Professional Documents

Culture Documents

Heathrow Terminal Ammonia Chillers

Uploaded by

cefa84Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heathrow Terminal Ammonia Chillers

Uploaded by

cefa84Copyright:

Available Formats

Advance Proof.

Private to members

Copyright © 2009 The Institute of Refrigeration

No publication or reprinting without authority

THE INSTITUTE OF REFRIGERATION

A Cooling Case Study

Heathrow Terminal 5 Ammonia Chillers

by

George Adams , Derek Moore2

1

1.SPIE Matthew Hall

2.Sabroe UK (Johnson Controls)

(Session 2008-2009)

To be presented before the Institute of Refrigeration at

London South Bank University, Nelson Haden Lecture Theatre,

Keyworth Street, London SE1 6NG

On Thursday 2nd December 2008 at 5.45pm

Abstract • the challenges presented by the cooling

The paper describes the design and needs of the Terminal 5 project

construction of the Energy Centre for the • the development and management of the T5

Terminal 5 development at London’s Heathrow project building services by SPIE Matthew

airport. T5 consists of a series of large buildings Hall

and infrastructure with their own utility • the selection and application of chillers for

services. All heating water, cooling water and the project and why ammonia refrigerant

domestic water is supplied by a central energy was chosen

centre. • the design concept, construction and testing

employed

The paper further describes the ammonia

chillers selected for the project from the Heathrow History [1]

perspective of the supplier and provides an London Heathrow is the UK's largest airport

insight into: and the world's busiest international airport,

Proc. Inst. R. 2008-09. 4-1

carrying over 68 million passengers and 1.3 Following the longest public inquiry in British

million tons of cargo each year. planning history – a total of three years and 10

months – the Government gave approval in

The site's aviation history began during the First November 2001 for BAA to build a fifth

World War and the location remained a terminal at Heathrow, but it was not until

military airfield until 1919. It then became the January 2003 that the London Borough of

privately owned Great Western Aerodrome Hillingdon finally granted consent and

and was largely used for test flying until it was construction began on the Terminal 5 site,

requisitioned by the Air Ministry to be which is situated within the airport's existing

developed as a major transport base for the boundary. When fully complete in 2011, the

Royal Air Force in 1944. The war ended before new terminal will have the capacity to handle 30

the work was completed. million passengers a year.

With the prospect of a large expansion in civil

aviation, London needed a large, modern September 2005 saw the Terminal 5 ‘topping

airport. Croydon Airport, London’s civil out’ ceremony, to celebrate completion of the

aviation facility since the 1920’s, was unsuitable spectacular building structure, and T5 was

for expansion. The partly-built site at Heathrow officially opened by the Queen in March 2008.

offered the ideal location. One runway was

ready for use and when the Ministry of Civil The Terminal 5 Project

Aviation took it over in 1946, a tented terminal Energy Centre

was quickly erected allowing operation to begin. Heating and cooling the new terminal buildings

By 1947 three runways had been completed and at Heathrow airport’s Terminal 5 development

a permanent building arose in the central area at is undertaken by a dedicated energy centre,

the start of the 1950’s which provides continuous supplies of hot and

chilled water for heating and air-conditioning

As air traffic grew Heathrow Airport found respectively. The hot water is provided by a

itself with an ever-increasing demand for combination of a local combined-heat-and-

passenger facilities. The Queen inaugurated a power source and natural gas boilers, whilst the

new building in 1955 (Terminal 2) and the chillers are powered by high-voltage electricity.

tunnel which provides the access to Heathrow's

central area was opened. Next came the new The centralised distribution of these services to

Oceanic terminal handling long-haul carriers, a the main terminal building, its satellites and

function it still performs as Terminal 3, followed ancillary areas was considered to be the most

by the opening of Terminal 1 in 1968. Increased effective solution based on construction,

congestion in the central area led to the birth of commissioning, operations and energy efficiency

Terminal 4 in 1986 on the south side of the considerations. It also enabled flexibility in

airport. terms of future development.

Prefabricated Mezzanine Boiler Flues Cooling Towers

Chillers

The Energy Centre ensures effective & sustainable supply of services to the T5

Proc. Inst. R. 2008-09. 4-2

The energy centre project was design and built cooling demands for the various buildings, which

by SPIE Matthew Hall (formerly AMEC), required close co-operation with other design

working in conjunction with other contractors, teams across the project. The design process

the principal designer PB Power and the client established the optimum operating

BAA’s technical team. It involved the large-scale temperatures, pressures and controls

off-site modularisation of mechanical and philosophy to reduce life-cycle costs. A full

electrical services and supporting structure, and energy metering system has been incorporated

included fast-track on-site assembly methods to monitor consumptions of all service

and technology. It also provided an early provisions.

opportunity to test the T5 information

technology network and control systems Delivery of the engineering systems was largely

integration. based on build off-site technology. Large

integrated sections of the works – incorporating

Definition and project requirements [2] mechanical and electrical systems and

When the engineering design for the energy equipment and, where appropriate, structural

centre started in 1998, assessments were made elements of the building framework – were

on the potential use of renewable energy and manufactured and delivered to site as complete

combined heat and power (CHP). It was modules.

concluded T5 should not have a dedicated CHP

system, but that a single CHP plant serving the In parallel, important elements of off-site testing

T5 and central terminal area (Terminals 1, 2 and were integrated into the process to assist in

3) would be more appropriate – though in the verification of plant and equipment

event this did not proceed. However, during performance. This also enabled the

the commissioning of the energy centre, it incorporation of manufacturers’ input to design

proved possible to integrate a CHP connection and fabrication processes, ensuring good

from the nearby Thames Valley Power plant technical co-ordination, physical fit and parallel

that also supplied the airport cargo area. manufacturing sequences.

The scope of the energy centre project Standards of Design

comprised: The design of the energy centre was carried out

• free cooling feature to the client’s engineering guidelines, EN

• centralised hot water standards and other appropriate industry

• centralised chilled-water plant guidance such as Building Services Research and

• heating, cooling and associated system Information Association reports, Chartered

distribution networks Institution of Building Services Engineers

• gas supplies guidelines and energy best-practice publications.

• high-voltage electrical supplies to chillers

• water treatment Systems design was based on the fundamental

• heat-rejection facilities criteria of:

• controls and information technology • energy provision is in the form of hot water

networks for heating and chilled water for air

• CHP supplies conditioning

• support systems such as lighting and fire • provision from a single energy centre

alarms

• chilled water store The key requirements for heating and cooling

demands were for business continuity of the T5

The design was influenced by the strategic operations, which were established by the

restriction on height and the then-new Building design teams for each separate building.

Regulations. In addition to the main plant

rooms, the building includes a control room, The complete process of design verification and

stores area, workshop, offices and support sign-off was conducted via project procedures

accommodation for the operator Heathrow including quality plans, risk assessments and

Airport Ltd. technical audits. This ensured the complete

design-to-commissioning process was

The overall design encompassed the heating and documented, transparent and structured.

Proc. Inst. R. 2008-09. 4-3

T5A T5B T5C

MSCP 1

M 25 Energy

HATC

SITE PLAN

Figure 1: Area plan of campus showing location of energy centre

The primary energy supply to the centre was client representatives

selected as natural gas for heating and high- • development of the construction health and

voltage electricity for power. safety plan

• commissioning process

Development Stage

This stage incorporated wider considerations of The philosophy through each stage of the

manufacturing, construction and commissioning. programme was to eliminate health and safety

Key members from the design definition stage risks during construction, commissioning and

were included, enabling buildability to be taken operations. Consideration of the project’s

into account and ensuring learning from the eventual demolition was also included.

design process was effectively taken forward.

Technical Content

Some of the key deliverables from the detailed The energy centre is located to south west

development stage were: corner of the T5 site (Figure 1). The heat

• detailed activity programmes, inclusive of rejection equipment located within the roof and

build off-site technology the main plant is located at the ground floor

• milestone definitions, including those from level with distribution occurring at mezzanine

the design definition stage level.

• change-management assessments

• detailed risk-management assessments The interconnection is via a series of below-

• buildability reports ground tunnels housing:

• cost and time evaluations • chilled-water pipes

• testing and commissioning plans • heating-water pipes

• procurement documentation • potable-water pipes

• three-dimensional drawings and fabrication • grey-water pipes

details • high-voltage power cables

• handover plan

• maintenance considerations and associated To support the main plant, the hydronic

technical reviews, involving appropriate pumping arrangements are as follows:

Proc. Inst. R. 2008-09 4-4

Heating - Primary heating pumps and circuit Figure 2 shows one of the five prefabricated

serves the boilers with secondary transfer mezzanine floor modules being stand-jacked into

pumps to the main terminal T5A, satellite position inclusive of integrated mechanical

terminal T5B and future satellite T5C. There systems. The benefits of the build off-site

are secondary exchange plant rooms within the methodology are as follows:

terminal buildings housing interface-plate heat

exchangers, which step down the primary Safety - Installing mechanical pipe work up to

supply temperature from 95°C to 72°C with 600mm diameter by traditional means at high

secondary pumps within each building for level would have significantly increased

general distribution. construction health and safety risks.

Chilled water - There are primary pumps Time - Jacking of the 6m by 30m sections as

associated with the chillers, coupled up by a shown in Figure. 2 is carried out in a matter of

common primary pipe work circuit. Secondary days as opposed to many weeks of traditional

pumps in the energy centre circulate the chilled construction methods. The overall benefit was

water directly to each point of use in each calculated to be around four months for the

terminal building. complete project.

Delivery Philosophy - Following the design Interfaces - The major modules incorporated

definition and design development stages, the steel beams that not only supported the

delivery of the energy centre project was modules but also became part of the building

conducted through the following key stages: structural frame, reducing the amount of

• fabrication design steelwork needed.

• manufacturing

• assembly Cost - Overall cost benefits were achieved, by

• commissioning reducing the length of the critical path in the

• integration programme and allowing earlier delivery of key

• handover plant items to site due to a faster availability of

associated space under the mezzanine floor and

The philosophy was to give due consideration getting the plant on line early.

to each of the above stages and achieve good

integration between designers, manufacturers, The use of three-dimensional modelling was an

engineers and project management functions important feature within the delivery process.

co-located on the T5 site. All parties were Not only was this used to develop fabrication

working to the unique and open style of the T5 and assembly details, but the model

agreement, which sets out how all parties visualisations facilitated better risk assessments,

should work together to common objectives improved understanding of the assembly

and deliverables. sequences and a better method of

communicating to all parties involved.

Energy Demand - The demands from the

terminal buildings are varied and quite dramatic

in their seasonal pattern the peak cooling

demand changes dramatically from low to high.

Whereas two or three compressors are needed

for the majority of the cooling season, this

rapidly increases to the full eight compressors at

peak condition for a relatively shorter period of

time. The controls and pipe work strategy

accommodates these variations.

To minimise the energy consumption by the

Figure 2: Prefabricated 6m by 30m energy centre, the following technology has

mezzanine floor modules been incorporated into the design:

Proc. Inst. R. 2008-09. 4-5

• efficient plant selections next commissioning stage. The client arrived at

• heat recovery from the lead boiler the handover stage, having been involved in

• incorporation of heat supply from CHP every preceding section of the delivery process.

plant

• efficient pump selections with energy- The handover plan was not just about a formal

saving controls incorporated transference of responsibility and information;

• high-efficiency plate heat exchangers the process encompassed all of the following:

• heat exchanger coupled to one dedicated • record information and drawings

tower/refrigeration plant configuration to • maintenance documentation

provide an amount of free cooling facility • training schedules for client’s operations

(i.e. using this tower to cool the return staff

chilled-water line from the terminal • operational training for systems

buildings when appropriate to utilise the • risk residuals

facility) • witnessing of commissioning results and site

• variable-speed drives on all associated acceptance tests

pumps • sign off inspections by the building control

• variable flow systems representative

• asset coding schedules

Commissioning and Handover

The commissioning process was put in place All of these were co-ordinated within a

during the design development phases. The specifically drafted handover agreement, so that

process was based upon a number of key stages a summary of all the documentation references

delivered through ‘gateways’. These gateways is located in place.

enable the integration of a number of related

sub-systems into a common and auditable The key to the handover was to develop the

process (Figure 3). client’s operational staffs’ knowledge and

information so that they could operate and

Each of the gateways incorporated a detailed maintain the systems effectively, safely and with

schedule of requirements that had to be understanding of the dynamics of the

satisfied and signed off prior to the move to the engineering solutions.

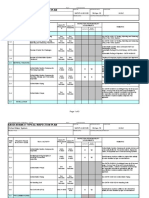

TESTING & COMMISSIONING - CHILLED WATER

PROJECT: ENERGY CENTRE T5

WITNESS WITNESS

RESULTS OF ATTENDANCE WITNESS ATTENDANCE SYSTEMS

F.A.T.’S COMMISSIONING

A CHW 2.1 TEST PLANS/MS A CHW 3.2 TEST/COMMISSION A CHW 5.1

A CHW 2.4 A CHW 4.1

SYSTEM/SUB SYSTEM

INSTALLATION SUB SYSTEM SYSTEM/SUB SYSTEM INTEGRATED PROVING TRIALS

A CHW 2 A CHW 3 A CHW 4

COMPLETION TESTING COMMISSIONING TESTING A CHW 5

CHW/Z1/A CHW 1

ABCM2 ABCM3 ABCM4

BCMS

LOCALLY BCMS BCMS

AVAILABLE COMPLETE OPERATIONAL

MAKE READY NEEDS TEST SCHEDULE CHECKS OUTCOME

Figure 3: The Commissioning process was based on a series of key gateways

Proc. Inst. R. 2008-09. 4-6

The Chillers that standby capacity was not installed, but to

In 2003 Sabroe, via its parent Johnson Controls reduce the impact on one or more units being

(formerly York International), were invited to unavailable, a sufficient number of units should

participate in the design and development of the be installed. Moreover, the design of the

chillers to serve the AC services for the T5 chillers should incorporate features to limit the

project. possibility of downtime due to plant failure or

maintenance.

The assessment involved a number of stages

supervised and assessed by SPIE Matthew Hall A chilled water storage system was

these included: incorporated into the design to reduce the

• Chiller performance and efficiency installed chiller capacity by ‘peak lopping’, as

• Main drive, motor voltage & starting well as increasing the possibility of free cooling

• ‘Worst Case’ Ammonia leak assessment by capturing and storing night time and low

• Machinery room design (heat gains, ambient temperature cooling opportunities.

ventilation, emergencies)

• Noise level Phase 1 – Terminal 5 Cooling Capacity Profile

• Control system Quantity Type Rating

• Maintenance requirements and proposals 1

Thermal Chilled Water 2.6 MW

• HAZOP study store (8%)

6.7 MW

4 NH3 Chillers

The primary considerations for the chillers were (23%)

that they should offer the maximum operation Hours / year % Annual

Plant % Peak

demand not kWh not

efficiency, proven design and that they should be available Load

met supplied

completely assembled and tested at the

Store + 4

manufactures works prior to shipment to Chillers

100 0 0

ensure the minimum site installation time. 4 Chillers 92 11 0.03

3 Chillers 69 97 0.46

2 Chillers 46 552 2

1 Chillers 23 4480 21

Table 1: Terminal 5 cooling capacity

profile

Table 1 [3] shows the installed capacity profile

for the project. It can be seen that more than

99.5% of the annual demand can be met with

the store and one chiller unavailable and, hence,

the probability of any impact on the comfort

level in the terminal is very low. Moreover, it is

very unlikely that the store would physically fail;

in practice it is more likely that a circulation

Two of the 4, 6.6 MW chillers

pump could fail, however, the provision of run

and stand-by pumps overcome this.

The thermal load

The HVAC design engineers had conducted the

Ammonia [5]

evaluation of the chilled water load profiles.

Ammonia was chosen as the primary refrigerant

Typically, air-conditioning applications have high

because of its superior thermodynamic and

peak loads, but low average loads and this is

transport properties. It offers many desirable

true for the Terminal 5 profile. Such profiles

qualities:

result in a high capital cost refrigeration plant

• A naturally occurring, bio-degradable

standing idle for significant periods or substantial

chemical.

periods of ‘part load’ operation.

• Part of the Earth’s natural nitrogen cycle

• Short atmospheric lifetime

The high capital cost is exacerbated if additional

• Does not contribute to Ozone Depletion

capacity is installed for redundancy.

or Global Warming

Consequently, the design team recommended

Proc. Inst. R. 2008-09. 4-7

• Very efficient refrigerant. High specific

cooling capacity, heat transfer, high COP,

low TEWI.

• Very easily detected

• Has been safely used for over a century

Moreover, ammonia is a ‘future proof’

refrigerant from an environmental view point. It

is of course a toxic alkaline and, if not contained

in a properly constructed plant, potentially

lethal to humans. However, ammonia can be Figure 5: A terminal 5 chiller unit

safely contained and has been widely used in

thousands of refrigeration plants for over a The condenser and evaporators are Alfa-Laval

century. It is well understood by refrigeration plate heat exchangers. Sabroe has had a long

engineers and requires no special engineering cooperation with Alfa Laval in the development

beyond the well established thermodynamic, and application of their laser welded cassette

mechanical and material engineering heat exchanges for ammonia chiller applications.

technologies. Figure 6 shows the typical plate construction.

The cassettes are mounted in a support frame

The Chillers to provide the required heat exchange surface

The Sabroe range of PAC (Packaged Ammonia area. The secondary cooling medium is

Chillers) was introduced in the mid 1990’s circulated through the gasketed section of the

following development and competitive heat exchanger and the ammonia through the

availability of laser welded plate heat enclosed section of the welded cassettes. The

exchangers. The benefits of plate heat gasket arrangement, including a double seal at

exchanger technology had been understood for the interconnecting portholes, prevents

many years, but the risk of ammonia leakage secondary fluid and ammonia escape. Moreover,

from earlier gasketed exchangers had been an if the porthole gasket at the ammonia

impediment to their use. interconnection were to fail, there is a clear

leakage path to atmosphere to avoid

The basic chiller is a simple, so called, flooded contamination of the secondary fluid. Various

chiller as depicted in Figure 4. It comprises a grades of stainless steel or titanium plates are

compressor unit, plate heat exchanger available. The T5 units utilised ANSI 316

condenser, float regulator and plate heat stainless steel.

exchange evaporator. In essence, it is the

simplest of vapour compression refrigeration The mechanical design of these heat exchangers

systems. The reality is a little more complex, has been proven over many year of operation

but not particularly so. A total of four unit’s and the construction and test, including a final

identical unit were delivered for the project helium leak test, ensures the utmost security.

(Figure 5).

The evaporator is mounted together with a

COMPRESSOR

EVAPORATOR CONDENSER

EXPANSION VALVE

Figure 4– Basic PAC Chiller Function

Proc. Inst. R. 2008-09. 4-8

compressor units from Sabroe’s Uniscrew range

and two independent compressor units per

chiller unit were chosen to provide the best

load management and maintenance flexibility.

Each oil injected compressor unit incorporates

independent oil separation, cooling, filtration

and temperature management systems. The oil

separators incorporate high efficiency coalescing

elements to reduce the oil leaving the

compressor unit to minimal levels, whilst the oil

system ensure the oil delivered to the

compressor is maintained at the correct

temperature and quality.

Figure 6: PHE plate arrangement

Independent water cooled oil coolers are

suction/liquid separator to provide a natural incorporated for each compressor unit to

circulation, flooded operation. The use of a ensure that the oil is maintained at the required

thermosyphon system allows close approach operating temperature. This arrangement

temperatures to be utilised. Importantly, this allowed for one complete compressor unit to

means the total heat exchange surface may be be maintained whilst the other remains in

utilised at part load and the LMTD will reduce operation. The cooling water circuits are

with reducing load. This design ensures a allowed to operate at design flow to minimise

‘wetted’ heat exchange surface to maximise the fouling, but the oil temperature is accurately

heat transfer efficiency and the suction regulated by a thermostatic three-way valve in

separator disengages liquid droplets entrained in the oil circuit.

the ammonia vapour leaving the evaporator,

ensuring that only dry saturated vapour is For increased efficiency, each chiller unit

drawn back to the compressors. operates with a common ‘open flash’

economiser. The economiser is an established

The condenser was to be water cooled for this method of improving the thermodynamic

project. As for the evaporator, the LMTD in the performance of a screw compressor by

condenser will reduce as the thermal load expanding the main liquid stream into an

decreases. The combined effect is to improve intermediate vessel and drawing the ‘flash gas’

the part load performance of the unit (Figure 7). generated into the compressor via an

intermediate port which is closed to the suction

side. There is no reduction to the suction

volume, thus the mass flow entering the

Co-efficient of Performance

compressor is unchanged, but the cooled liquid

stream entering the evaporator has an increased

enthalpy of vaporisation and, therefore, an

increased total cooling effect. The added gas

volume imposes additional compression power,

but there is a thermodynamic advantage. In this

application the economiser pressure is regulated

0% 20% 40% 60% 80% 100% to maintain a minimum pressure differential

Compressor Capacity

over the evaporator.

Figure 7: Typical part load The chillers operate with a, so called, critically

characteristic for PAC chillers charged system – meaning that they contain a

minimum quantity refrigerant. The flow or

Within the PAC series it is possible to select refrigerant is controlled by a liquid level sensor

reciprocating or screw compressor units, either mounted at the condenser outlet which allows

with single or dual compressor options. The all condensed liquid refrigerant to pass through

capacity for the T5 project required to the economiser. Equally, a similar

arrangement in the economiser allows liquid to

Proc. Inst. R. 2008-09. 4-9

pass on into the evaporator. The flow is for this project, 11 KV motors with DOL

regulated through appropriate regulating valves. starting secured the lowest realised cost.

Water cooled motors were chosen to reduce

Albeit, the compressors have very low oil carry- the ventilation requirements for the plant

over, there will be a small quantity of oil leaving rooms and the motor cooling systems

the compressor units and, if not recovered, will integrated into the compressor oil cooling

accumulate. Being heavier than ammonia, the circuits.

oil is collected in a vessel placed at the bottom

of the evaporator. The vessel is equipped with The units were completely assembled in Sabroe

a float switch having a precisely weighted sensor factory in Aarhus, Denmark. The design,

that will float on oil, but not in ammonia. construction and testing followed Sabroe’s ISO

Consequently, when sufficient oil has 9000 approved QA procedures and complied

accumulated, an automatic ejection system fully with EU and PED/EN 378 requirements.

returns the oil to the operating compressors. After assembly, each unit was subjected to a

Factory Acceptance Test. The Sabroe factory

Each compressor unit is equipped with Sabroe’s already had an extensive end-of-line test facility

Unisab II microprocessor controller. This for its normal production of PAC units and this

monitors, controls and supervises all of the facility was extended to accommodate the full

functions of the unit. All pressures, performance testing of the first of the T5 units.

temperatures, current, etc are continuously This was only undertaken for the first unit, as it

monitored and regulated to maintain stable was necessary to utilise one of the actual 11 KV

operation. Each Unisab II may operate ‘stand starters from the project to be able to operate

alone’ or may communicate with others for both compressors simultaneously. The

optimum part load capacity regulation. remaining units were fully tested, but only

Moreover, there are a variety of external operating one compressor unit at a time using

communication options, enabling each package the test centre equipment.

to be integrated into the overall BMS control

for the installation. The physical size of the units meant that they

could not be transported from Denmark to

PAC 283L(T) Chiller Unit Operating Data

England as fully assembled units. Consequently,

Design Cooling Capacity 6660 kW they were manufactured with flanged

Power consumption 2 x 618.4 kW connection allowing each unit to be separated

Condenser Rejection 7421 kW into three sections for shipping. After testing,

Oil Cooling Duty 2 x 243 kW the refrigerants were removed from the unit

Full Load Coefficient of Performance 5.38 and the sections separated. Each section was

Cooled Water Inlet Temperature 14.0o C

sealed with blanking flanges, evacuated and

Cooled Water Outlet Temperature 5.5o C

Cooled Water Flow 676 m3/h charged with a holding charge of dry nitrogen.

Cooling Water Inlet Temperature 29.0o C Upon arrival at site, the sections were off

Cooling Water Outlet Temperature 35.0o C loaded and reassembled in the plant room by

Cooling Water Flow 1074 m3/h Johnson Controls installation team. The units

Oil/Motor Cooling Water Flow 2 x 38.4 m3/h were pressure tested, evacuated and charged

Drive Motor (ABB 11 kV) 2 x 750 kW with the refrigerant and oil. This design of unit

Shaft speed 2970 rpm operates with a low refrigerant change.

Ammonia charge 1370 kg

Oil Charge (PAO 68) 930 kg

The site

Operating weight 50000 kg

Water was selected as the appropriate cooling

Table 2: Terminal 5 chiller operating data medium for the chillers. A common cooling

tower water circuit is utilised to ensure all

The drive motors of this project were carefully towers are available to whichever chillers are

considered. The Terminal 5 Energy Centre had operating. Cooling water was supplied to each

11 kV, 3.3 kV and 400 V supplies. Fixed and unit by the energy centre pumps and regulated

variable speed drive options were examined. A according to the demand on the chillers. Each

detailed analysis of power supply, starting chiller package incorporated auxiliary water

options and part load operation concluded that, pumps to circulate cooling water through the

Proc. Inst. R. 2008-09. 4-10

Chiller Unit Shipping Data A HAZOPS was conducted for the Energy

Weight Length Width Height Centre, including the refrigerated water chillers,

to evaluate the operation under normal,

Suction Separator Section

degraded and emergency situations. The study

4700 kg 5100 mm 2300 mm 2000 mm considered the effects of flow, temperature,

Heat Exchanger Section pressure, corrosion, levels, toxicity, fire, noise

and vibration. A systematic valuation method

17300 kg 9600 mm 2150 mm 3950 mm was imposed.

Compressor/Motor Section

Conclusion

21500 kg 9650 mm 2700 mm 3800 mm

The energy centre lies at the heart of the £4.3

Assembled Unit Dimensions (net) billion T5 development, ensuring the effective

43500 kg 9650 mm 4113 mm 7000 mm

and sustainable supply of energy services to the

terminal buildings.

Table 3: Terminal 5 chiller shipping data

The selected chillers demonstrate the

compressor oil cooler and motor cooling optimisation of an integrated cooling system,

circuits. whilst having regard for the environment and

operating efficiency. They provided for the

Each chiller unit was to be placed in its own design demand for off site construction and

acoustic enclosure. A detailed sound analysis testing, with minimum site installation and

was provided for the chiller unit enabling the commissioning time.

enclosure to be appropriately constructed.

Sufficient cooling tower capacity was installed to The robustness of the design, build and

reduce the impact of single unit failure. commissioning processes has delivered a project

that provides critical business continuity for the

A detailed analysis of the ‘worst case’ ammonia airport operator, airline operators and retail

escape was conducted. The potential heat gains concessionaires.

were estimated and the maximum

concentration of ammonia in the exhaust air References

calculated. Additionally, the heat loss form the [1]http://www.heathrow-airport-guide.co.uk/

pack was calculated to determine the minimum history.html

ventilation rates required. It was possible to [2]Wolstenholme A., Fugeman I.C.D. and

determine the appropriate ventilation rate for Hammond B. Heathrow Terminal 5:

each unit compartment to maintain a sensible delivery strategy. Proceedingsof the Institution of

room temperature and for emergency Civil Engineers, Civil Engineering,2008, 161, Special

ventilation. issue – Heathrow Airport Terminal 5 May 60-

64.

Ammonia scrubbers were incorporated into

[3] General Study, Energy Services. Plant

extract system to reduce the concentration to

Resilience & Redundancy. Project Document

acceptable limits in the event of leakage. The

T5-RN-SS-48-27G-EC-00004

scrubber consisted of a low pressure shell with

[4] Heathrow Airport Terminal 5 Briefing

packing through which the ammonia/air is

Documents

extracted. The packing is soaked with a dilute

[5] Ammonia as a Refrigerant, International

acid solution by a series of nozzles.

Institute of Refrigeration, ISBN 2.903.633.64.9

Each unit enclosure was equipped with ammonia

detectors to automatically trigger the Acknowledgement

emergency ventilation and unit electrical The authors acknowledge the information and

isolation in accordance with EN 378. The support provided by their respective

extract system was equipped with run and organisations and colleagues, without who’s help

stand-by fans, dual fed from independent and assistance the paper could not have been

transformers connected to separate primary accomplished.

circuits.

Proc. Inst. R. 2008-09. 4-11

The venue for the evening paper is

London South Bank University, Nelson Haden Lecture Theatre, nearest

entrance is Faraday Wing, Keyworth Street, London SE1 6NG

Presentation will

take place in the

Nelson Haden

Lecture Theatre,

nearest entrance is

the Faraday Wing on

Keyworth Street.

Public Transport

Train and Tube:

The closest stations are Borough, Waterloo, London Bridge , Elephant & Castle, all are within a

walkable distance of the campus.

By bus - numbers 1, 12, 35, 40, 45, 53, 63, 68, 100, 133, 148, 155, 168, 171, 172, 176, 188, 196, 333,

344, 360, 363, 453, 468, C10 and P5.

Car

Parking in Central London is very difficult and it is not possible to park in the University grounds or

the surrounding roads.

Proc. Inst. R. 2008-09. 4-12

You might also like

- Vdocuments - MX Profibus DP Typical Cpu PrintDocument2 pagesVdocuments - MX Profibus DP Typical Cpu Printcefa84No ratings yet

- Refregerstion System ManualDocument106 pagesRefregerstion System ManualahmadNo ratings yet

- Solflex Catalogue 05 2022 ENDocument25 pagesSolflex Catalogue 05 2022 ENcefa84No ratings yet

- Industrial Refrigeration Energy Saving OpportunitiesDocument15 pagesIndustrial Refrigeration Energy Saving Opportunitiescefa84No ratings yet

- BB 2014-Refrigeration Day 2-V5Document33 pagesBB 2014-Refrigeration Day 2-V5cefa84No ratings yet

- Industrial Refrigeration Projects: Challenges and Opportunities For Energy EfficiencyDocument12 pagesIndustrial Refrigeration Projects: Challenges and Opportunities For Energy Efficiencycefa84No ratings yet

- Commissioning - A Process To Achieve Sustainable Refrigerated FacilitiesDocument5 pagesCommissioning - A Process To Achieve Sustainable Refrigerated Facilitiescefa84No ratings yet

- Energy Star GuideDocument100 pagesEnergy Star Guidecefa84No ratings yet

- Industrial Refrigeration Best Practices Guide PDFDocument19 pagesIndustrial Refrigeration Best Practices Guide PDFManoj TiwariNo ratings yet

- 4 38 PDFDocument6 pages4 38 PDFcefa84No ratings yet

- Ammonia Refrigeration Design For Leed Certification PDFDocument20 pagesAmmonia Refrigeration Design For Leed Certification PDFcefa84100% (1)

- 2015-03Document97 pages2015-03DESTGEERNo ratings yet

- Cogeneration Case Studies Handbook FinalDocument40 pagesCogeneration Case Studies Handbook FinalMelumzi NontanganaNo ratings yet

- 4 38 PDFDocument6 pages4 38 PDFcefa84No ratings yet

- GEA Evaporation-Technology Brochure EN tcm11-16319 PDFDocument24 pagesGEA Evaporation-Technology Brochure EN tcm11-16319 PDFItsartNo ratings yet

- A Review of Organic Rankine, Kalina and Goswami CycleDocument16 pagesA Review of Organic Rankine, Kalina and Goswami Cyclecefa84No ratings yet

- Case Study EmersonDocument3 pagesCase Study Emersoncefa84No ratings yet

- FM EXGas HazardPosterDocument1 pageFM EXGas HazardPosterrocket-vtNo ratings yet

- Adiabatic CoolingDocument28 pagesAdiabatic Coolingcefa84No ratings yet

- Hallscrew Product Range BrochureDocument4 pagesHallscrew Product Range Brochurecefa84No ratings yet

- Projections of CHP Capacity Use To 2030 2204Document38 pagesProjections of CHP Capacity Use To 2030 2204cefa84No ratings yet

- District Heating and CoolingDocument215 pagesDistrict Heating and Coolingcefa84100% (1)

- Poster SessionDocument2 pagesPoster Sessioncefa84No ratings yet

- GPG280Document64 pagesGPG280Zul FaisalNo ratings yet

- Cogeneration Case Studies Handbook FinalDocument40 pagesCogeneration Case Studies Handbook FinalMelumzi NontanganaNo ratings yet

- Thesis Chiller Hongxi Yin Appendix ADocument20 pagesThesis Chiller Hongxi Yin Appendix Acefa84No ratings yet

- A Review of Absorption RefrigerationDocument30 pagesA Review of Absorption RefrigerationSoni Rodríguez Castellanos100% (1)

- Ammonia ChillerDocument9 pagesAmmonia ChillerOke EmmanuelNo ratings yet

- EAX CycleDocument5 pagesEAX Cyclecefa84No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SKAA 2032 - Part 3Document65 pagesSKAA 2032 - Part 3Jason DouglasNo ratings yet

- Ir. Raymond WAN - Advanced Dry Mortar Technology For Construction IndustryDocument19 pagesIr. Raymond WAN - Advanced Dry Mortar Technology For Construction IndustryhksmallrayNo ratings yet

- q07 g3 Ahmad AmalludinDocument4 pagesq07 g3 Ahmad AmalludinAmal AmranNo ratings yet

- Permissible Strenth of Structural Bolts As Per Is 800: 2007Document2 pagesPermissible Strenth of Structural Bolts As Per Is 800: 2007Hutia ComNo ratings yet

- Al-Moiz Sugar Mills Limited at Pharrpur Di Khan Hospital Building Revised Summary of Cost (Phase # 1) Dated 24-02-2021 S. No. Particulars Cost RsDocument26 pagesAl-Moiz Sugar Mills Limited at Pharrpur Di Khan Hospital Building Revised Summary of Cost (Phase # 1) Dated 24-02-2021 S. No. Particulars Cost RsZaid AliNo ratings yet

- Tank Suction FloatDocument9 pagesTank Suction FloatthawdarNo ratings yet

- Taller 3 - Propiedades MecánicasDocument2 pagesTaller 3 - Propiedades MecánicasJuan Pablo Rinc�n Ru�zNo ratings yet

- Strengthening Mechanisms in Polycrystalline Multimodal Nickel-Base SuperalloysDocument16 pagesStrengthening Mechanisms in Polycrystalline Multimodal Nickel-Base SuperalloysEngels OchoaNo ratings yet

- Installation and Operating Manual For The EFM Wood/Coal BoilerDocument16 pagesInstallation and Operating Manual For The EFM Wood/Coal BoilerpolNo ratings yet

- Impact of Fire Attack Streams on Firefighter SafetyDocument68 pagesImpact of Fire Attack Streams on Firefighter SafetyyesidNo ratings yet

- Comp Carly Scre Refrig 2004Document52 pagesComp Carly Scre Refrig 2004Deco DluxeNo ratings yet

- Jacketed Piping CalculationDocument9 pagesJacketed Piping CalculationKamran Shaikh0% (1)

- Scaffold Erect ProceduresDocument4 pagesScaffold Erect ProceduresDak SerikNo ratings yet

- Causes and Types of Glaze Cracking in CeramicsDocument2 pagesCauses and Types of Glaze Cracking in CeramicsAsad SaeedNo ratings yet

- Etansare Filete SteamsealDocument2 pagesEtansare Filete Steamsealconstantin.iacomi3837No ratings yet

- IEEM 215: Manufacturing ProcessesDocument55 pagesIEEM 215: Manufacturing ProcessesVijaya Prabhu KumarasamyNo ratings yet

- Flexible Circuits Manufacturing GuideDocument66 pagesFlexible Circuits Manufacturing GuideSelvakumar NatarajanNo ratings yet

- OmniClass 23A 2012-05-16Document1,804 pagesOmniClass 23A 2012-05-16Stephan Espindola de MouraNo ratings yet

- Astm A897 - A897m-22Document11 pagesAstm A897 - A897m-22anant11235No ratings yet

- Ordinary Portland Cement, 33 Grade - Specification: Indian StandardDocument12 pagesOrdinary Portland Cement, 33 Grade - Specification: Indian StandardAmbrishNo ratings yet

- 3.1 Casting ProcessDocument4 pages3.1 Casting Processزينب عبد الخالق كاملNo ratings yet

- Lacroix DeflectographDocument3 pagesLacroix DeflectographLokesh GuptaNo ratings yet

- INDUSTRIAL PSR BELTING SPEC SHEETDocument6 pagesINDUSTRIAL PSR BELTING SPEC SHEETDiego PascualNo ratings yet

- Materials Science - Alloys System - 2Document16 pagesMaterials Science - Alloys System - 2Sumit JoshiNo ratings yet

- Worship XP Lights - 2Document25 pagesWorship XP Lights - 2Krizzia Anne ShengNo ratings yet

- Perfomance Rated I-Joits Roof Framing DetailsDocument10 pagesPerfomance Rated I-Joits Roof Framing DetailsCeyanezNo ratings yet

- Vernacular Term Quiz 1Document85 pagesVernacular Term Quiz 1Zane BevsNo ratings yet

- GIB EzyBrace Systems 2016 August PDFDocument32 pagesGIB EzyBrace Systems 2016 August PDFSteveNo ratings yet

- Life Cycle Energy Analysis of A Glazed Commercial Building Using (BIM) ToolsDocument7 pagesLife Cycle Energy Analysis of A Glazed Commercial Building Using (BIM) ToolsMustapha El MetouiNo ratings yet

- SAUDCO ID/PID FORM REV 1 - 010109 Chilled Water SystemDocument3 pagesSAUDCO ID/PID FORM REV 1 - 010109 Chilled Water Systemimrankhan220% (1)