNo ratings yet

- Name: SignDocument1 pageName: SignAdel AlKhedawyNo ratings yet

- Injury Statistics SheetDocument4 pagesInjury Statistics SheetEslam IsmaeelNo ratings yet

- Safety Practices for Compressed Gas CylindersDocument4 pagesSafety Practices for Compressed Gas CylindersjeyesbelmenNo ratings yet

- Breaker Machine Safety ChecklistDocument1 pageBreaker Machine Safety ChecklistNair R RakeshNo ratings yet

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDocument42 pagesBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanNo ratings yet

- EHS October 2019 Calendar Safety Training AuditsDocument1 pageEHS October 2019 Calendar Safety Training AuditsSiddharth RanaNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- JHA - (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA - (Power Brush & Touch-Up Painting Activities 1)shaiful annuarNo ratings yet

- JSA For Purging NitrogenDocument1 pageJSA For Purging Nitrogenlina ekawatiNo ratings yet

- SWP Air Compressor FixedDocument1 pageSWP Air Compressor FixedTosif AliNo ratings yet

- Safe Air Compressor ProcedureDocument1 pageSafe Air Compressor ProcedureANNA FILEXNo ratings yet

- Common Materials That May Contain AsbestosDocument14 pagesCommon Materials That May Contain AsbestosPerwez21No ratings yet

- Asbestos Information and TrainingDocument7 pagesAsbestos Information and TrainingPerwez21No ratings yet

- Management LeadershipDocument1 pageManagement LeadershipPerwez21No ratings yet

- Why Implement a Safety and Health Program to Reduce Costs and Improve BusinessDocument1 pageWhy Implement a Safety and Health Program to Reduce Costs and Improve BusinessPerwez21No ratings yet

- Workplace Vehicle Safety Tips Under 40 CharactersDocument2 pagesWorkplace Vehicle Safety Tips Under 40 CharactersPerwez21No ratings yet

- Const PK Qa&Qc Ms C PCL 02 Concrete WorkDocument8 pagesConst PK Qa&Qc Ms C PCL 02 Concrete WorkPerwez21No ratings yet

- Adults Can Make New Brain Cells Even in Their 70s: NewsweekDocument5 pagesAdults Can Make New Brain Cells Even in Their 70s: NewsweekPerwez21No ratings yet

- Guide Emp RecognitionDocument8 pagesGuide Emp RecognitionPerwez21No ratings yet

- Const PK Qa&Qc Ms C PCL 14 Method Statementfor CF Silo Concrete WorksDocument7 pagesConst PK Qa&Qc Ms C PCL 14 Method Statementfor CF Silo Concrete WorksPerwez21No ratings yet

- HSE Flyer On Falling ObjectsDocument1 pageHSE Flyer On Falling ObjectsPerwez21No ratings yet

- The Surahs Prophet (S.a.w) Used To ReciteDocument16 pagesThe Surahs Prophet (S.a.w) Used To RecitePerwez21No ratings yet

- Construction Dust Control Measures GuideDocument3 pagesConstruction Dust Control Measures GuidePerwez210% (1)

- Management LeadershipDocument1 pageManagement LeadershipPerwez21No ratings yet

- Hilti 1-9-16 SDS Max Rotary Hammer DrillDocument10 pagesHilti 1-9-16 SDS Max Rotary Hammer DrillPerwez21No ratings yet

- Virtues and Laws Pertaining To BismillahDocument18 pagesVirtues and Laws Pertaining To BismillahPerwez21No ratings yet

- Managment Walk DownDocument2 pagesManagment Walk DownPerwez21No ratings yet

- Guide Emp RecognitionDocument8 pagesGuide Emp RecognitionPerwez21No ratings yet

- The Surahs Prophet (S.a.w) Used To ReciteDocument16 pagesThe Surahs Prophet (S.a.w) Used To RecitePerwez21No ratings yet

- Power of DoaDocument76 pagesPower of DoaAbu MusaNo ratings yet

- JSA-For Hot Jobs NRL (E-64)Document3 pagesJSA-For Hot Jobs NRL (E-64)Perwez21No ratings yet

- Pioneer Cement Project Color Coding: Color Code For Rigging GearsDocument1 pagePioneer Cement Project Color Coding: Color Code For Rigging GearsPerwez21No ratings yet

- Facility List Disney September 2014Document254 pagesFacility List Disney September 2014testing accountNo ratings yet

- Gap Analysis Report For Keya - Group (MM & WM)Document12 pagesGap Analysis Report For Keya - Group (MM & WM)shetupucNo ratings yet

- Company Profile DMA UpdateDocument8 pagesCompany Profile DMA UpdateYandi RaifaNo ratings yet

- Indirect Tax Laws Vol.-Iii (Practice Manual) - g2Document231 pagesIndirect Tax Laws Vol.-Iii (Practice Manual) - g2caatulgarg6023100% (1)

- Calorie ChartDocument3 pagesCalorie Chartsandip_parulkarNo ratings yet

- Apple Case StudyDocument6 pagesApple Case StudySanket JadhavNo ratings yet

- Silegen Softener SIS enDocument5 pagesSilegen Softener SIS enarkcgem100% (1)

- Apple Inc Supply Chain Case StudyDocument28 pagesApple Inc Supply Chain Case StudyDhruv MishraNo ratings yet

- Ashok Griha Udyog Kendra (P) LimitedDocument9 pagesAshok Griha Udyog Kendra (P) LimitedAmit BhattacherjiNo ratings yet

- What Is PU Leather? All-In-One Overview of Latest PU Leather !!Document7 pagesWhat Is PU Leather? All-In-One Overview of Latest PU Leather !!nurseerror9No ratings yet

- Tokwa't Baboy Recipe: IngredientsDocument3 pagesTokwa't Baboy Recipe: IngredientsMarlene FortezaNo ratings yet

- Master SMV Sheet Machinist OperationsDocument9 pagesMaster SMV Sheet Machinist OperationsMD JAWED AKHTARNo ratings yet

- Douglas Phan's Cheerios Cereal Product RedesignDocument12 pagesDouglas Phan's Cheerios Cereal Product RedesignDouglas PhanNo ratings yet

- 2012 Yamaha MT03 Accsheet GB enDocument7 pages2012 Yamaha MT03 Accsheet GB enspscribd1No ratings yet

- Seamless Fully Fashioned Clothing Their Advantages DisadvantagesDocument2 pagesSeamless Fully Fashioned Clothing Their Advantages DisadvantagesHarleen Kaur100% (1)

- List of MarketingDocument78 pagesList of MarketingMohamad IchwanNo ratings yet

- Comparative Case Study of UNIQLO and MUJI Slides KasparDocument15 pagesComparative Case Study of UNIQLO and MUJI Slides KasparKaspar Chabot100% (1)

- Copeland Scroll Low Temperature Compressors For Refrigeration en Us 5399944Document2 pagesCopeland Scroll Low Temperature Compressors For Refrigeration en Us 5399944suresh muthuramanNo ratings yet

- E-COMMERCE IN INDIA - A SUNRISE SECTORDocument8 pagesE-COMMERCE IN INDIA - A SUNRISE SECTORHarsha VardhanNo ratings yet

- Operation ManagementDocument16 pagesOperation ManagementAbdullah Al-RafiNo ratings yet

- Trade Magazine PDFDocument5 pagesTrade Magazine PDFTejaswi BandlamudiNo ratings yet

- Shimano SPD Pedal AdjustmentsDocument1 pageShimano SPD Pedal AdjustmentsAlex SolomidesNo ratings yet

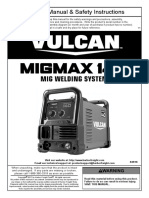

- MIGMax 140 WelderDocument32 pagesMIGMax 140 WelderVooDooJake100% (1)